油田用新型环氧树脂修补材料开发及应用研究毕业论文

2021-12-05 17:35:15

论文总字数:19890字

摘 要

在油气开采的过程中,井漏和出砂问题时有发生,这导致油井的产量大幅降低,严重影响油田的经济效益。而且由于近年来我国环氧树脂相关产品受到技术的封锁,因此我国亟需自主研制新型的环氧树脂油田修复材料以应对越来越复杂的修复难题。

环氧树脂的综合性能良好,耐腐蚀性好,毒性小,适合作为油田修复材料的基体。酮亚胺相比于其它环氧树脂固化剂,有污染小、毒性低等优点,而且酮亚胺作为潜伏型固化剂,受到湿气的作用才会分解出胺类发生固化反应,因此干燥的环境中酮亚胺/环氧树脂体系可以长期存放。这样需要时可以直接使用,减少了临时配置的麻烦。综合上述的优点,本文选用双酚A型环氧树脂E-51作为基体,选用异佛尔酮二胺作为水环境固化剂。当实际使用时,把堵漏剂泵入需修复的部位,再因为环氧树脂体系的流动性,它可以进入细微的空隙并固化后形成一定强度的屏障,从而使钻井达到堵漏的效果,使油井可以继续高效地从事生产。本文的主要研究内容如下:

- 研究酮亚胺的水环境固化机理;

- 测试环氧树脂堵漏剂的性能并分析;

- 测试环氧覆膜石英砂的性能并分析。

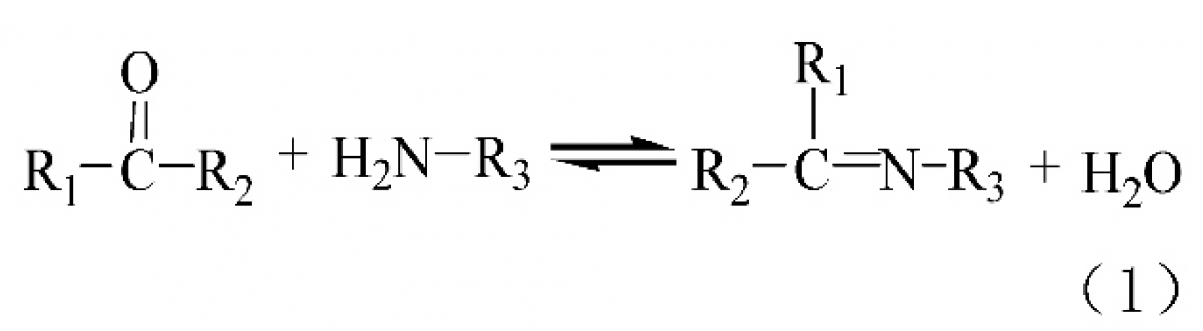

对酮亚胺水环境固化机理进行研究,了解到酮亚胺固化剂在水的作用下分解成胺和酮,分解所得的胺类则对环氧树脂进行固化反应。反应物酮的化学结构,即羰基所相连基团的电子效应和位阻效应,会对中间产物的稳定性产生影响,从而影响酮亚胺/环氧体系的贮存稳定性。

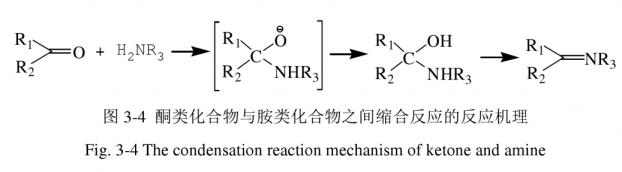

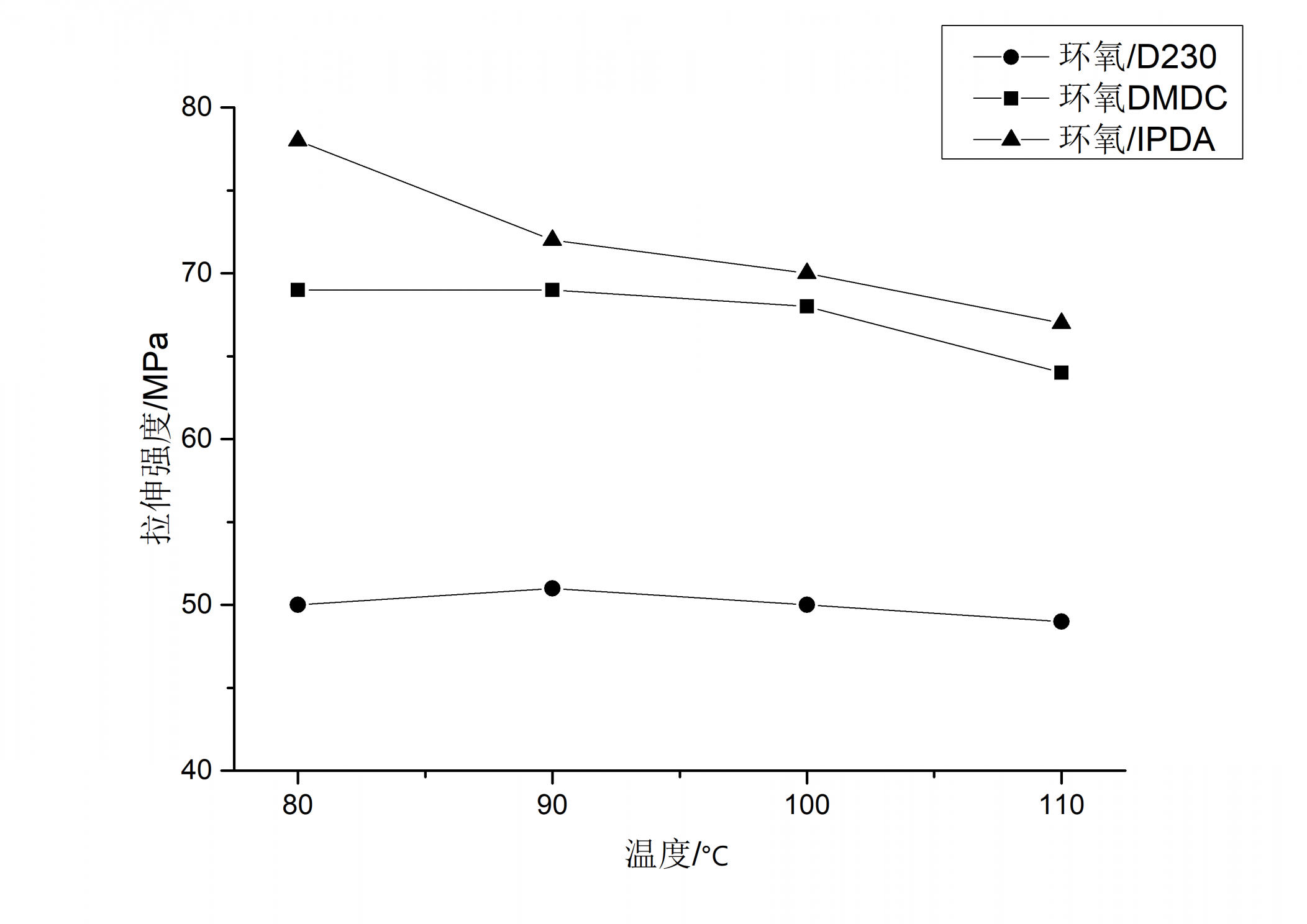

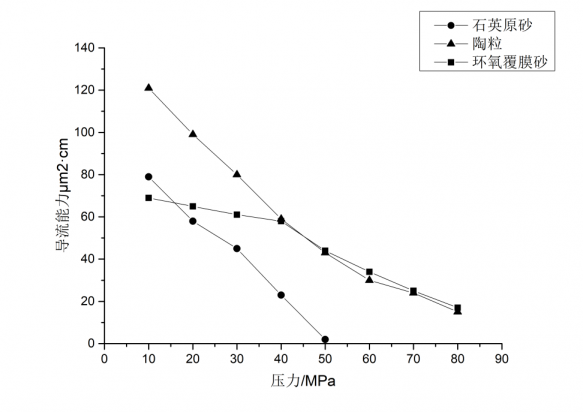

从环氧树脂堵漏剂的性能参数可以说明,异佛尔酮二胺固化剂的固化速度较快,堵漏剂有合适的表干和实干时间;该堵漏剂也有较高的强度,可以满足堵漏剂的要求。从环氧树脂覆膜砂的性能参数表明,环氧树脂覆膜砂的破碎度和圆球度较未处理的石英砂都有很大的提升,性能也有提升。而异佛尔酮二胺相较于其它固化剂,所形成的包覆膜的强度也有优势。

关键词:环氧树脂,水下固化,酮亚胺,堵漏,固砂,

Abstract

In the process of oil and gas exploitation, the problems of lost circulation and sand production occur from time to time, which leads to a significant decrease in the output of oil wells and seriously affects the economic benefits of oil fields. Moreover, due to the technical blockade of epoxy resin-related products in my country in recent years, my country urgently needs to independently develop new epoxy resin oilfield repair materials to cope with the increasingly complex repair problems.

Epoxy resin has good comprehensive performance, good corrosion resistance, and low toxicity, and is suitable as a matrix for oilfield repair materials. Compared with other epoxy resin curing agents, ketimine has the advantages of low pollution and low toxicity. Moreover, ketimine, as a latent curing agent, will only decompose amines to undergo curing reaction under the action of moisture. The ketimine / epoxy resin system can be stored for a long time in the environment.Based on the above advantages, this article selects bisphenol A epoxy resin(E-51) as the matrix and isophorone diamine as the water environment curing agent. When actually used, pump the plugging agent into the area to be repaired, and because of the fluidity of the epoxy resin system, it can enter the fine gaps and solidify to form a certain strength barrier, so that the drilling can achieve the effect of plugging, so that the oil well can continue to engage in efficient production. The main research contents of this article are as follows:

(1) Study the water environment curing mechanism of ketimine;

(2) Test and analyze the performance of epoxy resin plugging agent;

(3) Test and analyze the performance of epoxy coated sand.

The ketimine water environment curing mechanism was studied, and it was learned that the ketimine curing agent decomposes into amines and ketones under the action of water, and the resulting amines cures the epoxy resin. The chemical structure of the reactant ketone, that is, the electronic effect and steric hindrance of the carbonyl group, will affect the stability of the intermediate product, which will affect the storage stability of the ketimine / epoxy system.

The performance parameters of epoxy resin plugging agent can show that the curing rate of isophorone diamine curing agent is faster, and the plugging agent has a suitable surface drying and solid drying time; the plugging agent also has a high strength and can meet plugging agent requirements. The performance parameters of the epoxy resin coated sand show that the crushing degree and sphericity of the epoxy resin coated sand are greatly improved compared with the untreated quartz sand, and the performance is also improved. Compared with other curing agents, isophorone diamine also has advantages in the strength of the coating film formed.

Key word: Epoxy resin, Curing underwater, Ketimine, Leaking stopping, Sand control

目 录

第一章 绪论 1

1.1研究背景 1

1.2水下固化环氧树脂及其国内外研究现状 1

1.2.1环氧树脂 1

1.2.2水环境固化剂 2

1.2.3颜料、填料 3

1.2.4稀释剂 3

1.2.5偶联剂 3

1.2.6促进剂 3

1.3堵漏材料 3

1.4防砂固砂技术 4

1.5实验方案 4

1.6本文的研究内容及研究的意义 5

第二章 固化机理 6

2.1多元胺的固化机理 6

2.2酮亚胺 6

2.2.1潜伏型固化剂 6

2.2.2酮亚胺的合成 7

2.2.3酮亚胺水下固化机理 8

2.3本章小结 8

第三章 水下环氧体系的配制及性能测试 9

3.1环境条件 9

3.2主要原材料 9

3.3环氧体系的制备 9

3.4环氧树脂堵漏剂评价指标及方法 10

3.5本章小结 12

第四章 采油井固砂用环氧覆膜砂 13

4.1原料 13

4.2环氧覆膜砂的制备 14

4.2.1仪器设备 14

4.2.2制备工艺 14

4.2.3施工工艺 14

4.3性能测试 14

4.3.1水中固化时间 14

4.3.2导流能力 14

4.3.3机械强度比较 15

4.3.4其他指标 15

4.4本章小结 15

第五章 结论与展望 16

参考文献 17

致谢 19

第一章 绪论

1.1研究背景

石油天然气是我国重要的不可再生资源,在全世界能源中都占有很大比重,可以很大程度上影响到国家的经济命脉和发展。中国经济迅速发展对油气资源的需求量快速上升,而且中国原油对外依存度较高,另外,现下浅部地层因为将近开采结束和一些污染,石油的开采慢慢向陆地深部、海洋发展,这也将面临更艰巨的难题、更复杂的地址环境。因此迫切需要各项技术的进步,提高采收率,提高油气产量。

在钻井、固井、完井等各种井下作业过程中都会发生井漏,这种情况的发生不仅仅增加材料成本,还会增加钻井作业时间[1,2]。因此需要进行堵漏来减少经济损失。同时因为石油是和水的悬浊液,石油开发过程中也会加入水,所以堵漏剂还要求能够在水下进行修复。

堵漏的同时,防砂固砂也需要重视。油田开采过程中可能会因为人为的原因对油井的地层产生破坏,也有可能是因为地质天然就比较松散的原因,诸如此类的因素都有可能造成压力系统被破坏,导致地层大量出砂进入油井。如果发生了堵漏现象可能会造成油层堵塞,冲砂和清洗又会造成消耗大量的时间和产量。最严重有可能会造成坍塌,因为地层出砂会会产生地层的空穴[3]。因此防砂固砂也是开发油气资源重要的措施。

1.2水下固化环氧树脂及其国内外研究现状

请支付后下载全文,论文总字数:19890字

相关图片展示: