白云石和石灰石微粉对水泥抗硫酸盐侵蚀性能的影响毕业论文

2020-06-28 20:12:25

摘 要

石灰石微粉在水泥混凝土中做掺合料会降低水泥用量,符合可持续发展的理念。然而,石灰石微粉会对混凝土的长期性能有很大影响。掺入石灰石微粉的水泥混凝土在受到硫酸盐侵蚀后会导致水泥浆体膨胀、剥落、开裂和分层,对混凝土的耐久性构成了严重的威胁,而在低温环境中还会有发生碳硫硅钙石侵蚀的风险。在水泥混凝土中掺入白云石也能与水泥中铝质反应生成碳铝酸盐,与石灰石微粉一样在混凝土中具有积极效应。而对白云石在水泥混凝土中受到硫酸盐侵蚀的影响却鲜有系统性的研究。

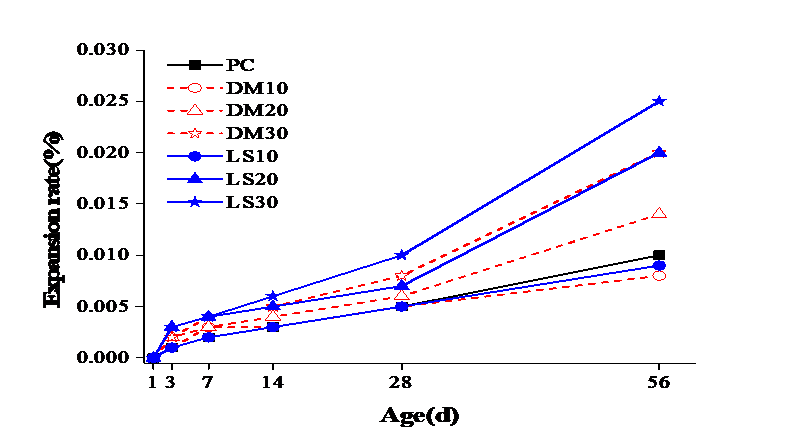

为了探究掺入白云石微粉后对水泥抗硫酸盐侵蚀性能的影响,本文以PC为参照,与同等掺量石灰石微粉取代的试件相对比,设计10%,20%与30%的单掺水泥及掺入粉煤灰,矿渣及偏高领土的复掺水泥在清水,质量浓度为3%及质量浓度为5%的硫酸钠溶液中的抗侵蚀性能的影响,通过测试侵蚀经过不同龄期的试件长度来分析试件的膨胀率,以及对比在清水中及在5%质量浓度的硫酸钠溶液中共同侵蚀28d的试件抗折性能来分析试件在硫酸盐侵蚀环境中的抗侵蚀性能随辅助填料的种类与掺量的变化对其造成的影响。并采用XRD的测试方法来分析试件受硫酸盐侵蚀后内部的产物,以此对白云石微粉在硅酸盐水泥抗硫酸盐侵蚀性能方面的表现进行了初步的阐述,并以此探讨白云石在混凝土水泥中对抗硫酸盐侵蚀的相关机制。本文研究主要得出以下结论:

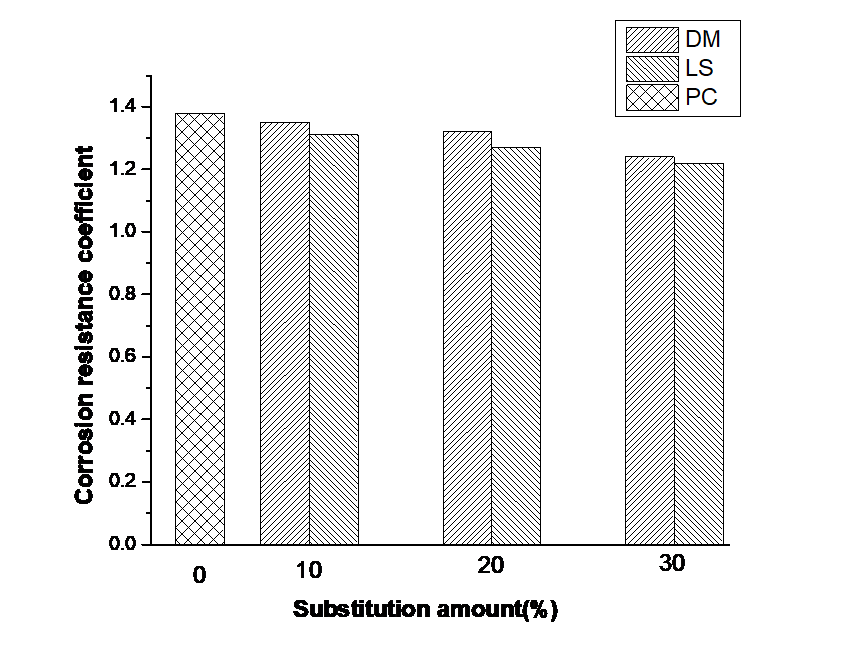

在硅酸盐水泥中引入碳酸盐岩微粉会导致水泥受到硫酸盐侵蚀后膨胀率升高,抗折强度及抗蚀系数下降,且随着掺量的提高水泥劣化程度更加严重;

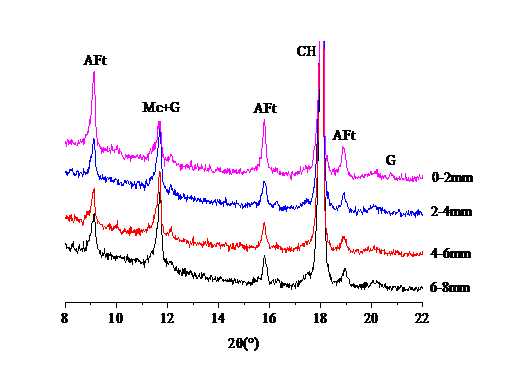

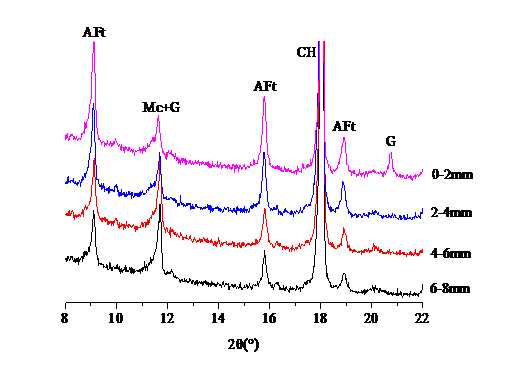

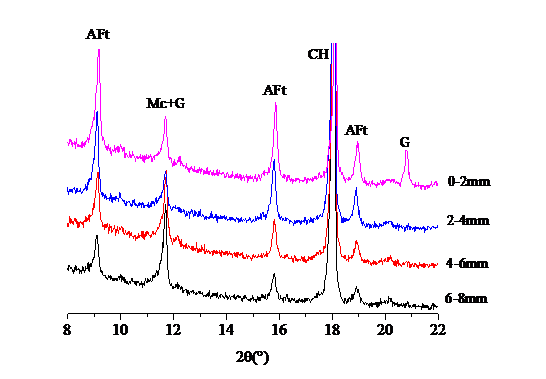

与石灰石相比,白云石对水泥抗硫酸盐侵蚀效果更好,从XRD图谱分析得知水泥受到硫酸盐侵蚀后的产物石膏可能为影响白云石水泥抗硫酸盐侵蚀性能的原因。

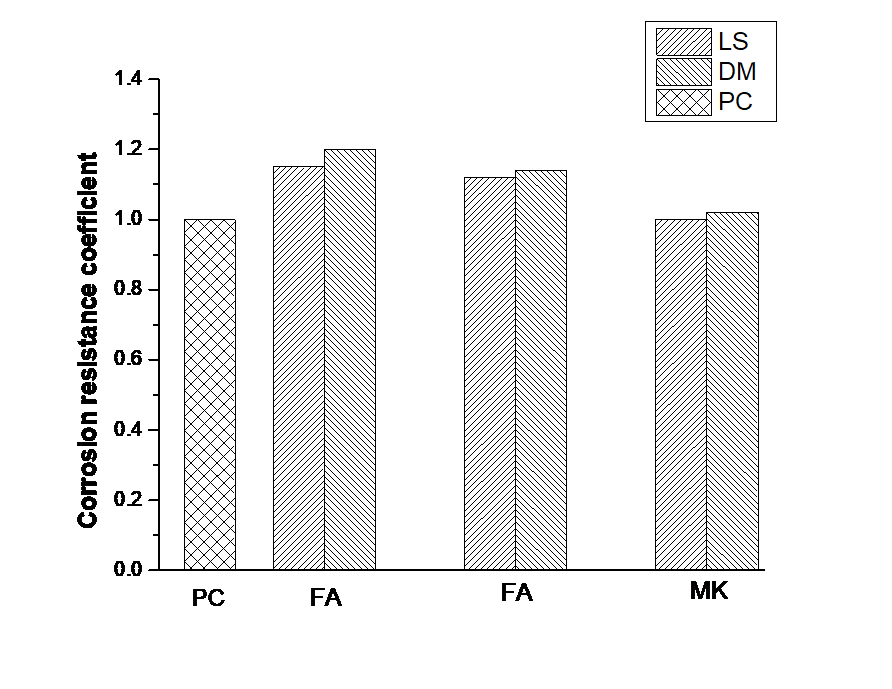

在水泥中掺入复合掺合料可有效改善水泥受到硫酸盐侵蚀后强度下降问题,不同掺合料对水泥影响不同,其中粉煤灰的掺入对水泥抗侵蚀效果提升最好,而掺入偏高领土的水泥在复掺水泥中劣化最为严重。

关键词:硅酸盐水泥 白云石 石灰石 硫酸盐侵蚀

Effect of dolomite and limestone powder on the sulfate resistance of cement

Abstract

The application of auxiliary cementing filler can reduce the carbon emission of cement, save cost, reduce the actual consumption of cement, save energy, and have good economic effect and ecological affinity. When limestone powder is used as admixture in cement concrete, the early strength of cement will be increased to produce calcite and gypsum, and the micro-pore structure of cement will be improved. Existing studies have shown that dolomite powder can also produce similar effects to limestone powder when it is added into cement as filler. The aluminum phase component in the cement reacts with the micro powder to form carboaluminate, filling the micro holes in the concrete forming process. However, the long-term durability of cement will be greatly reduced by the addition of these carbonate rocks.

The main environmental factors affecting the durability of concrete structures are chloride and sulfate. Especially in a variety of salt in the form of sulfate (for example, sodium sulfate, magnesium sulfate, potassium sulfate and calcium sulfate), the salt and the water in the cement compound reaction can lead to water slurry expansion, peeling, cracking and delamination. Therefore, the deterioration of concrete structure in soil and groundwater eroded by sulfate poses a serious threat to the durability of concrete.

Although had been put forward many theories about the mechanism of sulfate attack, but due to its complex behavior, the problem is still not well explain [. In the past few decades, people have been trying to go to a better understanding of the problem, in order to develop more effective solutions.

Limestone powder added to make cement concrete sulfate attack effect has a lot to ascend, and in the low temperature (4 ℃) in the environment there will be risk of carbon and erosion of thaumasite. However, there is little systematic study on dolomite in cement concrete. To explore adding dolomite powder cement concrete on the effect of sulfate erosion, based on the PC for reference, and the same dosage of limestone powder to replace concrete, design of 10%, 20% and 30% of the mixed cement and mixed with fly ash, slag and cement in the clear water of high territory of mixed, mass concentration of 3%, and the mass concentration of 5% sodium sulfate solution erosion resistance, the influence of by testing the specimen length of erosion through different age to analyze the expansion rate of the specimens, And contrast in clean water and the sodium sulfate solution in 5% mass concentration common erosion 28 d of specimen bending performance to analyze the specimen in the erosion resistance of sulfate erosion environment along with the change of the kinds and dosage of auxiliary packing to its effects. Using XRD test method to the analysis of product within the specimen by sulfate erosion of dolomite powder in Portland cement sulfate erosion resistance performance are preliminarily described, and to explore the dolomite in the cement concrete against sulfate erosion mechanism. This paper mainly draws the following conclusions:

Introduction of carbonate rocks in Portland cement powder will result in higher cement is sulfate erosion and expansion rate, bending strength and corrosion resistance coefficient, and with the increase of dosage of the cement degradation is more serious;

Compared with limestone, dolomite of cement resistance to sulfate erosion effect is better, learn from XRD spectrum analysis product gypsum cement is sulfate erosion and has the potential to affect the cause of the dolomite cement sulfate erosion resistance.

Mixed with compound admixture in cement can effectively improve the strength of cement is sulfate erosion and degradation, the influence of different admixture on cement, fly ash of the incorporation of cement erosion resistance increases, the best cement and mixed with high territory degradation is most severe in the mixed cement.

Key words: Portland cement dolomite limestone sulfate attack

目录

摘要…………………………………………………………………………………I

ABSTRACT………………………………………………………………………II

第一章 绪论………………………………………………………………………1

1.1课题背景及意义……………………………………………………………1

1.2硫酸盐侵蚀机理……………………………………………………………3

1.3石灰石微粉对水泥抗硫酸盐侵蚀性能的影响……………………………5

1.4白云石微粉在水泥中的应用………………………………………………6

1.5研究内容……………………………………………………………………6第二章 实验原料与实验方法…………………………………………………7

2.1实验原料……………………………………………………………………7

2.1.1水泥与骨料…………………………………………………………7

2.1.2碳酸盐岩微粉………………………………………………………7

2.1.3复合掺合料…………………………………………………………7

2.2 配合比方案…………………………………………………………………7

2.3实验方法……………………………………………………………………8

第三章 含碳酸盐岩微粉水泥抗硫酸盐侵蚀性能………………………10

3.1潜在膨胀性试验方法(P法)……………………………………………10

3.1.1试件表观特征…………………………………………………………10

3.1.2砂浆试件膨胀数据分析………………………………………………10

3.2浸泡抗蚀性能试验方法(K法)…………………………………………12

3.2.1掺入碳酸盐岩微粉砂浆抗硫酸盐侵蚀性能…………………………12

3.3水泥净浆试件抗硫酸盐侵蚀机制分析……………………………………13

第四章 结论……………………………………………………………………16

参考文献 ………………………………………………………………………17

第一章 绪论

1.1课题背景及意义

作为当今基础设施及建筑建设不可替代的原材料,水泥配方一直是混凝土研究领域中一直研究发展的对象。发展至今其种类与配方各式各样,除传统水泥外还发展出了快速修补水泥,抗严峻环境水泥(如酷寒,酸碱度等)等特种水泥[1]。而传统水泥根据其主要原料大致分为硅酸盐水泥与硫铝酸盐水泥两类。通常情况下,由于自然因素,外力及铺设环境的影响,混凝土会因各种侵蚀而降低使用寿命。一般混凝土寿命都在几十年间。一方面,我国正处于经济发展阶段,现代工程建设离不开水泥砂浆,对于混凝土原料的粘土或制成的水泥生粉的需求逐年升高,各类外加剂的产量也一直居高不下[2]。另一方面,从环境保护及可持续发展角度来看,我国积极倡导工厂节能减排,减少污染;发达国家前期建设使用的水泥砂浆不达标准,道路等基础设施不断耗资返修养护的先例也对混凝土的强度,模量,抗侵蚀性能等提出了更高的标准与要求[3]。在这种环境下,向水泥中添加填料,辅助性胶凝材料(SCMs)以提高产量,节约成本[4];同时发展填料与外加剂对混凝土的抗侵蚀性能的影响是当今学界对水泥砂浆研究的主要方向。

相关图片展示: