油酸甲酯接枝聚硅氧烷的改性研究毕业论文

2020-07-02 22:58:47

摘 要

随着有机硅工业的发展,有机硅产品也日趋丰富。但现国内有机硅产业与国外有机硅产业发展仍存在一定的差距,有机硅的需求与供给并不能达到平衡,随着有机硅单体产能的过剩,而市场对高品质有机硅材料需求的增长,有机硅下游产品的研发与应用拓展成为国内有机硅产业的一个桎梏。在有机硅产品中,硅油作为第二大有机硅产品,仅次于硅橡胶,越来越受到人们的关注。

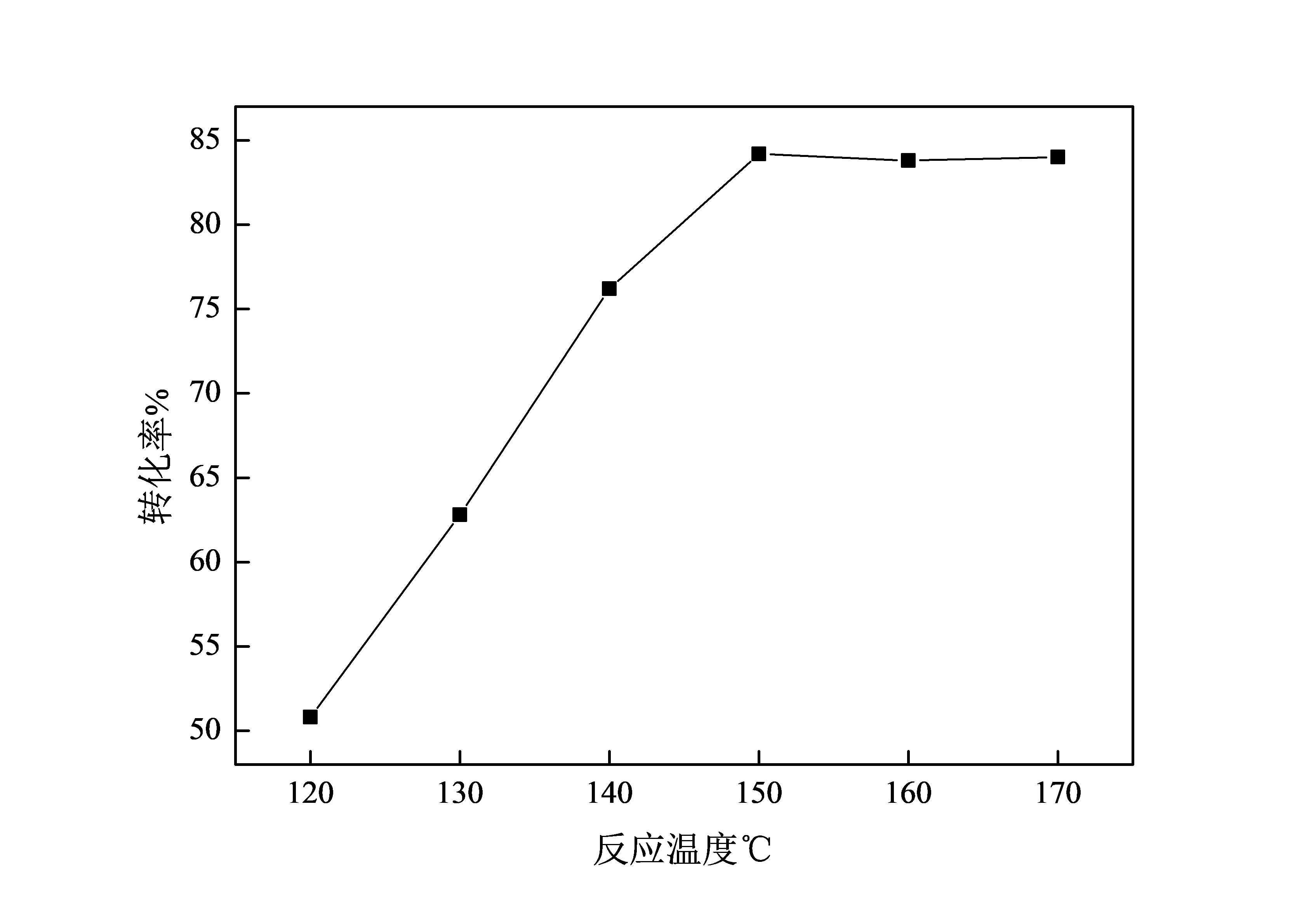

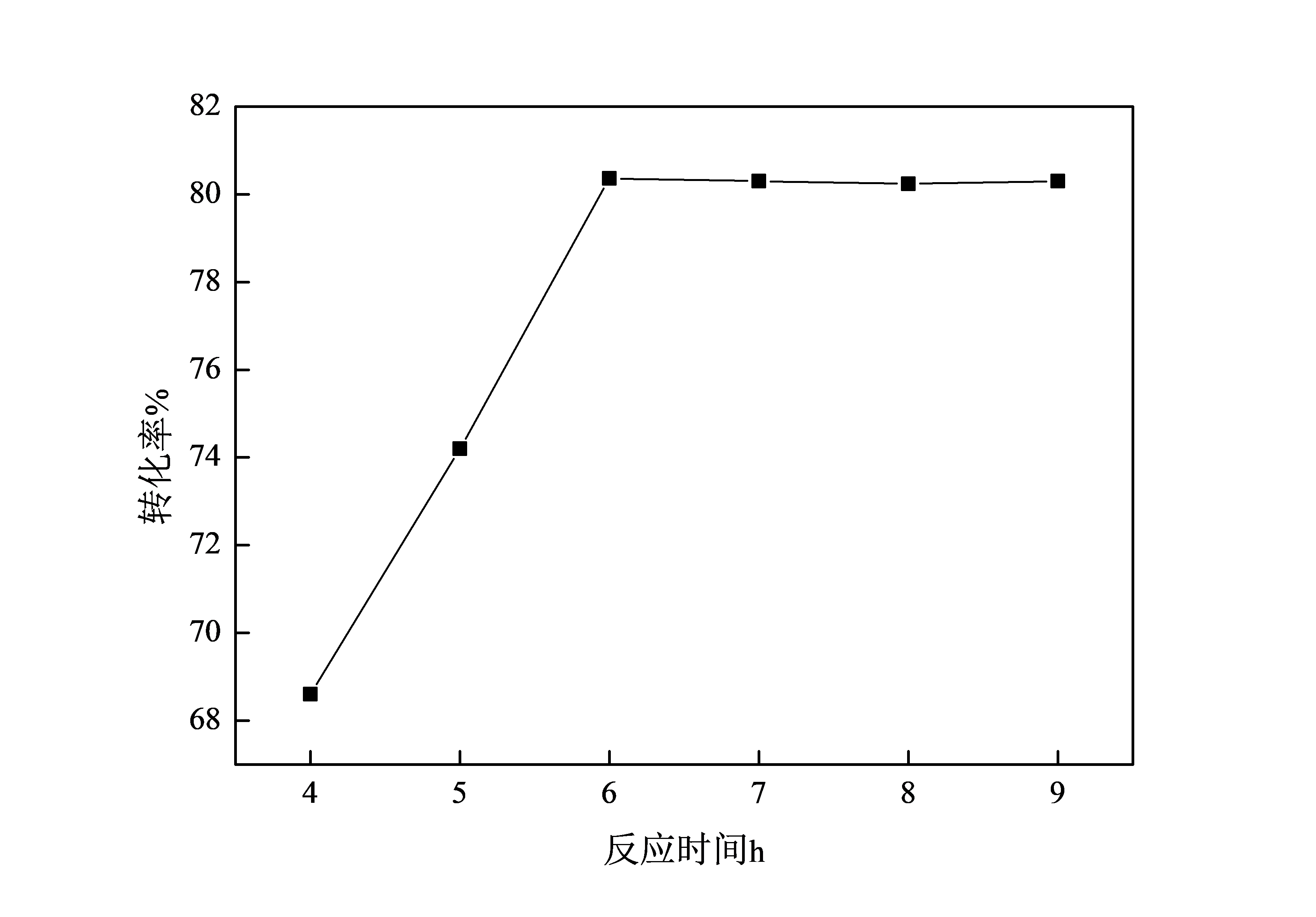

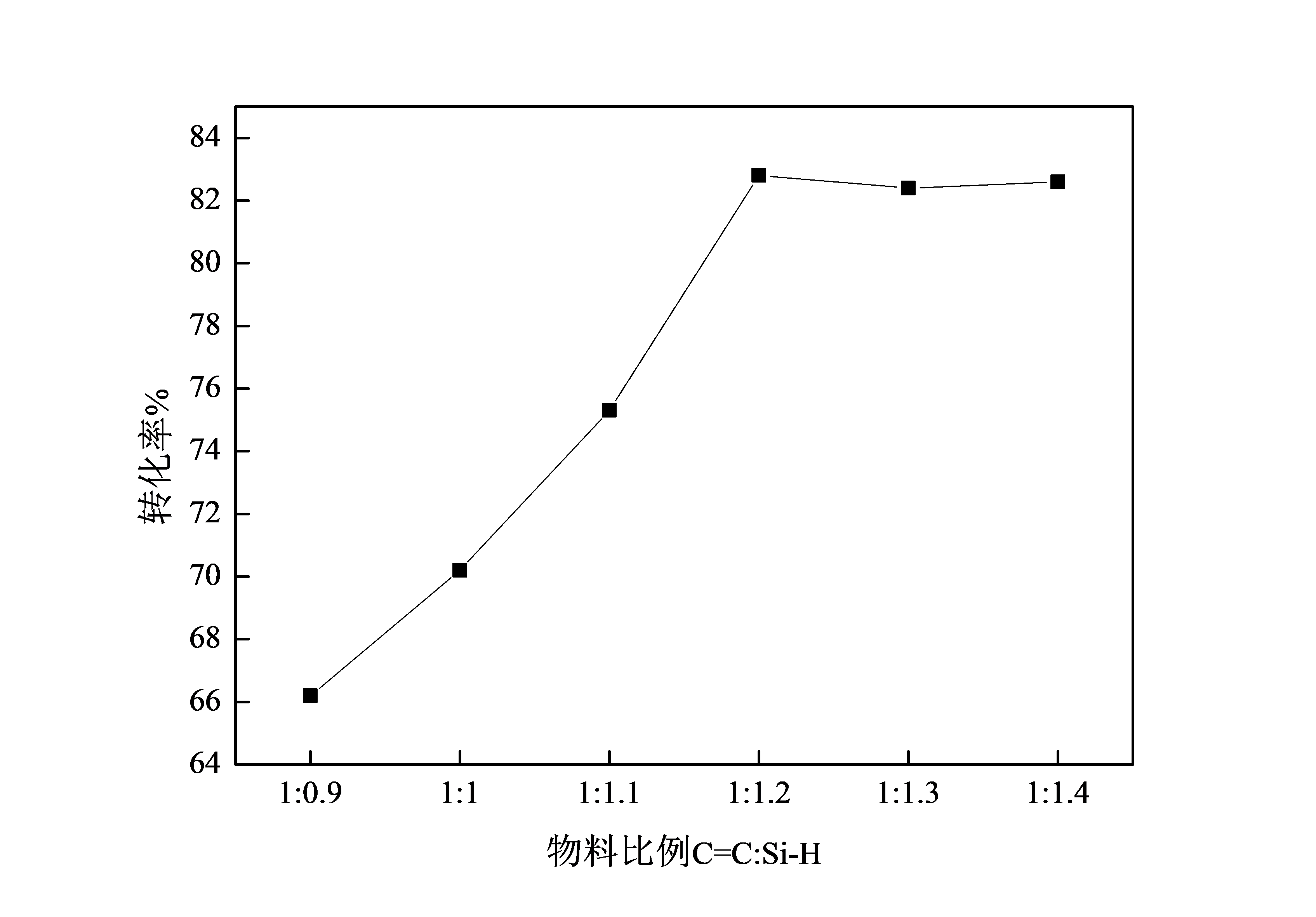

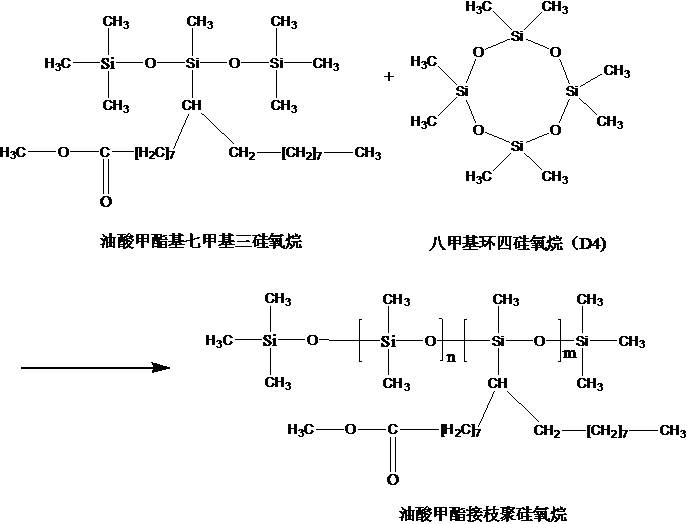

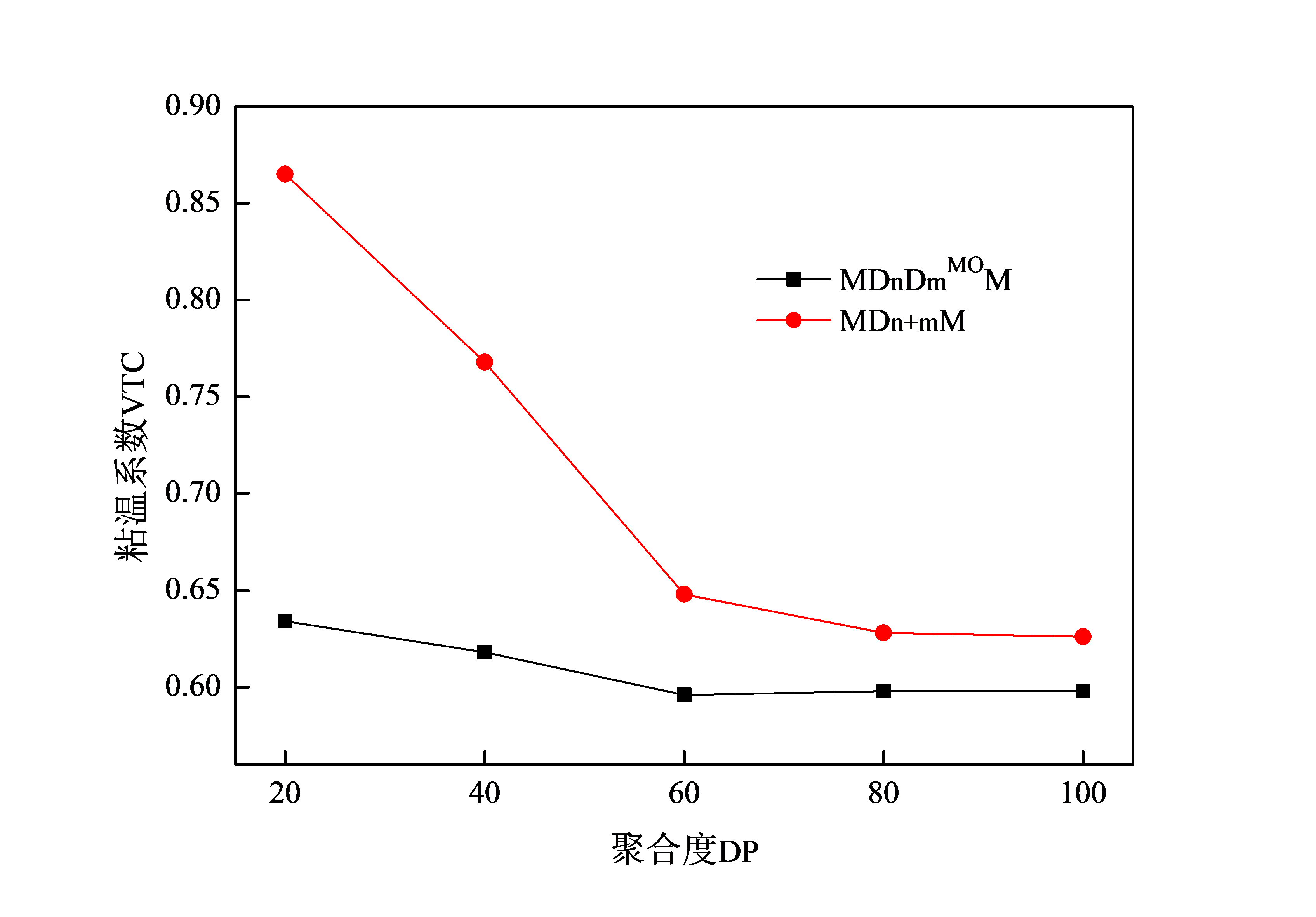

本课题以油酸甲酯(MO)、七甲基三硅氧烷(MDHM)为原料,通过硅氢加成反应合成了MO接枝的三硅氧烷(MDMOM)。通过单因素实验考察硅氢加成催化剂、反应时间、反应温度、物料比例(C=C:Si-H)和催化剂用量对反应的影响,得出了最佳反应条件:催化剂为六水合氯铂酸异丙醇溶液,反应温度为150℃,反应时间为6h,物料比C=C:Si-H为1:1.2,催化剂用量为6%。以MDMOM、八甲基环四硅氧烷(D4)为原料通过开环调聚反应制备了MO接枝的聚硅氧烷产品MDnDmMOM。通过改变原料的比例,设计合成了不同聚合度的MDnDmMOM,并对其粘温性能进行了研究。研究发现:MDnDmMOM的密度、粘度、表面张力随聚合度增大而增大,低聚合度时,MDnDmMOM的粘温系数随聚合度增大而降低,高聚合度时,分子间作用力达到一个定值,粘温系数基本不变,且与相同聚合度二甲基硅油(MDn mM)相比,MDnDmMOM的粘温性能也有所提高。

关键词:油酸甲酯 改性硅油 硅氢加成 聚合度 粘温性能

Synthesis and Properties of Polysiloxane Grafted with Methyl Oleate

Abstract

With the development of organic silicon industry, organic silicon products are becoming more and more abundant. However, there is still a certain gap in the development of organic silicon industry between domestic and foreign. The supply of organic silicon can not cater the demand. With the excess production of organic silicon monomers and the increasing demand for high-quality organic silicon materials, Silicone's Ramp;D and application of silicone downstream products have become a challenge in the domestic silicone industry. In silicone products, silicone oil, as the second largest organic silicone product, second only to silicone rubber, has attracted more and more attention.

In this study, MO-grafted trisiloxane (MDMOM) was synthesized by hydrosilylation reaction using methyl oleate (MO) and heptamethyltrisiloxane (MDHM) as raw materials. The effects of hydrosilylation catalyst, reaction time, reaction temperature, ratio of materials (C=C:Si-H) and catalyst dosage on the reaction were investigated by single-factor experiments, and the optimal reaction conditions were obtained: the catalyst was hexachloroplatinum hexahydrate Acid isopropanol solution, reaction temperature is 150℃, reaction time is 6h, material ratio C=C:Si-H is 1:1.2, and the dosage of catalyst is 6%. The MO-grafted polysiloxane product MDnDmMOM was prepared by ring-opening telomerization using MDMOM and octamethylcyclotetrasiloxane (D4) as raw materials. By varying the proportion of raw materials, MDnDmMOM with different degree of polymerization was designed and synthesized, and its viscosity-temperature performance was studied. The study found that the density, viscosity, and surface tension of MDnDmMOM increase with increasing degree of polymerization. When the degree of polymerization is low, the viscosity-temperature coefficient of MDnDmMOM decreases as the degree of polymerization increasing, and when the degree of polymerization is high, the intermolecular force reaches a fixed value. The viscosity and temperature coefficient was almost constant, and the viscosity-temperature performance of MDnDmMOM was also improved compared with the same degree of polymerization of dimethyl silicone oil (MDn mM)

Key words: methyl oleate; modified silicon oil; silicon hydrogenation; degree of polymerization; viscosity-temperature performance

目 录

摘要…………………………………………………………………………………I

ABSTRACT………………………………………………………………………III

第一章 文献综述 1

1.1 有机硅概述 1

1.2 有机硅的分类及应用 1

1.3 国内有机硅工业的发展 3

1.4长链烷基改性硅油 4

1.4.1长链烷基改性硅油简介 4

1.4.2长链烷基改性硅油的合成方法 5

1.5研究内容和目的 6

第二章 油酸甲酯接枝七甲基三硅烷的合成 8

2.1 主要试剂、原料及仪器设备 8

2.1.1 主要试剂、原料 8

2.1.2 实验仪器 8

2.2 实验过程及分析方法 9

2.2.1 MDMOM的合成 9

2.2.2 分析方法 10

2.3 MDMOM的合成条件研究 10

2.3.1 催化剂的选择 10

2.3.2 反应温度 11

2.3.3 反应时间 12

2.3.4 物料比例(C=C:Si-H) 12

2.3.5 催化剂用量 13

第三章 油酸甲酯基聚硅氧烷的制备及性能研究 16

3.1 主要试剂、原料及仪器设备 16

3.1.1主要试剂及原料 16

3.1.2主要仪器设备 16

3.2 实验过程及分析方法 16

3.2.1 MDnDmMOM的合成 16

3.2.2 原料配比及产物设计结构 17

3.2.3分析方法 17

3.3 MDnDmMOM制备及性能研究 19

3.3.1 MDnDmMOM的制备 19

3.3.2 MDnDmMOM的粘温性能研究 20

第四章 结论与展望 22

参考文献 24

致 谢 27

第一章 文献综述

1.1 有机硅概述

硅作为过渡元素,在地球中的含量极为丰富,在地壳中的质量含量为25.7%,仅次于氧。由于具有特殊性质,硅的应用范围极其广泛,有机硅化合物也因此倍受青睐。有机硅,又俗称“工业味精”,是现代工业必不可少的一类材料,现已知结构的有机硅产品多达六、七万种[1]。

硅原子对于氧原子来说,有极大的亲和力,这导致自然界中硅主要以氧化物的形式存在,如二氧化硅和硅酸盐等。硅的共价半径为0.117nm,核电荷数较多,但核内电荷得到较好的屏蔽,硅原子的最外层电荷数为四,即为价电子,其处于亚稳态状态,这是硅能作为半导体导电材料的根据,同时也导致硅电负性较低,使它可同时与电负性较高的元素(如F、O、Cl等)和电负性较低(H-、CH3-、C6H5-等)的官能基团或非官能基团结合,形成多种稳定化合物。常见的硅化合物中大多含有Si-O共价键,键能达1014.2KJ/mol,故热稳定性很高[2]。

相关图片展示: