聚酰亚胺基电介质复合材料的制备与性能研究毕业论文

2021-12-10 17:45:09

论文总字数:24994字

摘 要

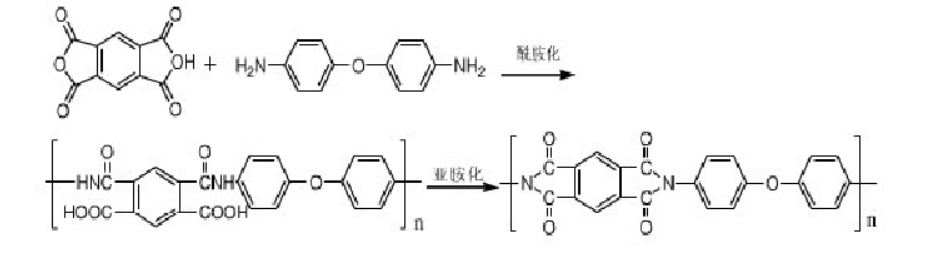

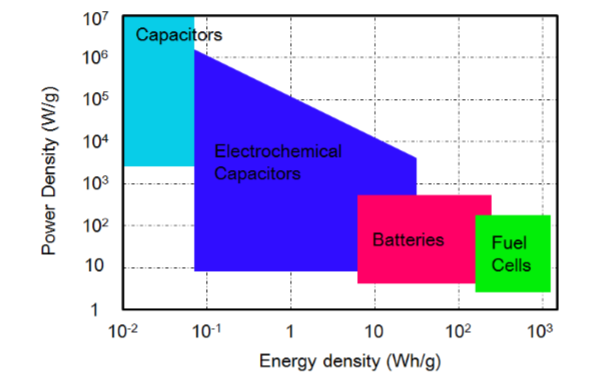

电子产品在高温下的高功率应用,如电动汽车、飞机和脉冲电力系统的兴起,推动了向电容储能方向发展的新一代高温介电材料的需求。聚合物介质具有重量轻、可扩展性、机械柔性、高介电强度和高可靠性等特点,而现有的BOPP电介质薄膜使用的上限温度仅为70℃,聚酰亚胺具有优异的热稳定性、电气绝缘性能以及良好的成膜性能,具备发展为高温介电储能材料的潜在优势。聚酰亚胺自身能量密度过低,无法满足高功率系统,能源系统对高储能密度的需求,且材料的介电常数和击穿场强存在难以同时提高的问题。本文设计了一种以聚酰亚胺(PI)作为基体,通过溶液复合流延技术在其中添加氮化硼纳米片(BNNS)和α-氧化铝纳米颗粒(Al2O3 NPs),制备出BNNS-Al2O3-BNNS型PI基三明治结构复合薄膜。研究结果如下:

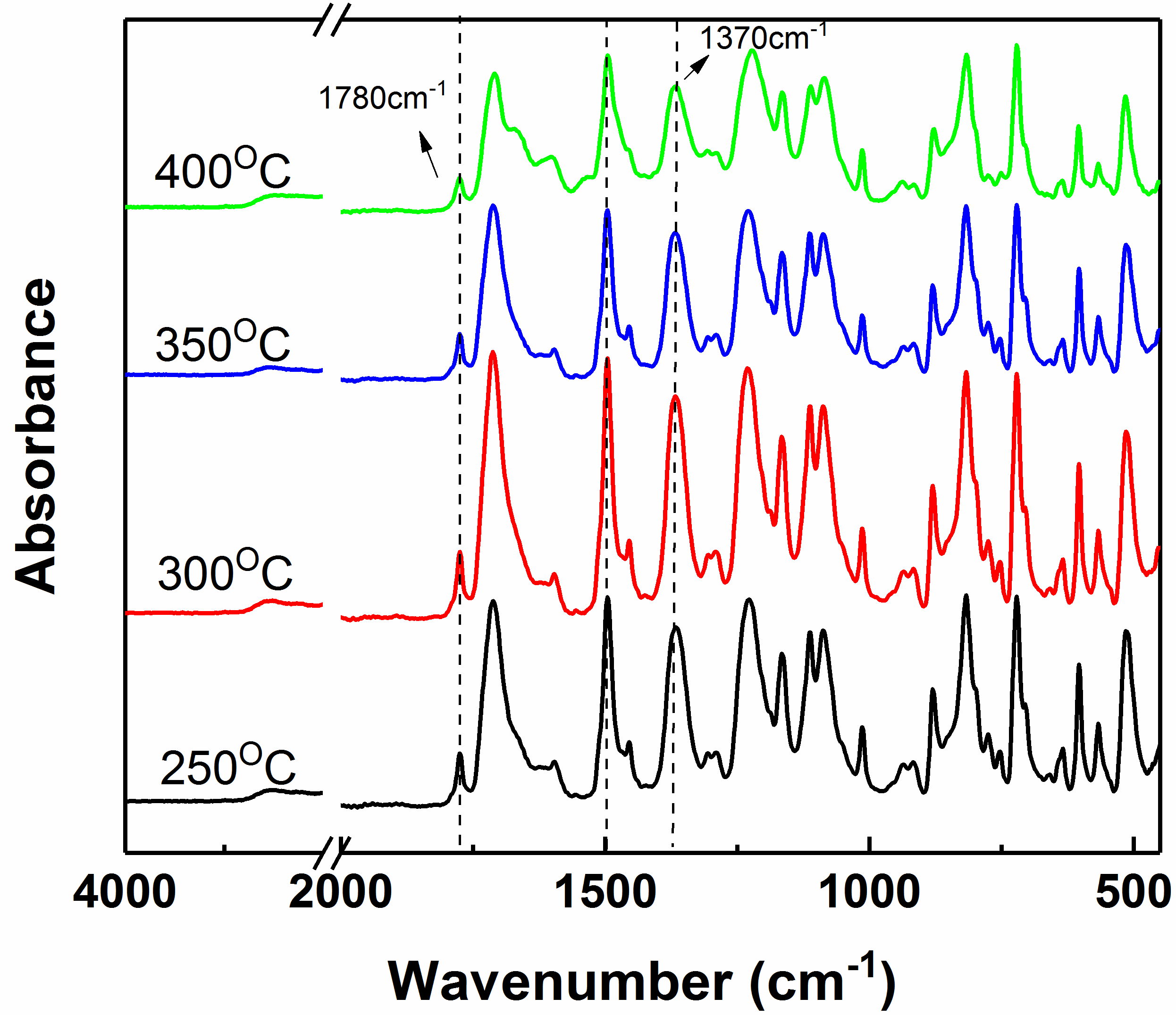

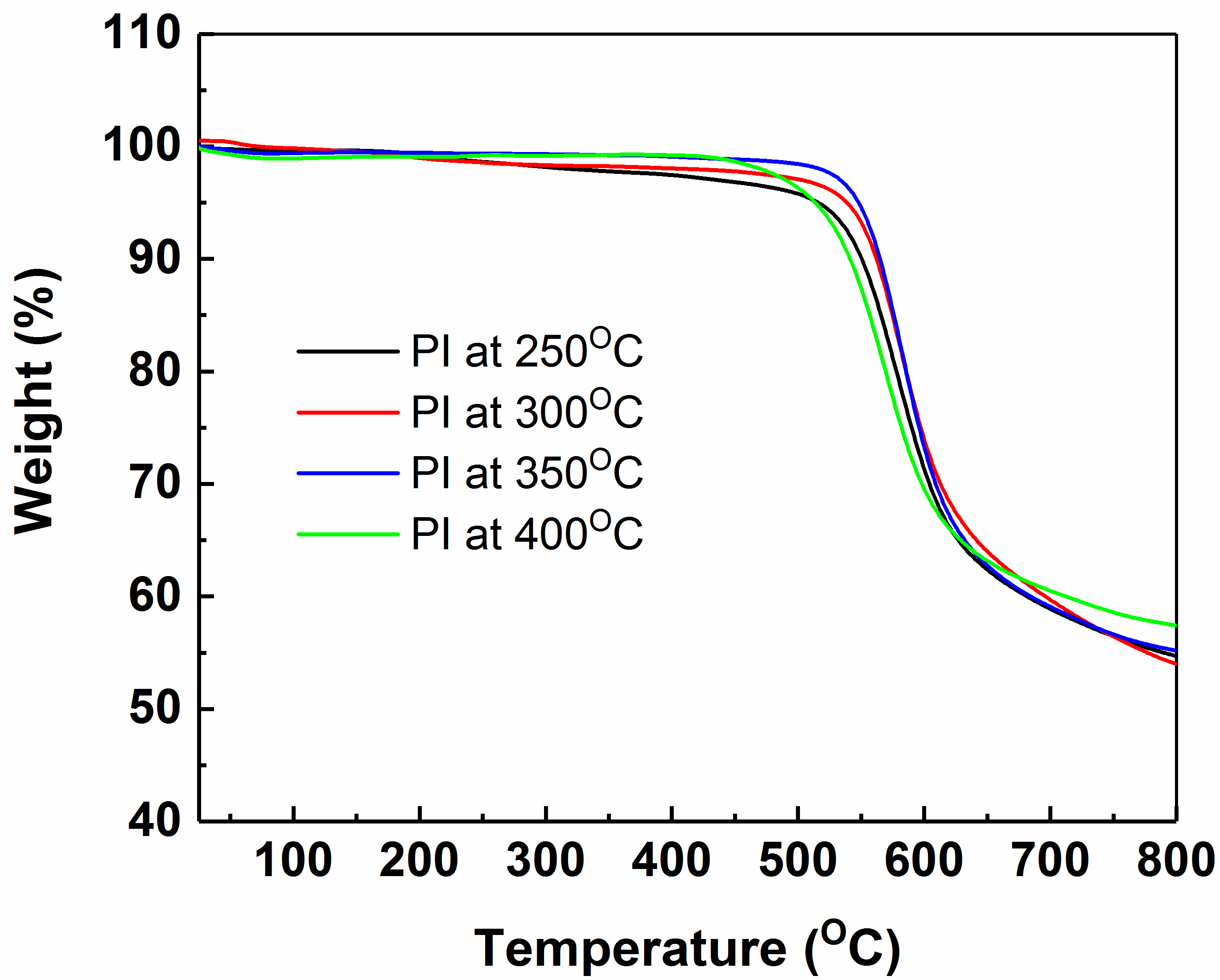

- 对制备PI薄膜的工艺流程进行了探索,设计了不同流程的梯度升温进行热亚胺化,其中在350℃下进行热亚胺化的流程所制备出的纯PI薄膜在300MV/m下的能量密度为2.0J/cm3,充放电效率为94%,为同组最高。

设计BNNS-Al2O3-BNNS型PI基三明治结构复合薄膜,表层材料为PI/7vol.% BNNS,内层材料为PI/x vol.% Al2O3,变化内层材料中纳米氧化铝的体积分数x,制备出一组复合薄膜。通过对比各个样品能量密度与充放电效率发现,在PI基三明治结构复合膜的中间层添加氧化铝纳米颗粒虽然可以依靠其较高的介电常数,提高整个材料的介电常数,但同时也降低了充放电效率,导致材料的放电能量密度不增反降。在场强为200MV/m下,纯PI的放电能量密度为0.9J/cm3,充放电效率为95%;性能最佳的样品PI/7vol.% BNNS/1vol.% Al2O3复合膜在此场强下的放电能量密度为1.1J/cm3,充放电效率为96%,相对稍有提升但提升甚微。且随着内层纳米氧化铝含量的上升,复合膜储能密度和充放电效率呈现下降的趋势,200MV/m下PI/7vol.% BNNS/10vol.% Al2O3复合膜的放电储能密度仅为0.8J/cm3,充放电效率下降至78%。

关键词:电介质,纳米复合材料,三明治结构,聚酰亚胺,储能密度

Abstract

The rise of high-power applications for electronics at high temperatures, such as electric cars, aircraft and pulsed power systems, has driven demand for a new generation of high-temperature dielectric materials that are moving toward capacitive energy storage.Polymer medium has a light weight, flexible, high scalability, mechanical, dielectric strength and high reliability etc, and the existing BOPP dielectric film using the upper limit of temperature is 70 ℃, only polyimide has excellent thermal stability and electrical insulation performance and good film-forming performance, has the development for the high temperature dielectric potential advantages of energy storage materials.The energy density of polyimide is too low to meet the demand of high power system and energy system for high energy storage density, and the dielectric constant and breakdown field strength of the material are difficult to improve at the same time.In this paper, polyimide (PI) was used as matrix, and boron nitride nanobaterials (BNNS) and brine-alumina nanoparticles (Al2O3 NPs) were added to the solution composite fluidization technology to prepare the BNNS-Al2O3-BNNS type PI sandwich composite film.The results are as follows:

(1) the technological process of PI film preparation was explored, and the gradient temperature rise of different processes was designed for thermal imitization. In the process of thermal imitization at 350℃, the energy density of pure PI film prepared at 300MV/m was 2.0J /cm-3, and the charge and discharge efficiency was 94%, which was the highest in the same group.

(2) the composite film of BNNS-Al2O3-BNNS type PI-based sandwich structure was designed, the surface material was PI/7vol.% BNNS, and the inner material was PI/x vol.% Al2O3. A group of composite films were prepared by changing the volume fraction of nano-alumina in the inner material x.By comparing the energy density and the sample charge and discharge efficiency, found that in PI intermediate sandwich structure composite film adding nanoparticles of alumina may rely on its high dielectric constant, dielectric constant of the material, but also reduce the charge and discharge efficiency, causes the material discharge energy density has not grown much.When the field intensity is 200MV/m, the discharge energy density of pure PI is 0.9J /cm3, and the charge and discharge efficiency is 95%.The discharge energy density of the best sample PI/7vol.% BNNS/1vol.% Al2O3 composite membrane under this field intensity was 1.1J /cm3, and the charge and discharge efficiency was 96%, which was slightly improved but not significantly.Moreover, with the increase of inner nano-alumina content, the energy storage density and charge and discharge efficiency of the composite membrane presented a decreasing trend. Under 200MV/m, the discharge energy storage density of PI/7vol.% BNNS/10vol.% Al2O3 composite membrane was only 0.8J/cm3, and the charge and discharge efficiency decreased to 78%.

Keywords: dielectric, nanocomposite, sandwich structure, polyimide, energy storage density

目录

第一章 绪论.................................................................1

1.1 引言..................................................................1

1.2 介电储能基础原理......................................................2

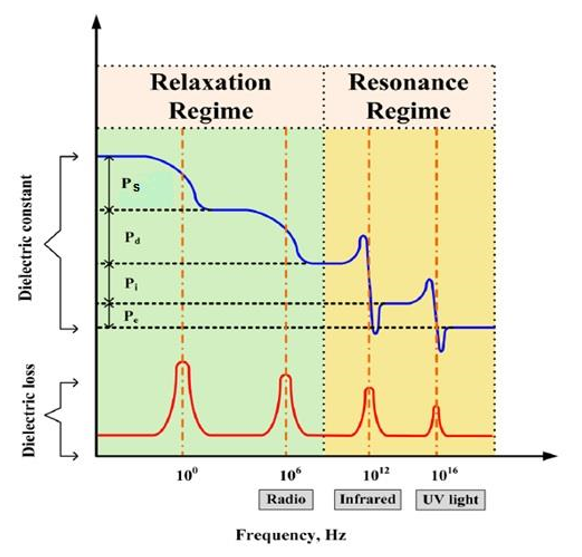

1.2.1 电介质的极化......................................................2

1.2.2 电介质的介电常数与介电损耗........................................4

1.2.3 电介质的击穿场强..................................................5

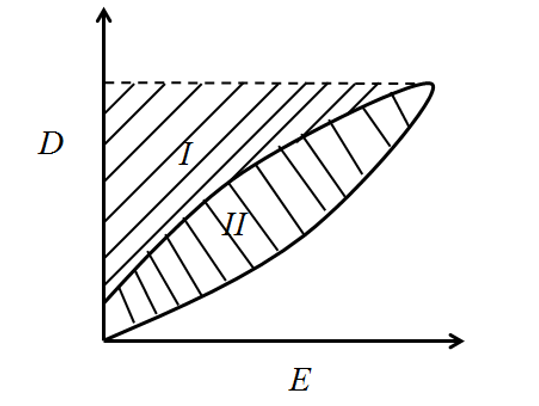

1.2.4 电介质的能量密度及效率............................................5

1.3 聚合物基电介质材料研究进展............................................6

1.3.1 高储能密度聚合物基电介质..........................................6

1.3.2 耐高温聚合物基电介质..............................................8

1.4 本文研究内容..........................................................8

第二章 研究内容.............................................................9

2.1 引言..................................................................9

2.2 实验部分.............................................................10

2.2.1 实验原材料.......................................................10

2.2.2 实验设备.........................................................10

2.2.3 实验步骤.........................................................11

2.2.3.1 纯PI薄膜的制备.............................................11

2.2.3.2 BNNS-Al2O3-BNNS型PI基三明治结构复合薄膜的制备............11

2.2.4 测试与表征.......................................................11

2.3 结果与讨论...........................................................12

2.3.1 制备PI薄膜最佳工艺流程的探索....................................12

2.3.2 BNNS-Al2O3-BNNS型PI基三明治结构复合薄膜的介电储能性能.........16

第三章 结论与展望..........................................................22

3.1 结论.................................................................22

3.2 展望.................................................................22

致谢.......................................................................24

参考文献...................................................................25

第一章 绪论

1.1引言

随着能源与环境问题日益突出,可持续清洁能源的生产和利用越来越受重视,发达国家们更是将新能源技术的开发和利用作为经济增长的新引擎。在过去十几年中,各种可持续绿色能源如水电、生物质能、太阳能、风能、潮汐能等的开发得到了快速的发展,新能源的开发和利用对能源存储技术也提出了更高的要求。此外,智能电网建设、电动机车的发展也使得大容量储能技术被列为需要突破的关键攻关技术。

请支付后下载全文,论文总字数:24994字

相关图片展示: