电磁屏蔽复合材料的制备与性能研究毕业论文

2020-02-14 10:33:40

摘 要

碳化硅具有优异的物理和化学性质,如高强度和硬度,抗高温氧化性,低热膨胀系数和良好的耐化学性。由于其优异的吸收特性并且在高的温度范围内耐高低温,可满足航空航天领域中发动机、尾喷等高温区域的吸收电磁波的要求。与此同时,碳化硅的介电性能具有可调性,通过掺杂改性可实现轻质,薄层,宽频带吸收,非常适用于制备航空航天领域中电磁屏蔽复合材料。酚醛树脂在300℃以下非常稳定,不易发生热分解,而采用将硼元素引入了酚醛树脂中形成的硼酚醛树脂,将在原来基础上进一步提升其耐热性和耐瞬时高温性能。2.5D编织技术是在3D编织技术的基础上发展的一种编织技术,它弥补了以2D纤维编织复合材料层与层间易在剪切力作用下发生分离的缺点,也解决了3D编织复合材料在生产过程中遇到的工艺繁琐,生产经济成本和时间成本高等缺点。并且力学强度突出,成为近年来研究的重点。本文选择碳化硅为吸波填料,酚醛树脂为基体,制备吸波树脂,进行变温红外测试,研究碳化硅吸波填料在固化过程中与酚醛树脂产生的反应。将吸波树脂用手工糊制的方法涂刷在2.5D编织体上,制备成预浸料,采用模压法将预浸料制成具有吸波性能的复合材料,对不同碳化硅含量的试样进行弯曲强度测试,探究碳化硅含量对弯曲性能的影响,通过SEM、TG等测试分析手段对试样的微观形貌,破坏形式,热残留率等进行分析,并且使用矢量网络分析仪探究了复合材料的吸波性能与碳化硅含量的关系。

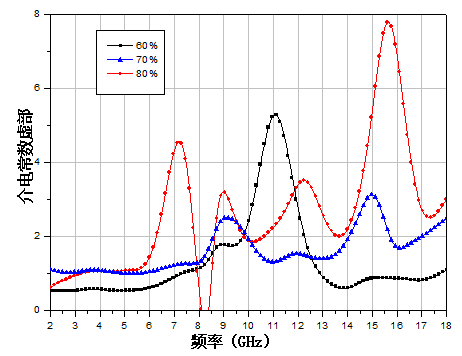

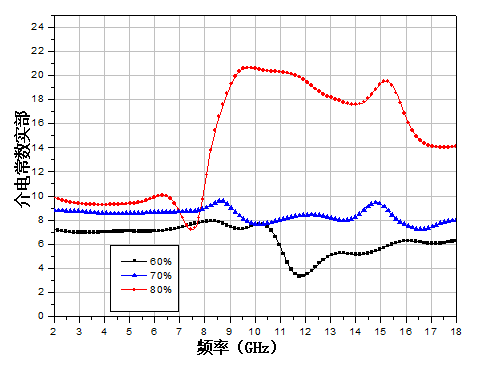

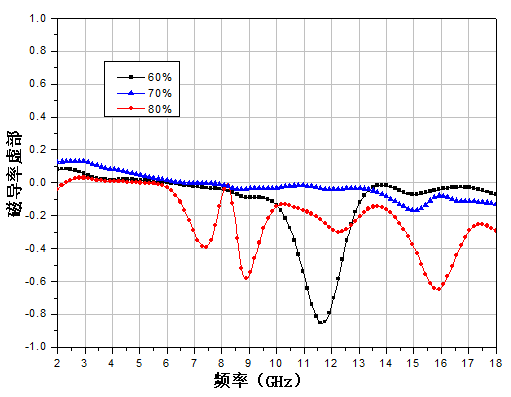

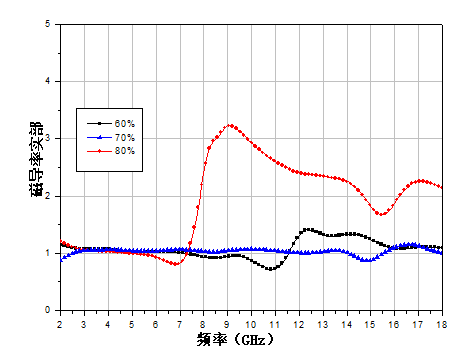

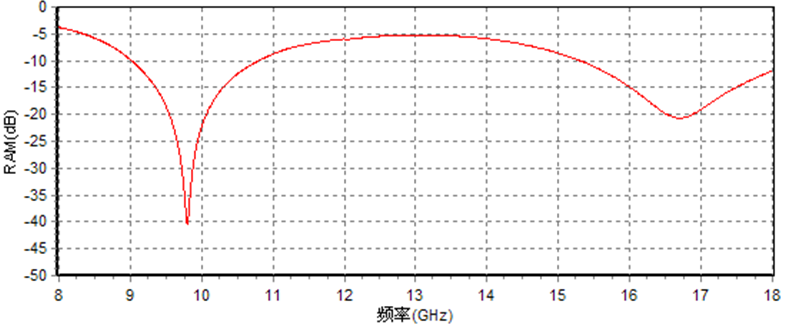

研究结果表明,对比加入碳化硅填料和不加入碳化硅填料固化后的酚醛树脂红外光谱图,我们可以发现,加入碳化硅填料只存在883cm-1的6H-SiC的伸缩振动吸收峰处的差别,其他红外吸收峰数目和强度类似,因此可以得出碳化硅填料的加入不对酚醛树脂固化过程产生影响。通过热性能测试数据我们得到,在碳化硅含量在30%~70%之间时,碳化硅含量越高,材料热性能越好,当碳化硅含量为70%时得到的复合材料的耐热性能最好,热分解残留率为77.20%。力学性能测试中发现,材料的弯曲性能受到碳化硅含量的影响,通过改变碳化硅含量,能够很大程度上影响复合材料的力学性能。弯曲强度随复合材料的碳化硅含量先上升后下降。树脂将碳化硅颗粒相互连接,使碳化硅填料在基体中可充任补强材料。当碳化硅含量过多时,树脂基体的粘度会增大,导致树脂不能很好地浸渍纤维编织体,导致材料中存在孔隙和缺陷,在受力时会产生应力集中,使材料所受应力大于材料的强度上限,从而发生破坏。此外在对试样破坏后的SEM测试中发现,试样在弯曲破坏后,纤维和树脂的结合情况良好,只有少量纤维从树脂基体中拔出,并且纤维编织体经纬向和纵向的结合紧密,没有发生层与层之间的分离。使用矢量网络分析仪对材料的电磁参数进行分析,发现随着碳化硅填料含量的增加,电磁屏蔽复合材料的弛豫峰数目和强度均增大。与此同时,介电常数实部和虚部增大,且当含量超过一定范围时,实部突然增大,导致最终损耗因子降低,材料损耗能力下降;磁导率的实部随着碳化硅含量增大而增大,当含量超过一定范围时,实部突然增大,但因为当碳化硅填料为60%和80%时,磁导率虚部为负值,向外辐射磁能,不利于材料对电磁波的吸收,因此当碳化硅填料含量为70%时,材料的吸波能力最强。通过材料反射率测试分析,可以看到当碳化硅填料为70%时,材料的反射率小于-10dB的有效吸收宽度为10.5~15.5GHz,满足电磁屏蔽材料对10GHz以上材料有效吸收的要求,具有良好的电磁波吸收效果。

关键词:电磁屏蔽;酚醛树脂;碳化硅;复合材料

Abstract

Silicon carbide has excellent physical and chemical properties, such as high strength and hardness, high temperature oxidation resistance, low thermal expansion coefficient and good chemical resistance. Due to its excellent absorption characteristics and resistance to high and low temperature in the high temperature range, it can meet the requirements of electromagnetic wave absorption in high-temperature areas such as engine and tail jet in. the aerospace field. At the same time, the dielectric properties of silicon carbide are adjustable, and it can achieve light, thin layer and wide band absorption by doping modification, which is very suitable for preparing electromagnetic shielding composites in the field of aerospace. Phenolic resin under300 C is very stable, not easy decomposition, and by introducing elements of boron phenolic resin in the form of boron phenolic resin, will be in the original basis to further improve its heat resistance and instantaneous high temperature resistance. 2.5d braiding technology is a new type of composite material braiding technology developed in recent years. It makes up for the shortcomings that 2D fiber braided composite materials are easy to separate from each other under the action of shear force. It also solves the disadvantages that 3D braided composite materials encounter in the production process, such as complicated technology, high production cost and time cost. And due to its excellent mechanical properties, it becomes the focus of research in recent years. In this paper, silicon carbide absorbing filler and phenolic resin were selected as the wave absorbing filler, and the wave absorbing resin was prepared with phenolic resin as the matrix. The way of absorbing resin paste is made by hand brushing on the 2.5 D braided body, preparation of presoak material, moulding method is adopted to presoak material made with absorbing performance of the composite materials, with different content of silicon carbide sample bending strength test, the effects of silicon carbide content on the bending performance, through the test and analysis methods such as SEM, TG microstructure of sample, failure modes, thermal residual rate is analyzed, and using vector network analyzer, explores the absorbing performance of the composite material relationship with the content of silicon carbide.

The results showed that the FTIR spectra of phenolic resin cured with or without SiC filler showed that only 883cm of sic filler was present I The difference in. the stretching vibration absorption peak of 6h-sic and the number and strength of other infrared absorption peaks are similar, so it can be concluded that the addition of silicon carbide filler has no effect on the curing process of phenolic resin. According to the thermal performance test data, when the content of silicon carbide is between 30% and 70%, the higher the content of silicon carbide, the better the thermal performance of the material. When the content of silicon carbide is 70%, the composite material has the best thermal performance and the thermal decomposition residual rate is 77.20%. In the test of mechanical properties, it was found that the bending performance of the material was affected by the content of silicon carbide. By changing the content of silicon carbide, the mechanical properties of the composite material could be greatly affected. When the silicon carbide content of the composite increases, the bending strength first increases and then decreases. The resin links the silicon carbide particles to each other so that the silicon carbide filler can act as reinforcing material in the matrix. When the content of silicon carbide is too much, the viscosity of the resin matrix will increase, leading to the failure of the resin to properly impregnate the fiber braid, resulting in the existence of pores and defects in the material. Stress concentration will occur when the material is under stress, so that the stress on the material is greater than the upper limit of the strength of the material, resulting in damage. In addition, it was found in the SEM test after the failure of the specimen that the combination of fiber and resin was good after the bending failure of the specimen, only a small amount of fiber was pulled out from the resin matrix, and the fiber braided body was tightly bound in thewarp and weft direction and longitudinal direction, without the separation between layers. The network vector analyzer was used to analyze the electromagnetic parameters of the materials. At the same time, the real and imaginary parts of the dielectric constant increase, and when the content exceeds a certain range, the real part suddenly increases, resulting in a reduction in the final loss factor and a decrease in the material loss capacity. Magnetic permeability of the real component with silicon carbide content increases, when the content is more than a certain range, suddenly become more real, but because of when the sic filler is 30% and 70%, permeability for negative imaginary part, magnetic energy outward radiation_ is not conducive to material on the absorption of electromagnetic wave, therefore when SiC filler content is 50%, the absorbing ability of the strongest material. It can be seen from the test and analysis of material reflectivity that when the silicon carbide filler is 50%, the effective absorption width of material reflectivity less than -10dB is 10.5-15.5GHz, which meets the requirement of electromagnetic shielding materials for effective absorption of materials above 10GHz and has good electromagnetic wave absorption effect.

Keywords: Electromagnetic shielding; Phenolic resin; Silicon carbide. Composite materials

目录

第1章 绪论 1

1.1 研究背景 1

1.2 电磁屏蔽材料的分类 1

1.3 吸波材料的分类及理论基础 2

1.3.1 吸波材料的分类 2

1.3.2 吸收型吸波材料的机理 4

1.4 电磁波吸收复合材料的介绍 4

1.4.1 酚醛树脂基体的介绍 4

1.4.2 多维编织增强材料的介绍 6

1.5 国内外研究现状 7

1.6 本论文的研究目的、意义及内容 7

1.6.1 论文的研究目的、意义 7

1.6.2 论文的主要内容 8

第2章 碳化硅填料对酚醛树脂热性能及固化影响的研究 9

2.1 实验部分 9

2.1.1 实验原料与设备 9

2.1.2吸波型酚醛树脂的制备 9

2.2树脂固化过程及热性能测试与表征方法 10

2.2.1 红外光谱(IR)测试与表征 10

2.2.2热重(TG)测试与表征 10

2.3结果与讨论 10

2.3.1变温红外光谱测试分析结果 10

2.3.2热重(TG)测试分析结果 12

2.4本章小结 14

第3章 电磁屏蔽复合材料力学性能与破坏形式的研究 16

3.1实验部分 16

3.1.1实验原料与设备 16

3.1.2 电磁屏蔽复合材料的制备 16

3.2复合材料性能测试与表征 17

3.2.1复合材料力学性能测试与表征 17

3.2.2扫描电镜(SEM)测试与表征 17

3.3结果与讨论 17

3.3.1复合材料力学性能测试分析结果 17

3.3.2扫描电镜(SEM)测试分析结果 19

3.4本章小结 20

第4章 电磁屏蔽复合材料吸波性能的研究 22

4.1实验部分 22

4.1.1实验原料与设备 22

4.1.2 电磁屏蔽复合材料的制备 22

4.2复合材料吸波性能测试和表征方法 23

4.2.1测试与表征 23

4.3结果与讨论 23

4.3.1矢量网络分析仪测试分析结果 23

4.4 本章小结 25

第5章 结论与展望 26

参考文献 27

致谢 29

第1章 绪论

1.1 研究背景

电子通信和雷达监测技术手段的飞速发展,使士兵大大提高了在战争中对敌军目标搜索和追踪能力,在战争中所用武器装备的隐蔽性明显降低。电磁屏蔽材料的出现,为武器装备的隐蔽问题提供了有效的解决办法。我们利用材料的电磁屏蔽性能,通过吸收侦察波和衰减反射信号来提高武器装备的隐蔽能力。与此同时,电磁屏蔽材料还可用于雷达、通信、天线等设备上,以减小战争中敌方对我方设备的干扰,提高设备的灵敏度和通信质量,在战争中赢得主动权。目前,大多数武器装备的使用环境都很恶劣,常常面临几百度甚至上千度的高温,例如在航空航天应用中,飞行器的发动机和尾喷管等,工作时产生的摩擦和燃料燃烧释放的能量非常大,短时间内来不及释放,导致温度急剧上升,有时可达到一千多摄氏度;与此同时飞行器的速度随着其技术升级也在不断提高,由于飞机高速飞行时会与前方空气相遇,空气突然被压缩并与飞机表面产生强烈摩擦,释放出大量热量,导致飞机温度瞬间升至300°C以上。因此,对电磁屏蔽材料来说,不仅要继续提高其电磁屏蔽能力,还需要提高其耐高温性能。此外军用飞机、火箭以及导弹等在高速运动中,由于受到大气气流的冲击,会产生拉力、剪切力等作用力,使得部分结构承受较大载荷,为了保持制件结构的稳定,对于电磁屏蔽材料除耐高温、吸波性能出色的要求以外,还需要具备较高力学强度。

在材料选择方面,考虑到金属材料的密度高,质量大,使飞行器的安全性能降低,能耗增大,不利于飞行器的长期发展,因此提出飞行器轻量化的要求。近年来复合材料由于优异的热、力学性能得到迅速的发展,其轻质、高强的特性与轻量化的要求完美地契合。

就耐高温性而言,纤维具有优异的热性能,并且通过将纤维与耐高温树脂基质组合而形成的复合物具有高的热稳定性。复合材料的热绝缘性好,导热系数小,因此材料在短时间、超高温的条件下还能保持一定的力学性能,适合飞行器高速飞行的条件。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: