1070型电动货车后轮制动器设计毕业论文

2020-04-11 17:43:12

1070型电动货车后轮制动器设计

学院(系):国际教育学院

专业班级:车辆工程1403班

学生姓名:李庚

指导教师:韩爱国

学位论文原创性声明

本人郑重声明:所呈交的论文是本人在导师的指导下独立进行研究所取得的研究成果。除了文中特别加以标注引用的内容外,本论文不包括任何其他个人或集体已经发表或撰写的成果作品。本人完全意识到本声明的法律后果由本人承担。

作者签名:

年 月 日

学位论文版权使用授权书

本学位论文作者完全了解学校有关保障、使用学位论文的规定,同意学校保留并向有关学位论文管理部门或机构送交论文的复印件和电子版,允许论文被查阅和借阅。本人授权省级优秀学士论文评选机构将本学位论文的全部或部分内容编入有关数据进行检索,可以采用影印、缩印或扫描等复制手段保存和汇编本学位论文。

本学位论文属于1、保密囗,在 年解密后适用本授权书

2、不保密囗 。

(请在以上相应方框内打“√”)

作者签名: 年 月 日

导师签名: 年 月 日

Abstract

Decelerating or even stopping the driving cars, keeping the speed of the downhill cars steady, and keeping the parked cars motionless, these actions are collectively referred to as car braking, and the corresponding series of specialized devices are called braking systems. Brake, as a component of a brake system to generate a force that impedes the tendency of a vehicle to move or trend, generally applies a braking torque to a rotating element through a fixed element therein, so that the rotational angular speed of the latter is reduced, while relying on the attachment of the wheel to the road surface, the effect is to generate braking force on the road surface against the wheels so that the car can slow down.

Drum brakes use the brake drum as a rotating element in the friction pair to act as a brake. There are two types of drum brakes: inner tension type and outer beam type. The current mainstream type is inner tension type. The brake shoe is located on the inner side of the brake wheel. When the brake is released, the brake block opens outwards, causing friction with the inner side of the brake wheel, to achieve the purpose of braking. This design is based on the theory of inner tension type drum brake, and reference to actual market products, to design Type 1070 Electric Truck Rear Brakes according to China's current design standards and theoretical design requirements. According to the characteristics of drum brakes, this design will calculate the key data of each structure, such as the maximum braking torque, synchronous adhesion coefficient, etc., and reasonably select the structural parameters and raw materials of each major component according to the actual production, assembly and performance requirements, and finally complete the assembly drawing and parts drawing.

Key Words: Brake system; Drum brake; Maximum braking torque; Performance requirements; Structural parameters.

CONTENT

1.Preface 1

1.1 Design background and significance 1

1.2 The requirements of braking system 2

1.3 The main content and focus of the design 3

2. Brake type and structure selection 5

2.1 Brake type and selection 5

2.2 Brake structure and selection 6

3. Main parameters and calculations of brake 9

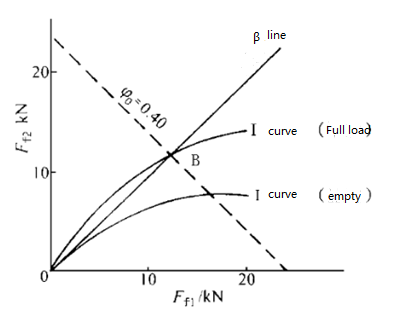

3.1 Braking force and braking force distribution coefficient 9

3.2 Synchronous adhesion coefficient 14

3.3 Maximum braking torque of brake 15

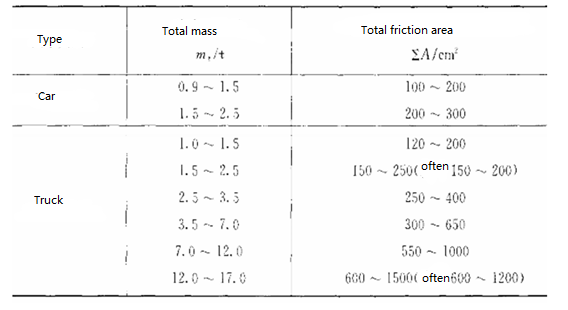

4. Main structural parameters and friction coefficient 17

4.1 Braking drum diameter D 17

4.2 Brake shoe friction liner angle and width 18

4.3 Friction liner start angle β0 19

4.4 Friction coefficient of friction liner 19

4.5 Calculation of driving brake effectiveness 19

5. Structural Design of Main Parts of Brake 21

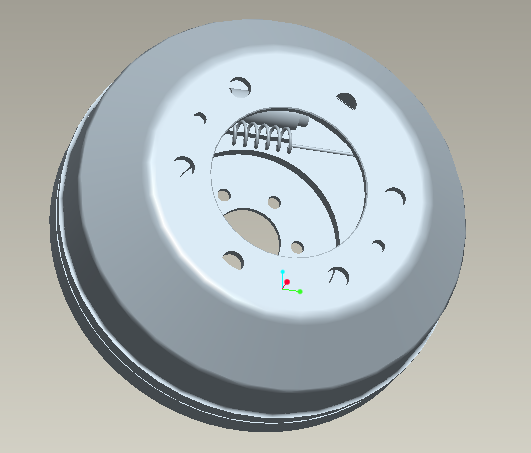

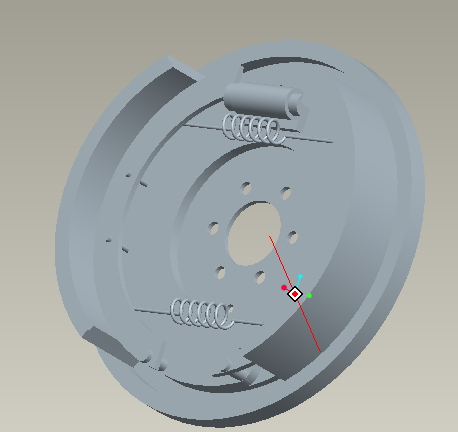

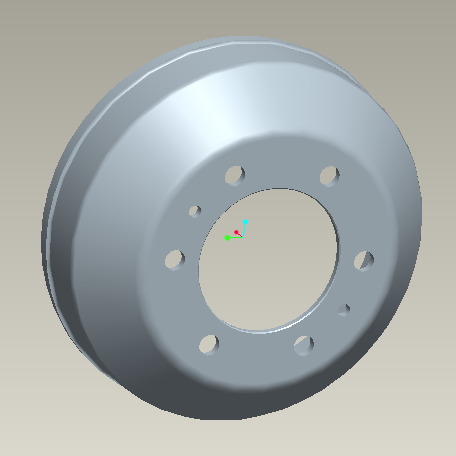

5.1 Brake drum 21

5.2 Brake shoes 22

5.3 Brake bottom plate 22

5.4 Brake shoe support 22

5.5 Brake cylinder 23

5.6 Friction material 23

5.7 Brake gap 24

6. Design and Calculation of Hydraulic Drive Mechanism 25

6.1 Brake wheel cylinder diameter d 26

6.2 Brake main cylinder diameter d0 26

6.3 Brake pedal force FP and brake pedal working stroke s 27

Conclusion 29

References 30

Appendix 31

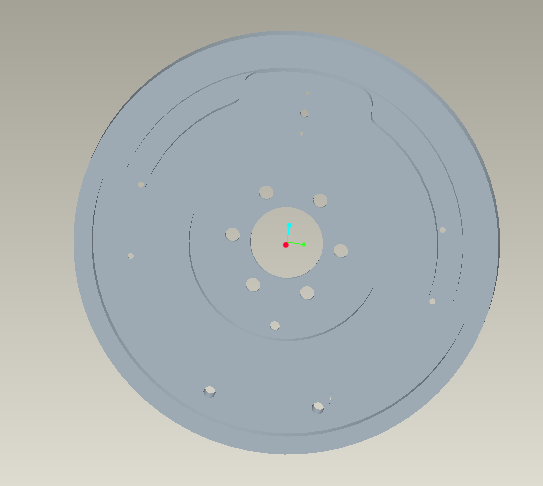

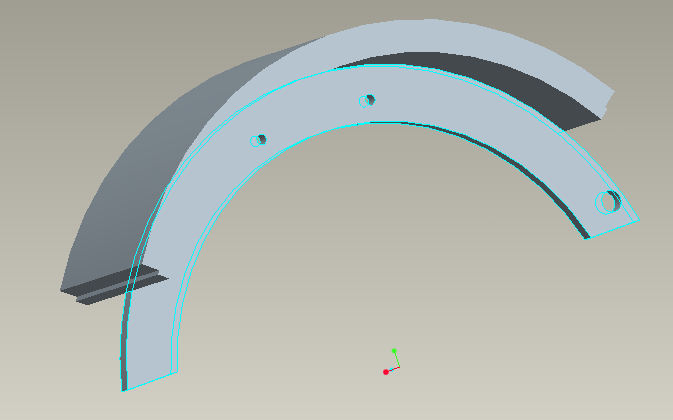

Appendix A. 3D Engineering drawing screenshots 31

Appendix B. Programming of calculation parameters and results 34

Acknowledgement 36

1.Preface

1.1 Design background and significance

With the rapid growth of the national economy, the demand for logistics and transportation in the market is increasing day by day. As a significant member of logistics transport, the development of trucks is crucial to the development of logistics. Not only that, with the extensive use of new energy technologies, the selection of clean energy to replace traditional fossil fuels is a general trend. Under this trend, the technology of electric trucks is also rapidly becoming mature and gradually occupy a place stably in domestic and foreign markets.

Electric trucks are economical, with lower charging fees than fuel costs. Because logistics vehicles value economy cost and require less comfort, electric vehicles are economically superior to ordinary fuel trucks. From the point of view of car purchase cost, electric logistics vehicles not only enjoy central and local double subsidies, but also have purchase tax exemption when buying cars. However, the high original price may lead to higher selling prices than traditional logistics vehicles, but in general, electric vehicles with low charging costs have obvious economic advantages.

According to the research report on the current situation of China's electric logistics vehicle market from 2018 to 2025 published by the China Industry Research Network, many large cities do not limit the green light of pure electric vehicles, but also give priority to licensing and free parking. Compared to those fuel trucks which can only be used at night, pure electric trucks can work at anytime and in anywhere, whose competitive advantage is obvious. At the same time, electric trucks have the characteristics of no pollution, low noise, high energy efficiency, simple structure, easy maintenance and so on, and these advantages are in line with the current market requirements; however, electric vehicles are not as good as they see, especially the short battery life and low energy storage, which lead to unsatisfactory mileage after a single charge. However, from a developing point of view, with the advancement of science and technology, the problems of electric vehicles will be gradually solved, and electric vehicles will be widespread.

The function of the braking system is to force the vehicle in motion to slow down or stop, keep the downhill vehicle at a stable speed, and make the parked vehicle park still on the ground or on the slope[1], which is an important safe guarantee for the driving trucks. In recent years, with the continuous development of the automotive industry, the ever-increasing number of vehicles on the road and faster and faster speeds have caused the development of the brake system to receive close attention from many parties: Only vehicles with good braking performance and stability can fully exert their performance and provide drivers with adequate safety guarantees. For large environments, it means higher logistics efficiency and a better road driving environment.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: