地震载荷作用下的复合材料埋地管道分析毕业论文

2020-04-12 14:08:31

摘 要

玻璃纤维增强塑料管具有耐腐蚀、高强度、损耗小、易安装、轻材质等优点广泛应用于城市供水、输油、电力等行业中。并且随着国民经济的迅速发展,包括玻璃纤维增强塑料管在内的复合材料结构在工程中发挥着更重要的作用。

由于我国地域广阔,许多城市位于地震多发带,因此,玻璃纤维增强塑料加砂管的抗震性能也引起了人们的重视。本文利用有限元软件ANSYS分析了埋地玻璃纤维增强塑料管在横向地震剪切波作用下的力学响应。本文主要工作如下:

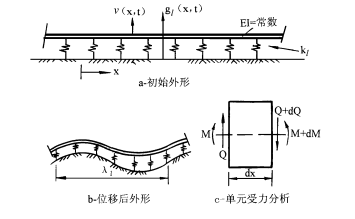

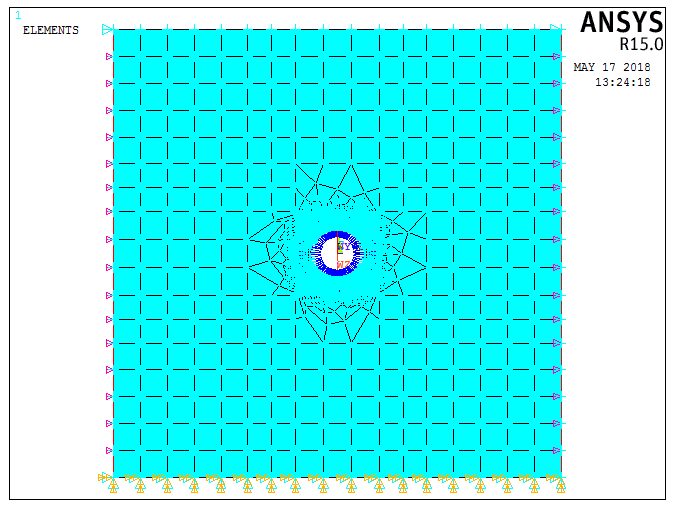

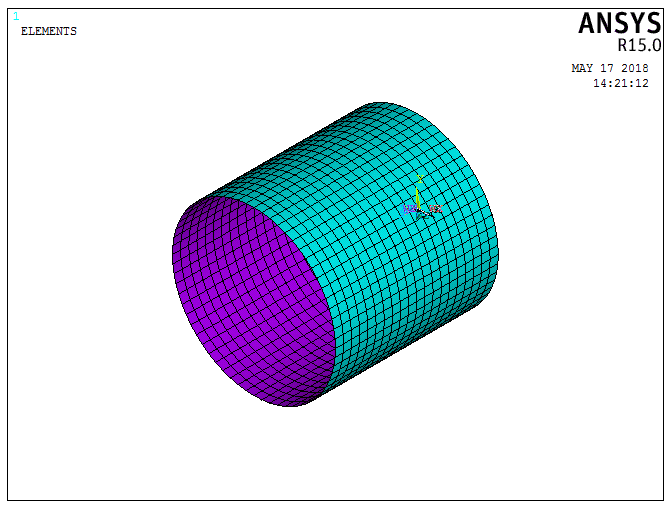

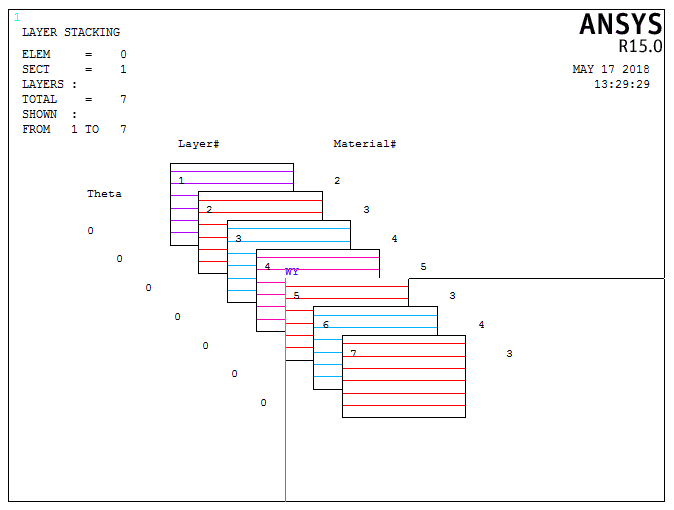

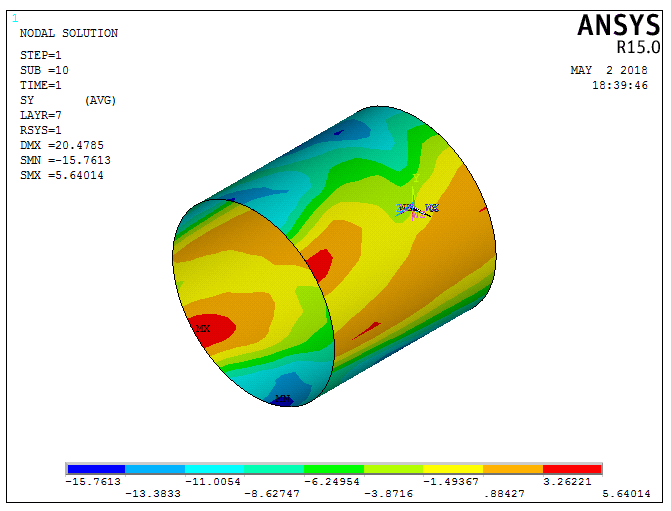

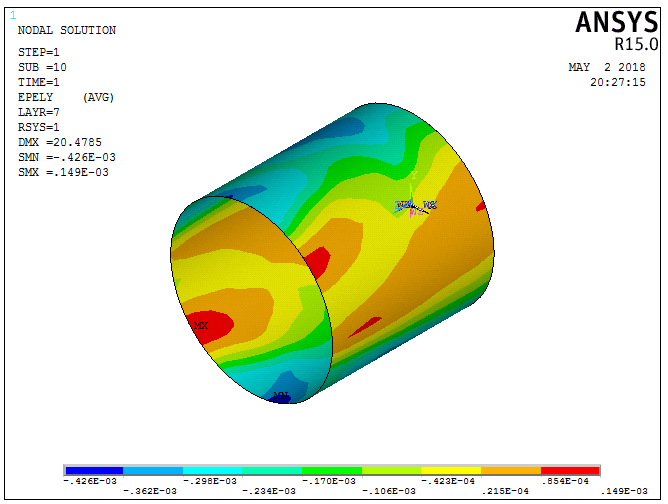

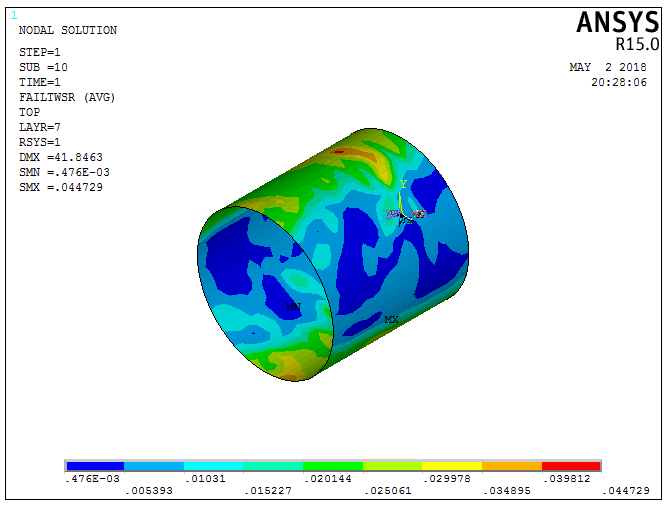

- 针对地震致瞬时土壤变形引起的管道响应,建立了横向剪切波作用下的管土模型,通过将地震引起的最大自由场应变等效为准静态位移,分析了横向剪切波作用下埋地玻璃纤维增强塑料管的力学响应。研究了刚度、管径、管土摩擦系数、埋深、内压、土体种类等因素对管道地震响应的影响。结果表明,在横向地震剪切波作用下,玻璃纤维增强塑料管的环刚度是管道抗震的重要因素;在保持内压强度与环刚度不变的情况下,管径较小的玻璃纤维增强塑料管抗震性能更好;随着埋深的增加,管道土压力增加,导致其环向应力极值迅速增大,表明埋深是管道抗震性能中不可忽视的因素;随着管土摩擦系数和内压的增加,环向最大拉压应力减小且强度比增大。因此增大管土摩擦系数和内压有利于提高管道抗震性能;通过对不同土体弹性模量的结果进行对比,发现随着土体弹性模量的增加,管道的环向最大拉压应力均下降,且强度比明显增大。说明在保证其他工程需求的前提下,地基土应选择弹性模量较大的土质。

- 基于振动力学及相对变形理论,考虑了管土之间的滑移,针对地震剪切波作用下埋地管道的运动特点,考虑了地震波入射角以及管土相互作用等因素,利用前人已推导的埋地管道在地震载荷作用下的振动方程,基于地震地面运动加速度推导得到埋地管道在地震作用下的简化算法,并探究了管径这一影响因素对横向弯曲应力的影响,同时利用有限元软件ANSYS进行了相关计算。结果表明,随着管径的增加,横向弯曲应力也会增大,即增加管径不利于提高埋地玻璃纤维增强塑料管的抗震性能,与有限元分析法的结果相一致,且与有限元计算的结果的误差在可接受范围内,拓宽了埋地玻璃纤维增强塑料管在横向地震剪切波作用下的力学响应的分析方法。

关键词:玻璃纤维增强塑料管,横向剪切波,地震响应,有限元法,影响因素

Abstract

Glass fiber reinforced plastic pipe has the advantages of corrosion resistance, high strength, low loss, easy installation, light material and so on. It is widely used in urban water supply, oil transportation, electric power and other industries. With the rapid development of national economy, composite structures, including glass fiber reinforced plastic pipes, play a more important role in engineering.

Because of the vast area in China, many cities are located in earthquake-prone zone, therefore, the seismic behavior of glass fiber reinforced plastic sand pipe has also attracted people's attention. In this paper, the mechanical response of buried glass fiber reinforced plastic pipe under transverse seismic shear wave is analyzed by using finite element software ANSYS. The main work of this paper is as follows:

(1)In view of the pipeline response caused by transient soil deformation caused by earthquake, the pipe-soil model under the action of transverse shear wave is established. The strain of the maximum free field caused by earthquake is equivalent to quasi-static displacement. The mechanical response of buried glass fiber reinforced plastic pipe under transverse shear wave was analyzed. The effects of stiffness, pipe diameter, friction coefficient of pipe soil, buried depth, internal pressure and soil type on the seismic response of pipeline are studied. The results show that the ring stiffness of glass fiber reinforced plastic pipe is an important factor in the seismic resistance of the pipe under the action of transverse seismic shear wave, and the glass fiber reinforced plastics with small diameter is kept constant under the condition of constant internal pressure strength and ring stiffness. With the increase of buried depth, the maximum value of circumferential stress increases rapidly, which indicates that the buried depth is an important factor in the seismic performance of pipeline, and with the increase of friction coefficient and internal pressure of pipe and soil, the maximum value of circumferential stress increases rapidly with the increase of buried depth. The maximum tensile and compressive stress decreases and the strength ratio increases. By comparing the results of different soil elastic modulus, it is found that with the increase of soil elastic modulus, the maximum tensile and compressive stress of pipeline decreases with the increase of soil elastic modulus. And the strength ratio is obviously increased. It shows that under the premise of ensuring the demand of other projects, the elastic modulus of foundation soil should be larger.

(2)Based on the theory of vibration dynamics and relative deformation, the slippage between pipe and soil is considered. According to the motion characteristics of buried pipeline under earthquake shear wave, the incident angle of seismic wave and the interaction between pipe and soil are considered. Based on the vibration equation of buried pipeline under earthquake load and the acceleration of earthquake ground motion, the simplified algorithm of buried pipeline under earthquake action is obtained. The influence of pipe diameter on the transverse bending stress was investigated and the correlation calculation was carried out by using the finite element software ANSYS. The results show that the transverse bending stress increases with the increase of pipe diameter. The results of finite element analysis are consistent with the results of finite element analysis to improve the seismic performance of buried glass fiber reinforced plastic pipes, and the error of the results of finite element calculation is within the acceptable range. The analysis method of mechanical response of buried glass fiber reinforced plastic pipe under transverse seismic shear wave is broadened.

Key words: GFRP pipe, transverse shear wave, seismic response, ANSYS, influencing factors

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: