厨刀用马氏体不锈钢热处理工艺及性能研究毕业论文

2021-12-05 17:30:03

论文总字数:24624字

摘 要

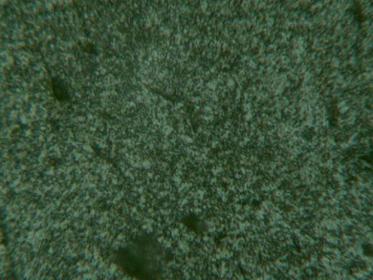

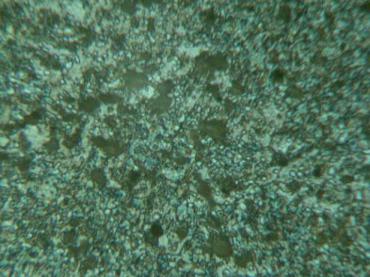

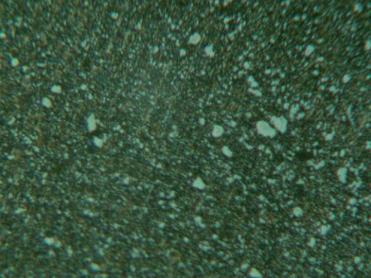

厨刀是我们生活中不可或缺的工具之一,通常采用不锈钢作为原材料。近年来,随着厨刀行业的不断发展,对厨刀质量问题的研究探讨成为了重中之重。本文采用热处理炉、光学显微镜、显微硬度计、洛氏硬度计等仪器对厨刀用马氏体不锈钢进行了热处理及性能研究。

论文主要内容是对厨刀用1.4116马氏体不锈钢进行的一系列热处理工艺,并对其性能进行了研究。通过对结论的分析,找出最适合的热处理工艺条件,通过最优的热处理工艺来提高厨刀的性能,解决厨刀在使用过程中可能遇到的一系列问题,比如腐蚀,刀刃钝化等等,延长其使用寿命。通过研究得到以下结果:1.4116马氏体不锈钢的最佳热处理工艺参数为:1030℃×30min,深冷处理,100℃×2h回火,空冷处理。

关键词:1.4116马氏体不锈钢;热处理工艺;深冷处理;性能研究

Abstract

Kitchen knife is one of the indispensable tools in our life, usually using stainless steel as raw materials. In recent years, with the continuous development of the kitchen knife industry, the research on the quality of kitchen knives has become a top priority. In this paper, the heat treatment and properties of martensite stainless steel for kitchen knives were studied by means of heat treatment furnace, optical microscope, microhardness tester and rockwell hardness tester.

The main content of this paper is a series of heat treatment process of 1.4116 martensitic stainless steel used for kitchen knives, and its properties are studied. Through the analysis of the conclusion, find out the most suitable heat treatment process conditions, through the optimal heat treatment process to improve the performance of kitchen knives, kitchen knives in the use process may encounter a series of problems, such as corrosion, blade passivation, and so on, to extend its service life. The optimal heat treatment parameters of martensite stainless steel are: 1030℃×30min, cryogenic treatment, 100℃×2h tempering, and air cooling treatment.

Key Words:1.4116 martensitic stainless steel; Heat treatment process; Cryogenic treatment; Performance study

目录

摘要................................................................................................................................................Ⅰ

Abstract........................................................................................................................................Ⅱ

第一章 绪论...................................................................................................................................1

1.1 研究背景.........................................................................................................................1

1.2 不锈钢概述......................................................................................................................1

1.3 厨刀用马氏体不锈钢........................................................................................................2

1.3.1 马氏体不锈钢.......................................................................................................2

1.3.2 马氏体不锈钢中常见元素及其作用........................................................................2

1.3.3 常见厨刀用马氏体不锈钢牌号...............................................................................3

1.3.4 现代厨刀的性能要求.............................................................................................3

1.4 马氏体不锈钢的热处理....................................................................................................4

1.5 本课题的研究意义及主要内容..........................................................................................5

1.5.1 研究意义..............................................................................................................5

1.5.2 研究内容..............................................................................................................6

1.5.3 研究目标..............................................................................................................6

1.6 选题对社会、健康、安全、成本以及环境的影响..............................................................6

第二章 实验过程............................................................................................................................7

2.1 实验样品.........................................................................................................................7

2.2 实验耗材与实验设备........................................................................................................7

2.2.1 实验耗材..............................................................................................................7

2.2.2 实验试剂..............................................................................................................7

2.2.3 实验设备..............................................................................................................7

2.3 热处理工艺方案设计.......................................................................................................9

2.3.1 不同热处理工艺...................................................................................................9

2.3.2 回火实验.............................................................................................................10

2.3.3 注意事项.............................................................................................................10

2.4 分析测试方法.................................................................................................................11

2.4.1 金相显微组织分析...............................................................................................11

2.4.2 硬度测试.............................................................................................................11

第三章 实验结果与讨论................................................................................................................12

3.1 不同淬火工艺对1.4116马氏体不锈钢组织性能的影响....................................................12

3.1.1 不同加热温度对材料性能的影响..........................................................................12

3.1.2 不同保温时间对材料性能的影响..........................................................................14

3.1.3 不同冷却方式对材料性能的影响..........................................................................15

3.2 回火工艺对1.4116钢材组织性能的影响.........................................................................15

第四章 结论..................................................................................................................................18

4.1 总结.............................................................................................................................18

4.2 展望.............................................................................................................................18

参考文献.......................................................................................................................................19

致谢..............................................................................................................................................20

请支付后下载全文,论文总字数:24624字

相关图片展示: