螺栓连接结构的有限元建模方法研究毕业论文

2020-04-12 14:12:27

摘 要

本文主要通过研究螺栓连接方式的结构,来建立有限元模型,在预紧力条件下的静力学和模态分析来得出研究结论的。螺栓连接结构的研究对于当下机械化和交通等方面的发展来说是有重要意义的,文中通过在前人的研究对螺栓连接和有限元建模发展上来进一步细化,通过对比连接结构的有限元模型的建立和研究来得出更加详细可靠的结果。

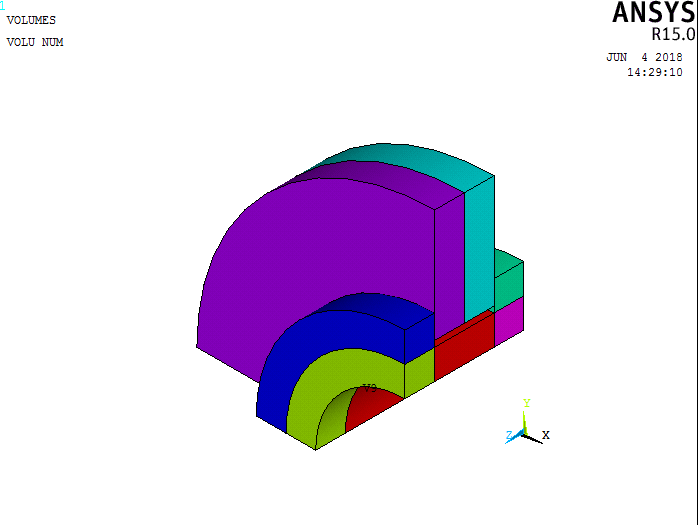

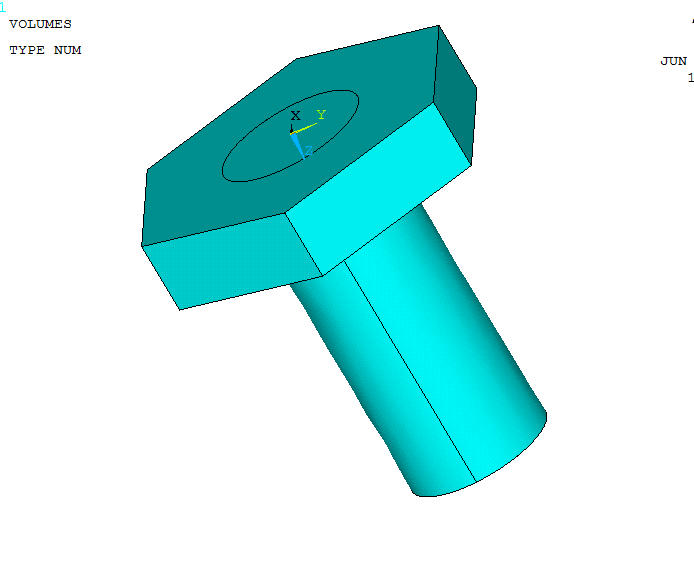

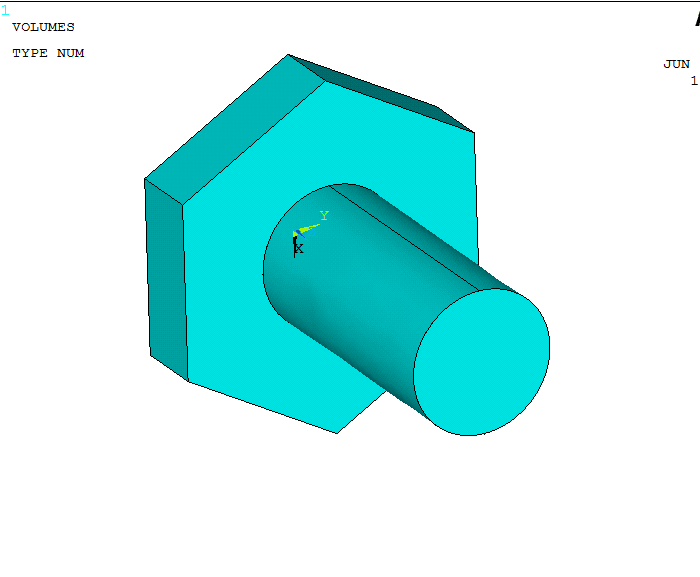

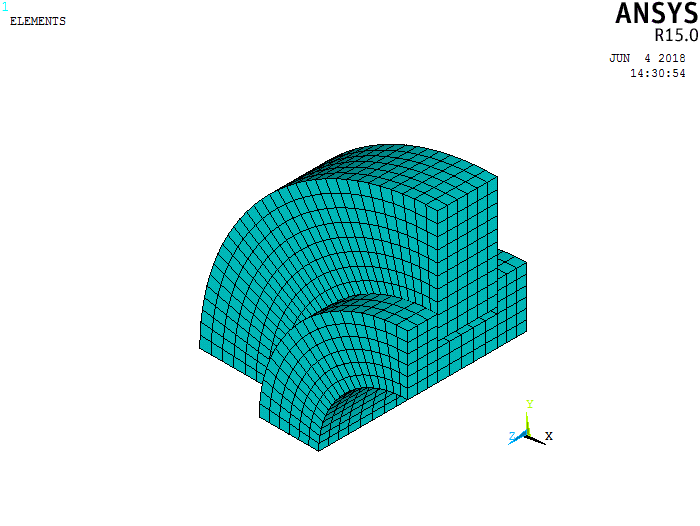

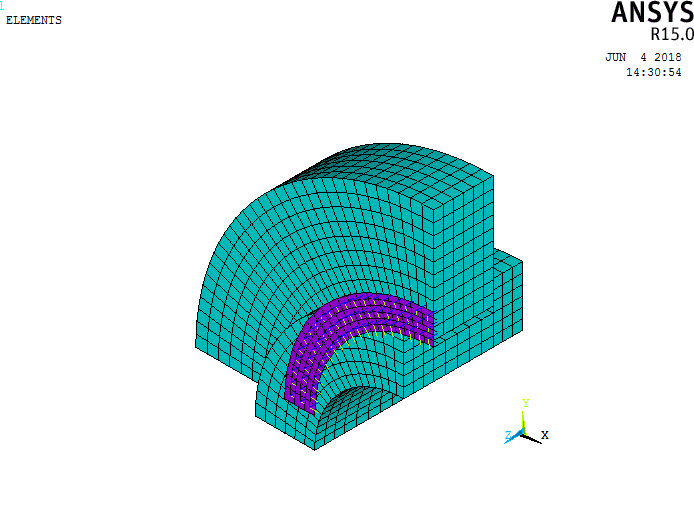

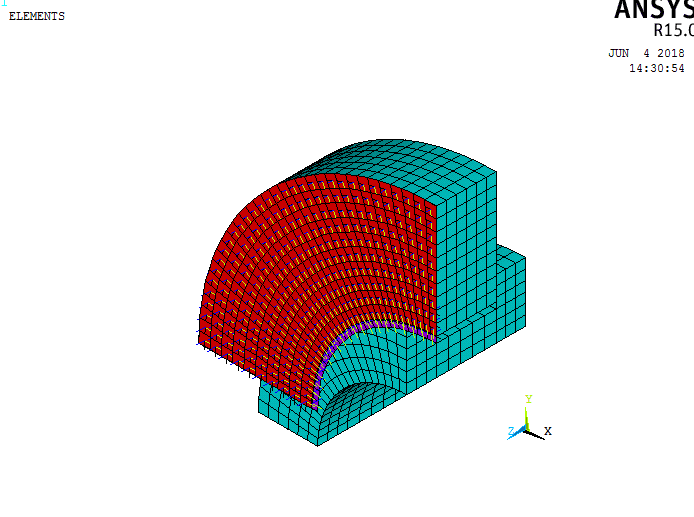

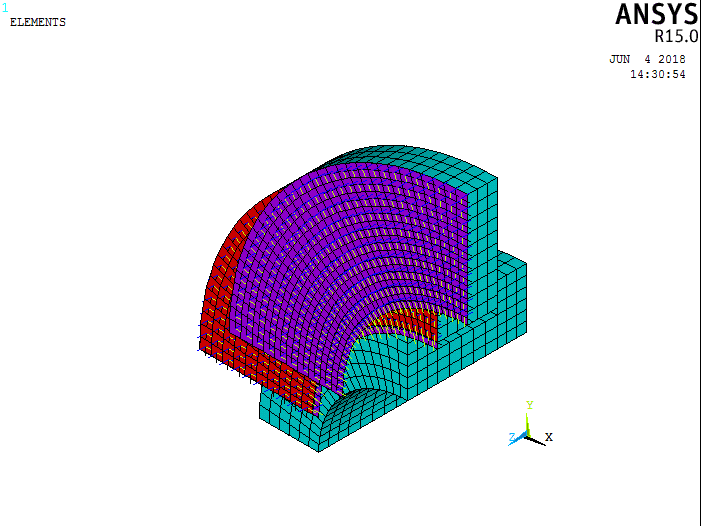

在有限元和建模分析研究中,本文采用了ANSYS软件进行建模和各应力模态分析,重点讲述了螺栓连接结构的有限元建模的过程,各类型螺栓模型建立过程中特点,以及在建立时所选取的材料模型和几何模型,各个建立的指令分析,后面重点对建模模型进行的接触分析。在整个模型建立过程,单元类型选取是最基本的也是最重要的,边界条件和载荷也是有一定的条件存在,然后通过网格划分来产生更加细化和深入的结果分析。螺栓预紧力是重要的因素,螺栓预紧力的接触分析通过单元螺栓的接触来起到相应的效果,施加预紧力条件下的受力分析,也可以获得更好的对比性。另外在文中内容中,通过进行静力学的各项分析来达到效果分析,同时分析得出螺栓模型连接结构的优越性。通过不同条件下的预应力模态研究对比,通过对比之后进行静力学分析研究验证,得出可用模态分析的结果,最后进行模型的简化分析和比较,得到了本文所要研究的成果,为了生成有螺栓连接结构的有限元模型,通过螺栓截面方法演示了螺栓螺纹模拟的简化建模技术。 这种方法提供了近似精确的螺纹螺纹模型的近似结果,但不需要详细的螺纹几何形状和细化的网格离散化。突出显示了以下功能和功能:通过将螺栓部分分配给接触元件来建模2-D / 3-D螺栓螺纹,使用预紧载荷。 螺栓截面法还可显着节省模拟时间。

最后,通过对螺栓建模方法研究结果对比,螺栓截面方法比真正的螺纹仿真在计算上花费更少。 MPC方法在计算上花费最少,但是线程效应丢失。建议使用节点接触检测方法和技术进行建模分析过程。

关键词: 螺栓连接结构,有限元建模,预紧力,静力学分析,模态分析

Abstract

In this paper, the finite element model is established by studying the structure of the bolt connection method, and the conclusions of the study are drawn from the static and modal analysis under the preload conditions. The study of the bolted joint structure is of great significance for the current mechanization and traffic development. In the article, the previous research on the development of bolting and finite element modeling is further refined, by comparing the finite element of the connection structure. The establishment and study of the model leads to more detailed and reliable results.

In the study of finite element and modeling analysis, this paper used ANSYS software for modeling and stress modal analysis, focusing on the process of finite element modeling of bolted connections, the characteristics of various types of bolts during the establishment process, and The material model and geometric model selected at the time of establishment, the analysis of each established instruction, and the contact analysis of the modeling model are highlighted later. During the entire model building process, the selection of element types is the most basic and the most important. There are certain conditions for the boundary conditions and loads, and then a more detailed and in-depth result analysis is performed through the meshing. Bolt pre-tightening force is an important factor. The contact analysis of the bolt pre-tightening force has a corresponding effect through the contact of the unit bolts, and the force analysis under the pre-tightening force conditions can also obtain better contrast. In addition, in the content of the article, the analysis of the effects of statics is used to achieve the effect analysis. At the same time, the superiority of the connection structure of the bolt model is obtained. Through the comparison of prestressed modal studies under different conditions, the results of the available modal analysis were obtained through comparison and verification of static analysis, and finally the simplified analysis and comparison of the model was performed, and the results to be studied in this paper were obtained. A finite element model with bolted joints was used to demonstrate the simplified modeling techniques for bolt threading simulations using the bolt section method. This method provides an approximate result of an approximate thread thread model, but does not require detailed thread geometry and refined mesh discretization. The following functions and functions are highlighted: Modeling 2-D / 3-D bolt threads by assigning bolt portions to contact elements using preload. Bolt section method also saves significant simulation time.

Finally, through the comparison of bolt modeling methods, the bolt section method is less computationally expensive than the real thread simulation. The MPC method spends the least on computation, but the threading effect is lost. It is recommended to use node contact detection methods and techniques for model analysis.

Keywords:Bolt connection structure,Finite element modeling,Preload,Static analysis,Modal analysis

目 录

摘 要 I

Abstract II

第1章 绪论 1

1.1前言 1

1.2螺栓连接结构有限元建模发展研究的目的及意义 1

1.3 螺栓连接结构的有限元建模研究的历史及现状 2

1.4 本文主要研究工作 3

第2章 单个螺栓连接方式有限元建模分析 5

2.1有限元模型建立方法简要 5

2.1.1有限元建模方法研究简介 5

2.1.2关于ANSYS软件发展运用简述 6

2.2.单个螺栓建模过程分析 7

2.2.1关于螺栓连接问题分析 7

2.2.2建立模型过程 8

2.2.3单个螺栓连接接触分析 9

2.3螺栓连接结构的建模与分析 14

2.3.1螺栓连接建模条件 14

2.3.2模型建立的造型分析 16

2.4螺栓连接结构建立过程的条件分析 19

2.4.1 单元类型的选取 19

2.4.2 模型特点 21

2.4.3 边界条件与载荷 21

2.4.4 材料特性 23

第3章 螺栓连接结构的应力分析 24

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: