1.6L乘用车驱动桥虚拟设计开题报告

2020-04-13 14:31:45

1. 研究目的与意义(文献综述)

with the increase in the number of passenger cars at present, its ramp;d is also immensely necessary. the design of the drive axle is essential in the development of the automobile. the performance of the drive axle can be determined to a large extent. whether the vehicle design is reasonable[1,2].

drive axle, whose structure is closely related to the suspension structure of the vehicle, is mainly composed of main reducer, differential, axle shaft and drive axle housing. there are two types, the integral drive axle and the disconnection drive axle. when the vehicle adopts a non-independent suspension, for example, in the vast majority of trucks and a small number of cars, an integral drive axle is adopted, and its axle housing is mostly carrier-type[3]. taking into account the more space, easier to drive, better security and part of the cost reasons, the 1.6l passenger cars currently in the market are mostly in the form of ff. in order to achieve better ride performance and passing ability, independent suspensions such as mcpherson-style independent suspensions and double-wishbone independent suspensions are adopted. the independent suspension is matched with the disconnection drive axle, whose final drive is fixed on the frame, and its drive axle housing supports are divided and connected by hinges[4].

the automobile drive axle, as the main part in the automobile transmission system, has experienced more than 100 years of development. with the continuous progress and development of automotive technology, the development of automobile drive axle technology has also undergone great changes. in terms of the specific details of the axles technology, the gap between china and the world is still relatively large. in the final analysis, the function of the front axle is steering and driving; in terms of structure, the use of single-stage drive axles is increasing; in terms of technology, the requirements for lightweight and riding comfort will gradually increase. in the process of driving, the axle housing is mainly subject to bending fatigue, when the fatigue life of the axle shaft sleeve is mainly due to the residual stress during the manufacturing stage and the influence of the manufacturing process[5]. in the process of designing the drive axle, analyzing the parameters affecting the life of the drive axle, determining the local stress values by finite element method, setting the local stress loading time and load spectrum and combining them to fatigue life load theory and local stress generation phenomenon is a commonly used technical method to make fatigue life prediction[6]. the three-dimensional design and finite element technology of the drive axle have been long developed in foreign universities. m.m. topac etc. form dokuz eylül university finished the three-dimensional modeling of a truck drive axle housing, stress and fatigue analysis based on the catia and ansys. besides the location of cracks in the axle housing was determined and an improvement plan was proposed[7]. chris k. mechefske from queen’ university realized the lifetime prediction and determination of the fatigue crack zone of the driving axle housing of a mine dump truck by combining the dynamic strain measurement method and the finite element method based on ansys[8]. with the increasing recognition of the three-dimensional design of the drive axle and the finite element technology in china, the structure of the drive axle assembly has been optimized to make its structure simple and its carrying capacity enhanced, which further improves the product's reliability. various universities in china are also working with auto companies to continuously improve cad/cae design technology and capabilities. based on solidworks and ansys software, and aiming at the shortcomings of traditional drive axle design methods used by domestic drive axle plants, zhou qunui from qingdao university of technology has used the database technology and parameterized technology to develop software systems for the design and calculation of drive axles, and realized zero-distortion conversion of key data between the cad/cae software[9]. chang xueyi and zhang tao from changchun university of technology analyzed the structure of various components in ca1040p90l2 light truck driving axle, achieved 3d modeling by using catia, and implemented 3d assembly simulation and motion simulation based on parameter selection and design calculations. by research on drive axle design methods, it realized the full parametric modeling of components[10].yang zhiqing from nanjing university of technology combined with the development of a medium-sized vehicle drive axle housing, used catia software to model the axle and axle housing , then optimized the model through hypermesh software. the drive axle housing was optimized and reformed by using the partial reinforcement of the axle housing itself, which has achieved a good improvement[11]. huang xiaohua of wuhan university of technology used pro/e software to model and analyze the drive axle housing structure of a commercial vehicle of dongfeng, and optimized the design of the axle housing to achieve a 2.05% mass reduction and improving the practicality of the product[12].

2. 研究的基本内容与方案

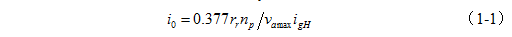

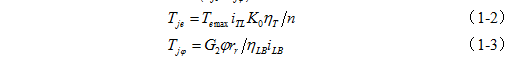

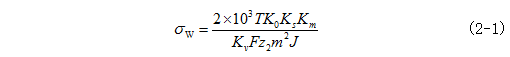

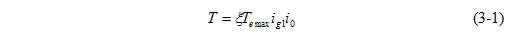

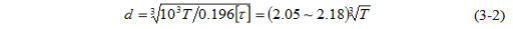

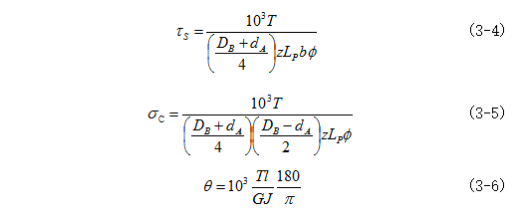

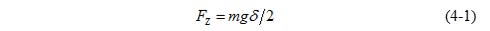

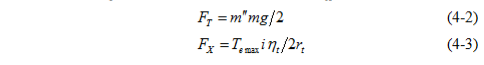

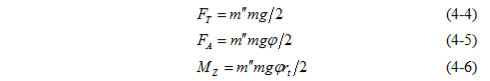

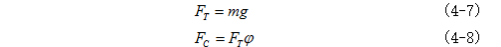

| 2.1 Basic content and goals The selected type of drive axle is the disconnection drive axle. Although its structure is complex and its cost is high, it significantly reduces the unsprung mass, then improves riding comfort and increase the average speed of the car; it reduces the dynamic load acting on wheels and axles while the car is moving, improves the service life of parts, and increases the ground clearance. Due to better contact between the driving wheels and the road surface, better adaptability to various terrains, the anti-slipping capability of the vehicle is increased theoretically. If the independent suspension guide mechanism matched with the drive axle is reasonably designed, the understeer characteristics of the automobile can be increased, and the handling stability of the automobile can be improved[16]. In view of the advantages and disadvantages of the disconnected drive axle, aiming at the Dongfeng Fengshen AX7, it is hoped that to make a reasonable design proposal based on what has been learned form theory and reality. 2.2 Technical solutions and measures (1) Through market sampling survey, the selected model was Dongfeng Fengshen AX7, which was arranged as a FF and the front suspension was McPherson-style independent suspension. Therefore, the drive axle structure is selected as a disconnection drive axle. The main reducer selected as single-stage single-speed main reducer with helical gear drive. It works smoothly and can withstand large loads. The differential is selected as an ordinary symmetric conical planetary gear differential which has simple structure, stable operation, convenient manufacture and is very reliable on highway vehicles. The axle shaft is selected as the full-floating half shaft, which theoretically only withstands the torque of the drive train. It works reliably. The axle housing is selected as a monolithic axle housing, specifically steel plate stamping and welding integral axle housing, which has simple manufacturing process, high material utilization rate, low reject rate, high production efficiency and low manufacturing cost. In the meantime it also has higher strength, small quality and other advantages[17]. (2) Design of main reducer. ① Calculation of main reduction ratio; ② The calculation load of the main reducer, which is usually the smaller of the torque on the driven gear when the maximum torque of the engine is matched with the lowest gear ratio of the power train and when the driving wheel begins to slip on a good road surface; ③ Determination of gear parameters,mainly includes the number of teeth , the diameter of the pitch circle of the driven bevel gear, the module of the end face, the width of the teeth, the helix angle, the direction of the spiral, the normal pressure angle and other parameters.; ④ Calculation of gear strength; ⑤ Calculation of bearing; ⑥ Selection of gear materials, using carburizing alloy steel, followed by quenching, temperingand shot peening. (3) Design of differential. ① Determination of gear parameters, mainly includes the number of planetary gears, number of teeth, radius, module, pressure angle, diameter and depth of the mounting holes of planetary gears, etc.; ② Calculation of gear size; ③ Calculation of gear strength, main consideration of bending stress; ④ Selection of gear materials, using carburizing alloy steel, followed by quenching, temperingand shot peening. (4)Design of axle shaft. ① Determination of load of axle shaft; ② Determination of axle shaft diameter; ③ Strength calculation of axle shaft; ④ Calculation of spline strength ,main consideration of shear stress、extrusion stress and maximum twist angle; ⑤ Heat treatment of materials, induction hardening, and the depth of hardened layer on the surface of the axle shaft is about 1/4-1/3 of its radius.。 (5) Design of axle housing. ① Theory static analysis of drive axle, but in the analysis process, it can not fully consider the impact of the external environment of the car and driving inertia and other external conditions. It mainly includes four typical stress conditions to check whether the drive axle meets the design standard strength requirements; Maximum vertical force conditions, when the vehicle is driving on uneven roads, the axle housing bears various impact loads transmitted through the wheels, maximum vertical force; Maximum driving condition, when the car is driven with the maximum driving force, the lateral force is ignored. The vertical force and the driving force are both absorbed. The vertical force on the side of the drive axle and maximum driving force; Maximum braking condition, during emergency braking, the drive axle is subjected to maximum braking force, braking force generated by ground vertical reaction force and driving inertia. The vertical force on the side of the drive axle、maximum braking force and Inertia braking torque; Maximum lateral force condition, when a car slides sideways, the vertical and lateral forces on the sides that produce sideslips reach a maximum, and the other side is in a state of zero force with the ground. The vertical force on the side of sideslips and maximum lateral force. ② Finite element method strength analysis based on ANSYS. (6) Inspection and verification of components such as final drives, differentials, axle shafts and axle housings. (7) 3D modeling and 2D drawing based on CATIA. (8) Finishing the graduation design specification. |

3. 研究计划与安排

19th -20th week of 7th semester:

determination of graduation design topics, graduation design assignments (related parameters), collection of on-campus information.

1st week of 8th semester:

4. 参考文献(12篇以上)

[1] tian xin. development status and countermeasures of chinese independent brand

passenger cars[j]. china prices,2015(01): 89-91.

[2] wang zhiyuan. analysis of development prospect of electric drive bridge

[j].modern components,2013(9): 66-68.

[3] james d. halderman. manual drivetrains and axles(eighth edition)[m]. pearson,