3D打印快速成型水凝胶人工血管性能毕业论文

2021-12-10 17:47:10

论文总字数:30482字

摘 要

随着心血管疾病等引起血管病变的增多,应用于外科手术的可移植性血管的需求量也在逐年增大,依靠人体自身移植血管不仅来源有限,且因为二次手术、供区缺血等不良影响,因此人工血管的研究迫切而重要。

目前人工血管的制备材料主要包括普通的高分子聚合物材料,如聚膨体四氟乙稀、氧化再生纤维素等,但是缺点是缺乏生物活性,且价格昂贵,在制备成型过程中耗时长,力学性能和管径大小与血管不匹配,限制了人工血管的进一步应用。因此,探讨一种价格低,快速成型且生物相容性良好的人工血管是当前研究的突破点和难点。

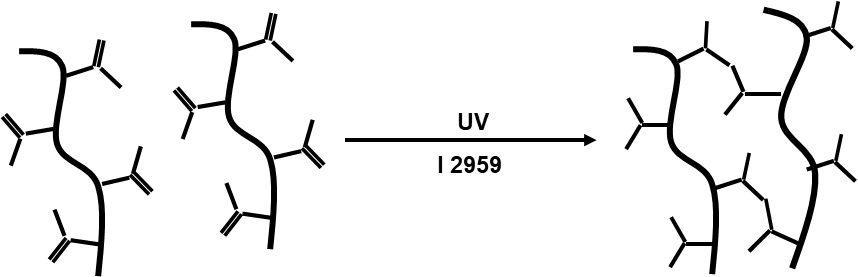

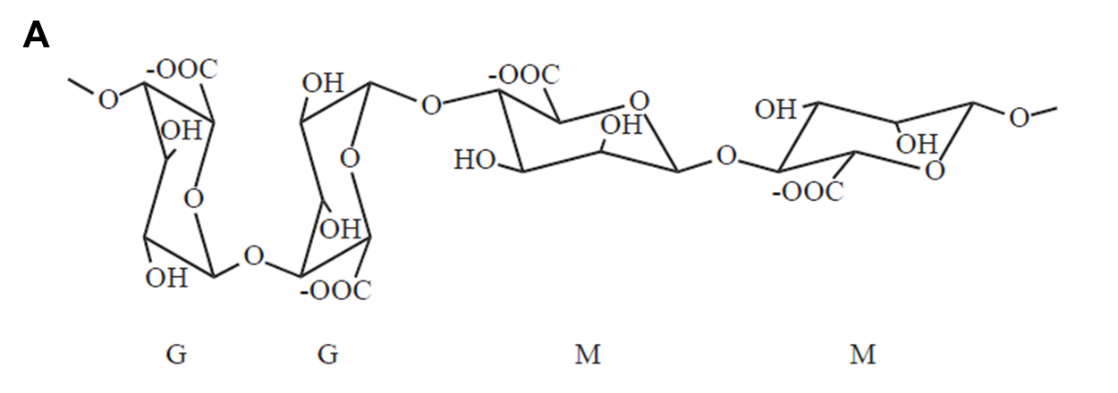

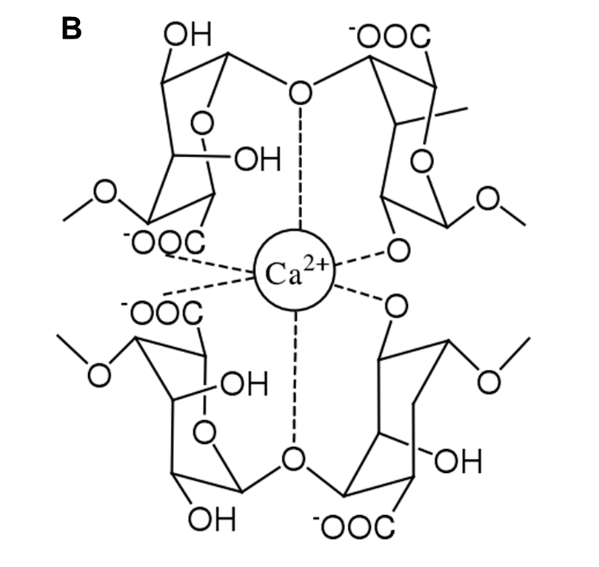

GelMA由明胶与甲基丙烯酸酐反应制得,具有突出的生物活性,可以促进细胞的粘附、生长,生物相容性良好,但纯GelMA水凝胶力学强度低,不适合作为支撑性材料。海藻酸钠水凝胶具有较高的力学强度,且能在氯化钙溶液快速交联成型,但其细胞亲和性有待提高。基于此,本文充分利用GelMA和海藻酸钠两种交联聚合物水凝胶各自的优势,通过溶液-紫外两步交联的方式制备GelMA/海藻酸钠复合水凝胶,利用3D打印快速成型,通过对不同配比的水凝胶的力学性能测试来探究水凝胶最佳配比,并以改善GelMA/海藻酸钠水凝胶的力学性能和生物相容性目标,进行了如下研究:

(1)探究了不同的海藻酸钠与GelMA配比对于水凝胶力学性能的影响以及材料的降解性能。结果表明:随着海藻酸钠质量分数的提高,水凝胶的压缩模量有明显增大的趋势,并且海藻酸钠质量分数每增加0.5%,压缩模量平均会增加80 kPa。海藻酸钠含量为3wt%时,水凝胶的压缩模量为167 kPa,超过现有报道关于海藻酸钠压缩模量的测试结果(150 kPa左右)。而随着GelMA含量的增加,水凝胶的压缩模量与杨氏模量都存在着先增加后减少的变化趋势且在含量为3wt%左右有最大值。并确定了复合水凝胶的最佳原料配比:海藻酸钠与GelMA含量均为3wt%。材料的降解性能测试结果表明开始降解的前24小时材料降解较快,但24小时候降解速率变得极为缓慢,降解后的21天后,残余量仍有30%,证明该水凝胶材料是一种比较耐久的材料。

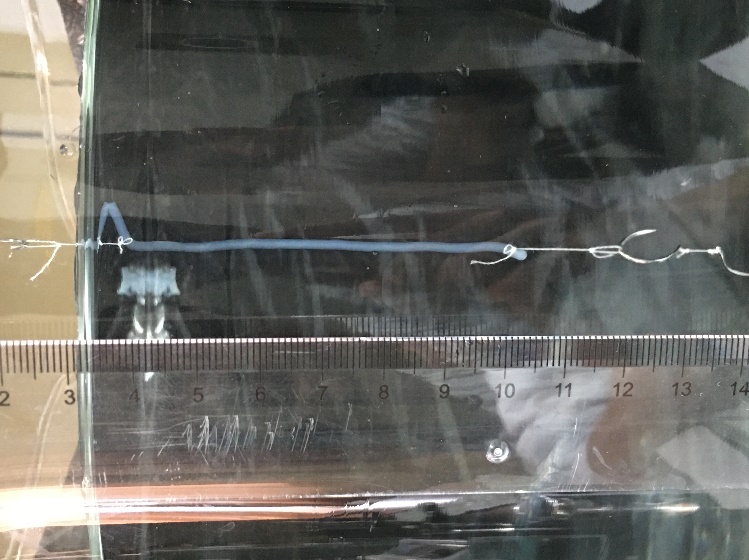

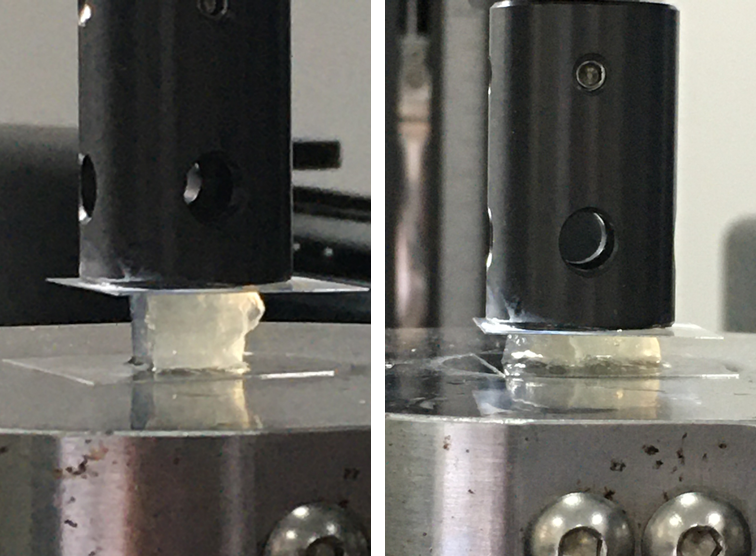

(2)利用3D打印技术将GelMA/海藻酸钠水凝胶快速打印成型为人工血管,并进行了结构、力学性能及渗透性等表征。结果表明:GelMA/海藻酸钠水凝胶打印墨水可以即打即成型, 快速成型的中空人工血管孔径和壁厚可调,且具有致密平滑稳定的宏观结构,同时也有微小的孔结构。这两点分别与材料良好的拉伸性能、渗透性能相对应:打印成型的人工血管最大拉伸长度可达原长度的2.5倍,并且拉伸后可以回弹至原长度2倍左右,此力学性能较众多人工血管具有明显的优势;该快速打印成型的GelMA/海藻酸钠人工血管对大分子和小分子有着明显不同的渗透性,小分子可以均匀的扩散但大分子和红细胞不能透过管壁,能满足血液、药物释放等生理、病理需求。

(3)对GelMA/海藻酸钠人工血管材料进行了生物学评估,结果表明:复合水凝胶的溶血率为0.63%,具有良好的血液相容性,并且复合水凝胶的溶血率低于纯海藻酸钠水凝胶,说明GelMA的加入提高了水凝胶的血液相容性;通过血管内皮细胞与GelMA/海藻酸钠人工血管相互作用结果表明复合水凝胶对细胞生长、增殖的促进作用要大于单纯的海藻酸钠水凝胶和GelMA水凝胶;生物3D打印血管内皮细胞与GelMA/海藻酸钠复合材料后,经Hamp;E染色,显示血管内皮细胞可以在多孔水凝胶内生长良好。

(4)GelMA/海藻酸钠人复合水凝胶材料可快速打印成型,力学性能与人工血管匹配,降解性能、血液相容性和细胞亲和性良好,具有应用于动、静脉、血管神经等组织修复的良好应用潜能。

关键词:GelMA;海藻酸钠;人工血管;3D打印成型;力学性能;生物相容性

Abstract

With the increase of cases of vascular diseases such as cardiovascular diseases, the demand for transplantable blood vessels used in surgery is also increasing. It is not enough to rely on the human body to transplant blood vessels, and it may also cause adverse effects. The research of artificial blood vessels is very important for treating such diseases. At present, the preparation materials of artificial blood vessels mainly include ordinary polymer materials (such as polytetrafluoroethylene, etc.), and hydrogel materials (such as GelMA hydrogel, alginic acid) that are very popular in the field of tissue engineering materials. Sodium hydrogel, etc.).

GelMA is produced by the reaction of gelatin and methacrylic anhydride. It has prominent biological activity and can promote cell adhesion, growth and other activities. However, pure GelMA hydrogels are relatively weak and is not suitable as a supporting material. Compared with GelMA, sodium alginate hydrogel has higher mechanical strength, and can be quickly cross-linked with calcium chloride solution to form a network structure. However, sodium alginate is too hydrophilic, resulting in its relatively low biocompatibility. Therefore, this paper makes full use of the advantages of these cross-linked polymer hydrogels to prepare composite hydrogels. From the perspective of improving the mechanical properties of the hydrogels, the following studies are performed:

(1) The effects of different ratios of sodium alginate and GelMA on the mechanical properties of hydrogels were investigated. The results show that with the increase of the sodium alginate mass fraction, the compression modulus of the hydrogel tends to increase significantly, and each 0.5% increase in the sodium alginate mass fraction increases the average compression modulus by 80 kPa. When the sodium alginate content is 3% by weight, the compression modulus of the hydrogel is 167 kPa, which exceeds the test results (about 150 kPa) about the compression modulus of sodium alginate reported in the prior art. With the increase of GelMA content, both the compression modulus and the Young's modulus of the hydrogel have a tendency to increase first and then decrease, and have a maximum value of about 3wt%, presumably because too much GelMA makes the seaweed The molecular spacing of sodium is increased, and the structure after cross-linking is looser, so the mechanical properties show a downward trend. The optimal raw material ratio of the composite hydrogel was determined by experiments: the content of sodium alginate and GelMA were both 3wt%.

(2) The 3D printing molding process was used to shape the hydrogel into an artificial blood vessel, and the basic characterization was performed. It was found that the artificial blood vessel has a dense and smooth macrostructure, and also has a relatively small pore structure. These two points correspond to the good tensile properties and permeability of the material: the maximum stretch length of the printed artificial blood vessel can reach 2.5 times the original length, and it can rebound to about 2 times the original length after stretching; artificial blood vessels There are obviously different permeability to large molecules and small molecules. Small molecules can diffuse uniformly but large molecules cannot penetrate the wall of the tube.

(3) The biological evaluation of the composite hydrogel was conducted, and the results showed that the hemolysis rate of the composite hydrogel was 0.63%, which was highly hemocompatible, and the hemolysis rate of the composite hydrogel was lower than pure sodium alginate Hydrogel, indicating that the addition of GelMA improves the overall biocompatibility of the hydrogel; cell proliferation / toxicity tests have also verified that the composite hydrogel promotes cell growth and proliferation more than the sodium alginate hydrogel and GelMA Hydrogel; H amp; E staining results show that endothelial cells can grow well in the hydrogel, which also shows that the hydrogel can deliver nutrients in the medium to the cells through its micropore structure.

Key Words:GelMA; sodium alginate; 3D printed artificial blood vessel; mechanical properties; biocompatibility

目 录

第1章 绪论 2

1.1 研究目的与意义 2

1.2 国内外研究进展及存在的问题 3

1.2.1 国内外研究进展 3

1.2.2 存在的问题 4

1.3 研究内容与技术路线 4

1.3.1 研究内容 4

1.3.2 技术路线 5

1.4 可行性分析 5

1.4.1 研究的理论基础 5

1.4.2 研究的实验基础 9

第2章 复合水凝胶的制备、成型与性能测试 10

2.1 实验材料及仪器 10

2.1.1 实验原料 10

2.1.2 实验器材 10

2.1.3 GelMA的制备 10

2.1.4 复合水凝胶生物墨水的合成 11

2.1.5 水凝胶的成型 11

2.2 测试与表征 11

2.2.1 水凝胶力学性能测试 11

2.2.2 水凝胶降解性能测试 12

2.3 结果与讨论 12

2.3.1 生物墨水的打印性能 12

2.3.2 复合水凝胶的力学性能 13

2.3.3 水凝胶的降解性能 15

2.4 本章小结 15

第3章 人工血管的3D打印成型与表征 17

3.1 实验材料与仪器 17

3.1.1 实验材料 17

请支付后下载全文,论文总字数:30482字

相关图片展示: