球形纳米CeO2粉体的合成毕业论文

2021-11-29 21:17:50

论文总字数:19129字

摘 要

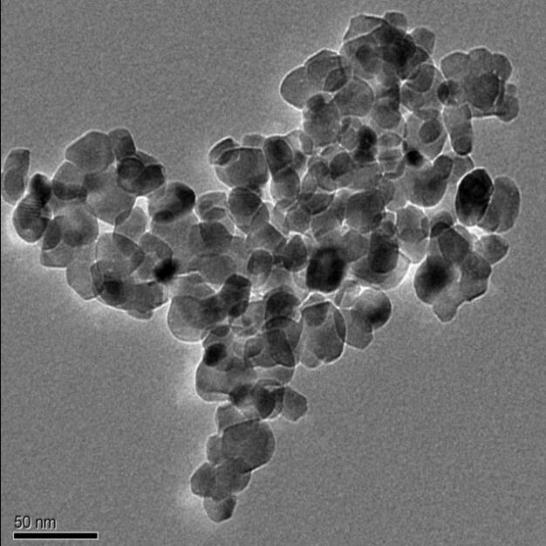

纳米二氧化铈颗粒作为化学机械碾磨法工艺流程中的主要打磨材料之一,对于可以制造集成电路的硅晶片的制造有着举足轻重的影响。二氧化铈纳米颗粒在不同的合成条件下呈现的形貌是多种多样的。然而不规则晶体颗粒的棱角在打磨硅晶片等对表面平整度有较高要求的材料时会造成表面划痕和缺陷,影响了这些材料的精细度,干扰了其进一步使用。

纳米CeO2粉体不仅可用于打磨硅晶片,而且在对实际工业领域当中,都包括在橡胶、玻璃、陶瓷等等各种各样的领域当中,都有着极为广泛的应用。另外,在一些环保领域当中,例如对于汽车尾气的净化,臭氧催化氧化处理废水等场合中,纳米氧化铈都发挥出了比较显著地功能作用。而且,能够预计的是,这种纳米CeO2粉体必定会在能源储存、转换以及生物医学等领域发挥重要作用。

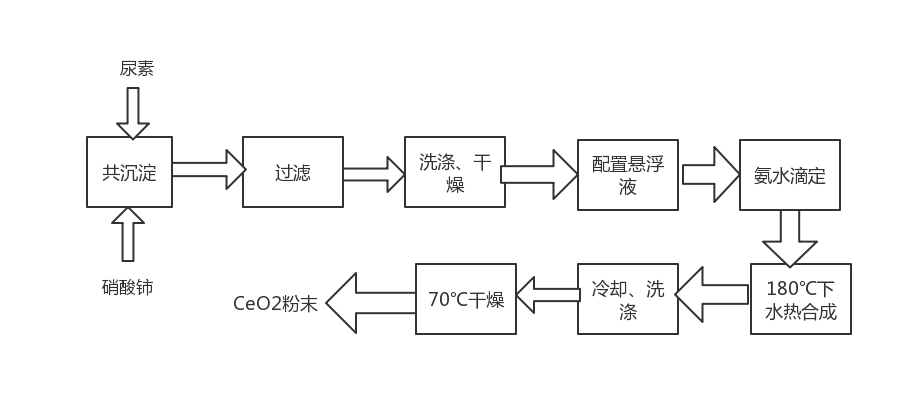

本课题将研究化学共沉淀与水热法相结合制备球形纳米CeO2球形粉体的方法,对比化学共沉淀、水热合成的条件对CeO2粉体形貌的影响;研究将化学共沉淀产生的氢氧化物,作为水热合成前驱体反应物所制备出最终产物的各种工艺控制条件。

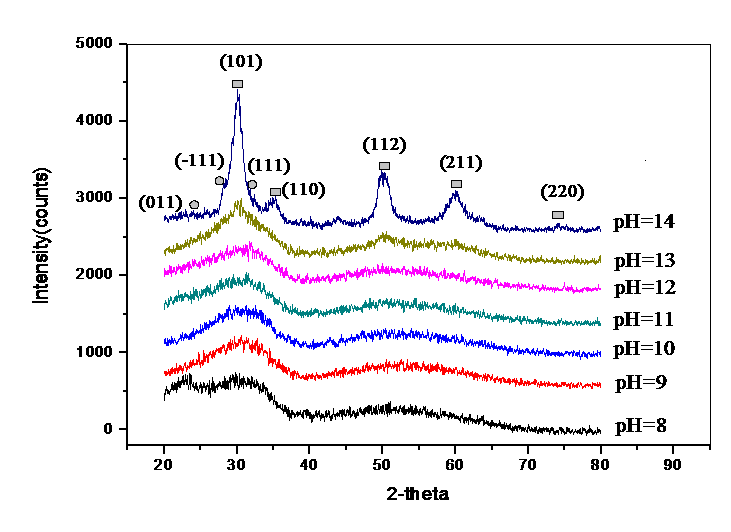

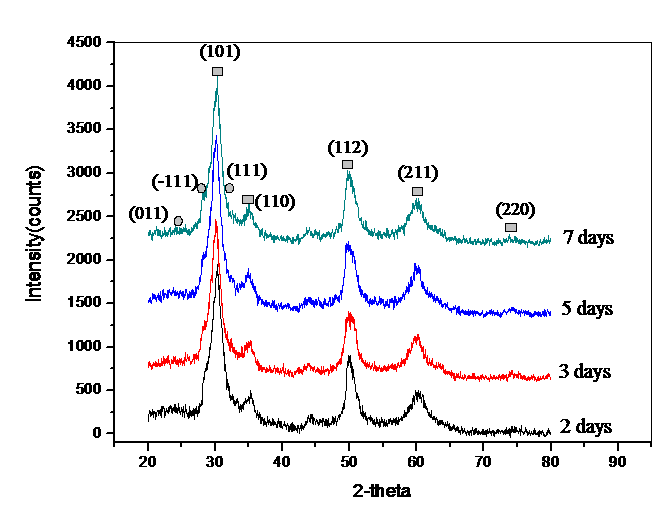

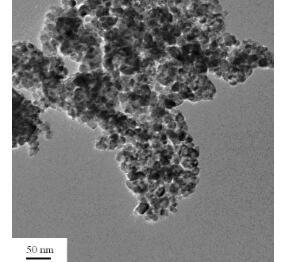

实验结果表明,在化学共沉淀法中,沉淀剂与Ce3 离子的浓度比为40:1时粉体形貌最为良好。除此之外,水热合成过程中溶液pH=14时可以获得颗粒大小均匀,结晶良好的氧化铈粉体,而水热合成时间及反应物浓度对最终产物形貌影响不大。实验最后还通过喷雾造粒得到了分散性良好的球形氧化铈粉体。

关键词:球形纳米CeO2;共沉淀;水热合成

Abstract

As one of the main grinding materials in the process of chemical mechanical grinding, nano cerium dioxide particles play an important role in the manufacturing of silicon wafers that can be used to manufacture integrated circuits. The morpHology of CeO2 nanoparticles is varied under different synthesis conditions. However, the edges and corners of irregular crystal particles will cause surface scratches and defects when they are used to polish materials with high requirements for surface flatness, such as silicon wafers, which will affect the fineness of these materials and interfere with their further use

Nano CeO2 powder can not only be used to polish silicon wafer, but also has a very wide range of applications in practical industrial fields, such as rubber, glass, ceramics and other fields, will be applied to this material. Nano-CeO2 has more oxygen vacancies and lower redox potential. Therefore, this kind of material can also be used in some environmental protection fields and occasions. For example, in the purification of automobile exhaust, ozone catalytic oxidation of wastewater and other occasions, this material has played a more significant role. Moreover, it can be predicted that the nano CeO2 powder will play an important role in energy storage, conversion, biomedicine and other fields.

In this paper, the method of preparing spHerical Nano-CeO2 powders by chemical coprecipitation and hydrothermal method is studied, and the influence of the conditions of chemical coprecipitation and hydrothermal synthesis on the morpHology of CeO2 powders is compared; the various process control conditions of preparing the final products by using the hydroxide produced by chemical coprecipitation as the precursor reaction of hydrothermal synthesis are studied.

Experimental results show that the powder has the best morphology when the concentration ratio of precipitant to Ce3 ion is 40:1. Besides, cerium oxide powder with uniform particle size and good crystallization can be obtained pH=14:00 in the hydrothermal synthesis process, but the hydrothermal synthesis time and reactant concentration have little effect on the final product morphology. Finally, the spherical cerium oxide powder with good dispersion was obtained by spray granulation.

Key Words: spHerical nanometer CeO2, coprecipitation, hydrothermal synthesis

目 录

第一章 绪论

1.1纳米材料的研究背景......................................................1

1.1.1研究纳米材料的意义.................................................1

1.1.2纳米材料的制备方法.................................................2

1.2球形纳米氧化铈的研究现状................................................1

1.2.1纳米氧化铈的作用...................................................1

1.2.3纳米氧化铈的制备方法...............................................2

1.2.3控制氧化铈纳米尺度的机理...........................................3

1.2.4纳米氧化铈制备方法中存在的问题.....................................4

1.2.5课题研究内容.......................................................4

- 实验过程

2.1实验材料与仪器........................................................5

2.2实验方案..............................................................6

2.3测试与表征方法........................................................7

第三章 结果与讨论

3.1共沉淀的配方设计......................................................7

3.2硝酸铈-尿素溶液共沉淀条件的研究.......................................8

3.3水热合成条件对最终产物物相及形貌的影响................................8

3.4反应浓度对最终产物形貌的影响..........................................9

3.5 球形CeO2粉体的制备...................................................11

第4章 结论与展望

4.1结论...................................................................12

4.2未来展望...............................................................12

参考文献...................................................................14

致谢.......................................................................15

附录.......................................................................16

- 绪论

1.1纳米材料的研究背景

1.1.1研究纳米材料的意义

目前,纳米陶瓷、纳米金属蓬勃发展,纳米管,纳米丝层出不穷[1,2],人们用各种实验对纳米材料进行结构上的设计,达到特殊用途。利用新方法,新理论设计得到更多新的纳米器件以及纳米复合材料是现阶段国内外众多专家学者们的研究探索热点内容[3,4]。

1.1.2纳米材料的制备方法

请支付后下载全文,论文总字数:19129字

相关图片展示: