基于热障涂层技术的高性能船舶柴油机性能研究毕业论文

2020-04-12 09:08:01

摘 要

柴油机作为汽车船舶和工业的原动机,已经经历了长时间的发展和普及。这些年来各个种类的发动机需要满足高转速,低耗能等要求,因此使柴油机气缸燃烧室中的燃烧气体的温度和压力逐渐增大,燃烧室内的工作条件变得越来越恶劣。高性能柴油发动机受热零部件承受热负荷较高,活塞是核心部件,其热负荷问题更为突出。为保证柴油机保持正常工作状态,减少活塞热损耗,提高工作效率,现已提出在柴油机活塞顶部覆盖热障涂层以求在燃烧室中的高温载荷下,在活塞顶部形成沿厚度方向上的的温度梯度,以减少燃烧室由活塞顶部向活塞基体的传热,降低活塞的工作温度,并增大活塞对热腐蚀,氧化和磨损的抵抗力。本文凭借 YC6 MK型发动机试验台架和 SOLIDWORKS,ANSYS软件,根据实际试验和有限元仿真两方面对 YC6 MK375 N-30型柴油机活塞所承受热负荷进行研究,并对比与活塞顶部覆盖 MgZrO_3热障涂层后的温度场区别。

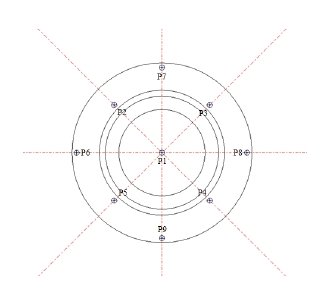

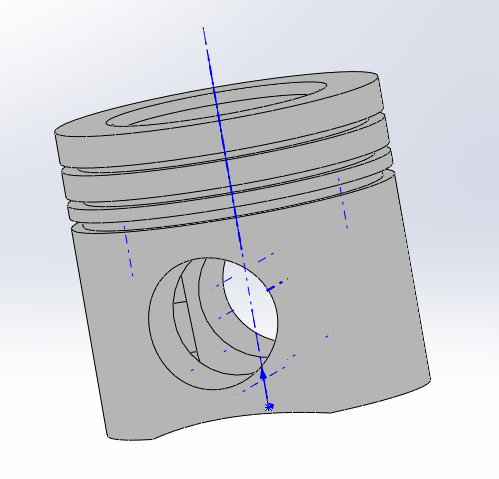

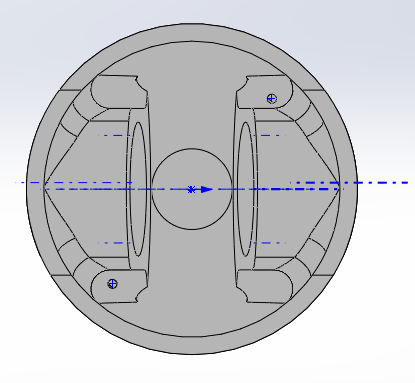

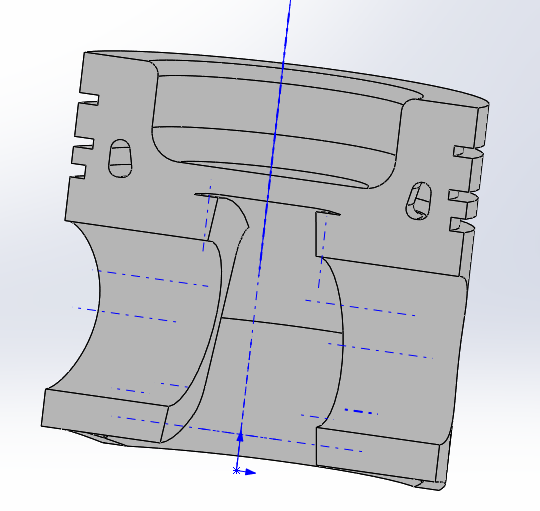

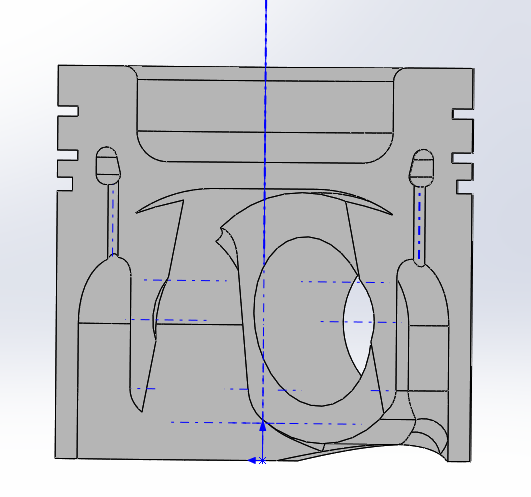

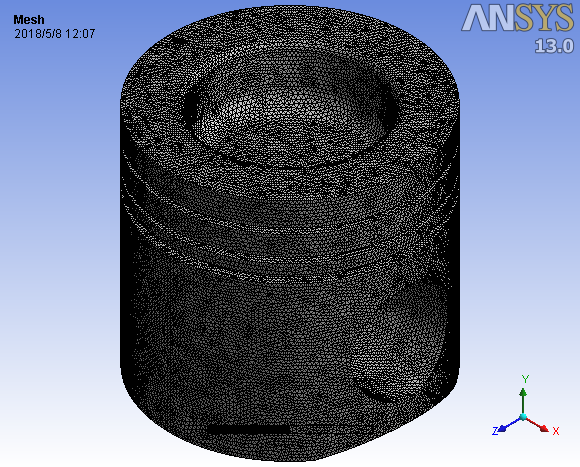

首先,建立YC6MK发动机试验台,以在校准工作条件下测量柴油机活塞的温度场。接着,根据实际的活塞模型,使用SOLIDWORKS软件绘制活塞的三维模型,并使用ANSYS软件对活塞的三维模型进行网格划分,建立活塞有限元模型。根据经验公式和发动机功率图计算活塞校准条件的热边界条件,并与实验数据进行比较,计算出比较准确的稳态活塞温度场。

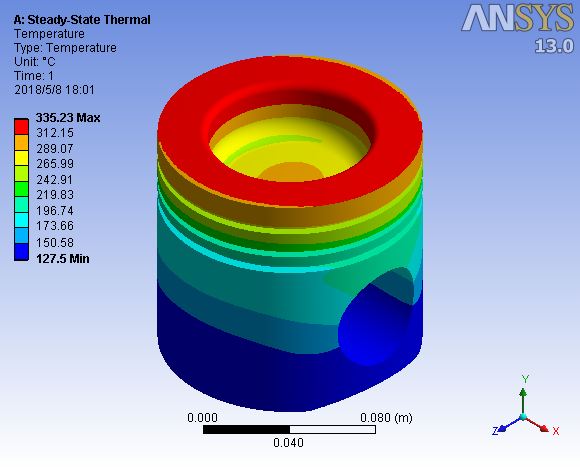

最后,在前面的计算数据的基础上,将活塞校准工况的温度条件添加到ANSYS中以获得活塞温度场图。接着导入在SOLIDWORKS上绘制的不同厚度陶瓷隔热层活塞的三维模型,在ANSYS中计算,并对比不同厚度陶瓷隔热层活塞的温度场云图。

通过分析计算结果,我们可以得出:YC6MK型发动机活塞在标定工作状况下活塞承受较大的热负荷,从温度场图来看活塞体内温度沿活塞环槽和内部油道方向向外发散。在覆盖氧化锆热障涂层后的活塞工作温度有明显的降低,并且在一定限度内随氧化锆热障涂层厚度增加而降低的更多

关键词: 发动机;活塞;有限元分析;温度场;氧化锆;热障涂层

Abstract

As the original motive of automobile ship and industry, diesel engine has been developed and popularized for a long time. Over the years various types of engines need to satisfy the high speed, low energy requirements, thus make the temperature of the diesel engine cylinder combustion gas in the combustion chamber and the pressure increases gradually, the combustion chamber is becoming more and more bad working conditions. High performance diesel engine heating parts with high thermal load, piston is the core component, its thermal load problem is more prominent. Piston diesel engine in order to ensure the normal working state, low heat loss, improve the work efficiency, has been put forward in the diesel engine piston at the top of the cover under the thermal barrier coating for high temperature load in the combustion chamber, the piston at the top of the formation of the temperature gradient along the thickness direction, in order to reduce the combustion chamber by the piston at the top to the piston heat transfer matrix, reduce the working temperature of piston, and increase the piston of hot corrosion, oxidation and wear resistance. In this paper, with the engine test-bed YC6 MK and SOLIDWORKS, ANSYS software, according to the practical test and finite element simulation of YC6 MK375 N - 30 type diesel engine piston under heat load is studied, and compared with the piston at the top of the cover after MgZrO_3 thermal barrier coating temperature difference.

First, the YC6MK engine test-bed was established to measure the temperature field of the piston in the diesel engine under the working conditions. Then, according to the actual piston model, the 3d model of the piston was drawn using SOLIDWORKS software, and the 3d model of the piston was divided by using ANSYS software, and the finite element model of the piston was established. According to the empirical formula and engine power diagram, the thermal boundary conditions of piston calibration conditions are calculated and compared with the experimental data to calculate the accurate steady-state piston temperature field.

Finally, on the basis of the previous calculation data, the temperature condition of the piston calibration condition is added to ANSYS to obtain the piston temperature field diagram. Then, the 3d model of the piston of different thickness ceramic insulation layer is imported on SOLIDWORKS, and the temperature field cloud diagram of the piston of different thickness ceramic insulation layer is calculated and compared in ANSYS.

By analyzing the calculation results, we can conclude: YC6MK engine piston in calibration under the condition of the piston work under thermal load, from the temperature field of piston body temperature along the piston ring groove and the internal oil way direction spread outward. The working temperature of the piston after coating the zirconia thermal barrier was significantly reduced, and it decreased with the increase of the coating thickness of zirconia thermal barrier in a certain extent.

Key Words: engine; piston; Finite element analysis; Temperature field; Zirconium oxide; Thermal barrier coating

目 录

第1章 绪论1

1.1 课题研究背景及意义1

1.2 国内外研究现状1

1.2.1 活塞温度场测量技术现状1

1.2.2活塞有限元仿真技术研究现状2

1.3 本文主要工作7

第2章 活塞温度场试验测量5

2.1活塞温度场试验方法介绍5

2.1.1 常规方法5

2.1.2 非常规方法6

2.2 YC6MK375N-30型发动机性能介绍6

2.3 硬度塞测温法测量活塞温度场6

2.3.1 试验前步骤6

2.3.2 试验过程及结果8

第3章 活塞稳态温度场仿真计算10

3.1 活塞热分析理论10

3.1.1 活塞导热微分方程10

3.1.2 热分析的三类边界问题10

3.1.3 活塞导热问题的有限元解法11

3.2 活塞稳态温度场仿真计算11

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: