类水滑石催化剂的制备及对MgH2储氢性能的影响毕业论文

2020-04-26 12:49:49

摘 要

氢能是解决当前能源匮乏的可替代能源之一。固态储氢又是理想的储氢方式,因此寻找具有优异性能的固态材料尤为重要。镁基储氢材料因高储氢容量 (7.6 wt.%) ,来源广泛,成本较低等特点被认为是理想的储氢材料。然而,它的动力学缓慢热力学稳定阻碍了其作为商业材料的使用。为解决此问题,本课题基于双金属特殊的物理化学性质,并利用水滑石高温煅烧过程中结构拓扑转变的特点,制备高分散类水滑石催化剂来改善MgH2的储氢性能。本文对材料的微观结构,采用X射线衍射 (XRD) 、扫描电子显微镜 (SEM) 分析和场发射电子显微镜 (FESEM) 分析等方法进行表征,储氢性能通过压力-成分-温度测试仪 (PCT) 进行测试。

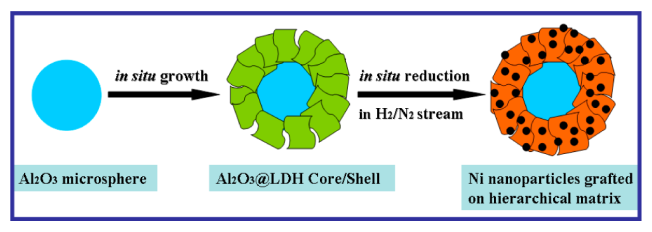

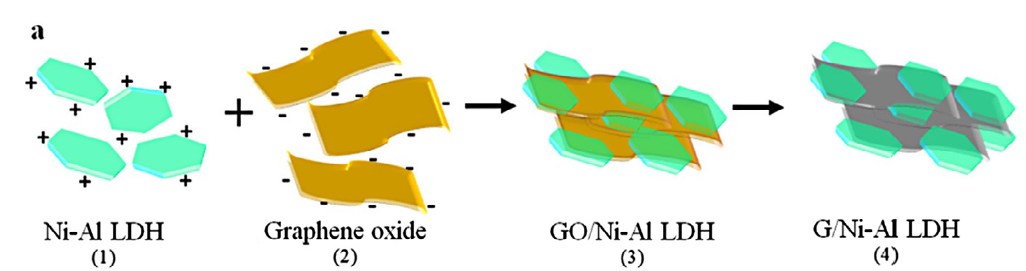

本课题以自制的NiFe-LDH水滑石为前驱体,经过高温煅烧制备出类水滑石催化剂 (Ni3Fe) ,并以氧化石墨烯 (rGO) 为基体成功制备氧化石墨烯负载类水滑石基催化剂 (Ni3Fe/rGO) ,最后将催化剂与MgH2球磨复合后进行性能测试。结果显示出Ni3Fe/rGO显著改善了MgH2的储氢性能,MgH2-Ni3Fe/rGO起始脱氢温度降低至约200 ℃左右。MgH2-Ni3Fe/rGO样品在100 ℃,90 s内达到6.4 wt.%饱和吸氢量;125 ℃下,70 s内达6.5 wt.% 吸氢量,300 ℃下样品仅需要500 s就放氢完全。通过研究发现,该催化剂的优异性能来源于Ni3Fe与氧化石墨烯的协同作用。

关键词:镁基储氢材料 氧化石墨烯 类水滑石 Ni3Fe

Preparation of Hydrotalcite-like Catalysts and Their Effects on Hydrogen Storage Properties of MgH2

ABSTRACT

Hydrogen energy is one of the alternative energy sources to solve the current energy shortage. Solid-state hydrogen storage is an ideal way to store hydrogen, so it is especially important to find solid materials with excellent properties. Magnesium-based materials are considered to be ideal hydrogen storage materials because of their high capacity (7.6 wt.%), abundant source and low cost. However, thermodynamic stability and slow kinetics hinder its use as a commercial material. In order to solve this problem, this thesis based on the special physical and chemical properties of bimetals, and utilizes the characteristics of structural topological transformation during high-temperature calcination of hydrotalcite to prepare high-dispersion nickel-based catalysts to improve the hydrogen storage performance of MgH2. In this paper, the microstructure of the material was characterized by XRD, SEM and FESEM analyses. Hydrogen storage performance was tested by a pressure-composition-temperature apparatus (PCT).

In this paper, the self-made NiFe-LDH hydrotalcite was used as the precursor, and the hydrotalcite-like catalyst (Ni3Fe) was prepared by high-temperature calcination. The graphene oxide-loaded hydrotalcite catalyst (Ni3Fe/rGO) was successfully prepared, finally the catalyst was combined with MgH2 by ball milling. The results showed that Ni3Fe/rGO significantly improved the hydrogen storage performance of MgH2, and the initial dehydrogenation temperature of MgH2-Ni3Fe/rGO reduced to 200 ℃. The MgH2-Ni3Fe/rGO sample reached 6.4 wt.% saturated hydrogen absorption at 100 °C in 90 s; at 125 °C, it reached 6.5 wt.% hydrogen absorption in 70 s. The sample completely released hydrogen within 500 s at 300 oC. It has been found that the excellent performance of the catalyst is derived from the synergistic effect of Ni3Fe and graphene oxide.

Key words: Magnesium-based hydrogen storage material; Graphene oxide; Hydrotalcite-like; Ni3Fe

目录

摘要 I

ABSTRACT II

第一章 绪论 1

1.1 引言 1

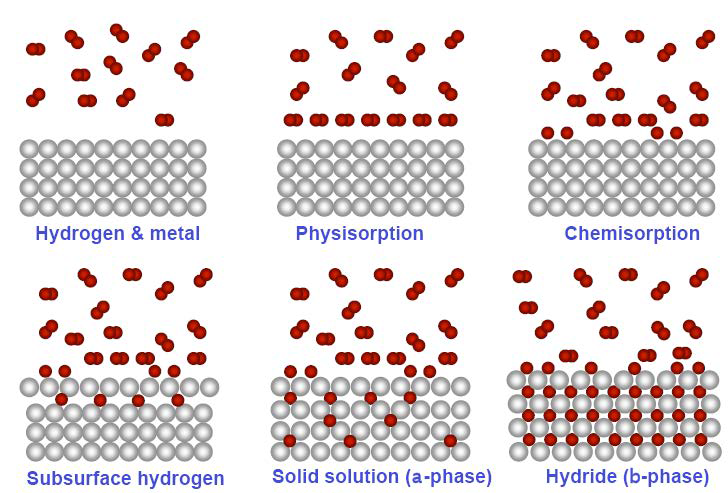

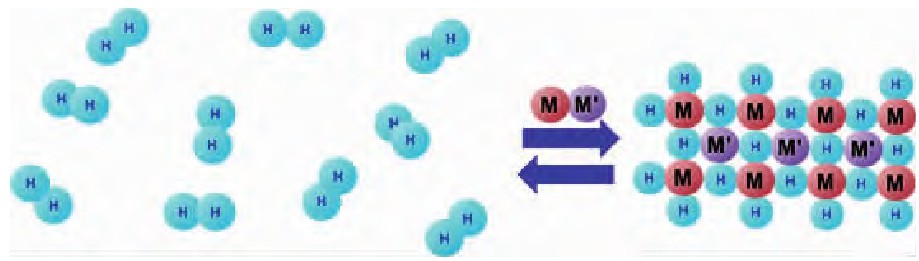

1.2 金属氢化物概述 2

1.3 镁基储氢材料的概述 4

1.3.1 镁基储氢材料简介 4

1.3.2 纳米化改性 5

1.3.3 合金化改性 6

1.3.4 催化改性 6

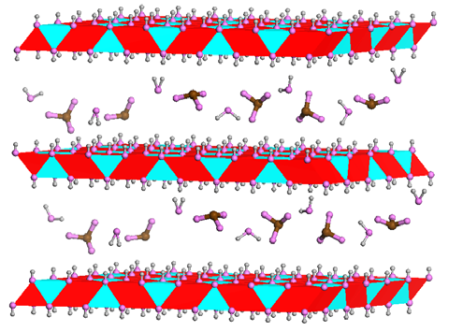

1.4 水滑石的简要概述 7

1.5 问题提出和研究内容 9

第二章 实验方法 11

2.1 实验所用原料与试剂 11

2.2 材料合成设备 11

2.2.1 合成设备 11

2.2.2 机械球磨处理 12

2.3 材料的制备 13

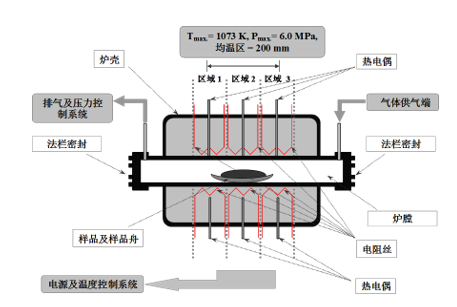

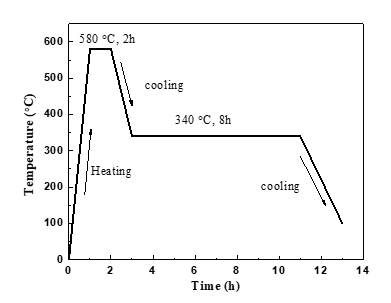

2.3.1 MgH2的制备 13

2.3.2 氧化石墨烯载类水滑石基催化剂的制备 13

2.3.3 类水滑石基催化剂的制备 14

2.3.4 MgH2-催化剂的制备 15

2.4 样品微观结构的表征及其储氢性能测试 15

2.4.1 X射线衍射分析 15

2.4.2 扫描电子显微镜分析与场发射电子显微镜分析 15

2.4.3 差示扫描量热分析 15

2.4.4 PCT测试 16

第三章 氧化石墨烯载类水滑石基催化剂对MgH2储氢性能的研究 19

3.1 催化剂相和复合体系成分结构分析 19

3.2 MgH2-Ni3Fe/rGO和MgH2-Ni3Fe的储氢性能 22

第四章 结论和展望 26

4.1 结论 26

4.2 展望 26

参考文献 28

致谢 31

第一章 绪论

1.1 引言

当前全球能源需求不断增加,传统的化石能源——石油、煤和天然气日渐枯竭 [1],这便导致了化石燃料供应紧张以及价格攀升,同时化石能源的大量消耗也带来环境恶化、生态平衡被破坏等一系列问题 [2]。在此形势下,为了保障社会的可持续发展,开发利用可再生清洁能源已经成为当前最为重要和迫切的研究课题之一 [3]。为此,众多研究者致力于开发新的清洁可再生的燃料替代品,比如风能、太阳能、氢能和生物质能等 [4-8]。在这些新能源中,氢能以其燃烧热值高、可再生、清洁无污染以及来源广泛等突出优势受到人们极大的关注。

氢是地球含量最多的元素,其本身无毒,燃烧的产物仅是水,且其发热值为142.351 kJ/kg,是汽油热值的3倍,并且由于水能够制氢,使得氢能具有循环可再生性 [9]。正是这样使得“氢循环”成为一种有效的可持续发展手段。

相关图片展示: