超高压绝缘子用水泥胶合剂的研究毕业论文

2021-11-29 21:22:25

论文总字数:32368字

摘 要

随着我国对电力的需求日益增长,采用超高压输电具有显著的经济效益和社会效益。绝缘子是输变电过程中的关键配套产品,它可以保证电力传输和分配的安全。而水泥胶合剂是用于绝缘子与铸铁挂件间的粘结剂,其性能优劣会影响电瓷产品质量。绝缘子需长期暴露于自然环境中,经受夏季高温、冬季冰冻,甚至遭受风暴雷击等恶劣环境。因此对绝缘子胶装用水泥胶合剂提出了更高的性能要求。

本文分别以硅酸盐水泥、高铝水泥为胶凝材料,制备出了两种水泥胶合剂。研究了膨胀剂和聚丙烯纤维对硅酸盐水泥胶合剂性能的影响规律。以及仅改变砂胶比或硅灰掺量时,高铝水泥胶合剂的性能变化。获得了如下主要结论:

(1)体系中掺入适量膨胀剂可以增加胶合剂的补偿收缩效应,有利于胶合剂体积的稳定性,从而避免了水泥胶合剂与绝缘子、铸铁挂件之间产生缝隙,提高了耐机电破坏的能力。膨胀剂对胶合剂有一定的缓凝作用,但影响并不显著。在硅酸盐水泥胶合剂体系中,掺入5%膨胀剂时可提高早期强度(相对于空白组)。

(2)膨胀剂和纤维以合适比例复配时,可以取得最佳复配效果,为胶合剂强度作贡献。加入膨胀剂和聚丙烯纤维可以提高水泥胶合剂的抗冻性,改善干湿循环条件下胶合剂的体积变形。

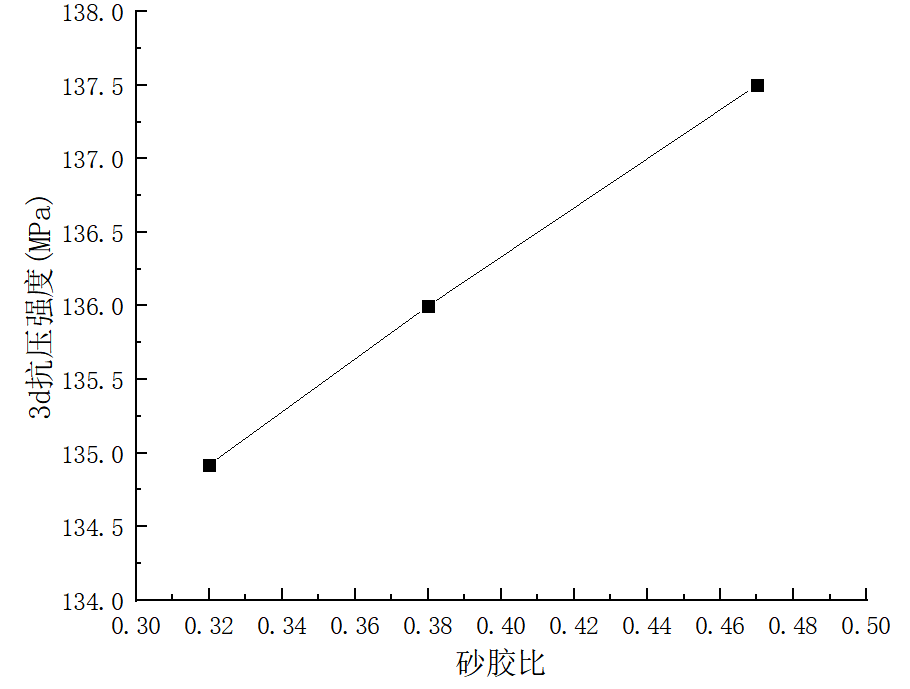

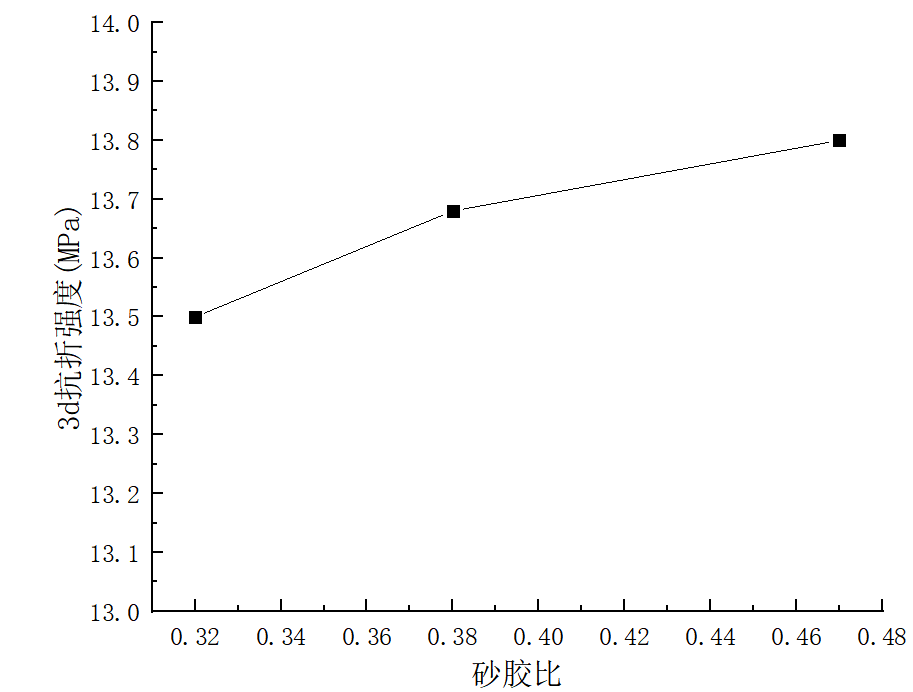

(3)砂胶比对高铝水泥胶合剂的性能有影响,本研究探讨砂胶比范围为0.31~0.47。在此范围内,砂胶比增大,流动性降低,初凝时间延长,3d抗压和抗折强度均增大,并且承受机电破坏能力也增强。

(4)往高铝水泥胶合剂体系中掺入硅灰时,随着硅灰的掺量增加,胶合剂的流动性降低;因硅灰比表面积大,需水量增加,使得体系中实际的水灰比降低,胶合剂的凝结时间缩短;随着硅灰掺量增多,3d抗压和抗折强度增大,机电破坏负荷大小也增大。

关键词:绝缘子;硅酸盐水泥;高铝水泥;胶合剂

Abstract

With the increasing demand for electricity in China, the application of ultrahigh voltage transmission can gain remarkable economic and social benefits. Insulator is a key fitting in the process of power transmission and transformation, which can guarantee the safety of power transmission and distribution. Cement adhesive is used as a binder between insulators and cast iron pendants, whose performance will affect the quality of electric porcelain products. Insulators have been exposed to natural environment for a long time, suffering from high temperature in summer,freezing in winter, and even severe environments such as storm and lightning. Therefore, higher performance requirements are put forward for cement adhesives used for insulator cementing.

In this paper,Portland cement and aluminate cement are used as cementitious materials respectively to prepare two kinds of cement adhesives.We controlled the content of expansion agent and polypropylene fiber to investigate their impact on the properties of Portland cement adhesive.And we also explored the performance of aluminate cement adhesive, when taking the ratio of sand to cement or the content of silica fume as variables.The main conclusions are as follows:

- Adding a proper amount of expansion agent into the system can increase the compensating shrinkage effect of the cement adhesive, which is beneficial to the stability of the volume , thus avoiding the gap between the cement adhesive and the insulator, cast iron pendant and improving the capability of resisting mechanical and electrical damage.Expansion agent has certain retarding effect on cement, but it is not significant.In the system of Portland cement,the early strength can be improved when 5% expansion agent is added(compared to the blank).

- When the expansion agent and fiber are compounded in a proper proportion, the best compounding effect can be obtained, which contributes to the strength of the adhesive.

- The ratio of sand to cement makes a difference to the performance of aluminate cement,

which is 0.31~0.47. When it increases,the mobility can grow worse, the initial condensation time can be lengthened, the compressive and flexural strength at 3 day can be build up , and the resistance to electromechanical damage is also enhanced.

(4)When silica fume is put into the aluminate cement adhesive, the fluidity of the binder decreases with the increase of silica fume content. Silica fume has large specific surface area, which will require more water ,so in fact the water-cement ratio of system is lowered, so that the initial setting is shortened. And the mechanical property of cement adhesive can be strengthed and the electromechanical failure load of insulators can be upgraded ,when the content of silica fume rises.

Keywords: insulator; Portland cement; aluminate cement; adhesive

目录

第1章 绪论 1

1.1课题研究背景及目的 1

1.1.1超高压绝缘子简介 1

1.1.2水泥胶合剂简介 1

1.1.3研究目的与意义 2

1.2国内外对水泥胶合剂的研究现状 2

1.2.1我国水泥胶合剂研究与应用所取成果及现状 2

1.2.2国内外水泥胶合剂研究与应用目前存在的问题 3

1.3研究目标与研究内容 4

1.3.1研究目标 4

1.3.2研究内容 4

1.3.3研究技术路线 5

第2章 试验原材料及试验方法 6

2.1实验原料 6

2.1.1石英砂 6

2.1.2.水泥 6

2.1.3减水剂 6

2.1.4消泡剂 7

2.1.5膨胀剂 7

2.1.6硅灰 8

2.1.7缓凝剂 8

2.1.8聚丙烯纤维 8

2.1.9水 8

2.2主要仪器设备 8

2.3试验方法 9

2.3.1流动度测定 9

2.3.2初凝时间测定(标准维卡仪法) 9

2.3.3力学性能测试 10

2.3.4热机和机械性能试验测试 10

2.3.5 F500次抗冻融循环与膨胀性能检测 10

第3章 硅酸盐水泥胶合剂的性能研究 12

3.1配合比设计 12

3.2膨胀剂和聚丙烯纤维对硅酸盐水泥胶合剂性能的影响 12

3.2.1流动性 13

3.2.2初凝时间 13

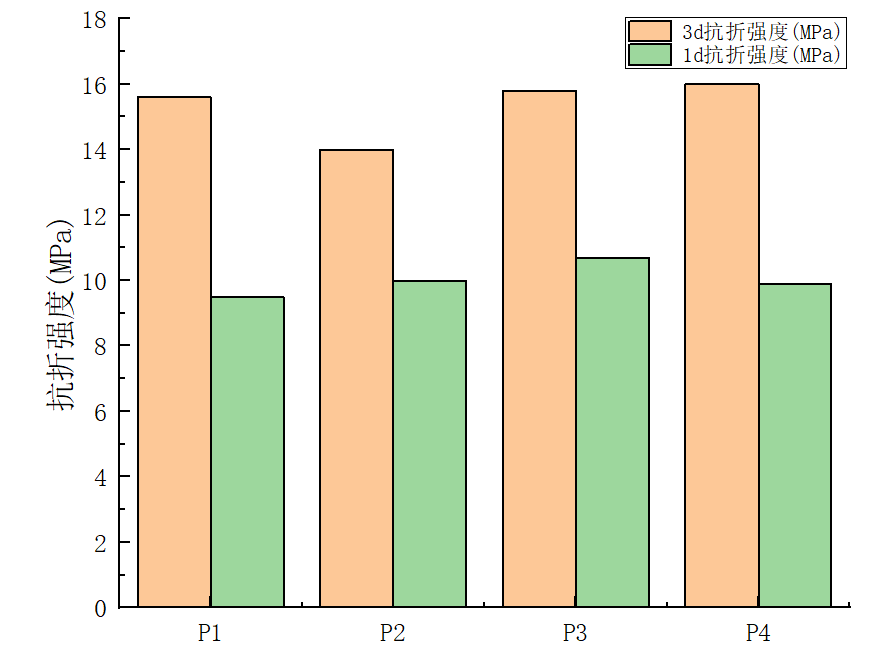

3.2.3力学性能 13

3.2.4热机和机械性能 15

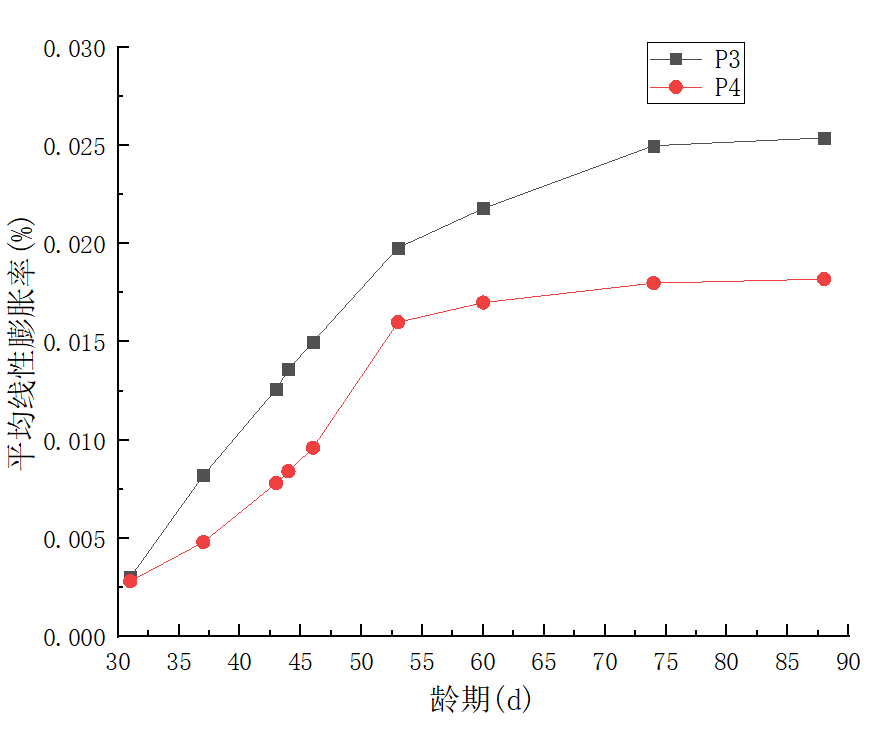

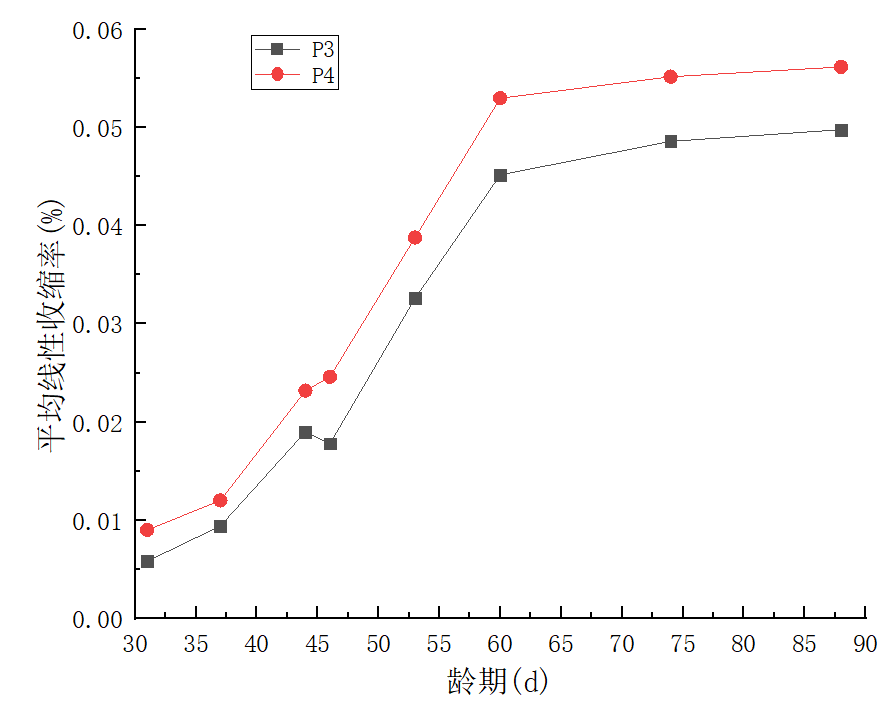

3.2.5冻融循环、各龄期干湿循环的收缩性 17

3.3本章小结 21

第4章 高铝水泥胶合剂的性能研究 23

4.1配合比设计 23

4.2砂胶比对高铝水泥胶合剂性能的影响 23

4.2.1流动性 23

4.2.2凝结时间 24

4.2.3力学性能 24

4.2.4热机和机械性能 25

4.3硅灰掺量对高铝水泥胶合剂性能的影响 27

4.3.1流动性 27

4.3.2初凝时间 27

4.3.3力学性能 28

4.3.4热机和机械性能 29

4.4 F500次冻融循环及膨胀性能检测 29

4.5本章小结 31

第5章 结论与展望 32

5.1结论 32

5.2展望 32

参考文献 34

致谢 37

第1章 绪论

1.1课题研究背景及目的

1.1.1超高压绝缘子简介

由于工业的快速发展和人类生活方式的改变,发展中国家的电能消耗显著增加[1],例如中国自改革电力体制17年来,电源装机剧增,从3.5亿千瓦增长至19.0亿千瓦[2],以适应人类社会对电能日益增长的需求。但我国能源需求与能源资源呈逆向分布,因此,应用能实现更远距离、更大容量、更低损耗的超/特高压输电,能改善资源分配、提高电能输送效率、保护环境,具有显著的综合经济效益和社会效益[3,4]。所谓超高压输电指使用500-1000千伏的电压等级输送电能。

绝缘子是输变电过程中的关键配套产品,它可以防止电流从电线通过地面支撑塔或电线杆流往大地,保证电力传输和分配的安全,对其质量要求严格[5]。依照国家标准GB/T 2900.B-1995《电工术语绝缘子》绝缘子被定义为:供处在不同电位的电气设备或导体电气绝缘和机械固定的器件[6]。按照绝缘材料可分为瓷绝缘子、玻璃绝缘子和有机材料绝缘子三大类[7]。在输配电系统中,瓷绝缘子是最常用的架空绝缘子材料[8]。研究发现,瓷绝缘子即使在潮湿环境中也能表现出优异的性能,例如高机械强度、强电稳定性和耐腐蚀性[9,10]。而且相比于需要工业加工的其他类型绝缘子,用于生产瓷绝缘子的原材料也是天然可得[1]。

请支付后下载全文,论文总字数:32368字

相关图片展示: