造孔剂对SiC多孔陶瓷性能的影响毕业论文

2020-04-24 11:19:23

摘 要

本课题主要研究造孔剂对SiC多孔陶瓷性能的影响。本实验以粒径为30μm的预制 SiC粉体为主 要原料,以不同的造 孔剂配方制备SiC多孔陶瓷。研究了造孔剂的含量、粒径大小 与形貌和种类,以及烧 成制度对碳化 硅多孔陶瓷性能的影响。并研究了造孔剂对添加烧结助剂后碳化硅多孔陶瓷的抗弯强度和显气孔率的影响。

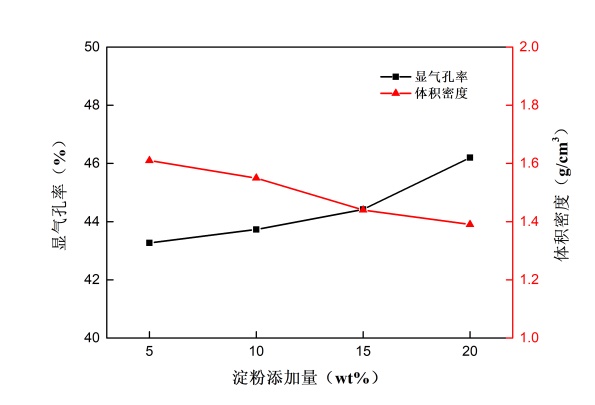

结果表明:随着造 孔 剂添加 量的增加,碳化 硅多 孔 陶瓷试 样的显气 孔率增大,体积 密 度减小,抗弯 强 度也减小;当造孔剂含量超过预制SiC粉体5wt%时,添加石墨粉制备的碳化硅 多孔陶瓷抗弯强度明显下降,而碳化 硅多孔陶瓷抗弯强度随淀粉含量的增加下降较为平缓;淀粉含量一定时,随着淀粉粒 径的减小,碳化硅多孔陶瓷的显气孔率和体积密度得到提升,抗弯强度下降;此外,相较于未添加造孔剂的陶瓷试样,添加造孔剂的陶瓷颗粒平均孔径增大,且孔径分布变宽。同时发现,造孔剂对添加烧结助剂的试样物相无影响。在预制碳化硅粉中加入15wt%的淀粉混合成型后,在氩气气氛中于1450℃烧成2h可制备出 显气孔率为44.42wt%、抗弯强度为10.637MPa的SiC多孔陶瓷,相较于未加造孔剂的SiC多孔陶瓷,其孔径数量增加,平均孔径由9μm提升至12μm。

关键词:碳化硅;多孔陶瓷;造孔剂;抗弯强度;显气孔率

Abstract

This topic mainly studies the effect of pore former on the properties of SiC porous ceramics. In this experiment, pre-formed SiC powder with a particle size of about 30 μm was used as the main raw material, and SiC porous ceramics were prepared with different pore-forming agents. The content, particle size, morphology and type of pore-forming agent and the effect of firing system on the properties of SiC porous ceramics were studied. The effect of pore-forming agent on the flexural strength and apparent porosity of SiC porous ceramics after adding sintering aid was studied.

The results show that as the amount of porogen added increases, the porosity of the SiC porous ceramic sample increases, the bulk density decreases, and the flexural strength decreases. When the pore-forming agent content exceeds 5wt% of the pre-formed SiC powder, the flexural strength of the silicon carbide porous ceramic prepared by adding the graphite powder is significantly decreased, and the flexural strength of the silicon carbide porous ceramic decreases with the increase of the starch content. When the starch content is constant, as the starch particle diameter decreases, the apparent porosity and bulk density of the SiC porous ceramics increase, and the bending strength decreases. Further, the ceramic particles to which the pore former was added had an increased average pore diameter and a wider pore diameter distribution than the ceramic sample to which the pore former was not added. At the same time, it was found that the pore former has no effect on the phase of the sample to which the sintering aid is added. After adding 15wt% starch to the pre-formed silicon carbide powder, the SiC porous ceramics with a porosity of 44.42wt% and a flexural strength of 10.637MPa can be prepared by firing at 1450 °C for 2h in an argon atmosphere. In the SiC porous ceramic without the pore former, the number of pores is increased, and the average pore diameter is increased from 9 μm to 12 μm.

Key words: silicon carbide; porous ceramic; pore former; bending strength; apparent porosity

目录

摘 要 2

Abstract 3

第一章 绪论 5

1.1引言 5

1.2 碳化硅材 料概述 5

1.2.1碳化硅 的特性 5

1.2.2碳化硅的用途 6

1.3 多孔陶瓷材料概述 6

1.4碳化硅多孔陶瓷概述 6

1.4.1碳化硅多孔陶瓷特性 6

1.4.2碳化硅多孔陶瓷的制备工艺 7

1.4.3碳化硅多孔陶瓷的研究进展 7

1.5 造孔剂对碳化硅多孔陶瓷性能的影响 7

1.6造孔 剂的研 究进展 8

1.6.1淀粉和石墨为造孔剂 8

1.6.2 纤维 素基 造孔剂 8

1.6.3 竹炭和硅溶胶为造孔剂 8

1.7 本文研究的主要内容 9

第二章 实验过程与方法 9

2.1实验仪器和原料 9

2.2 试样 制备与实验方法 10

2.3 原料配方 12

2.4 表征 方法与性能 测试 13

2.4.1 显气孔率和体积密度的表征 13

2.4.2 抗 弯强度 的测试 14

2.4.3 孔 结构的 表征 14

2.4.4 表 观形貌 分析(SEM) 14

2.4.5 物相结构分析(XRD) 15

第三章 结果与讨论 15

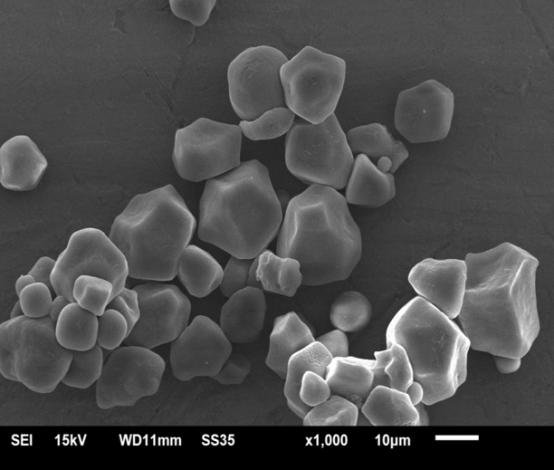

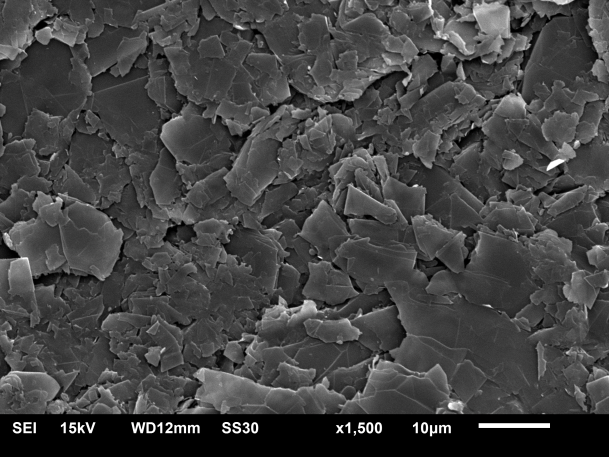

3.1 造孔剂种类及形貌 15

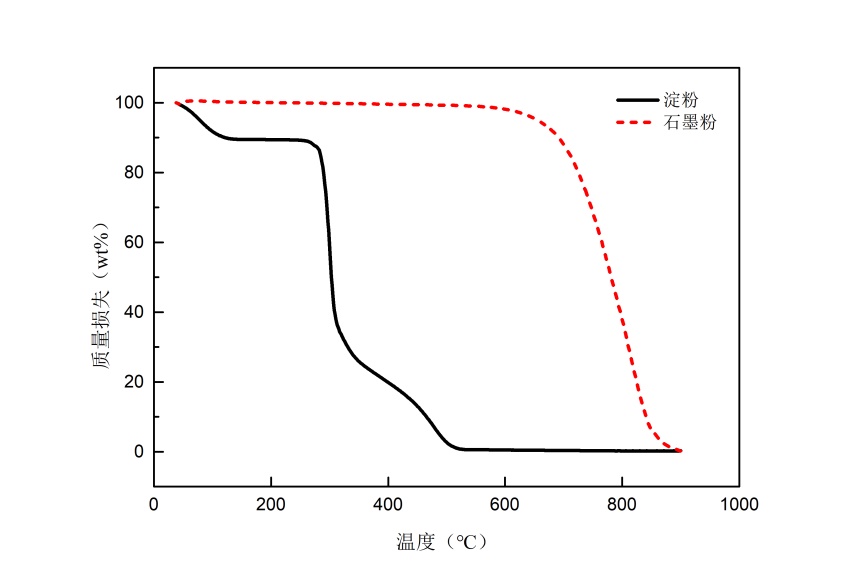

3.2 排胶制度的确定 15

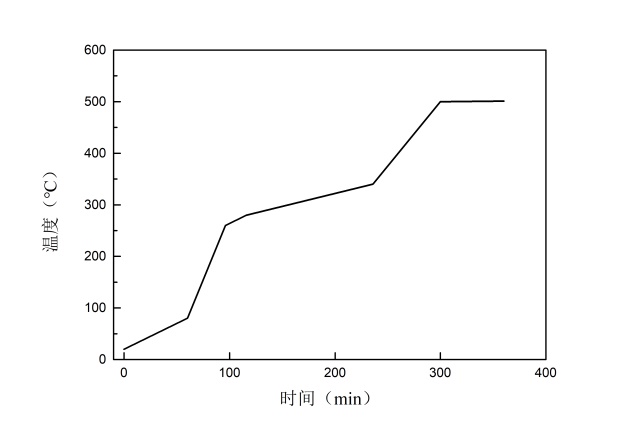

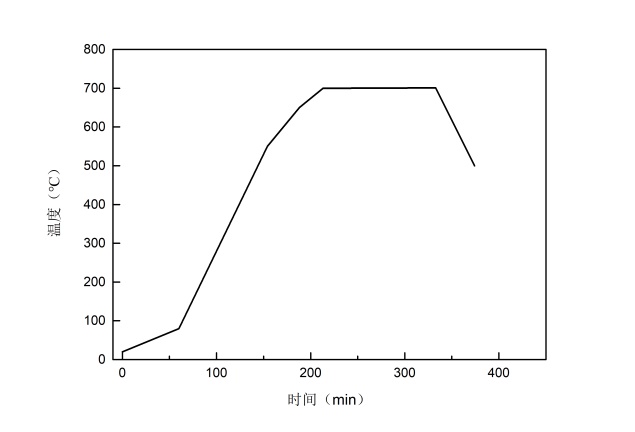

3.3 造孔剂种类、添加量对陶瓷性能的影响 17

3.4 造孔剂粒径对试样性能的影响 20

3.5 混合造孔剂对试样性能的影响 21

3.6 烧结助剂对试样性能的影响 22

3.7 造孔剂对试样微观结构和孔隙特征的影响 23

第四章 结论与展望 25

4.1 相关结论 25

4.2展望 26

参考文献 27

致谢 29

第一章 绪论

1.1引言

碳化硅陶瓷具有强度高、硬度大、良好的耐腐 蚀性和抗热冲 击性等优异性能,因此,SiC多孔陶瓷 可以在恶劣环境中作为很多介质之间的过滤材料,是理想的过滤材料之一[1]。我们可以利用造孔剂来调节气孔率,在烧成过程中实现宏观的非收缩变形,并且可以控制气孔的形状,该工艺过程简单可行,具有良好的应用前景。因此,在SiC多孔陶瓷的制备中,除了粘合剂之外,造孔剂对多孔陶瓷颗粒的组合也有一定的影响[2]。

相关图片展示:

您可能感兴趣的文章

- 蒸养纤维掺杂高铁低钙水泥混凝土的抗海水冲磨性能研究文献综述

- TIPA对水泥-锂渣体系力学性能和水化性能的影响外文翻译资料

- TEA对锂渣-水泥复合粘结剂流变性能及水化性能的影响外文翻译资料

- 硫酸铝无碱液体促进剂的效果研究烷醇胺对硅酸盐水泥水化过程的影响外文翻译资料

- 新型C-A-S-H/PCE纳米复合材料:设计表征和对水泥水化的影响外文翻译资料

- 工业中碳捕获技术以及以水泥回转窑作为核心的吸附再生器外文翻译资料

- Ca/Al层状双氢氧化物的制备及其结构对水泥早期强度的影响外文翻译资料

- 蒸汽养护后混凝土养护方法对混凝土机械强度和透气性的影响外文翻译资料

- 含白云石或石灰石的偏高岭土水泥在相组成与抗压强度的异同外文翻译资料

- 与硅质铁尾矿结合的混凝土的耐久性外文翻译资料