复合材料疲劳试验研究毕业论文

2020-04-12 16:47:05

摘 要

随着社会科学技术的进步, 土木工程结构学科的发展, 在很大程度上受益于性质优异的新材料、新技术的应用和发展。而FRP以其优异的力学性能及适应现代工程结构向大跨、高耸、重载、轻质发展的需求, 正被越来越广泛地应用于桥梁工程、各类民用建筑、海洋工程、地下工程中, 受到结构工程界广泛关注。所以良好的预测材料疲劳寿命以及失效损伤的方法极为重要,这也是工程界迫切需要解决的问题。

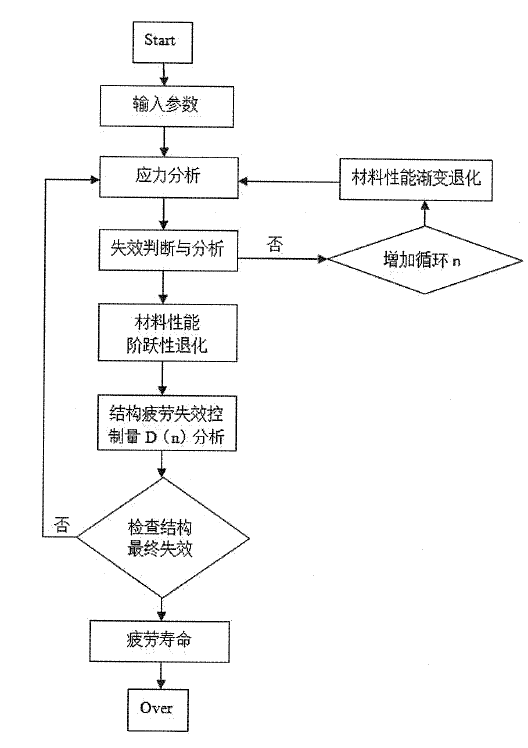

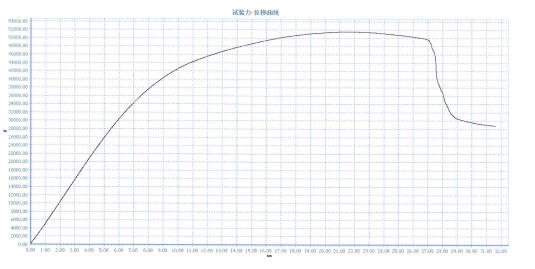

论文全面论述了夹芯复合材料结构的受力特点,结合已有的应劳寿命模型及渐变累积损伤方法的假设条件与适用范围,分析了复合材料在静载及交变权荷作用下的累积损伤失效过程,综合材料的局部损伤与整体失效等多因素影响,应用Hashin三维疲劳失效分析准则,对复合材料三个正交方向的材料损伤进行了判定分析,提出了材料性能阶跃性退化准则。采用损伤力学理论推导了整体结构损伤状态参量表达式,结合Miner疲劳线性理论分析方法,在对各损伤参数进行可行性分析的基础上,建立了以剩余刚度为表征参量的复合材料结构的疲劳累积损伤状态量的失效准则,最终提出了复合材料结构疲劳累积失效分析过程和寿命预测模型。

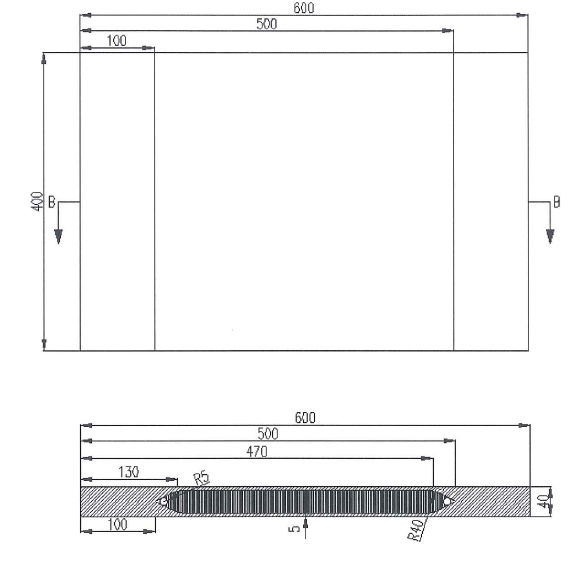

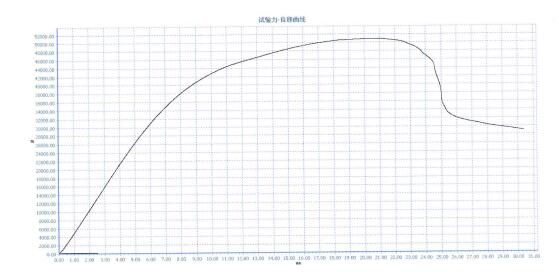

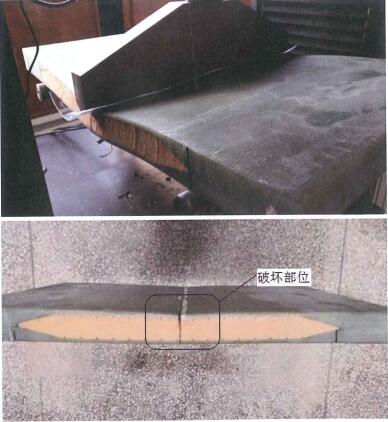

本文通过寿命预测模型推导了夹芯复合材料板在受载路径下,结构疲劳寿命的预测力,以夹芯复合材料板的疲劳试验为基础,以声发射裂纹探测技术对疲劳裂纹扩展及累积损伤过程进行了无损检测,实现了全寿期内裂纹发生、扩展直至最终破坏的整个疲劳累积失效过程进行追踪,扩展了适用于夹芯复合材料结构疲劳渐变累积损伤过程的材料性能渐降模型,夹芯复合材料结构疲劳累积失效分析依据交变载荷下材料性能渐降准则及累积损伤追踪过程的数据规律学模型。

关键词:夹芯复合材料;累计损伤;失效模式

Abstract

With the progress of social science and technology, the development of the subject of civil engineering structure, to a large extent, benefits from the application and development of new materials and new technologies with excellent properties. FRP is widely used in bridge engineering, civil architecture and marine engineering because of its excellent mechanical properties and the demand of modern engineering structure to develop into long span, towering, heavy load and light weight. In underground engineering, it is widely concerned by the field of structural engineering. It is very important to predict the fatigue life and failure damage of materials, which is an urgent problem to be solved in engineering field.

In this paper, the mechanical characteristics of sandwich composite structures are comprehensively discussed, and the assumptions and applicable scope of the existing fatigue life model and progressive cumulative damage method are discussed. The cumulative damage failure process of composites under static load and variable weight loading is analyzed. The local damage and global failure of composite materials are synthetically affected. The Hashin three dimensional fatigue failure analysis criterion is applied. The damage of composite materials with three orthogonal directions was analyzed and a step degradation criterion of material properties was proposed. Based on the damage mechanics theory, the expression of the damage state parameter of the whole structure is derived, and the formula of the damage state parameter is analyzed by combining the Miner fatigue linear theory. Based on the feasibility analysis of each damage parameter, the failure criterion of fatigue cumulative damage state D of composite structure characterized by residual stiffness is established. Finally, the fatigue cumulative failure analysis process and life prediction model of composite structures are presented.

Based on the fatigue test of sandwich composite plate and acoustic emission crack detection technology, the fatigue crack propagation and cumulative damage process are detected without damage. The whole fatigue cumulative failure process from propagation to ultimate failure is traced, and the model of material performance decline suitable for the fatigue gradual cumulative damage process of sandwich composite structures is extended. Fatigue cumulative failure analysis of sandwich composite structure based on the criterion of material performance decline under alternating load and the data rule of cumulative damage tracing process.

Keywords: sandwich composite; cumulative damage; failure mode

目 录

第1章.绪论............................................1

1.1 引言...............................................................................................................1

1.2 材料介绍.......................................................................................................1

1.3 研究现状及目标...........................................................................................1

第2章.复合材料力学理论................................3

2.1 引言...............................................................................................................3

2.2 力学理论分析...............................................................................................3

第3章.累计损伤及寿命预测..............................8

3.1.引言................................................................................................................8

3.2累计损伤分析................................................................................................8

3.3寿命预测........................................................................................................13

第4章.疲劳实验........................................15

4.1引言...............................................................................................................15

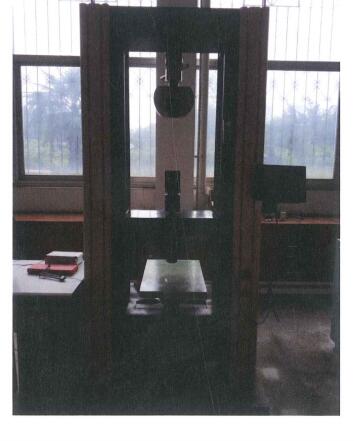

4.2试验理论.......................................................................................................15

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: