玻璃纤维增强聚苯醚尼龙6合金的性能研究毕业论文

2021-03-13 23:49:49

摘 要

本文通过硅烷偶联剂对玻璃纤维表面进行处理,引入活性基团,改善玻璃纤维与PPO/PA6表面结合性。采用SEBS-g-MAH对PPO/PA6进行增容改性,改善其界面相容性以及成型工艺性。用硅烷偶联剂处理制备不同含量的玻璃纤维增强PPO/PA6复合材料,研究纤维含量对材料力学性能的影响。

论文主要研究了(1)制备不同比例的PPO/PA6合金,测试其力学性能,流变性能。

(2)制备不同含量的SEBS-g-MAH增容PPO/PA6合金,测试其力学性能,流变性能,用红外光谱测试其表面元素活性,用电镜观测其断口形貌,观测相容性

(3)用KH-550改性玻璃纤维,制备不同比例玻璃纤维PPO/PA6复合材料,比较不同纤维含量对复合材料力学性能的影响,用XPS测试玻璃纤维元素组成。测试制样的力学性能,用电镜观测其断口形貌。

研究结果表明:PPO/PA6合金加入尼龙6可以降低聚苯醚的熔体黏度,改善聚苯醚的工艺性能.并且混合体系熔融指数会得到提高,可加工性变强。SEBS-MAH对于PPO/PA6合金有明显的增容效果。但过量加入会使力学性能降低。

玻璃纤维的加入能使PPO/PA6/SEBS-g-MAH混合体系的力学性能增强,因为玻璃纤维能均匀地分散在树脂基体中,起到主要承载作用,提高混合物的强度和模量。但随着玻璃纤维加入量的变多,使得玻璃纤维无法均匀分布,应力无法得到有效传递,使得力学性能降低。

本文所得结果对后续有关PPO/PA6的共混改性研究有一定的指导意义。

关键词:聚苯醚;尼龙6;玻璃纤维;SEBS-MAH

Abstract

In this paper, the surface of glass fiber was treated by silane coupling agent, and the active group was introduced to improve the surface bonding of glass fiber and PPO / PA6. The PPO / PA6 was modified by SEBS-MAH to improve its interface compatibility and molding process. The effect of fiber content on the mechanical properties of PPO / PA6 composites was studied by using silane coupling agent to prepare different kinds of glass fiber reinforced PPO / PA6 composites.

The paper mainly studies (1) to prepare PPO / PA6 alloy with different proportions, and tests its mechanical properties and rheological properties.

(2) Preparation of different content of SEBS-MAH compatibilized PPO / PA6 alloy, the mechanical properties and rheological properties were tested. The surface element activity was measured by infrared spectroscopy. The fracture surface morphology was observed by electron microscopy.

(3) PPO / PA6 composites with different proportions of glass fiber were prepared by using KH-550 modified glass fiber. The effects of different fiber contents on the mechanical properties of the composites were compared. The glass fiber elements were tested by XPS. The mechanical properties of the samples were tested and the fracture morphology was observed by electron microscopy.

The results show that the addition of nylon 6 to PPO / PA6 can reduce the melt viscosity of polyphenylene ether and improve the process performance of polyphenylene ether, and the melt index of the mixed system will be improved and the workability will be strengthened. SEBS-MAH has a significant compatibilizing effect for PPO / PA6 alloys. But excessive addition will reduce the mechanical properties.

The addition of glass fiber enhances the mechanical properties of the PPO / PA6 / SEBS-g-MAH blends because the glass fibers can be uniformly dispersed in the resin matrix and act as the main bearing to enhance the strength and modulus of the mixture. However, with the increase in the amount of glass fiber, making the glass fiber can not be evenly distributed, the stress can not be effectively transmitted, making the mechanical properties.

The results obtained in this paper have some guiding significance for the subsequent study on the blending modification of PPO / PA6.

Keywords: polyphenylene oxide, nylon 6, glass fiber, SEBS-MAH

目 录

第1章绪论 1

1.1 聚苯醚 1

1.1.1 概述 1

1.1.2聚苯醚结构与性能 1

1.1.3聚苯醚的改性 2

1.1.4改性聚苯醚的性能 2

1.2聚苯醚PPO/尼龙6 PA6合金 2

1.2.1尼龙6概述 2

1.2.2 SEBE-MAH改性聚苯醚/尼龙6合金 2

1.3玻璃纤维 3

1.3.1玻璃纤维简介 3

1.3.2硅烷偶联剂改性玻璃纤维 3

1.4玻璃纤维增强热塑性塑料 4

1.4.1玻璃纤维增强热塑性塑料简介 4

1.4.2玻璃纤维增强热塑性塑料研究进展 4

1.4.3玻璃纤维增强热塑性塑料界面 5

1.5课题目的,意义和内容 5

1.5.1课题的目的和意义 5

1.5.2课题的研究内容 6

第2章实验部分 7

2.1实验原料 7

2.2实验仪器 7

2.3实验内容 7

2.4性能测试 8

第3章 测试与分析 10

3.1测试仪器 10

3.2结果分析 10

3.2.1流变性能的分析 10

3.2.2对熔融指数图的分析 12

3.2.3对力学性能图的分析 13

3.2.4对红外图谱的分析 15

3.2.5未处理GF和处理后GF的XPS分析 16

3.2.6电镜SEM断口分析 19

第4章结果讨论 20

参考文献 21

致谢 23

第1章 绪论

1.1聚苯醚

1.1.1概述

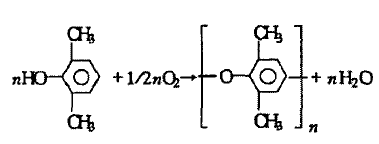

聚苯醚,简称PPO,是一种性能优秀的热塑性工程塑料。且聚苯醚(PP0)是性能最优秀、耐热性最好的材料在工程用塑料中,其在汽车、电子、机械等行业中应用非常广泛【1】。聚苯醚的研究在20世纪末时候才开始研究,美国研究员合成了里面不存在取代基的聚苯醚,只是其相对分子质量和成型收缩率都很低。在20世纪中期,美国通用电器公司GE采用氧化偶联法制得了和以往相比更高产率、高相对分子质量的聚苯醚。在后面的10年里,该公司对氧化偶联技术进行了改良,从而实现了工业化生产,建立了年产5000余吨的第一家工厂,该方法利用冬一二甲基苯酚作为该技术的单体,经过催化剂作用,经过氧化偶联聚合反应制得聚苯醚,其反应式如下