玻璃纤维棉增强聚合物基复合材料制备与性能分析毕业论文

2020-07-16 20:27:27

摘 要

随着科学技术的发展,纤维增强聚合物(FRP)复合材料越来越受到人们的重视,并且已在航空航天、汽车、船舶和建筑等领域中得到广泛的应用。相比于复杂的连续纤维增强,短纤维增强聚合物(SFRP)成本更低廉且易加工,更适合工业化批量生产。

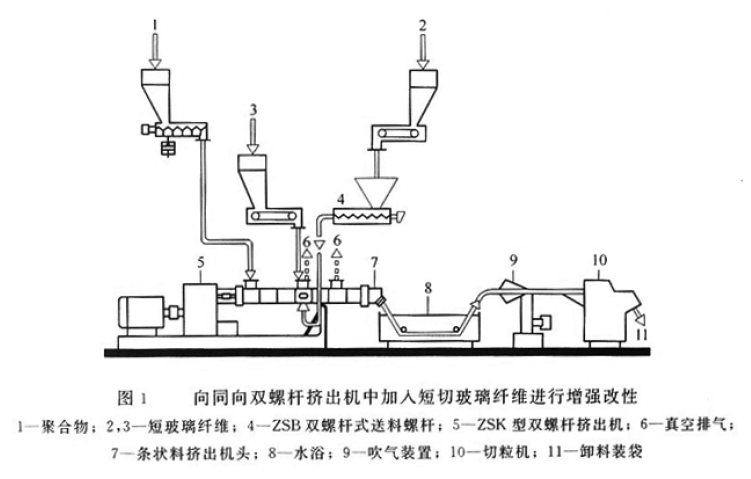

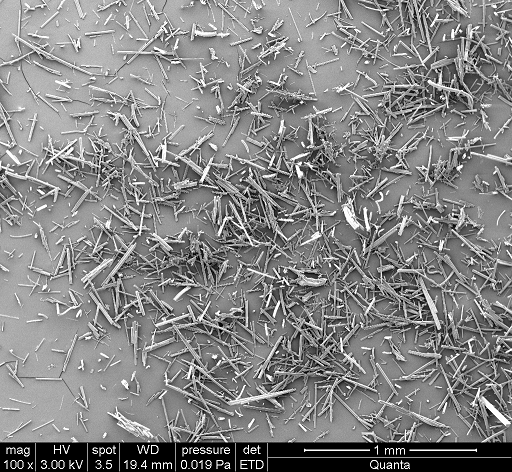

本文以玻璃纤维棉短纤维和聚丙烯(PP)为原料,利用双螺杆挤出机和注塑成型工艺制备了无纤维添加、5wt%、20wt%、30wt%、40wt%和50wt%6种玻璃纤维棉含量的增强PP复合材料。采用万能材料试验机测试断裂伸长率、拉伸模量和复合材料拉伸强度,采用热变形温度测定仪测试复合材料热变形温度,采用冲击强度试验机测试复合材料冲击强度,采用扫描电子显微镜(SEM)研究复合材料表面和断面微观形貌,分析不同含量的玻璃纤维棉对PP物理性能、力学性能和热性能的影响规律。结果表明:

(1)随着玻璃纤维棉掺杂含量的不断升高,复合材料的密度也不断升高,从900 kg/m3上升至1302 kg/m3,提高了44.7%;

(2)玻璃纤维棉的添加使PP流动速率下降;玻璃纤维棉含量在0wt%到50wt%时,热变形温度随着复合材料中玻璃纤维棉含量的升高不断升高,由120℃提高到136℃,提高了13.3%。

(3)在纤维含量0~40wt%区间内,拉伸强度和拉伸模量不断增加,拉伸强度从28MPa上升至59MPa,提高了110.7%;拉伸模量从1250MPa上升至5520MPa,提高了341.6%。当纤维含量从40wt%升至50wt%,拉伸强度和模量都下降;玻璃纤维添加不利于PP材料的抗冲击性能,但相对而言,40%玻璃纤维棉掺杂性能较好,证明玻璃纤维棉添加最佳含量在40wt%。

关键词:短纤维 玻璃纤维棉 聚丙烯 纤维增强复合材料

Preparation and Performance Analysis of Glass Fiber Reinforced Polymer Composites

ABSTRACT

With the development of science and technology, fiber-reinforced polymer (FRP) composite materials have attracted more and more attention, and have been widely used in aerospace, automotive, marine and construction fields. Compared to the complex continuous fiber reinforcement, short fiber reinforced polymer (SFRP) is cheaper and easier to process, and is more suitable for industrial mass production.

In this paper, glass fiber cotton staple fiber and polypropylene (PP) were used as raw materials. Fibers without fiber addition, 5wt%, 20wt%, 30wt%, 40wt% and 50wt% were prepared using twin screw extruder and injection molding process. Fiber cotton reinforced PP composites. The heat distortion temperature of the composites was measured with a heat distortion temperature tester. The impact strength of the composites was tested with an impact strength tester and the scanning electron microscope was used. (SEM) The surface and cross-section microstructures of composites were studied. The influence of different content of glass fiber cotton on the physical properties, mechanical properties and thermal properties of PP was analyzed. The results show:

(1) With the increasing of the content of glass fiber cotton, the density of the composite material also increased continuously, from 900 kg/m3 to 1302 kg/m3, an increase of 44.7%;

(2) The addition of glass fiber cotton decreased the flow rate of PP; when the content of glass fiber cotton was 0 to 50 wt%, the heat distortion temperature increased with the increase of the content of glass fiber cotton in the composite material and increased from 120°C to 136°C, an increase of 13.3%.

(3) In the range of 0-40 wt% fiber content, the tensile strength and tensile modulus increased continuously. The tensile strength increased from 28 MPa to 59 MPa, increased by 110.7%. And the tensile modulus increased from 1250 MPa to 5520 MPa. When the fiber content is increased from 40wt% to 50wt%, the tensile strength and modulus are both decreased; the addition of glass fiber is not conducive to the impact resistance of PP materials, but relatively speaking, 40% glass fiber cotton doping performance is better, proving that glass the best content of fiber wool is 40wt%.

Key Words: Short fiber; Glass fiber; Polypropylene; Fiber-reinforced composite

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1短纤维增强聚合物的背景与意义 1

1.2聚丙烯简介 2

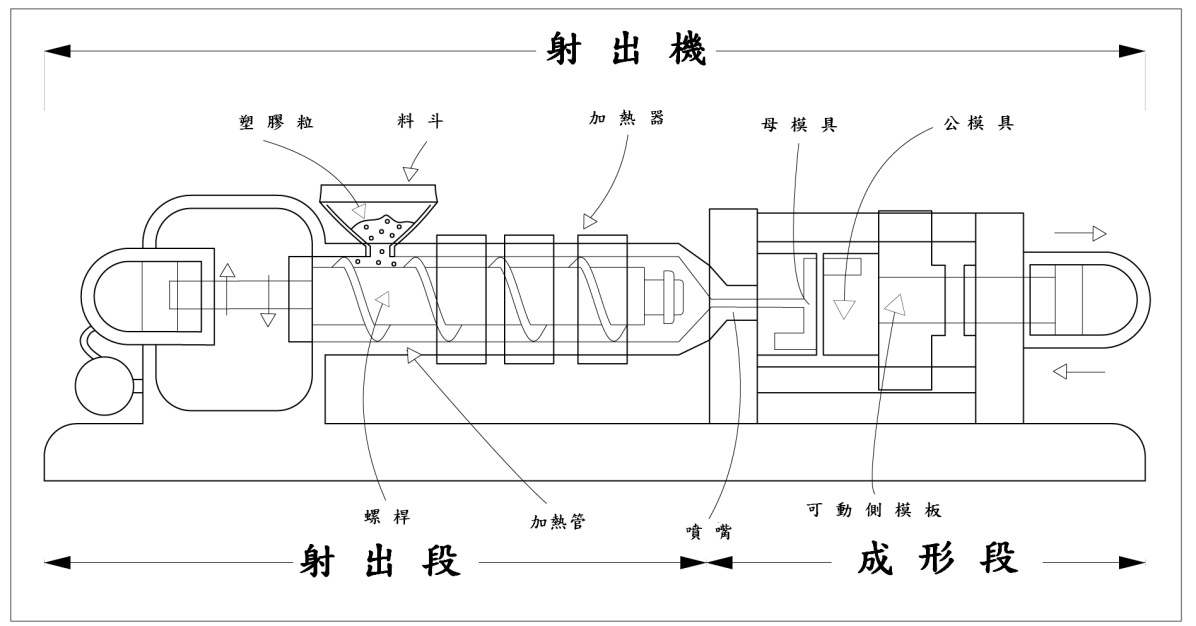

1.3短纤维增强聚合物合成方法-注塑成型 4

1.4研究内容 6

第二章 材料制备及性能表征 8

2.1 实验材料和仪器 8

2.2 测试表征 9

第三章 实验结果与讨论 12

3.1 玻璃纤维棉性能表征 12

3.2 不同玻璃纤维含量的影响 15

第四章 结论与展望 24

4.1 结论 24

4.2 展望 24

第五章 经济性分析 25

参考文献 26

致 谢 30

第一章 绪论

1.1短纤维增强聚合物的背景与意义

短纤维增强聚合物(SFRP)复合材料已经在商业机械零件、汽车、耐用消费品、运动商品和电子工业等领域中得到广泛的应用,因为它们的成本很低廉并且易于加工,而且其相对于普通聚合物优越的机械性能。注塑工艺和挤压复合这两种方法经常用于制造SFRP复合材料。与连续纤维复合材料的耗时复杂的生产工艺相比,使用这些常规制造技术来生产大规模SFRP复合材料部件使得这些复合材料的制造高效且便宜,这就使得它们更适合大批量生产[1]。在注塑成型的SFRP复合材料部件中,通常有一个玻璃纤维长度分布(FLD)和一个纤维取向分布(FOD)。FLD和FOD通常是由纤维长度,纤维含量,模具几何形状和加工条件决定。外加到聚合物基体的短纤维会使得复合材料表现出明显改进的强度和刚度。然而,断裂韧性或特定的断裂功(WOF)可能会增强或减少。强度、刚度和断裂韧性或短纤维复合材料的WOF已被证明严重依赖FLD和FOD[2]。

图1.1 SFRP在飞机制造方面的应用

相关图片展示: