船用夹芯结构冲击动力响应数值仿真研究毕业论文

2021-12-06 20:54:28

论文总字数:24579字

摘 要

传统的制造技术面临着重大改革,各种新型能源、新型材料的应用越来越广泛。船舶制造作为传统工业,为了顺应发展的趋势,改革势在必行。当下船舶结构正朝着大型化、轻量化发展。为了满足船舶结构轻量化的要求,具有轻质高强、抗冲击性能好等优点的新型夹芯结构成为了世界各国学者们的关注重点和研究热点。另一方面,船舶航行在海中可能会遭受各种冲击碰撞事故,导致船体结构发生变形和失效破坏。因此,对冲击载荷下船用夹芯结构动态响应的研究显得尤为重要。

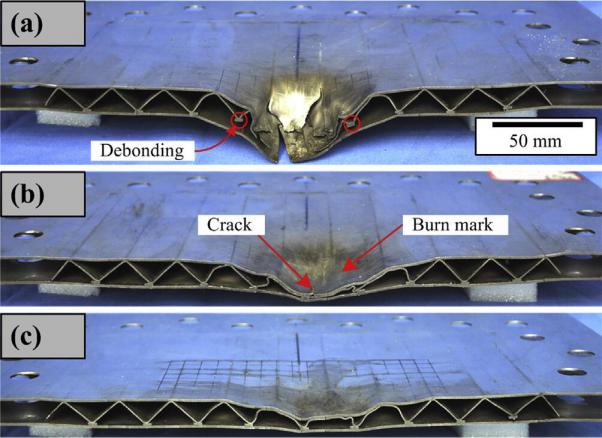

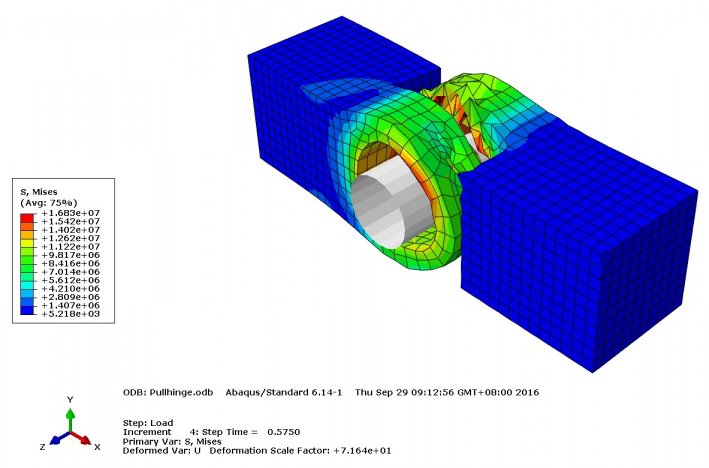

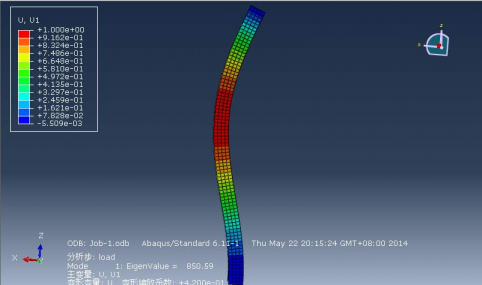

本文首先运用ABAQUS数值仿真软件建立了船体板结构冲击的数值计算模型,模拟了船体板结构受冲击的过程,并开展了相同情况下的实验,将两者方法所得结果进行对比,数值模拟结果与实验结果吻合较好,验证了数值方法的可靠性。在此基础上建立了船用金属波纹夹芯板的冲击动力响应模型,得到了船用金属波纹夹芯板的冲击力时程曲线、加速度时程曲线、结构的位移时程曲线和结构吸收能量的时间历程曲线等。在此基础上,研究冲击位置、冲击能量和冲头形状等冲击参数和上下面板厚度、芯层厚度等结构参数对波纹夹芯板冲击动力响应的影响。研究结果表明,当冲击位置在夹芯结构中心时,结构所受冲击力最大,上下面板变形最大,芯层变形最小,能量吸收率与其他两处位置相比较小;冲击力峰值和能量吸收都随冲击能量的增大而增大,冲击力峰值出现的时间随冲击能量的增大而减小;冲头形状对冲击力的影响较大,楔形冲头下的冲击力最小和能量吸收率最小,但上下面板位移均大于其他两种冲头;冲击力峰值随上、下面板和芯层的厚度增大而增大,出现时间也提前;总体而言,下面板厚度对波纹夹芯结构抗冲击性能的影响不如上面板和芯层厚度的影响大。

本文的研究工作建立了船用金属波纹夹芯结构冲击动力响应数值分析方法,揭示了金属波纹夹芯结构的冲击动力响应特性,为其在船舶与海洋工程结构安全与轻量化领域的应用提供了有益的参考。

关键词:船用夹芯结构;波纹夹芯;冲击动力响应;ABAQUS;数值仿真

Abstract

The traditional manufacturing technology is facing a major reform, and various new energy sources and new materials are being used more and more widely. Shipbuilding as a traditional industry, in order to conform to the trend of development, the reform is imperative. At present, ship structure is developing towards large scale and light weight. In order to meet the requirements of lightweight ship structure, the new sandwich structure with the advantages of light weight, high strength and good impact resistance has become the focus and research focus of scholars all over the world. On the other hand, ships in the sea may suffer from various impact and collision accidents, resulting in deformation and failure of the hull structure. Therefore, it is very important to study the dynamic response of Marine sandwich structure under impact load.

This article first hull plate was established by applying the numerical simulation software of ABAQUS, the numerical calculation model of structural shocks, simulates the process of hull plate structure impact, and experiment was carried out by the same situation, method, comparing the results between the two numerical simulation results are in good agreement with the experimental results, the reliability of the numerical method. On this basis, the dynamic response model of Marine metal corrugated sandwich plate is established, and the impact time curve, acceleration time curve, structural displacement time curve and structural energy absorption time history curve of Marine metal corrugated sandwich plate are obtained. On this basis, the influence of impact parameters such as impact position, impact energy and punch shape, as well as structural parameters such as upper and lower panel thickness and core layer thickness on the impact dynamic response of corrugated sandwich plate was studied. The results show that when the impact position is in the center of the sandwich structure, the structure suffers the maximum impact force, the upper and lower panels deform the most, the core layer deforms the least, and the energy absorption rate is smaller compared with the other two positions. The impact peak and energy absorption both increase with the increase of the impact energy, and the time of the impact peak decreases with the increase of the impact energy. The impact force is greatly influenced by the shape of punch. The impact force and energy absorption rate are the smallest under the wedge punch. However, the displacement of the upper and lower panels is larger than that of the other two kinds of punch. The peak value of the impact force increases with the thickness of the upper and lower panels and the core layer, and the time of its occurrence is also advanced. But in general, the thickness of the lower panel has less effect on the impact resistance of the structure than the thickness of the upper panel and the core layer.

In this paper, a numerical analysis method for the dynamic response of ship's metal corrugated sandwich structure is established, and the characteristics of the dynamic response of metal corrugated sandwich structure are revealed, which provides a useful reference for its application in the field of structural safety and lightweight of ships and Marine engineering.

Key words: Marine sandwich structure; corrugated sandwich plates; Impact dynamic responses; ABAQUS; Numerical simulation

目 录

摘 要 I

Abstract II

第1章 绪论 1

1.1 课题背景及意义 1

1.2 国内外研究现状 2

1.2.1 船舶结构冲击动态响应研究 2

1.2.2 船用夹芯结构冲击动态响应研究 3

1.3 本文的主要工作 4

第2章 船体板结构冲击动态响应数值方法与实验验证 6

2.1 ABAQUS软件介绍 6

2.2 船体板结构冲击动态响应数值模拟 7

2.2.1 有限元模型的建立 7

2.2.2 数值模拟结果 9

2.3 船体板结构冲击实验 12

2.3.1 冲击实验方案 12

2.3.2 冲击实验结果 13

2.4 数值仿真与实验方法对比 14

2.5 本章小结 16

第3章 船用波纹夹芯结构的冲击动力响应特性研究 17

3.1 船用波纹夹芯板冲击动态响应数值模拟 17

3.1.1 有限元模型的建立 17

3.1.2 数值模型结果和分析 19

3.2 各参数对冲击结果的影响分析 28

3.2.1 冲击位置 28

3.3.2 冲击能量 33

3.2.3 冲头形状 38

3.2.4 上面板厚度 43

3.2.5 芯层厚度 48

3.3.6 下面板厚度 52

3.3 本章小结 57

第4章 结论 58

4.1 结论 58

4.2 对未来工作的展望 58

参考文献 59

致 谢 61

第1章 绪论

1.1 课题背景及意义

船舶与海洋工程装备在航行与作业过程中不可避免遭受船、桥梁等碰撞冲击载荷作用,这使得其在航行和作业过程中的困难程度和危险系数大大增加。近来年发生的船舶碰撞、船桥碰撞事故(如图1.1和图1.2)也不在少数。为了提高船舶的碰撞防护能力,减少这类事故的发生,世界各国学者们做了许多这方面的研究。传统的防护方法主要从加强船体结构和加设防护装置两方面入手[1]。但不论是哪种方式,都会大大增加船体重量,对船舶总性能造成不好的影响。所以,目前研究问题的关键就是要找出一种既能满足耐撞性要求,又不明显增加船体重量的防护手段。

请支付后下载全文,论文总字数:24579字

相关图片展示: