2吨折叠式平板清障车设计及有限元分析毕业论文

2020-02-17 10:52:59

Abstract

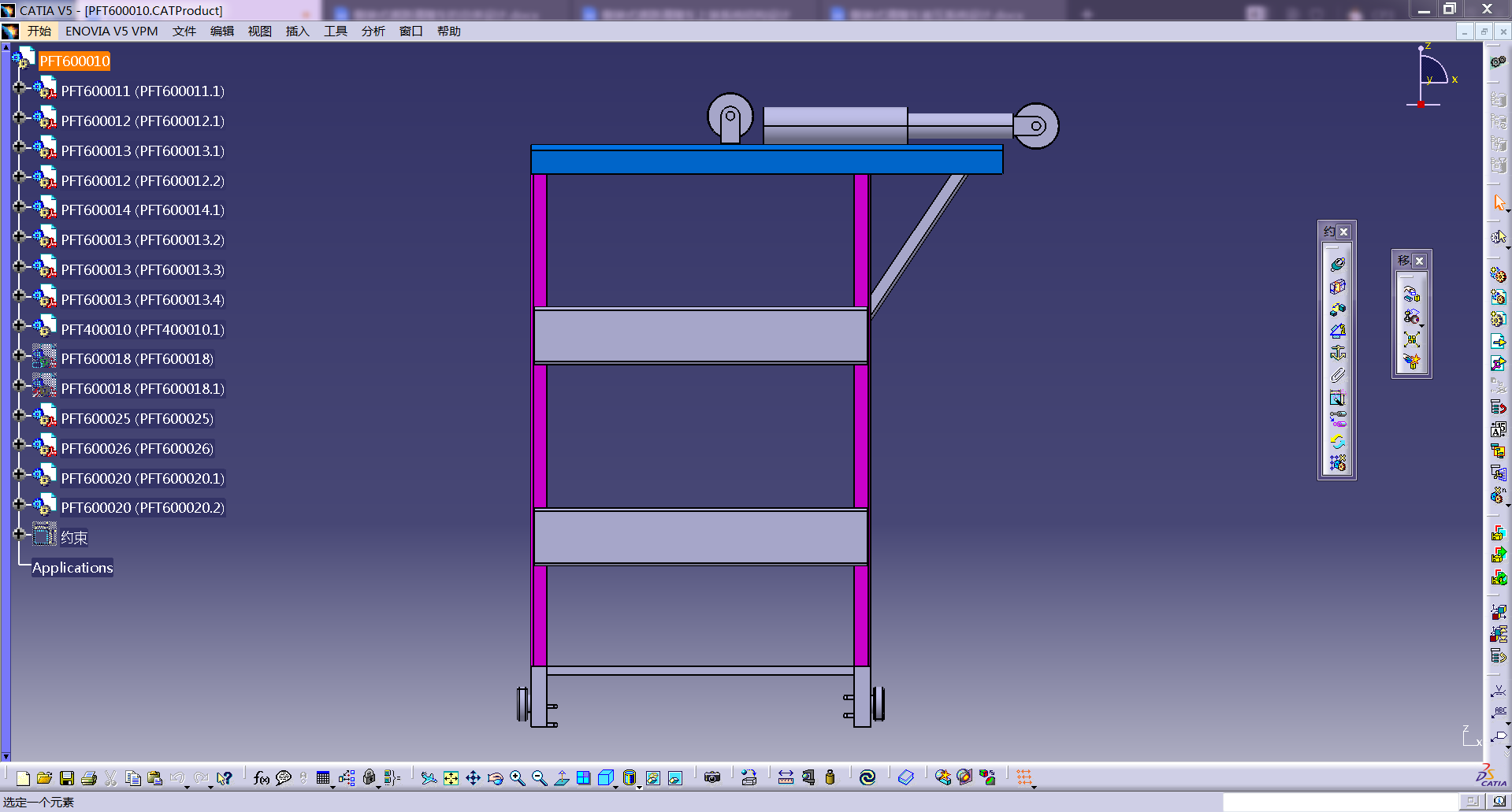

As a special vehicle equipped with obstacle removal and rescue equipment, the road repair vehicle can lift and tow the faulty or accident vehicles, so as to quickly leave the accident area and ensure the smooth road. As China's road network continues to spread on the map, car ownership is also growing. The obvious impact is the rapidly increasing urgent demand for the rescue of repair vehicles. In order to cope with the increasingly complex road conditions and increasingly severe operating conditions, repair vehicles are also developing towards the trend of multi-function. In this paper, based on the analysis of domestic road traffic accident obstacle removal and rescue needs and the investigation of the types of domestic road fault removal vehicles, a new type of road fault removal vehicle with a different structure from the existing domestic road fault removal vehicles is designed, that is, the side mounted road fault removal vehicle named after its structural characteristics. On the basis of careful study of the structure and working principle of the vehicle, the design principle of fully realizing the performance of the roadway vehicle was followed to clarify the overall design scheme of the folding flat-bed vehicle and draw the general layout design drawing.This paper introduces the calculation method of performance parameters of the folding flat-bed car.CATIA was used to design the top system of the 2-ton folding flat fault recovery vehicle, and motion simulation and finite element simulation of the top system were carried out. The structural improvement scheme of the top system of the 2-ton folding flat fault recovery vehicle was proposed.

Key words: Repair vehicle; Installation system design; CATIA; Motion simulation; Finite element analysis

目录

Abstract I

Chapter 1 Introduction 1

1.1 Background and significance of the research 1

1.2 Research status of domestic and foreign research on the technology of repair vehicles 3

1.2.1 Research status of foreign repair vehicle technology 3

1.2.2 Domestic research status of the technology of the repair vehicle 4

1.3 The development trend of the technology of the breakdown vehicle 5

Chapter 2 Overview of folding repair vehicle 6

2.1 Structure and application of the repair vehicle 6

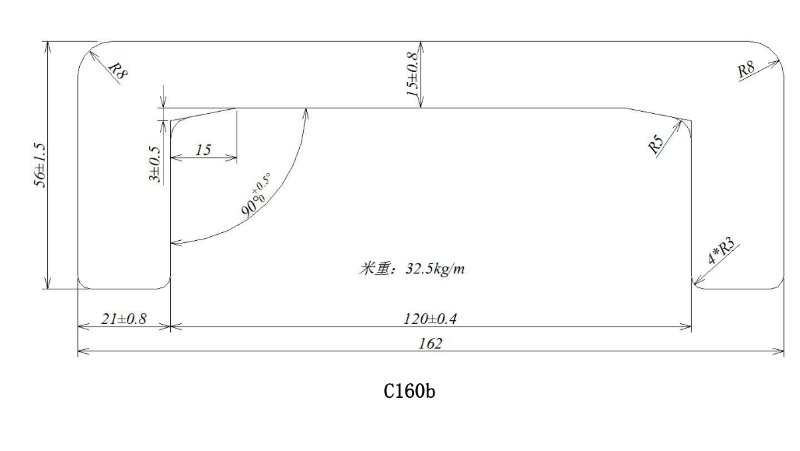

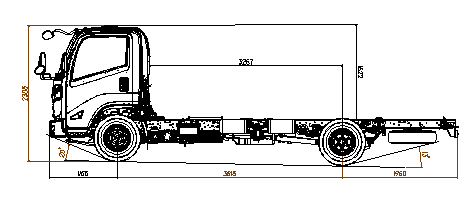

2.2 Selection of system structure parameters 9

2.2.1 Selection of chassis 9

2.2.2 Selection of vertical rail mechanism parameters 10

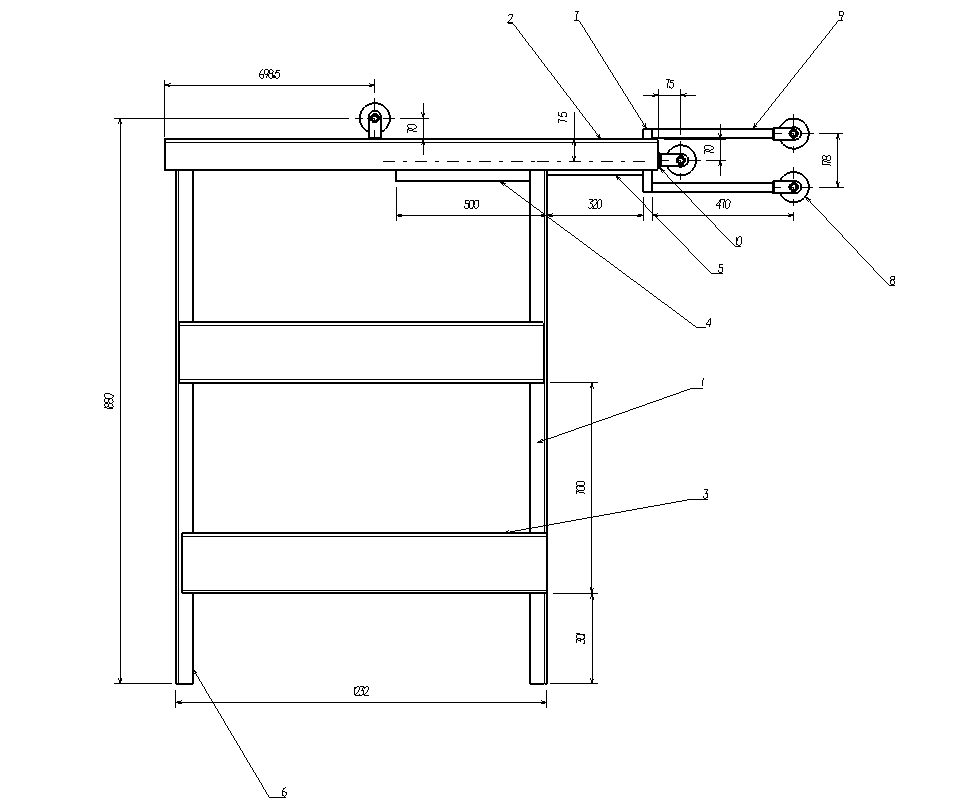

2.2.3 Vertical car composition 12

Chapter 3 Optimal design of the system 14

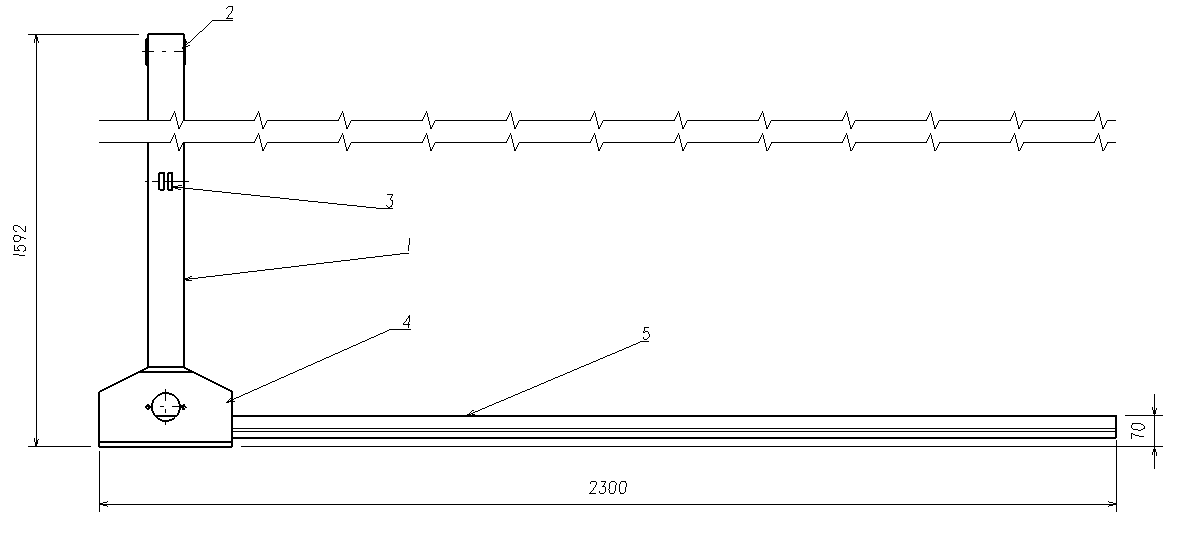

3.1 Quadruple vertical car design 14

3.1.1 Design and check of oil cylinder 15

3.1.2 Design and verification of wire rope 17

3.2 Layout of vertical trolley wire rope 18

3.3 Motion simulation of quadruple vertical car 22

Chapter 4 Finite element analysis of mounting system 24

4.1 Introduction to finite element method 24

4.2 Introduction to CATIA software 25

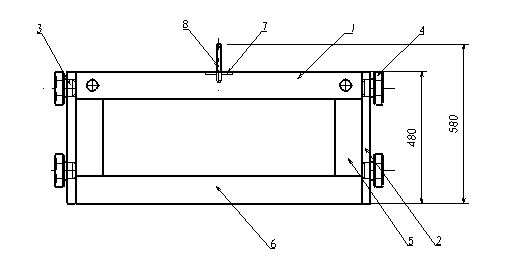

4.3 Double pulley support model 25

4.4 Scaffold material properties 26

4.5 Finite element analysis of double movable pulley mechanism 26

Chapter 5 Conclusion 31

Reference 32

Acknowledgement 33

Chapter 1 Introduction

1.1 Background and significance of the research

With the rapid economic development, people's living standards have been significantly improved, car ownership is increasing, and road traffic accidents are increasing. There are more and more broken cars on the road, so the broken cars play a very important role. And the folding road repair car can quickly clean up the car, quickly transport, mobility, and will not take up too much space, will not cause secondary damage to the car.Therefore, the folding road repair vehicle will certainly be favored by the traffic management department.

Repair car actually called road repair car, also known as the road because of the different relief vehicles, and the structure characteristics of tractor and trailer, but no matter how changes in the structure, generally has the following basic components, such as body, chassis, traction device, lifting gear, electric and hydraulic control system and the toolkit, generally can lift traction, pull and lifting movement, often on the highway and city road maintenance operations.The special vehicles equipped with all kinds of road rescue equipment are road maintenance vehicles.Accidents or breakdowns can never be completely avoided when a car is on the highway, especially on the high grade highway.The responsibility of the repair vehicle is to arrive at the scene of the accident in the shortest time after the accident, and at the same time immediately pull the accident vehicle or repair vehicle from the scene, so that the road is unimpeded, convenient for other vehicles.The car can be hoisted by the wire rope to the accident, damage or violate the vehicle, and then lift its front wheel, axle or beam or even its "back", etc., quickly away from the scene, in order to restore the order of the traffic accident part.Emergency vehicles are another name for road repair vehicles[3].The continuous construction of high-grade highways and the increase in the types and number of special vehicles also promote the continuous innovation of repairing vehicles.In its development process, some risk factors will inevitably appear.Therefore, maintenance vehicles should be removed in the process of obstacles and rescue work safety operation.

The repair vehicles can be divided into the following types according to their categories: towing separation and towing connection type, full floor and semi-floor type, one-tow-one-plate type, one-tow-two-plate type and multi-function repair vehicles[6]. The towed and separated type can be divided into two types: arm rotation for medium vehicles and non-rotation for medium and light vehicles. Light, medium and heavy duty is classified according to the working ability, sedans, minivans, and light trucks, light repair car rescue rescue operations, large and medium-sized passenger car and the medium-duty truck USES the medium-duty repair car rescue rescue operations, and heavy duty truck and super-heavy it can only choose super-heavy tractor-semitrailer repair car for repair. According to the classification of structural forms, simple fork, door frame fork and back type and arm set up heavy type repair truck are the four basic types of road repair truck. However, the operation process of these types of repair vehicles is relatively long, which may cause short-term congestion in some road sections where there are more vehicles. The fast operation time of the repair car is not negligible in the design. At the same time, there is no practical application of folding structure in China.The function of rescue accident or faulty vehicle is one aspect that we pay attention to in the development of folding type repair car. The performance of the repair car not only depends on the performance of each component, but also has an inseparable relationship with the coordination and cooperation among the components. For example, the design of the mounting system determines the efficiency and speed of the obstacle clearance.Therefore, a particularly important part of the design of the repair car is the design of the mounting system.

From the point of the development of nuclear domestic repair car, design research and development personnel in most of the repair car manufacturing companies in China to repair car parts of stiffness and strength of the school when the mainstream approach is still the traditional analytic method, this method is obvious limitation is the complicated structure, can only roughly estimate or processed based on the experience, making designed products are difficult to have a better performance, and therefore there is almost no market competitiveness, moreover also caused great waste, completely unable to meet the needs of the repair car of modern design. Therefore, it is very necessary to use the finite element method to carry out in-depth research on the repair vehicle. After the finite element analysis, we carry out reasonable improvement and optimization of the structure.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

![_0{1KT001SRDN@HO0~][]LF](http://www.biyelunwen.org/wp-content/uploads/2020/02/lw1115_2020217105256157.png)