低含氢硅油的合成和表征毕业论文

2020-06-19 21:52:27

摘 要

低含氢硅油可用作高级润滑油,防震油,绝缘油,消泡剂,脱模剂,擦光剂和真空扩散泵油等。传统工业上多使用液体酸作为催化剂合成低含氢硅油的,不仅会腐蚀设备,而且难于分离出产品。

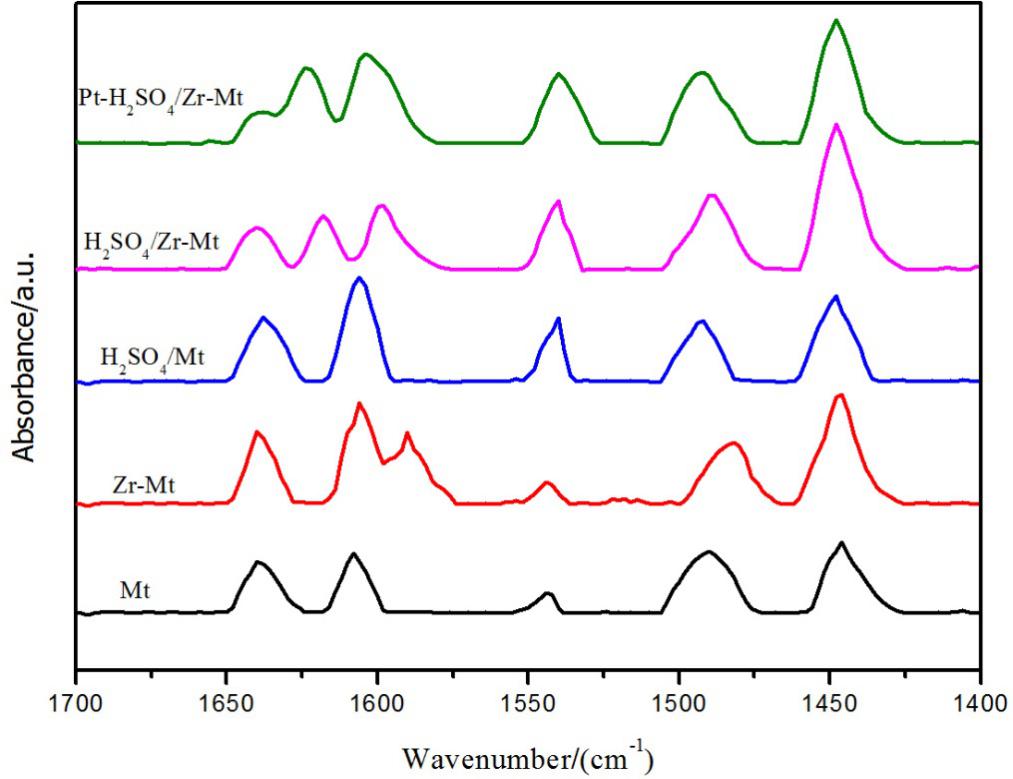

在本文中,主要研究了蒙脱石(Mt),Zr-Mt,H2SO4 / Mt,H2SO4 / Zr-Mt和Pt-H2SO4 / Zr-Mt对八甲基环四硅氧烷(D4)的液相开环。通过X射线荧光,X射线衍射,氮吸附-解吸,NH3-TPD和吡啶-FTIR检测Mt,Zr-Mt,H2SO4/Mt,H2SO4/Zr-Mt和Pt-H2SO4/Zr-Mt来研究催化剂的表征。与活性粘土相比,Zr-Mt催化剂在D4,聚甲基氢硅氧烷(D4H)和六甲基二硅氧烷(MM)的聚合中表现出更强的酸性和更优异的催化活性。相对于Zr-Mt,H2SO4/Zr-Mt的酸性显著改善,并且表现出更高的D4转化开环能力和低氢硅油的产率。

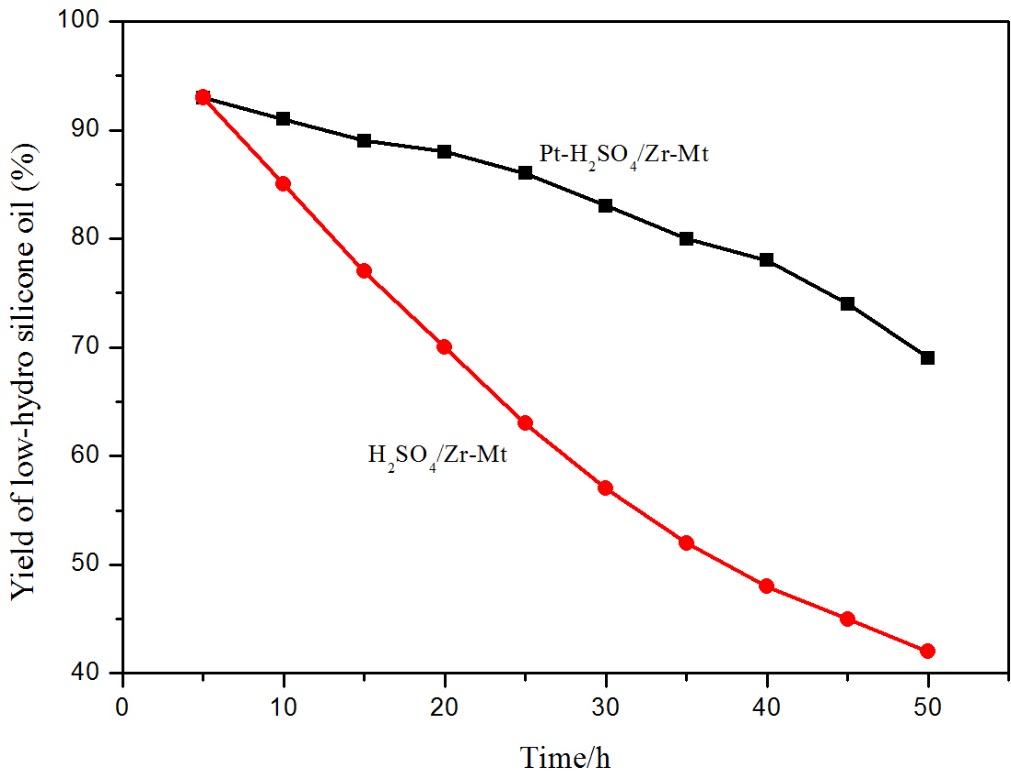

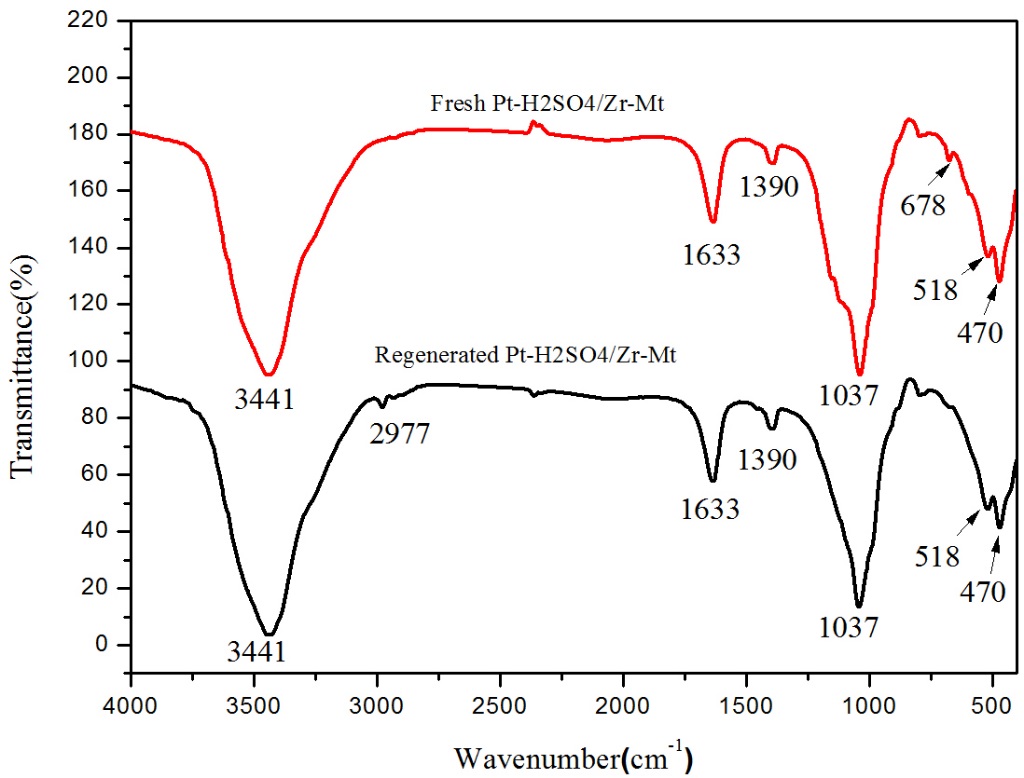

为了提高H2SO4/Zr-Mt催化剂的稳定性,掺杂少量的金属(Pt)。氮吸附-解吸结果表明,Pt-H2SO4/Zr-Mt的孔结构参数没有随着比表面积的增大而改变。与H2SO4/Zr-Mt相比,Pt-H2SO4-Zr/Mt催化剂的总酸度保持不变,但是布朗斯台德酸的含量增加,路易斯酸的含量降低。Pt-H2SO4-Zr/Mt催化剂显示更高的催化剂重现性。

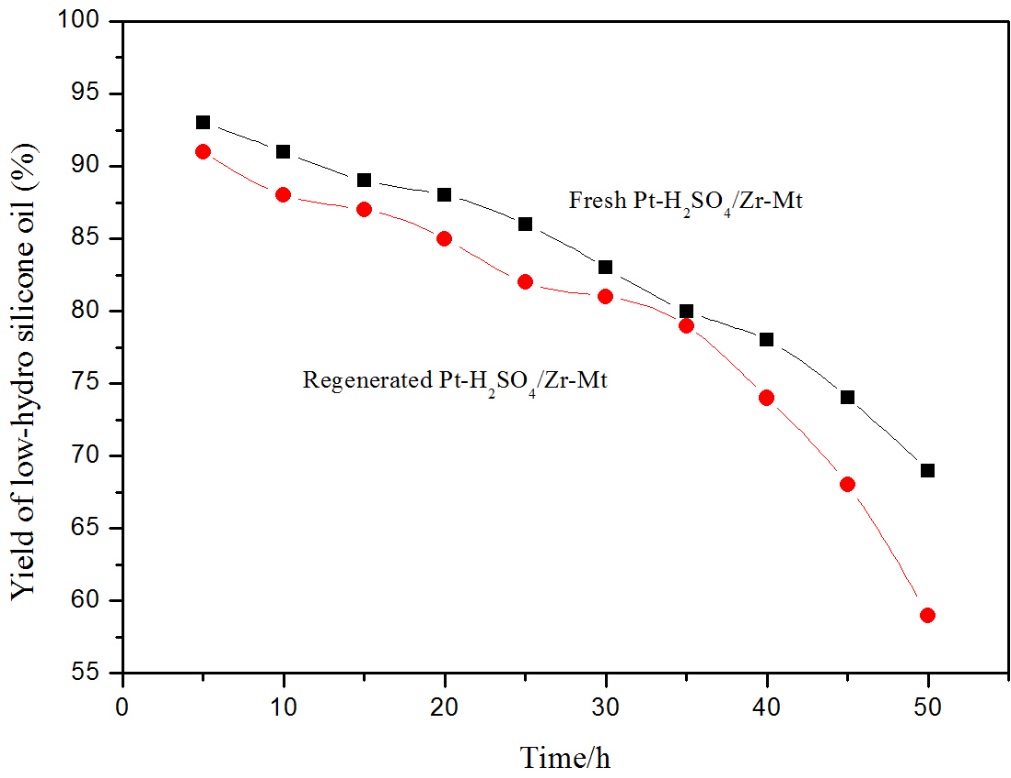

聚合反应40小时后,H2SO4/Zr-Mt催化剂合成低氢硅油的产率从93%降低到42%,而Pt-H2SO4/Zr-Mt催化剂合成低氢硅油的产率从93%降低至78%。在使用35h之后检测到Pt-H2SO4/Zr-Mt催化剂催化活性急剧下降。Pt-H2SO4/Zr-Mt在合适的条件下可以再生,并且在D4,D4H和MM中对低氢硅油显示出良好的稳定性。

关键词:Pt-H2SO4/Zr-蒙脱石 低氢硅油 催化剂 稳定性 再生

ABSTRACT

Low hydrogen silicone oil can be used as high-grade lubricants, shock oil, insulating oil, defoamer, release agent, polish and vacuum diffusion pump oil. Traditional industrial use of liquid acid as a catalyst for the synthesis of low hydrogen silicone oil, not only will corrode the equipment, and difficult to separate the product.

In this paper, the liquid phase open loop of octamethylcyclotetrasiloxane (D4) was studied on montmorillonite (Mt), Zr-Mt, H2SO4/Mt, H2SO4/Zr-Mt and Pt-H2SO4/Zr-Mt The The effects of Mt, Zr-Mt, H2SO4/Mt, H2SO4/Zr-Mt and Pt-H2SO4/Zr-Mt on the catalytic activity of the catalysts were investigated by X-ray fluorescence, X-ray diffraction, nitrogen adsorption-desorption, NH3-TPD and pyridine-FTIR Characterization. Compared with the active clay, the Zr-Mt catalyst exhibits stronger acidity and more excellent catalytic activity in the polymerization of D4, polymethylhydrogensiloxane (D4H) and hexamethyldisiloxane (MM) Become a low hydrogen silicone oil. The acidity of the Zr-Mt, H2SO4/Zr-Mt was significantly improved, and the catalyst exhibited higher D4 conversion ring-opening ability and low hydrogen silicone oil yield.

In order to improve the stability of H2SO4 / Zr-Mt catalyst, a small amount of metal (Pt) is doped. The results of nitrogen adsorption-desorption show that the pore structure parameters of Pt-H2SO4 / Zr-Mt do not change with the increase of specific surface area. Compared with H2SO4 / Zr-Mt, the total acidity of Pt-H2SO4-Zr / Mt catalyst remained unchanged, but the content of Brnsted acid increased and the content of Lewis acid decreased. Pt-H2SO4-Zr / Mt catalysts show higher catalyst reproducibility.

After the polymerization reaction for 40 hours, the yield of the low hydrogen silicone oil was reduced from 93% of the H2SO4 / Zr-Mt catalyst to 42% and the yield of the low hydrogen silicone oil decreased from 93% to 78% Zr-Mt catalyst from Pt-H2SO4. A sharp decrease in catalytic activity was observed after 35 h of Pt-H2SO4 / Zr-Mt catalyst. In addition, Pt-H2SO4 / Zr-Mt was completely regenerated under suitable conditions, and low hydrogen silicone oil showed good reproducibility in D4, D4H and MM.

KEYWORDS:Pt-H2SO4/Zr-montmorillonite;low hydrogen silicone oil;catalyst;stability;regeneration

目 录

摘 要 I

ABSTRACT II

第一章文献综述 1

1.1引言 1

1.2低含氢硅油的性质及用途 1

1.3低含氢硅油的合成方法 2

1.4催化剂的性质 2

第二章 实验 4

2.1主要试剂、原料及仪器设备 4

2.1.1主要试剂、原料 4

2.1.2主要仪器设备 4

2.3催化剂表征 6

2.4催化反应 7

第三章 结果与讨论 8

3.1催化剂的表征 8

3.2催化活性的探究 12

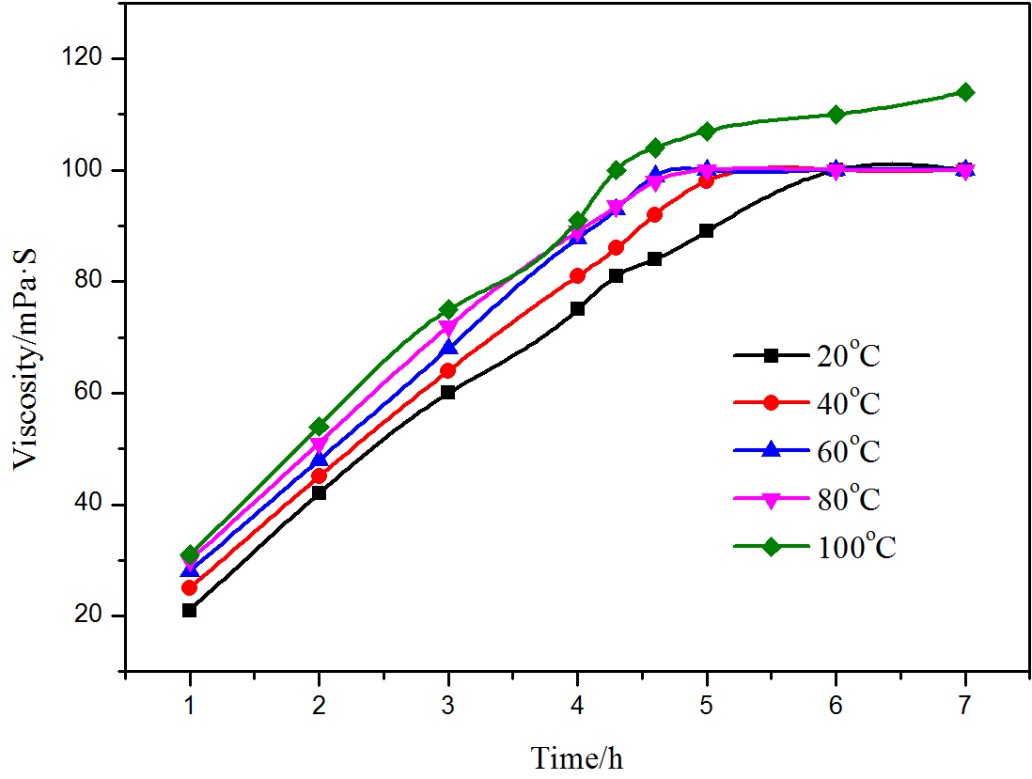

3.2.1反应温度对聚合反应的影响 12

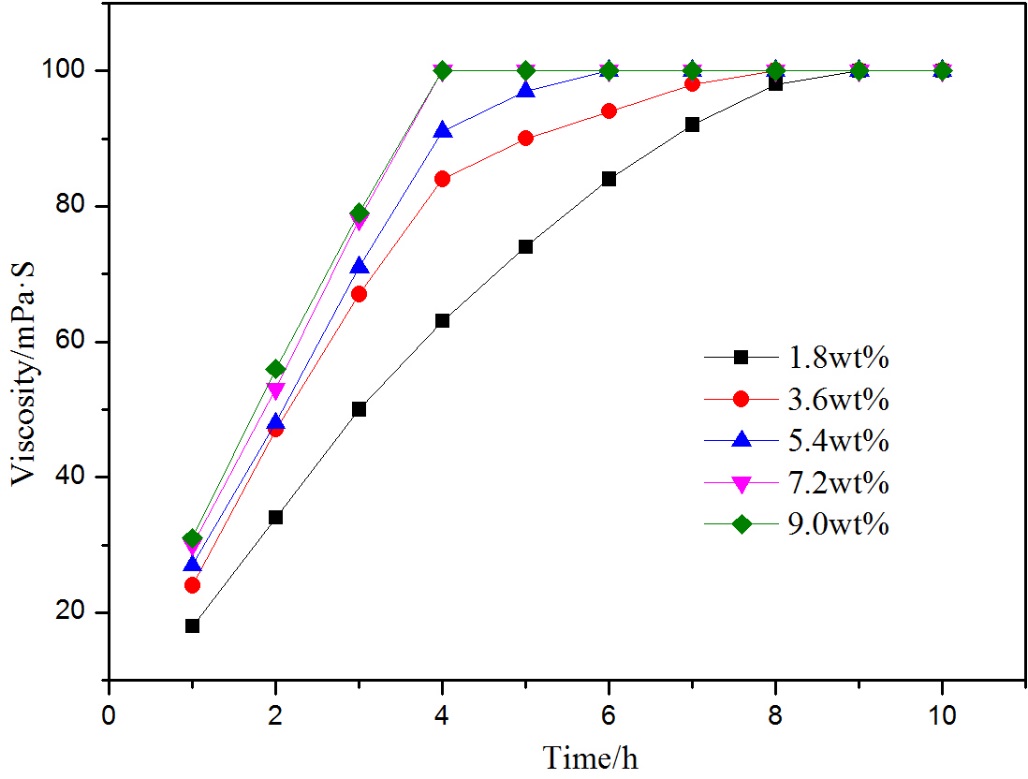

3.2.2催化剂用量对合成低含氢硅油的影响 13

3.2.3 Pt-H2SO4/Zr-蒙脱土稳定性的研究 14

3.2.4低收率条件制备低含氢硅油 15

3.2.5失活Pt-H2SO4/Zr-蒙脱土的再生试验 16

第四章 结论与展望 19

参考文献 20

致谢 25

第一章 文献综述

1.1引言

道康宁公司于20世纪40年代初第一次实现聚硅氧烷的工业化生产后,聚硅氧烷保持了高的开发速度[1,2]。随着多晶硅产品在社会各个领域的需求量的增加,低氢硅油作为聚硅氧烷聚合物的一种重要的化学中间体[3-6],各种固体酸催化剂如金属盐[7],金属氧化物[8,9],杂多酸[9,10],粘土[11],沸石固体酸[12]和交换树脂[13,14]低氢硅油的催化活性也越来越受关注。目前,主要制备路线是基于由蒙脱石(Mt)催化八甲基环四硅氧烷(D4),环四硅氧烷(D4H)和六甲基二硅氧烷(MM)的反应[15]。虽然成本低且容易获取[16,17],但Mt也存在一些缺点,比如催化活性弱,重复性差,硬活化等。为了克服这些缺陷并提高Mt在聚合反应中的催化性能,已经付出了许多努力。

1.2低含氢硅油的性质及用途

低含氢硅油(PHMS)外观为无色透明油状液体,粘度:(25C,rrrr12/S ):30-200,含氢量(%):0.1~0.2。硅油一般是无色(或淡黄色)、无味、无毒、不易挥发的液体。硅油不溶于水、甲醇、二醇和-乙氧基乙醇,但可与甲基乙基酮、苯、二甲醚、四氯化碳或煤油互溶,稍溶于乙醇、丙酮、二恶烷和丁醇。其拥有较小的蒸汽压、较低的凝固点和较高的闪点、燃点。随链段数的不同,分子量增大,粘度也会增高,因此硅油可拥有各种不同的粘度,从0.65厘斯(cSt)直到上百万厘斯(cSt)。如果要制得低粘度的硅油,可用酸性白土作为催化剂,并在180℃温度下进行调聚,或用硫酸作为催化剂,在低温度下进行调聚,生产高粘度硅油或粘稠物可用碱性催化剂。

硅油具有很好的的耐热性、电绝缘性、疏水性、生理惰性及较小的表面张力,除此之外还具有低的粘度系数和较高的抗压缩性,少数品种具有耐辐射的性能。

相关图片展示: