高密度封装用流延生瓷带研究毕业论文

2020-06-07 21:25:52

摘 要

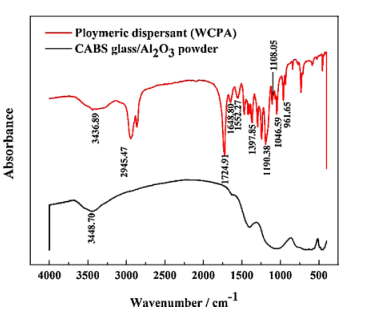

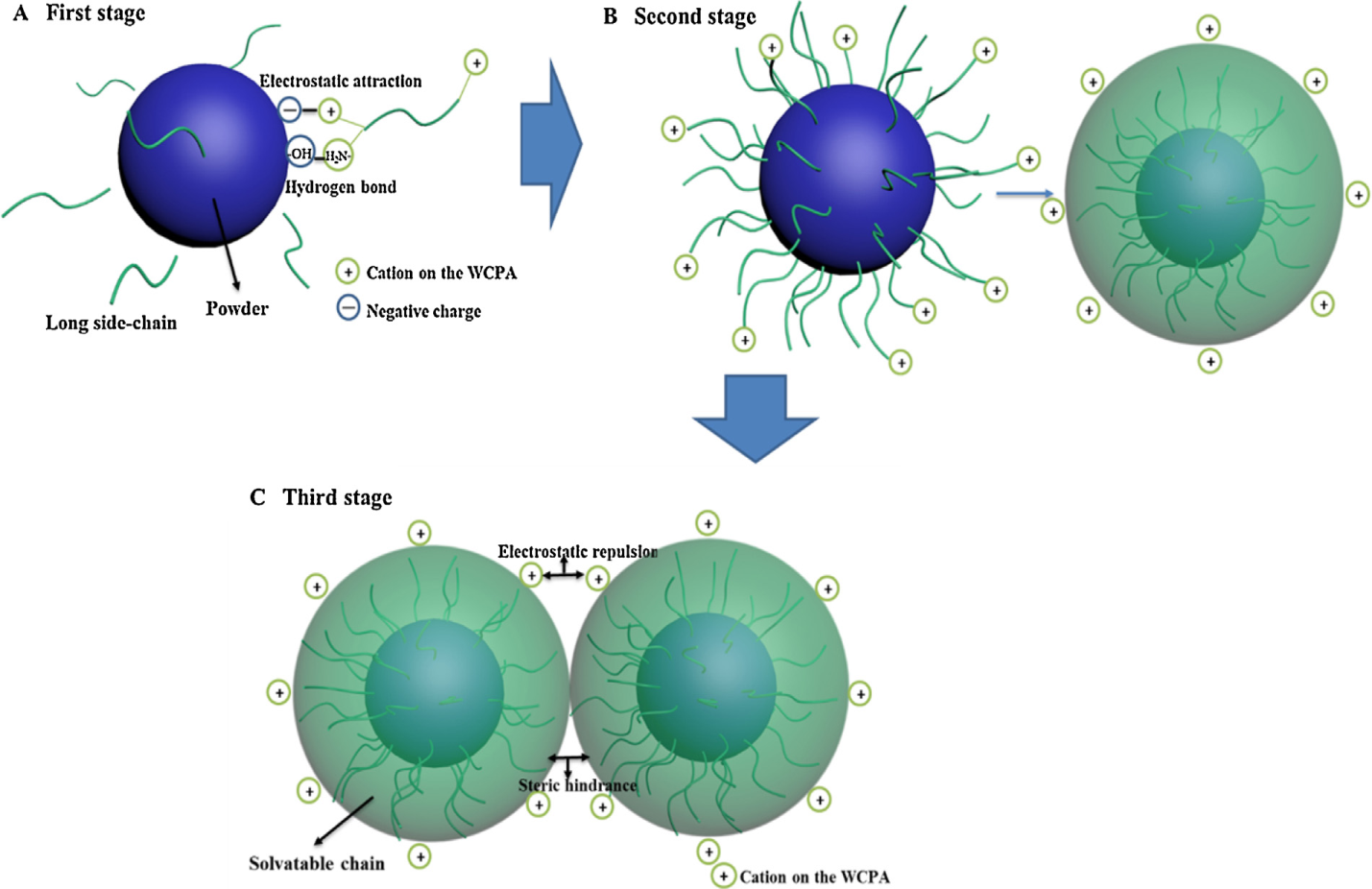

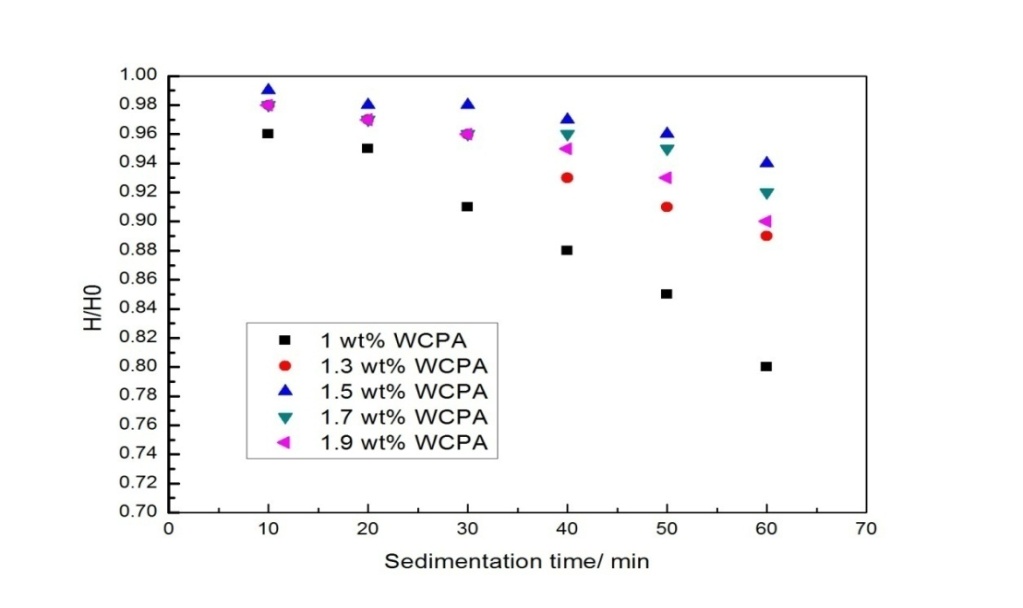

本文旨在研究性能优良的生瓷带以应用于低温共烧陶瓷(LTCC)材料,主要通过在硼硅酸盐玻璃/Al2O3流延体系中用一种高分子聚合物作为分散剂来达到实验目的。在实验中,对聚合物分散剂的分散机制进行了详尽的分析;对于聚合分散剂以及本实验室常用的分散剂蓖麻油作了生料带性能(密度以及抗拉强度)的对比实验,也通过沉积实验确定了两种分散剂的最佳用量值;利用原子力显微镜分析了生料带的表面粗糙度。除此之外,测试850℃下共烧试样的烧结性能和微波性能,也证实了生料带与银电极的的共烧相容性,二者的匹配性优良。最后,测试了烧结后基板材料的性能。质量分数为1.5%的高分子分散剂制备的生料带的密度和抗拉强度分别为2.03g/cm3,2.0Mpa;共烧后LTCC试样的密度为3.08g/cm3、7GHz下的介电常数和介电损耗分别为7.92和1.6×10-3。质量分数为2.0%蓖麻油制备的生料的密度为1.73g/cm3,抗拉强度为1.72MPa;烧结后的基板材料的密度为3.06g/cm3、介电常数为和介电损耗分别为7.90和1.9×10-3。通过所有的定性和定量的的测试,最后得出结论:质量分数为1.5%的WCPA制备的生料带性能各方面优异。

关键词:聚合物分散剂 低温共烧陶瓷 流延 生料带

Study on tape casting green sheets with high density packaging

Abstract

The purpose of this peper was to develop a high-performence green sheet for LTCC application using a kind of polymeric dispersant in tape casting process of borosilicate-based glass/Al2O3 ceramics.The dispersant mechnism of polymeric dispersnt was analyzed in detail .Moreover,the effects of polymeric dispersant and castor oil commonly used in our laborlatory on green sheets properties(bulk density and tensile strength) were compared .Besides,the optimal amount of the two dispersants addition was determined through sedimentation experiement and the surface roughness of the film was analyzed by AFM.In addition, the sintering and microwave properties of the composite fired at 850℃ were also determined. For the application of tape technology, the co-firing compatibility between the composite and Ag electrodes at 850℃ was also verified and the metal matching performance was excellent .Finally, the bulk density and tensile strength of the green sheet prepared by polymeric dispersant with the mass fraction of 1.5% were 2.03g / cm3 and 2.0MPa respectively and the sintered LTCC composite exhibited good properties with the density at 3.08 g/cm 3,εr = 7.92, and tanδ= 1.6 × 10 −3 at 7 GHz.For the green sheet prepared by 2.0wt% castor oil,the bulk density and tensile strength were 1.73g/cm3 and 1.70Mpa respectively and the sintered LTCC material had the properties with the density at 3.06g/cm3,εr=7.90,and tanδ=1.9×10-3.Both of the sintered LTCC materials had the similar properties. After testing and verification with different qualitative and quantitative instruments,a flexible film optimized by 1.5 wt% polymeric dispersant achieved the best overall performance.

Key Words: Polymeric dispersant; LTCC; Tape casting; Green sheet

目录

摘要..........................................................................................................Ⅰ

ABSTRACT...........................................................................................................Ⅱ

- 绪论 ........................................................................................................1

- 课题背景............................................................................................................................1

- LTCC 技术简述................................................................................................................2

1.2.1 LTCC技术特点.......................................................................................................2

1.2.2 LTCC技术优势......................................................................................................3

1.3 LTCC技术对材料的要求....................................................................................................3

1.3.1 LTCC技术对陶瓷介质材料的要求........................................................................3

1.3.2 LTCC技术对有机物的要求....................................................................................5

1.3.3 LTCC技术对金属布线材料的要求........................................................................6

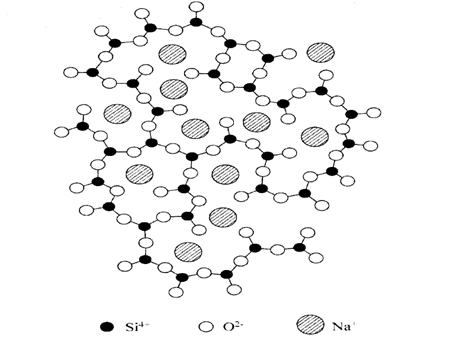

1.3.4 LTCC技术中的玻璃相............................................................................................6

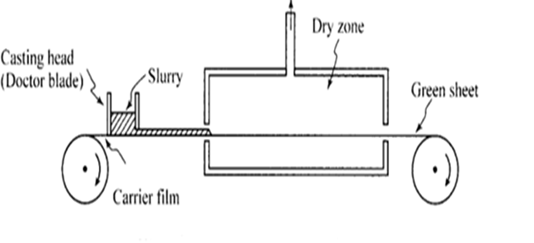

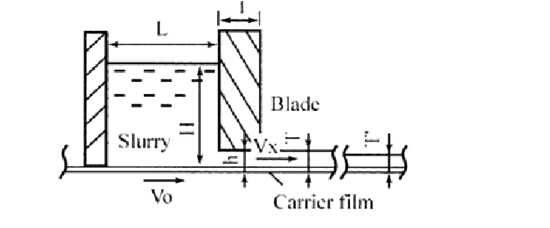

1.4 LTCC技术-流延成型工艺制备生料带...............................................................................8

1.4.1 流延设备...............................................................................................................8

1.4.2 生料带性能...........................................................................................................10

1.5 实验研究内容.....................................................................................................................11

第二章 实验内容..................................................................................................................12

2.1 实验原料..........................................................................................................................12

2.1.1 玻璃粉料的制备...................................................................................................12

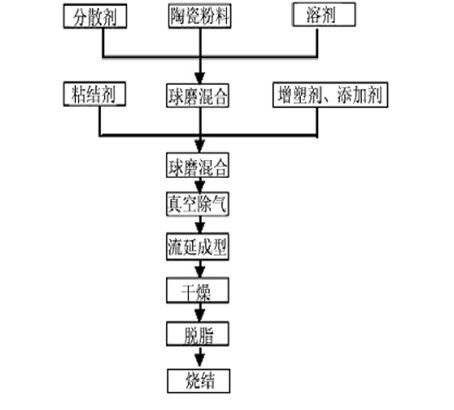

2.1.2 浆料制备...............................................................................................................12

2.2 实验工艺流程以及性能测试............................................................................................13

2.2.1 流延工艺...............................................................................................................13

2.2.2 性能测试...............................................................................................................15

第三章 实验结果与论.........................................................................................................17

3.1 红外光谱分析..................................................................................................................17

3.1.1 粉体及WCPA表面化学性质.............................................................................17

3.1.2 分散剂分散机制...................................................................................................18

相关图片展示: