丙酸产品分析和精馏分离研究毕业论文

2020-07-03 23:45:56

摘 要

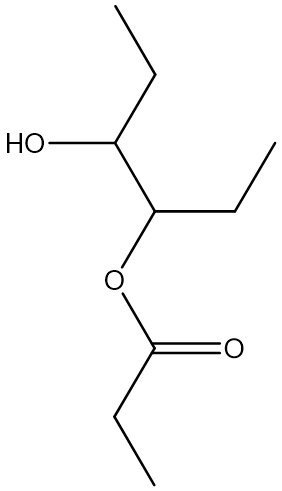

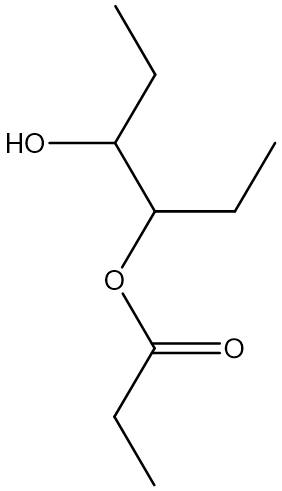

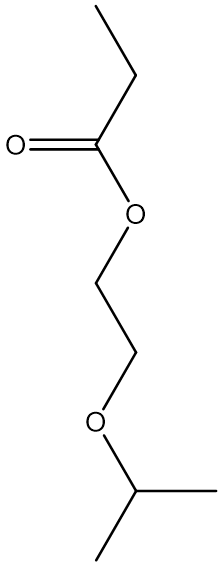

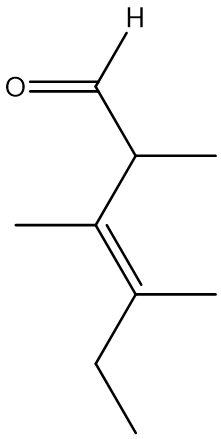

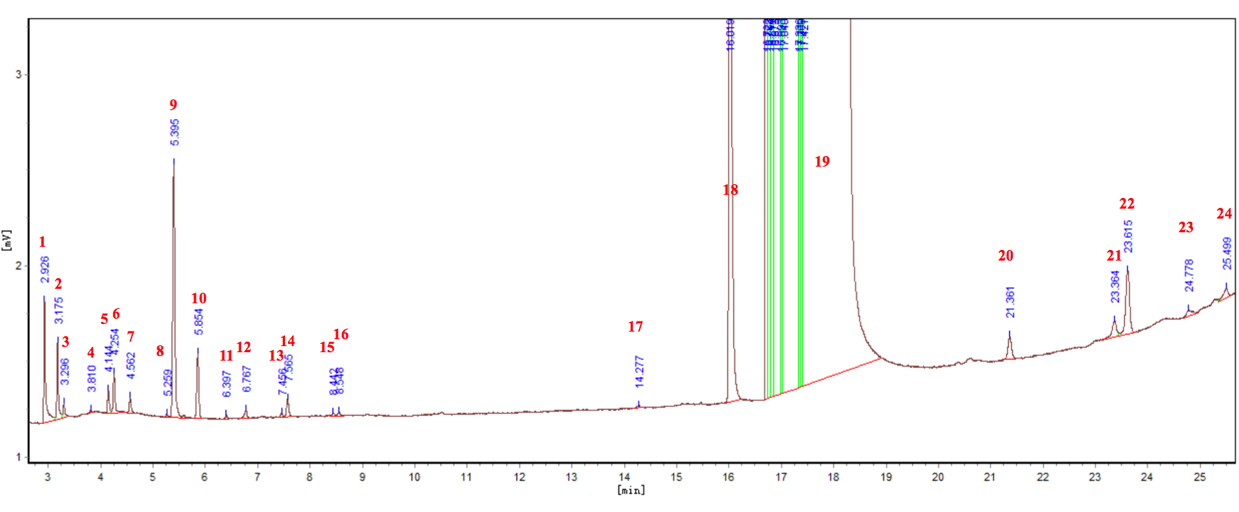

本文采用气质联用(GC-MS)对丙酸产品中的微量成分进行定性分析,采用气相色谱(GC)进行定量分析;通过气相色谱分析丙酸产品中醛含量(高于500ppm)的关键组成;采用间歇精馏模拟工厂中丙酸精馏分离过程,分析间歇精馏中各股物料的总醛含量。结果表明:(1)GC-MS全组分分析得到丙酸进料中约有28个组分,塔釜产物中约有57个组分。塔釜操作温度接近160℃,导致在精馏分离过程中发生了酯化、脱水和异构化等反应,反应过程中生成了一些新的醛或酮类组成,影响了丙酸产品的总醛含量。(2)采用外标法,通过GC分析了丙酸产品中的15个微量组分,对比亚硫酸氢钠反应前后的色谱图得到丙酸产品中的乙醛、丙醛、3-甲基-1-戊醛和2-甲基-2-戊烯醛是影响滴定分析的醛类组分。(3)通过间歇精馏模拟粗丙酸精馏分离过程,维持塔釜温度为141℃时,侧线丙酸产品醛含量均低于500ppm,纯度均高于99.5 wt%,符合产品要求。降低全塔操作温度后塔釜全组成成分明显减少,表明降低精馏操作温度可以使得丙酸精制过程产品达标。

关键词:丙酸 总醛含量 GC-MS 气相色谱 精馏

Research on Analysis and Distillation Separation of Propionic Acid Products

ABSTRACT

In this paper, GC-MS and gas chromatography were used to analyze trace constituents in the propionic acid product of a company. The key component of aldehyde content in the propionic acid product (above 500 ppm) were analyzed by gas chromatography. Distillation process in the company was simulated by a batch distillation. In this batch distillation process, the aldehyde content of each stock in the batch distillation was tested and analyzed. Results showed that (1) GC-MS analysis of all components were about 28 components in the propionic acid feed. There were about 57 components in the tower kettle products. The operating temperature of tower kettle was close to 160°C, which resulted in esterification, dehydration and isomerization reactions during distillation process. And some new aldehydes or ketones were formed during the process which influenced aldehyde content in propionic acid products. (2) There were 15 trace components in the propionic acid product were analyzed in GC-MS. Some components before and after reaction with sodium bisulfate were contrasted by gas chromatographs. It was shown that acetaldehyde, propionaldehyde, 3-methyl-1-pentane and 2-methyl-2-pentenal in propionic acid product were substances that mainly affected total aldehyde content. (3) Batch distillation were used to simulate crude propionic acid distillation process. When tower temperature was maintained at 141°C, the aldehyde content of side-propionic acid products was lower than 500 ppm and the purity was higher than 99.5 wt% which met the product requirements. After reducing operating temperature of the whole tower, total compositions of the tower kettle was significantly reduced, indicating that lowering operating temperature could make propionic acid product reach the standard by distillation process.

Key words:Propionic acid;Aldehyde content;GC-MS;Gas chromatography;Distillation;

目 录

摘 要 I

ABSTRACT II

第1章 概述 1

1.1 丙酸的性质及用途 1

1.2 丙酸合成方法 1

1.1.1乙烯羰基化合成法(Reppe) 1

1.1.2丙醛氧化法 2

1.1.3轻质烃氧化合成法 2

1.1.4生物氧化法 2

1.3 丙酸成分分析方法 3

1.3.1 丙酸产品国家标准 3

1.3.2 色谱分析 3

1.3.3 气质分析 4

1.4 丙酸精制方法 5

1.5 本文主要研究内容 6

第2章 实验 7

2.1 主要原料和试剂 7

2.1.1色谱标准样品 7

2.1.2分析试剂 7

2.2 主要仪器及设备 8

2.3 丙酸产品定性和定量分析方法 8

2.3.1 GC-MS全组分分析 8

2.3.2丙酸中微量组分含量测定 8

2.4丙酸中总醛含量测定 9

2.4.1 丙酸产品与亚硫酸氢钠反应实验 10

2.5 丙酸间歇精馏实验 10

第3章 结果与讨论 12

3.1 丙酸精馏系统物料组分分析 12

3.1.1 GC-MS全组分分析 12

3.1.2 醛或者酮结构分析 23

3.2 丙酸产品中组分含量 25

3.2.1 标样外标分析 25

3.2.2 亚硫酸氢钠反应前后丙酸产品GC分析 27

3.3 丙酸间歇精馏物料组成分析 28

3.3.1 醛含量滴定分析 28

3.3.2 塔釜产物GC-MS分析 29

第4章 结论与展望 33

4.1 结论 33

4.2 展望 33

参考文献 34

致谢 37

第1章 概述

1.1 丙酸的性质及用途

丙酸(propanoic acid),化学式为CH3CH2COOH,[1]是一种有三个碳的短链饱和羧酸。

国家日益发展[2-3],不管是工业生产还是日常生活,对丙酸的需求量逐年增大,而且对丙酸产品质量要求也不断提高。我国丙酸的生产用于各种行业,60%用于食品防腐剂,20%用于农药加工,20%用于生产香料。2000年后,我国丙酸需求迅猛增长。

纯的丙酸透明无色、有腐蚀性、可以燃烧,有一般羧酸物质的化学性质。丙酸有刺鼻性气味,可以刺激鼻腔呼吸道黏膜、皮肤,有低微毒性,如果有丙酸碰到皮肤,会有疼痛感,应立刻用大量水冲洗。

相关图片展示: