Ca固溶量对(1-x-y)BaTiO3-xCaTiO3-y(BaZr0.7Sn0.3)O3压电陶瓷的制备与性能影响的研究。毕业论文

2020-04-18 20:04:24

摘 要

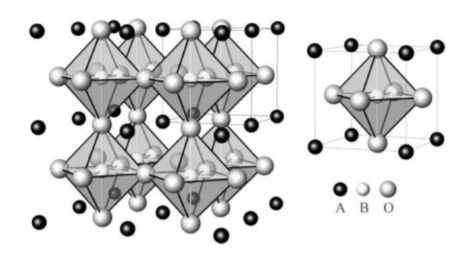

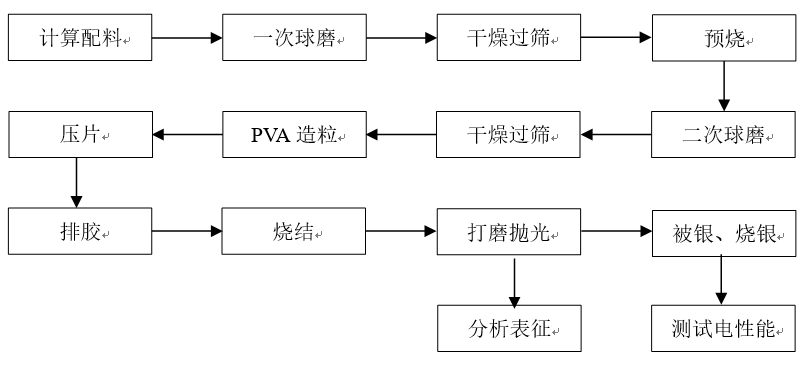

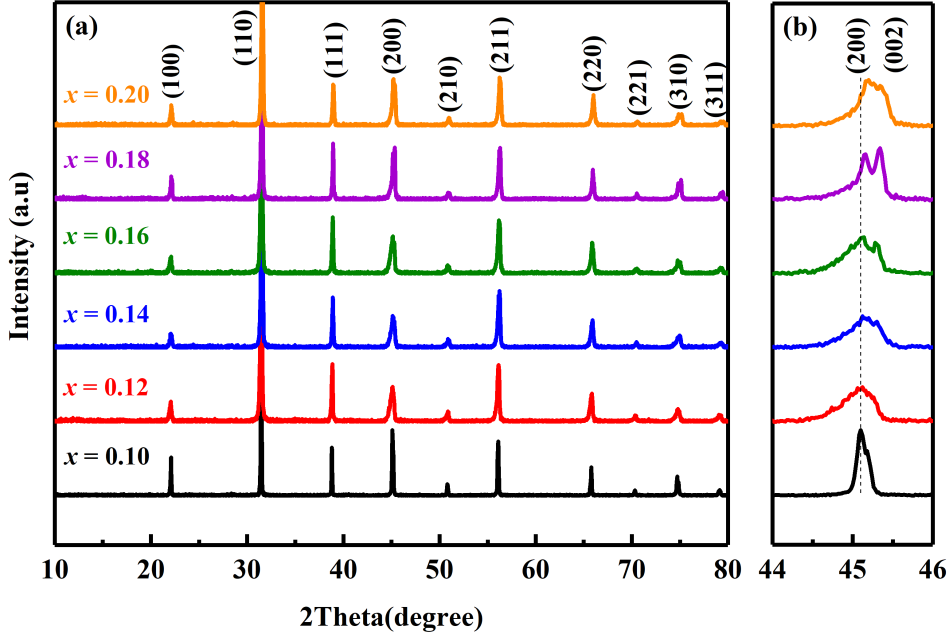

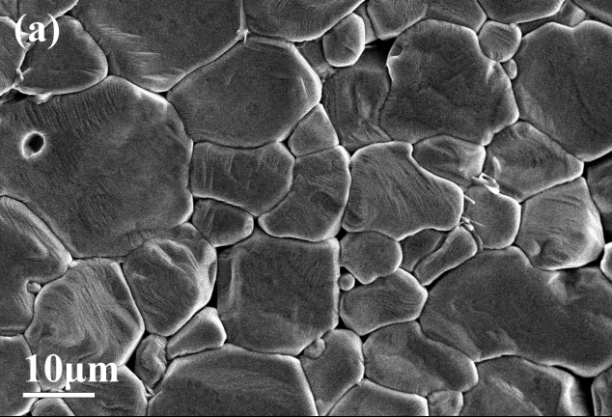

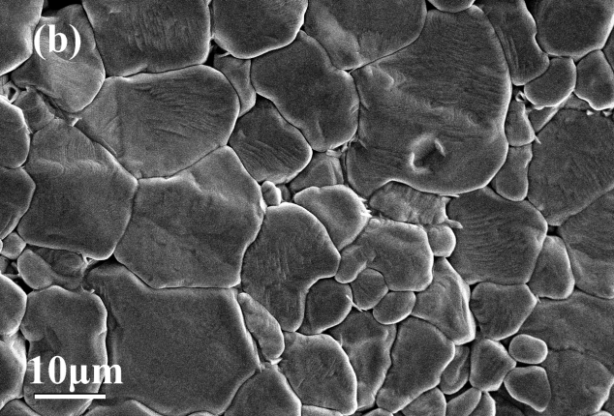

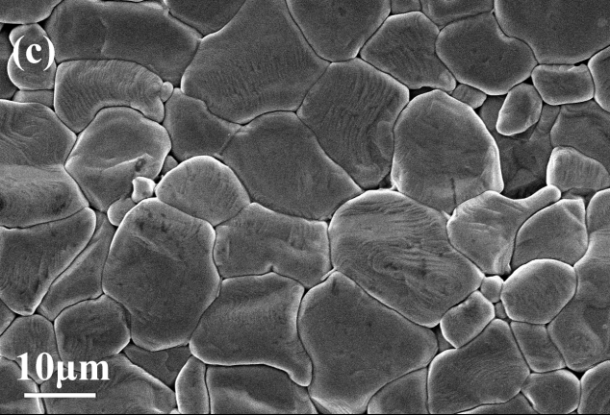

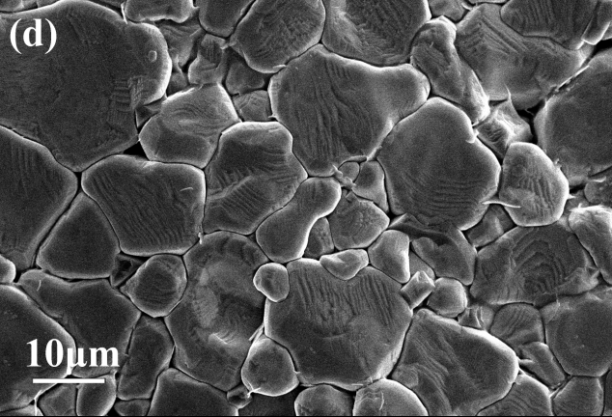

本篇论文采用固相反应法制得了(1-x-y)BaTiO3-xCaTiO3-y(BaZr0.7Sn0.3)O3(BT-xCT-BZS)压电陶瓷,并通过XRD和SEM等表征方法,研究准同型相界附近钙固溶量对(1-x-y)BaTiO3-xCaTiO3-y(BaZr0.7Sn0.3)O3压电陶瓷物相结构、微观形貌和电学性能的影响,并确定了综合性能最佳的钙固溶量。实验结果表明:(1)采用固相反应法制备的BT-xCT-BZS陶瓷均为单一的钙钛矿结构,没有发现第二杂相存在。当钙固溶量为0.10时,陶瓷的物相结构为三方相。随着钙固溶量的增加,(200)处单峰宽化,并且分裂为(200)和(002)两个峰,陶瓷物相结构从三方相向四方相转变。(2)不同钙含量的 BT-xCT-BZS陶瓷断面的SEM二次电子像显示,当Ca固溶量为0.10时,陶瓷的晶粒尺寸不均一,并且气孔较多;当钙固溶量为0.14时,晶粒尺寸较其他组分更为均匀致密。当钙固溶量进一步增加,晶界变得模糊且气孔变多。相对密度变化趋势为先增加后减小,在x = 0.14处获得最大相对密度96.8%。(3)随着钙固溶量的增加,应变先是增加,在x = 0.14处应变值达到最大Smax = 0.20%且迟滞相对较低,随着钙固溶量的进一步增加,应变开始减小。比较各组分的性能,在钙固溶量为0.14时,BT-xCT-BZS陶瓷综合性能最佳。

关键词:无铅压电陶瓷;固溶量;微观形貌;电学性能

ABSTRACT

In this paper, (1-x-y) BaTiO3-xCaTiO3-y(BaZr0.7Sn0.3)O3(BT-xCT-BZS) piezoelectric ceramics were prepared by traditional solid-state reaction method. The effects of Ca solid solubility near the quasi-isomorphic phase boundary on the phase structure, micro-morphology and electrical properties of (1-x-y)BaTiO3-xCaTiO3-y (BaZr0.7Sn0.3)O3 piezoelectric ceramics were studied by XRD and SEM characterization methods, and the best calcium solid solubility was determined. The experimental results show that: (1) The BT-xCT-BZS ceramics prepared by solid-state reaction method have a single perovskite structure and no second impurity is found. When the calcium solid solution amount is 0.10, the phase structure of the ceramic is a trigonal phase. As the amount of calcium solid solution increases, the single peak broadens at (200) and splits into two peaks of (200) and (002), and the ceramic phase structure changes from a trigonal phase to a tetragonal phase. (2) The SEM secondary electron image of the BT-xCT-BZS ceramic cross section with different calcium content shows that when the calcium solid solution is 0.10, the grain size of the ceramic is not uniform and the pores are more; when the calcium solid solution is 0.14, the grain size is more uniform and dense than the other components. When the calcium solid solution amount is further increased, the grain boundary becomes blurred and the pores become more. The change trend of relative density was first increasing and then decreasing, and the maximum relative density was 96.8% at x = 0.14. (3) As the amount of calcium solid solution increases, the strain increases first. At x = 0.14, the strain value reaches the maximum Smax = 0.20% and the hysteresis is relatively low. As the calcium solid solution increases further, the strain begins to decrease. Comparing the performance of each component, BT-xCT-BZS ceramics have the best comprehensive performance when the calcium solid solution is 0.14.

Key words: lead-free piezoelectric ceramics; solid solution content; micro-morphology; electrical properties

目录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1引言 1

1.2压电陶瓷以及铁电体材料的概述 1

1.2.1压电效应原理 1

1.2.2压电陶瓷 2

1.2.3铁电体材料概述 2

1.3 BCTZ压电陶瓷的新进展 3

1.4压电陶瓷的应用 4

1.5压电陶瓷的制备方法 5

1.6实验内容及目的 5

第二章 实验内容及性能表征 7

2.1实验原料 7

2.2实验步骤 7

2.3性能测试与表征 9

第三章 实验结果与分析 10

3.1钙固溶量对BT-xCT-BZS陶瓷物相结构的影响 10

3.2钙固溶量对BT-xCT-BZS陶瓷微观形貌的影响 10

3.3钙固溶量对BT-xCT-BZS陶瓷铁电性能的影响 13

3. 4钙固溶量对BT-xCT-BZS陶瓷应变的影响 13

第四章 结论与展望 16

4.1结论 16

4.2展望 16

参考文献 17

致谢 20

第一章 绪论

1.1引言

在20世纪40年代左右,在纯钛酸钡陶瓷(BT)中首次发现了压电特性[1-2],随后出现了压电性能更好的锆钛酸铅压电陶瓷(PZT),通过两者的比较,发现锆钛酸铅压电陶瓷其可用性更好,在当时直至现在铅基压电陶瓷仍然是压电材料领域的主力军[3]。然而,PZT压电陶瓷其主要组成包含铅元素,该元素以氧化铅的形式存在,铅是有毒物质,其氧化物较易挥发,使得PZT压电陶瓷在使用过程中,对环境造成破坏[4]。除此之外,在处于高温状态下,氧化铅不断挥发,致使之前设计的化学计量数发生改变,造成产品的可使用性降低,因此需要在密封条件下进行烧结,使得成本提高。

为了减少铅等有害物质污染,欧盟和日本等国颁布了“电器和电子设备中限制有害物质”法令[5-6] ,我国也制定了相关法律,因此无铅压电陶瓷的发展就成了重中之重。而钛酸钡基无铅压电陶瓷具有环境友好和压电响应高等特点,成为替代铅基压电陶瓷的理想选择。由于钛酸钡钙压电陶瓷(BCTZ)体系与铅基压电陶瓷相比,其不含挥发性元素,即使在高温煅烧过程和烧结过程中,该体系仍能很好地保持预先设计的化学计量比。近年来,经过国内外学者不断研究开发,通过掺杂、改变无铅压电陶瓷中其他组分的量从而使得其性能在一定程度上可以提升,从而使得含铅元素的压电陶瓷的使用率下降。这些改进都说明了BaTiO3基陶瓷材料的发展前景,也说明了BCTZ体系压电陶瓷的研究的必要性和可行性。这些无疑给无铅压电陶瓷的发展提供了不小的助力,也使得研究无铅压电陶瓷成为一个新的热潮 [7-9]。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: