液体模塑成型工艺中树脂流动前锋的监测识别毕业论文

2021-11-25 23:10:40

论文总字数:19732字

摘 要

复合材料液体模塑成型工艺(Liquid Composite Molding)是一种近年来比较热门的先进复合材料制造技术,这种制造技术成本低、性能优越的特点而广泛应用于复合材料制造领域。且能够很好地适应于现在复杂结构的复合材料批量化生产,进一步扩展了复合材料当下的应用范围。LCM工艺生产的制品有着重复使用率高、质量好、性能较为稳定等优点。近些年来受到了很好的推广,从民用产品到国防尖端制造,种类繁多,颇受欢迎。

渗透率是综合描述纤维织物渗透性能的参数,是LCM工艺渗透过程的重要影响因素。它不仅与充模时间有很大关系,还决定着树脂对增强纤维的浸润程度以及模具内力学流动性能,也是LCM工艺渗透过程智能化设计的关键参数。因此,进一步研究工艺渗透过程中树脂对于增强纤维的渗透性能以及浸润特性,并以此进行模具设计优化、控制影响因素、缩短制造周期、提高生产效率、保证制品质量,将对未来复合材料成型工艺的应用和发展有着很大的推进作用。传统的人工智能研究的手段对于LCM工艺渗透率的影响是通过监测与控制进行测量。鉴于这种方法有一定局限性,我有必要去开发一种更加理想的渗透特性研究方法。

本文提出采用智能化监测系统对LCM工艺中树脂流动前锋进行监测的方法。利用数字图像处理技术实现对流动前锋的检测识别,并以此测算渗透率。实验结果分析基本符合了传统人工测量的基本实验结果,即充分证实了系统的技术实用性以及系统的可靠性。同时结合LCM两种工艺测量系统的设计和测量技术标准,完成了产品质量监测管理系统设计总体方案的设计和实现。通过使用监测系统对实验和仿真结果分析,得到了渗透率结果,并对结果误差和系统误差做了分析。

本实验通过具体分析证明了该系统方案具有着较高的智能化程度,同时提高了渗透过程流动前锋的监测效率,得到了的渗透率测算结果也较为满意,有效地解决了传统人工测量渗透率技术中的监测过程复杂、计算复杂、实时性差等缺点,为复合材料树脂基渗透过程研究提供了行之有效的参考手段。

关键词:LCM;渗透率;流动前锋监测;数字图像处理

Abstract

Liquid Composite Molding (Liquid Composite Molding) is a relatively popular advanced composite manufacturing technology in recent years. This manufacturing technology has the characteristics of low cost and superior performance and is widely used in the field of composite manufacturing. And it can be well adapted to the mass production of composite materials with complex structures, which further expands the current application range of composite materials. The products produced by the LCM process have the advantages of high reuse rate, good quality and relatively stable performance. In recent years, it has been well promoted, ranging from civilian products to cutting-edge defense manufacturing, with a wide variety and popular.

Permeability is a parameter that comprehensively describes the permeability of fiber fabrics and is an important factor influencing the penetration process of the LCM process. It not only has a great relationship with the filling time, but also determines the degree of resin wetting of the reinforcing fibers and the mechanical flow properties in the mold. It is also a key parameter for the intelligent design of the LCM process infiltration process. Therefore, to further study the penetration performance and wetting characteristics of the resin to the reinforcing fiber in the process penetration process, and to use this to optimize the mold design, control the influencing factors, shorten the manufacturing cycle, improve the production efficiency, and ensure the quality of the product, the future composite molding process Application and development have a great role in promoting. The influence of traditional artificial intelligence research methods on LCM process penetration is measured through monitoring and control. In view of the limitations of this method, it is necessary to develop a more ideal method for studying permeability characteristics.

This paper proposes a method for monitoring the resin flow front in the LCM process using an intelligent monitoring system. Use digital image processing technology to realize the detection and recognition of the flow front, and use this to calculate the permeability. The analysis of the experimental results is basically in line with the basic experimental results of traditional manual measurement, which fully confirms the technical practicability and reliability of the system. At the same time, combined with the design and measurement technology standards of the two process measurement systems of LCM, the design and implementation of the overall design of the product quality monitoring management system were completed. By using the monitoring system to analyze the experimental and simulation results, the permeability results are obtained, and the results errors and system errors are analyzed.

Through specific analysis, this experiment proves that the system scheme has a high degree of intelligence, and at the same time improves the monitoring efficiency of the flow front of the infiltration process, and the obtained permeability measurement results are also satisfactory, effectively solving the traditional manual measurement of permeability The shortcomings such as complicated monitoring process, complicated calculation, and poor real-time performance in the technology provide an effective reference method for the study of the resin-based infiltration process of composite materials.

Keywords: LCM; permeability; flow front monitoring; digital image progressing

目 录

第1章 绪论 1

1.1研究背景 1

1.1.1LCM工艺的介绍 1

1.1.2LCM工艺的渗透率 1

1.2LCM渗透率计算方法 1

1.2.1孔隙率的计算方法 1

1.2.2渗透率计算方法 2

1.3图像处理的常见方法 3

1.3.1图像处理方法介绍 3

1.3.2本课题系统的图像处理方法 4

1.4研究的意义与内容 4

1.4.1研究意义 4

1.4.2研究内容 5

第2章 实验设计及结果 6

2.1引言 6

2.2实验材料及设备 6

2.3预制件渗透率研究方法 6

2.3.1试样的制备 6

2.3.2设备的确定及实现 7

2.4过程记录 7

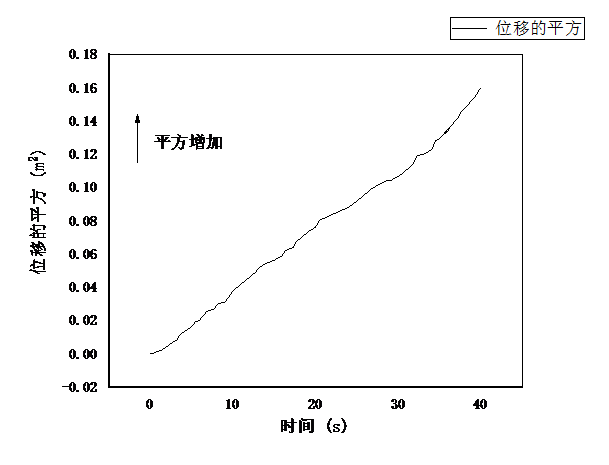

2.5结果分析 8

2.5.1流动前锋 8

2.5.2渗透率计算 9

2.6小结 11

第3章 运用图像处理技术进行渗透率计算 12

3.1引言 12

3.2图像处理 12

3.2.1图像的预处理 12

3.2.2图像的分割处理 12

3.3渗透过程的图像处理 13

3.3.1渗透过程图像滤波 13

3.3.2渗透过程图像二值化 14

3.4流动前锋长度提取 15

3.5程序渗透率计算 16

3.6小结 17

第4章 实验结果及误差分析 18

4.1实验结果分析 18

4.2误差分类及主要来源 18

4.3实验系统中的误差分析 19

4.4优化方法 19

4.5小结 20

第5章 总结与展望 21

5.1总结 21

5.2展望 21

参考文献 22

致谢 24

第1章 绪论

1.1研究背景

1.1.1LCM工艺的介绍

液体模塑成型技术(LCM),是指在纤维预制的封闭的模腔中注入液体聚合物,或将预先配置在空腔中的树脂膜加热熔融,在流动充模过程的同时,液体聚合物完成对纤维增强体的渗透,然后经过固化成型,是一种产品化的制备技术[1-2]。液体复合成型工艺的制造方法较为灵活且日益完善,充分体现了复合材料的可设计性,制作成本比较低,现已广泛应用于船舶制造、民用汽车、航空航天等工业领域,为复合材料在工业应用的领域拓宽了道路。可以制造轻质高强、耐腐蚀和耐疲劳性能的构件,例如起落架门、机翼、机身构件、螺旋桨叶片等;汽车制造业和船舶制造业也采用RTM技术制造出了车门、引擎盖、车顶棚、扰流板、壳体、汽车仪表板、游艇壳体等等[3-6]。

1.1.2LCM工艺的渗透率

请支付后下载全文,论文总字数:19732字

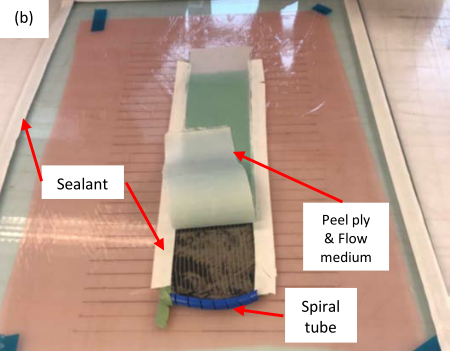

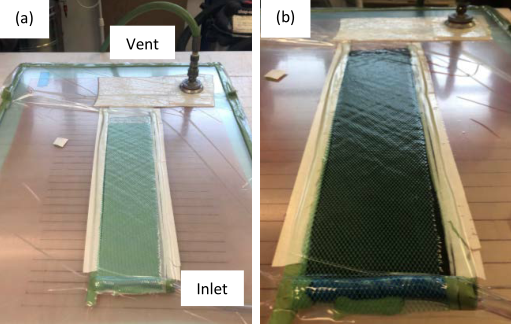

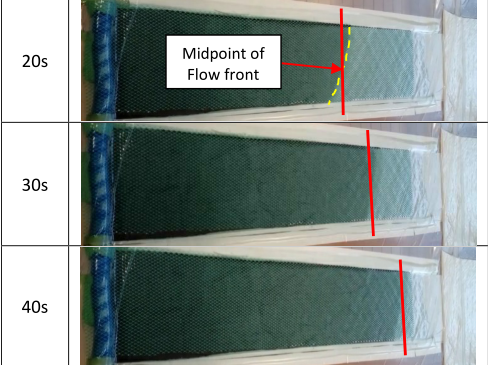

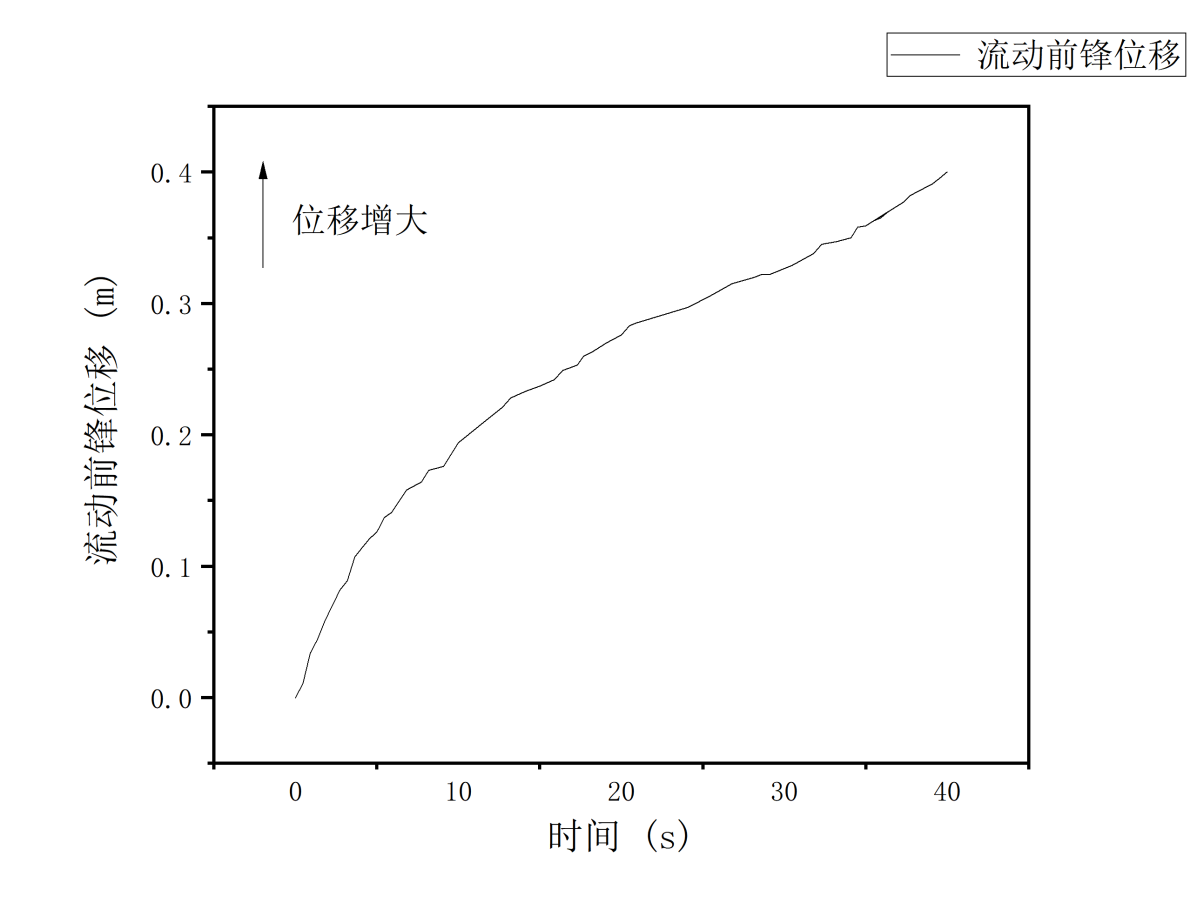

相关图片展示: