CBS系微晶陶瓷材料烧成特性与性能研究毕业论文

2020-04-18 19:58:54

摘 要

CaO-B2O3-SiO2(CBS)系微晶陶瓷以其优越的各种特性,能够很好地满足集成电路高集成密度、高信号传输速率等要求,是一种理想的低温共烧陶瓷(LTCC)材料,被广泛地应用于集成电路、电子通讯等领域。

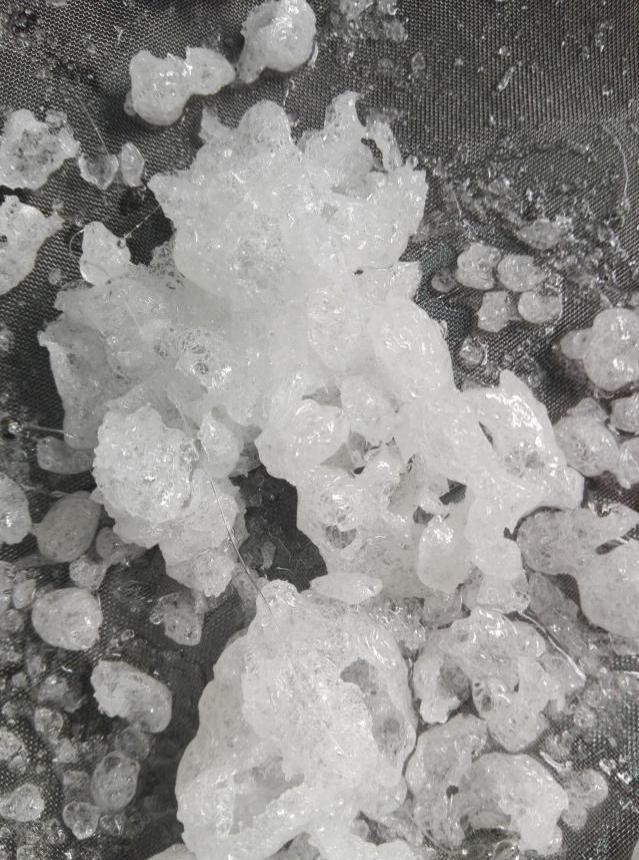

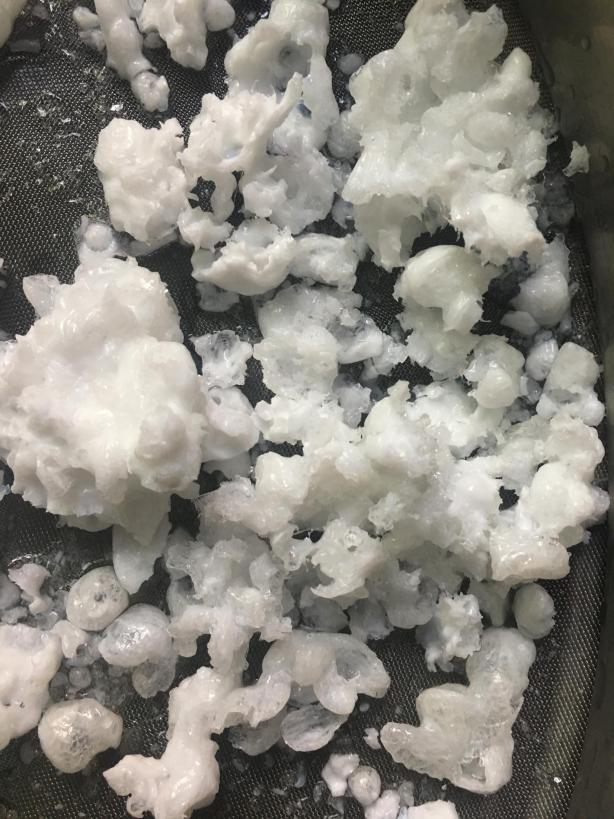

本论文细化研究钙硼硅多元组分对CBS微晶玻璃的形态、烧结性能以及介电性能的影响。首先固定B2O3的含量,研究含有不同Ca/Si比微晶玻璃的性能。通过对微晶陶瓷形态透光度的观察探究,可得CaO含量的提高有利于微晶玻璃析晶,从而使微晶玻璃失透,呈现出一片乳白色;再研究Ca/Si比值变化对于CBS微晶玻璃烧成性能影响的变化,通过对烧成温度及密度等的检测以及对SEM图样的观察,得出由于Ca/Si比不同时晶相和非晶相的相对含量不同,以及气孔含量的差异,所以对烧成温度的要求不同;再分析不同Ca/Si比对介电性能的影响,由于致密度越大,介电常数越高,随着Ca/Si比值的变大,试样内的晶相含量呈增多趋势,所以试样的介电常数也有逐渐上升的趋势。

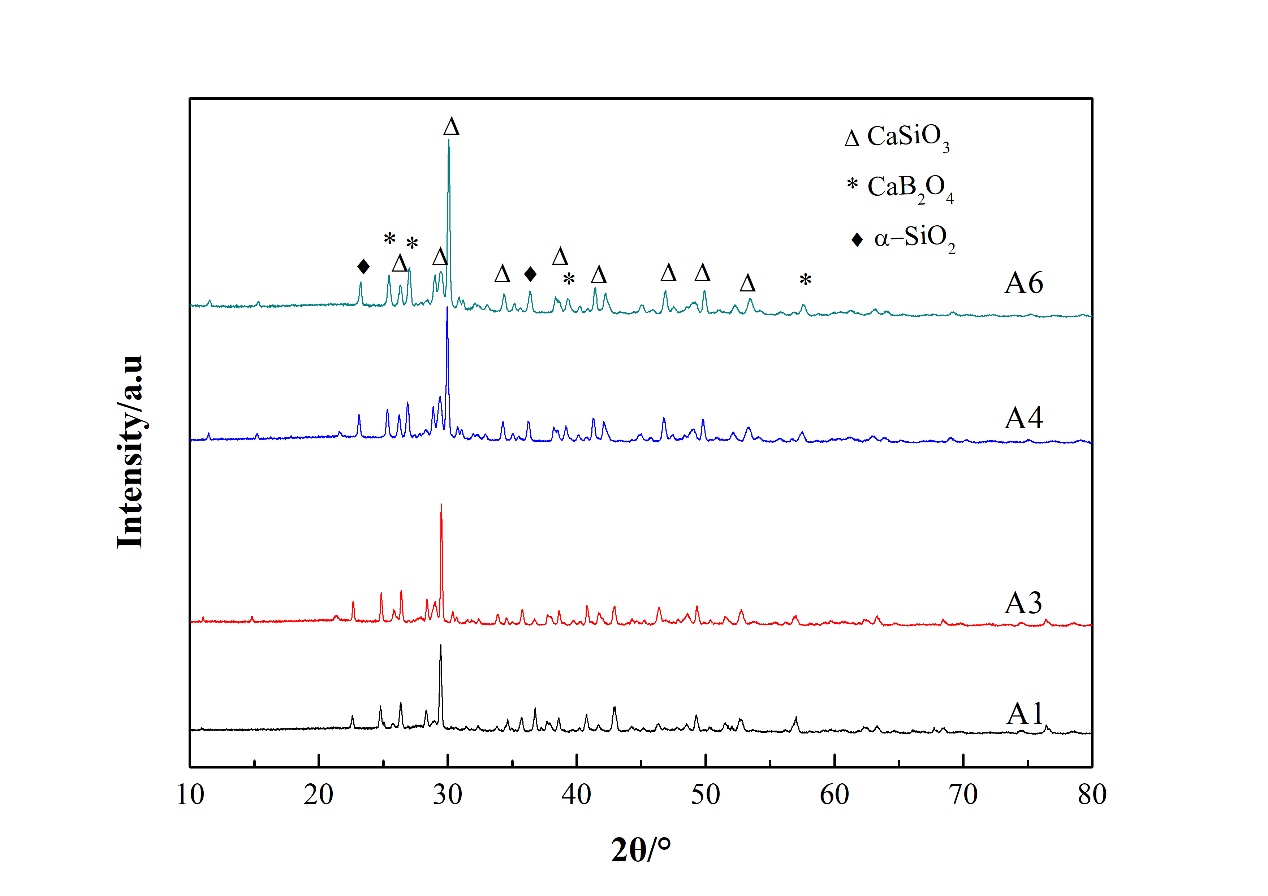

然后挑选一固定Ca/Si比,细调B2O3的含量,研究硼含量对于CBS微晶玻璃的影响。通过对微晶玻璃失透情况的分析,可得由于B2O3含量的增加,促进了微晶玻璃的析晶,同时也使熔体中的成分无法均匀一致,使玻璃分相,导致了玻璃的失透,根据XRD图样的分析得出微晶玻璃中随着硼含量的增加,[BO3]、[BO4]的数量都有所增加,提高了微晶玻璃中CaB2O4晶相的数量;通过对烧结温度的研究,得出微调硼含量对于微晶玻璃的析晶影响不是很大,而且当微晶玻璃的透明性越差时,其在低温下越难以完成烧结,而失透是由于玻璃的分相导致的;对介电性能的研究得出随着B2O3含量的增加,介电常数也随之增高。

关键词:CBS系微晶陶瓷 低温烧结 Ca/Si比 硼含量

Study on firing characteristics and properties of CBS microcrystalline ceramics

Abstract

CaO-B2O3-SiO2(CBS) is an ideal low-temperature co-fired ceramic (LTCC) material, which is widely used in the fields of integrated circuits, electronic communications and so on, because of its superior characteristics, it can well meet the requirements of high integrated density and high signal transmission rate of integrated circuits.

In this paper, the effects of calcium borosilicate multicomponent on the morphology, sintering properties and dielectric properties of CBS glass-ceramics were studied in detail. Firstly, B2O3 content was fixed to study the properties of glass-ceramics with different Ca/Si ratios. Through the observation and research on the morphological transmittance of microcrystalline ceramics, it can be found that the increase of CaO content is conducive to crystallization of microcrystalline glass, thus making microcrystalline glass devitrify and appear a milky white color. Through the detection of sintering temperature and density and the observation of SEM pattern, it was concluded that due to the different Ca/Si ratios, the relative content of crystalline phase and amorphous phase was different, and the difference of stomatal content, the requirements for the sintering temperature were different. The higher the density was, the higher the dielectric constant was. With the increase of Ca/Si ratio, the content of crystal phase in the sample increased, so the dielectric constant of the sample also increased gradually. Then, a fixed Ca/Si ratio was selected to fine adjust the content of B2O3 to study the effect of boron content on CBS glass-ceramics. Through the analysis of microcrystalline glass devitrification situation, can be due to the increase of the content of B2O3 promoted the microcrystalline glass crystallization, but also makes the melt in the composition is not uniform, the glass phase splitting, caused the glass devitrification, according to the analysis of the XRD pattern of microcrystalline glass with the increase of boron content, the number of [BO3], [BO4] increased, raised the microcrystalline glass CaB2O4 crystalline phases in number; Through the research of sintering temperature, it is concluded that the fine boron content has little influence on crystallization of glass-ceramics. Moreover, the worse the transparency of glass-ceramics is, the more difficult it is to complete sintering at low temperature. The study of dielectric properties shows that the dielectric constant increases with the increase of B2O3 content.

Key Words: CBS microcrystalline ceramics;Low temperature sintering;The Ca/Si ratio;B2O3 content

目录

摘要 I

目录 IV

第一章 绪论 1

1.1 LTCC基板技术 1

1.2微晶玻璃系LTCC基板 3

1.3研究目的与内容 4

第二章 实验原理与过程 6

2.1实验原料及设备 6

2.2实验工艺过程 8

图 1-1 LTCC 基板工艺流程 9

Fig.1-1 Process of LTCC substrate 9

2.2.1CaO-B2O3-SiO2玻璃的熔制 9

2.2.2 CaO-B2O3-SiO2玻璃的粉磨 10

2.2.3 CaO-B2O3-SiO2玻璃粉料的成型 10

2.2.4CaO-B2O3-SiO2玻璃生坯的烧成 11

2.3 试样的性能测试 11

2.3.1 CBS微晶玻璃中B2O3含量测定 12

2.3.2 体积密度的测定 12

2.3.3 收缩率的测定 12

2.3.4 微晶玻璃介电性能测试 12

2.3.5 微观形貌分析 13

2.3.6 X射线衍射分析 13

第三章 Ca/Si比对CBS微晶玻璃的性能影响 14

3.1 Ca/Si比对CBS微晶玻璃形态的影响 14

3.2 Ca/Si比对CBS微晶玻璃烧成性能的影响 16

3.3 Ca/Si比对CBS微晶玻璃介电性能的影响 19

第四章 硼含量对于CBS微晶玻璃性能的影响 22

4.1 硼含量对于CBS微晶玻璃形态的影响 22

4.2硼含量对于CBS微晶玻璃烧成性能的影响 24

4.3硼含量对于CBS微晶玻璃介电性能的影响 26

第五章、结论 29

参考文献 30

致 谢 32

第一章 绪论

1.1 LTCC基板技术

随着信息技术的飞速发展,作为其基本硬件技术之一的集成电路技术近年来得到了越来越广泛的研究[1]。随着对集成电路精细化、高密度化、大型化以及高速化要求的不断提高,对封装材料也提出了越来越高的要求[2],低温共烧陶瓷(Low Temperature Co-fired Ceramics,简称 LTCC)就是近几十年来兴起的一种电子封装材料技术,它有热导率高、介电性能好、热膨胀系数小、耐热性好、加工性能好、尺寸稳定性高等优点,这使之成为当今电子封装技术领域的首选材料,广泛用于基板封装、电子芯片及微波元器件等领域[3]。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: