铝模板装配序列规划设计毕业论文

2020-02-17 19:58:08

摘 要

现浇钢筋混凝土是当前建筑工程的主要组成结构。我国在2000年后逐渐引进铝合金模板作为现浇钢筋混凝土成型的主要模具,铝合金模板及支撑体系拥有着其他模板不可比拟的优异特性,可实现建筑结构一次性现浇,且浇筑后的混凝土表面成型质量好,因此受到了建筑施工行业的广泛青睐,也逐步代替原有的模板体系。

铝合金模板设计打破了传统模板的设计模式,避免了传统模式由理论计算所带来的设计效率过慢的问题。然而铝合金模板项目是一个动辄具有上万件模板件的超大型装配体,在铝合金模板设计装配施工过程中,对铝模板装配序列的规划设计占据了巨了大量的施工时间,消耗了大量的人力物力,因此铝模板的装配序列规划是铝模板工程施工效率的决定性因素。目前所采用的装配序列规划方法主要为工厂内预装配和三维模型虚拟装配两种方法。其中,工程内预装配是在铝模板设计制造完成后,直接在厂房内按照建筑物施工设计图纸对铝模板进行装配,通过实际的装配操作来规划最优装配序列,得到最优装配序列后将模板分批编号,然后运至施工现场,在现场按编号进行装配。此方法在实际应用过程中需要占据大面积的厂房车间,装配过程中需要投入大量的装配人员进行操作,而在优化过程中极度依赖施工人员的经验,因此人的主观因素对优化结果影响较大。虚拟装配是在计算机辅助设计(CAD)软件中进行铝模板的预拼装操作,过程与上述基本一致,省去了所占的车间以及大量的装配人员,但仍存在着对操作人员的主观经验依赖较大等问题。

由此可以看出,目前的铝模板应用过程中的装配序列规划仍然存在设计效率低下、智能化程度底等一系列问题,严重影响着施工效率。

本文基于粒子群算法对铝模板的装配进行序列规划,旨在提高铝模板装配施工效率,缩短施工时间,推动铝模板的发展,主要内容为:

- 分析建筑铝合金模板的施工现状,对铝模板的类型进行分类编号,并进一步分析铝模板构件之间的装配工艺以及铝模板装配产品的装配工艺。

- 基于无向图的思想建立了装配关系模型,根据无向图得出装配关系连接矩阵;基于树状图与无向图构建了装配信息模型。

- 根据所构建的装配关系连接图以及连接矩阵,代入装配难度系数装配时间以及装配可靠性等相关参数装配进行装配代价计算。

- 基于粒子群算法的迭代过程,设置相关参数进行迭代,求解装配序列规划。

通过实例分析,对装配序列规划系统检验,结果表明:树状图和无向图模型能够很好的表达模型的信息记忆装配关系,装配代价计算可以用具体数值来衡量装配难度成功去除了人的主观因素影响,粒子群算法可以达到装配序列规划的目的,系统最终能输出最优装配序列用于指导施工。

关键词:铝合金模板,信息建模,装配,无向图,粒子群算法

Abstract

Cast-in-situ reinforced concrete is the main structure of current construction projects.

Template in China gradually introduced after 2000 aluminum alloy as the main mold of cast-in-place reinforced concrete forming, aluminum formwork and supporting system with other templates incomparable excellent properties, which can realize one-time cast-in-situ building structure, and the pouring of concrete surface after forming of good quality and widely favored by the construction industry, therefore, also gradually replace the existing template system.

The aluminum alloy template design breaks the traditional template design pattern and avoids the problem that the traditional pattern design efficiency is too slow brought by the theoretical calculation.

Aluminum alloy template project is, however, a quick mega assembly, with tens of thousands of pieces of the template in the process of aluminum alloy template design assembly construction, for aluminum template assembly sequence planning and design has taken up much of the giant construction time, consumes a lot of manpower, so aluminum template assembly sequence planning is template construction efficiency is the decisive factor.

Currently, the methods of assembly sequence planning are mainly preassembly in factory and virtual assembly of 3d model.

Preassembly in among them, the project is in design and manufacture aluminum template is completed, the plant directly according to the building construction design drawings of aluminum template assembly, through the actual operation of assembly planning the optimal assembly sequence and get the optimal assembly sequence after the template batch number, and then shipped to the construction site, according to the number of assembly at the scene.

In the practical application process, this method needs to occupy a large area of workshop, and a large number of assembly personnel need to be invested for operation in the assembly process. However, in the optimization process, it relies heavily on the experience of construction personnel. Therefore, subjective human factors have a great impact on the optimization results.

Virtual assembly is the pre-assembly operation of aluminum template in the computer aided design (CAD) software. The process is basically consistent with the above mentioned, which saves the workshop and a large number of assembly personnel, but there are still some problems such as greater reliance on the subjective experience of operators.

It can be seen that there are still a series of problems in the assembly sequence planning in the application process of aluminum template, such as low design efficiency and low intelligence, which seriously affect the construction efficiency.

Based on particle swarm optimization (PSO) algorithm, this paper conducts sequence planning for aluminum template assembly, aiming to improve the construction efficiency, shorten the construction time and promote the development of aluminum template. The main contents are as follows:

(1) Analyze the construction status of aluminum formwork in buildings, classify and number the types of aluminum formwork, and further analyze the assembly process between aluminum formwork members and the assembly process of aluminum formwork assembly products.

(2) The assembly relation model is established based on the idea of undirected graph, and the connection matrix of assembly relation is obtained according to the undirected graph;

The assembly information model is constructed based on tree graph and undirected graph.

(3) According to the assembly relation connection diagram and connection matrix constructed, the assembly cost is calculated by substituting assembly difficulty coefficient, assembly time, assembly reliability and other related parameters.

(4) Based on the iterative process of particle swarm optimization, relevant parameters are set for iteration to solve assembly sequence planning.

Through case analysis, on the assembly sequence planning system test, the results showed that the tree and undirected graph model can well express assembly relationship model of information memory, the assembly cost, it can be measured by specific numerical assembly difficulty successfully removed the person's subjective factors, the particle swarm algorithm can achieve the purpose of assembly sequence planning, system will eventually output optimal assembly sequence is used to guide the construction.

Keywords: aluminum alloy template, information modeling, assembly, undirected graph, particle swarm optimization

目 录

摘 要 I

Abstract III

第1章 绪论 1

1.1研究背景、目的及意义 1

1.2国内外研究现状 3

1.2.1建筑铝模板数字化研究现状 3

1.2.2装配序列规划研究现状 5

1.3主要研究内容 6

第2章 建筑铝合金模板装配工艺及其信息建模 8

2.1建筑铝合金模板的装配工艺 8

2.1.1建筑铝合金模板概述 8

2.1.2建筑铝合金模板的装配工艺流程 10

2.2建筑铝合金模板信息建模 13

2.2.1铝模板基本结构与系统需求 13

2.2.2铝合金模板信息模型及其层次关系 15

2.2.3装配信息模型 17

第3章 基于粒子群算法的铝合金模板装配序列规划 20

3.1装配序列的评价 20

3.1.1装配难度与装配时间 20

3.1.2装配可靠性与装配代价 21

3.2基于无向图的装配序列规划模型 23

3.2.1无向图的建立 23

3.2.2适应性计算 24

3.3粒子群算法求解 25

第4章 装配序列规划的应用实例 28

4.1装配信息建模 28

4.2基于粒子群算法的装配序列规划求解 33

第5章 论文工作总结 35

5.1总结 35

5.2展望 35

参考文献 36

致谢 38

第1章 绪论

1.1研究背景、目的及意义

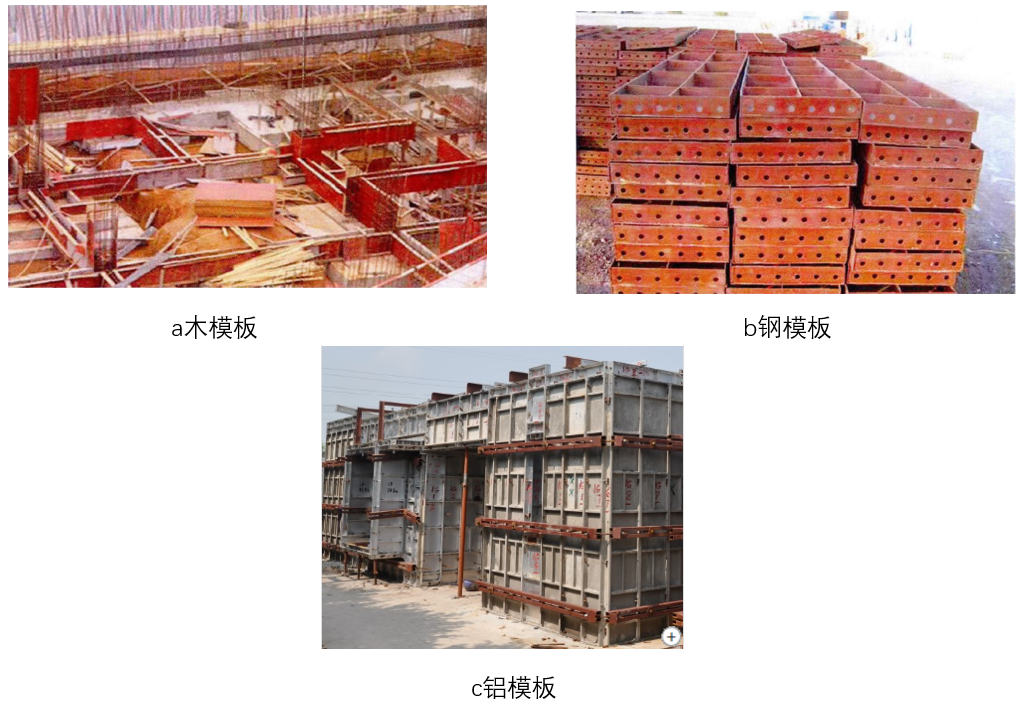

随着我国改革开放以来城镇化进程的持续推进,房地产业得以迅速发展,现已成为社会经济增长的主力。近年来,由于住房土地资源紧张高层建筑所占建筑物的比例不断增大,这也直接导致了钢筋混凝土结构工程不断增多,模板作为钢混结构工程的必须材料,需求量也越来越大。对于混凝土工程而言,特别是现场浇筑的混凝土工程模板工程是在其中有着举足轻重地位的一部分,模板工程直接影响着工程建设项目的质量、整个工程的施工所需费用以及工程参与企业的经济效益。据统计,模板工程的费用相当可观,大约为钢筋混凝土结构工程总费用的三成,模板工程的施工也消耗着大量的时间,这部分时间约为结构工程施工总工期的一半。近年来建筑模板正朝着多体系化趋势发展,建筑模板的材料多种多样,工程中的典型代表有木模板、钢模板、塑料模板、竹模板、铝合金模板等,模板的制作工艺也多种多样,且有着较长时间的发展,截止目前模板制作所奖励的阶段有木制散板、装配定型式木模板、大型木模板、铝合金组合定制模板等。

图1.1常用建筑模板

我国自上世纪60年代以来,响应国家政策,减少木材消耗,并且随着组合钢模板的大面积推广应用,在其他材料的方向上相继成功研发了塑料、玻璃钢、木胶合板、竹胶合板等多种材质的模板新品种。铝合金模板作为新一代模板工程中的模板,最早在上世纪七十年代由北美诸国研发并大量投入应用,我国在进入本世纪后引入铝合金模板技术,逐渐取代原有的模板体系。

与此同时,国内对高层建筑开始有大量需求,这些工程的大规模施工进一步推动了铝合金模板体系在国内的快速发展。铝合金模板体系主要应用于高层商业楼、住宅楼等的混凝土施工工程中,他的出现打破了传统模板的设计模式,在施工前就对模板设计标准化、系列化,避免了由理论计算带来的设计效率低下等问题,并以其重量轻、易拆装、可实现建筑结构的一次成型且成型质量好等优点,受到建筑业的广泛青睐。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: