填料型复合氧化物催化氧化合成E-己内酯的工艺研究毕业论文

2021-03-11 23:23:57

摘 要

ε-己内酯作为一种重要的化工原料,在化工工业中有着广泛应用,所以ε-己内酯的合成生产研究具有重大意义。ε-己内酯合成反应中需要使用到催化剂,在此之前,催化剂的制备工作已经完成,确定使用镁锡钨复合氧化物作为合成反应的催化剂,但还需要合适的催化剂载体。本论文从催化剂的载体方面着手,旨在通过实验找到合适的催化剂载体,并找出合适的负载方法并对负载条件进行优化。

本实验使用浆液涂覆法进行催化剂的负载工作,首先通过一组单因素实验找出了合适载体:蜂窝陶瓷,之后进行了两组正交实验,分别找出了使用铝溶胶和硅溶胶进行催化剂负载时的优化条件,并将在优化条件下负载的催化剂进行表征,得到了负载后的催化剂的理化性能指标,最后进行了多次浸渍实验,找出浸渍次数和负载量之间的关系。通过本实验找出了合成ε-己内酯中催化剂的合适载体,完成了催化剂负载条件的优化工作,在优化条件下负载后的催化剂对反应的催化效果也很理想,转化率和选择性都在较高水平。

关键词:ε-己内酯;催化剂载体;负载条件

Abstract

ε -caprolactone as an important chemical raw materials, has a wide range of applications in the chemical industry, so ε-caprolactone synthesis production research is of great significance. ε-caprolactone synthesis reaction, the preparation of the catalyst has been completed and the use of magnesium-tin-tungsten composite oxide as a catalyst for the synthesis reaction is determined, but a suitable catalyst carrier is also required. In this paper, we start from the carrier of the catalyst, aim to find the appropriate catalyst carrier by experiment and find the appropriate loading method and optimize the working conditions.

In this experiment, the impregnation method was used to carry out the loading of the catalyst. Firstly, a suitable one was used to find the honeycomb ceramics. Then, two orthogonal experiments were carried out to find out the effect of using aluminum sol and silica sol. And the physical and chemical properties of the catalyst after loading were obtained. Finally, a number of impregnation experiments were carried out to find out the relationship between the number of impregnation and the loading. A suitable carrier for the synthesis of ε-caprolactone was found by this experiment. The optimization of the catalyst loading conditions was completed. Under the optimized conditions, the catalytic effect of the catalyst after the loading was also ideal, and the conversion and selectivity were all At a higher level.

Key words: ε-caprolactone; catalyst carrier; load condition

目 录

摘 要 I

Abstract II

第1章 绪论 1

1.1ε-己内酯概况 1

1.1.1ε-己内酯物理性质 1

1.1.2ε-己内酯化学性质 1

1.1.3ε-己内酯的用途 2

1.2 ε-己内酯的合成概况 3

1.2.1 ε-己内酯合成法 3

1.2.2合成ε-己内酯的原料 4

1.2.3合成ε-己内酯的催化剂 4

1.3催化剂载体概况 6

1.4研究内容及立题依据 6

1.4.1研究内容 6

1.4.2立题依据 7

第2章 催化剂载体的筛选 8

2.1试剂与仪器 8

2.1.1实验试剂 8

2.2.2实验仪器设备 8

2.2 BET测试 8

2.3 负载对比实验 10

2.4数据分析 10

2.5 本章小结 10

第3章 负载条件的选择与优化 12

3.1试剂与仪器 12

3.1.1实验试剂 12

3.1.2实验仪器 12

3.2正交实验 13

3.2.1正交实验的设计 13

3.2.2正交实验操作 14

3.3评价工作 15

3.4数据分析 16

3.4.1铝溶胶正交实验结果分析 16

3.4.2 硅溶胶正交实验结果 17

3.5负载催化剂后载体的表征 18

3.5.1 SEM 18

3.5.2 XRD 20

3.6多次浸渍实验 21

3.6.1铝溶胶的多次浸渍实验 21

3.6.2 硅溶胶的多次浸渍实验 22

3.6.3数据分析 23

3.7本章小结 23

第4章 结论及展望 24

4.1结论 24

4.2展望 24

参考文献 25

致 谢 27

第1章 绪论

1.1ε-己内酯概况

1.1.1ε-己内酯物理性质

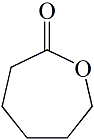

ε-己内酯(ε-CL)的单体是一种无色液体,它的相对密度为1.0693,沸点约98~99℃(一个大气压下),熔点约为-5℃,折射率为1.4611。它在水、乙醇、苯中易溶解,但不溶于石油醚等,加热时会变成二聚体或是高分子聚酯,当有氯化镁存在时,ε-己内酯能加热解聚。

1.1.2ε-己内酯化学性质

图1.1 ε-己内酯结构式