1万吨年对乙酰氨基酚承压设备设计毕业论文

2020-06-20 19:16:57

摘 要

就对乙酰氨基酚制取而言,可行的方法很多。在中国,目前主要采用PAP、对亚硝基酚、硝基酚等苯酚傍支还原成对氨基酚,然后再和冰醋酸反应的路线,技术相对比较成熟,适合大规模生产本课题致力于研究对乙酰氨基酚生产过程中的主要承压设备,从而更好的制造出所需设备投入生产。

- 与化工学院本课题设计团队的同学协同学习,运用 Aspen Plus 流程模拟设计软件,对对乙酰氨基酚工程进行工艺设计模拟,得到物料工艺参数及设备工艺尺寸。

- 参照《甲醇制氢生产装置案例》和《化工设备设计手册》等设计资料,完成了年对乙酰氨基酚主要承压设备设计、设备立面布置以及管道平面布置等,设计结果能满足工程设计要求。

- 按照 NB/T47041-2014《塔式容器》和 GB150-2011《压力容器》等相关标准要求,对精馏塔及酯化反应器进行结构及附件选型设计,采用SW6-2011软件对设备进行强度设计和校核,设计结果必须满足使用要求。

- 按照 GB/T151-2014《热交换器》和 GB150-2011《压力容器》等相关标准要求,对冷凝器和再沸器进行结构及附件选型设计,采用SW6-2011软件对设备进行强度设计和校核,设计结果必须满足使用要求。

- 参照《化工多学科工程设计与实例》、《过程装备成套技术设计指南》这两本书,绘制出管道设备图,符合生产要求。

- 参照《过程装备成套技术》等相关资料及标准要求,对本课题进行技术经济评价,预估了未来的经济效益。

关键词:设备设计;对乙酰氨基酚 ;填料塔;有限元分析;SW6

ABSTRACT

There are many ways to synthesize acetaminophen. There is a traditional two-step method of p-nitrophenol or p-nitrophenol by chemical reduction of p-aminophenol (referred to as PAP), and then acylated into APAP synthesis route; also developed a catalytic reduction of two-step, that is catalytic reduction Synthesis of p - Amino - phenol Re - acylation. One step is to combine the reduction and acylation into one step. Recently, Japan has also developed a biochemical synthetic route. At present, the main domestic use of p-nitrophenol or p-nitrophenol reduced to p-aminophenol and then acylation route. Through the study of the characteristics and use of methyl acetate.

According to the requirements of acetaminophen properties, process requirements, due to the reaction is reversible, subject to equilibrium limits. Use the distillation column to distill off the excess water (acetic acid reaction concentration requirements, in 62 ~ 75wt% between the desired yield). Because water and acetic acid are relatively volatile, ordinary distillation is difficult to achieve separation requirements, intended to use azeotropic distillation separation. To carry out the design of the hydrolysis section, including process selection, process design, pipe design, reaction equipment design and technical and economic evaluation. Mainly carried out the following work:

1.with the Institute of Chemical Engineering in this project design team of students to learn, using Aspen Plus process simulation design software, the acetaminophen engineering process design simulation, the material process parameters and equipment process size.

2.with reference to the "Chemical Technology Handbook" and "Chemical Equipment Design Manual" and other design information, completed the year of acetaminophen main pressure equipment layout, equipment, surface layout and pipeline layout, design results to meet the engineering design requirements The

3.according to NB / T47041-2014 "tower container" and GB150-2011 "pressure vessel" and other relevant standards, the distillation tower and esterification reactor structure and accessories selection design, the use of SW6 process preparation strength calculation software Mechanical strength design and verification, the design results to meet the relevant regulatory requirements.

4. according to GB / T151-2014 "heat exchanger" and GB150-2011 "pressure vessel" and other relevant standards, the structure of the preheater structure and accessories selection design, the use of SW6 process equipment strength calculation software for mechanical strength design And check the design results to meet the relevant regulatory requirements.

5.With reference to the "multi-disciplinary engineering design and examples", "process equipment, complete sets of technical design guidelines," these two books, drawing out the pipeline equipment map, in line with production requirements.

6.with reference to "process equipment, complete sets of technology" and other relevant information and standard requirements, the subject of technical and economic evaluation, estimated the future economic benefits.

Key words: equipment design; acetaminophen; packed tower; finite element analysis; SW6

目 录

摘 要 I

ABSTRACT II

目 录 IV

第一章 概 述 1

1.1 市场概述 1

1.2 工艺流程 1

1.3生产过程中的主要设备: 2

1.3.1板式精馏塔(T0101): 2

1.3.2再沸器 (E0101): 2

1.3.3冷凝器 (E0102): 3

第二章 设备的选型与管道布置 4

2.1 设备的选型 4

2.1.1 泵的选型 4

2.2 设备厂区布置设计 5

2.3 管道设计 5

2.3.1 管子选型 5

3.3.2 管道布置图 9

第三章 对乙酰氨基酚主要承压设备设计 10

3.1 精馏塔结构设计 10

3.1.1 精馏塔壳体结构 10

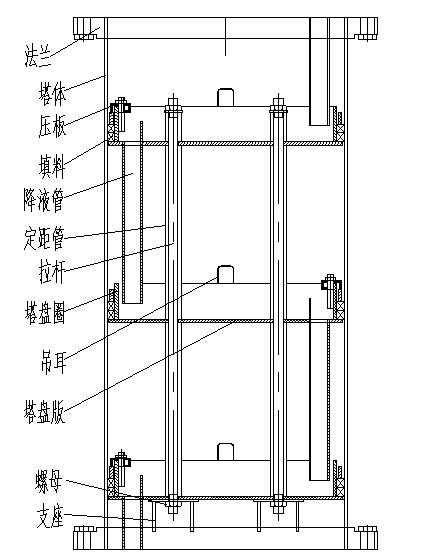

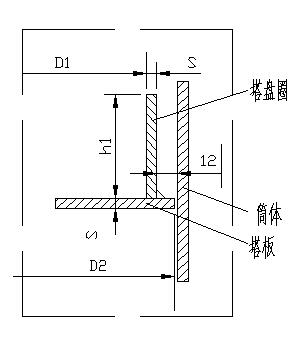

3.1.2 塔的塔盘结构 11

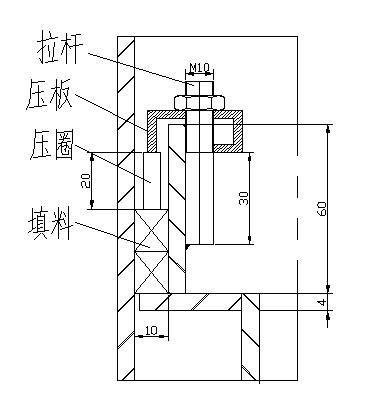

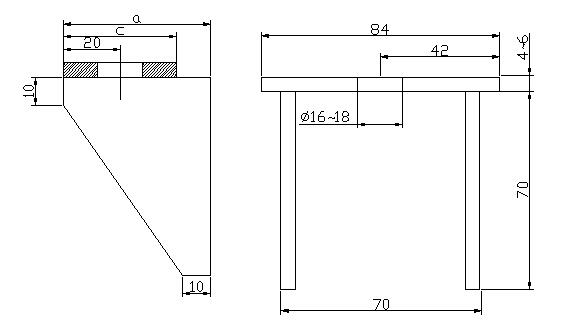

3.1.3 塔的其他结构 15

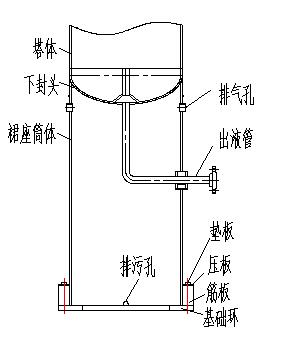

3.1.4 板式精馏塔塔的结构简图 17

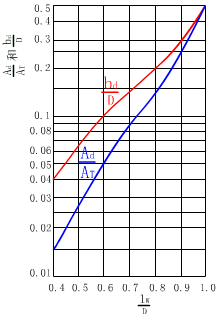

3.1.5板式精馏塔塔的强度校核 18

3.2 立式热虹吸再沸器结构设计 18

3.2.1 再沸器基本参数及选型 18

3.2.2 再沸器壳体结构 18

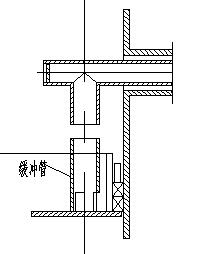

3.2.3 再沸器其他结构 19

3.2.4 立式热虹吸式再沸器的总体结构 22

3.2.5 再沸器的校核 22

3.3冷凝器结构设计 22

3.3.1冷却器基本参数及选型 22

2.3.2 冷却器壳体结构 23

2.3.3 冷却器其他结构 24

3.3.4 冷却器总体结构 26

3.3.5 冷却器的校核 26

第四章 经济核算 27

4.1 对乙酰氨基酚生产装置的投资估算 27

4.2 生产成本费用分析与估算 28

4.3 财务评价 29

4.3.1 盈利能力分析 29

4.3.2 盈亏平衡分析 30

总 结 31

参考文献: 32

附 录 34

致 谢 35

第一章 概 述

中国目前成为全球最大的化工原料生产工厂,在全球的生产制造中占有及其重要的位置。 近年来,国内外解热镇痛药市场呈现稳步增长态势,预计未来市场将继续扩大。以此,我国将面临巨大的机遇与挑战,然而现在生产对乙酰氨基酚的工艺技术相对比较成熟,使用的生产设备也大同小异,所以怎么用有限的资源创造出更多的价值是值得我们思考的,作为机械学院的学生,我希望设计出更优秀的塔设备以及换热设备,会更好的投入生产。

1.1 市场概述

进入21世纪,世界人口在逐年增加,短时间内里全球人口已增加了七十多亿,伴随人民生活水平的不断提高,人口老龄化严重,对药品的需求不断扩大。此外,随着科学的不断发展,新的药品也相继问世,而原先的一些药物也发现了新的用途。因此全世界范围内对解热镇痛药的需求一直只增不减,镇痛药这块大的蛋糕也一直吸引相关人士的目光。

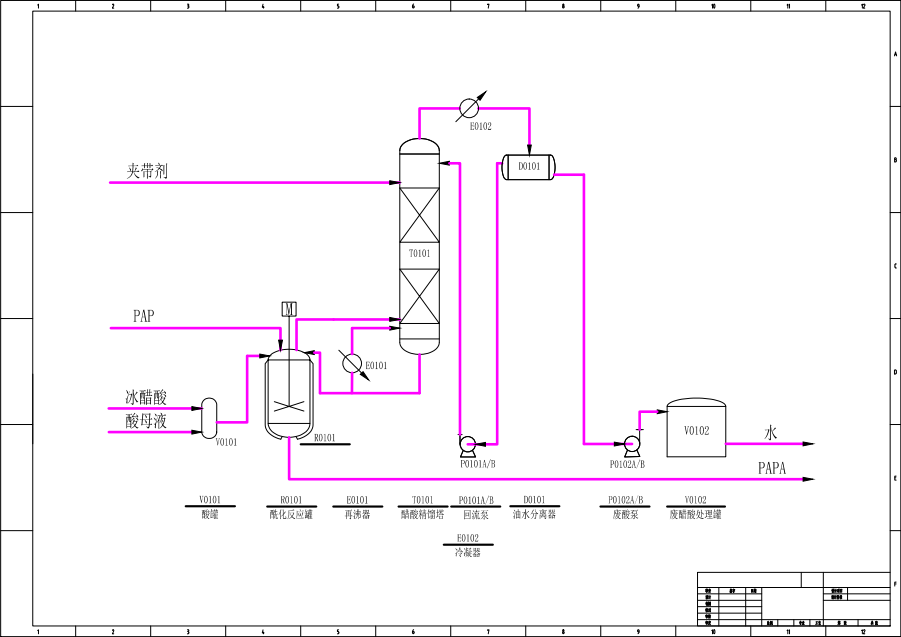

1.2 工艺流程

对乙酰氨基酚的合成方法有很多种,本课题采用PAP(氨基苯酚)与冰醋酸反应生成所需产物。

相关图片展示: