CHA分子筛膜的制备与氢分离性能研究毕业论文

2020-04-22 19:43:57

摘 要

分子筛膜具有规则的微孔结构和良好的热化学稳定性,被广泛应用于气体分离中。CHA分子筛呈三维八元环孔道结构,孔径为0.38 nm×0.38 nm,骨架硅铝比可以在2-∞区间进行调节,因而受到人们的广泛关注。本文采用二次合成法制备CHA分子筛膜并将其应用于氢气分离性能的研究中。

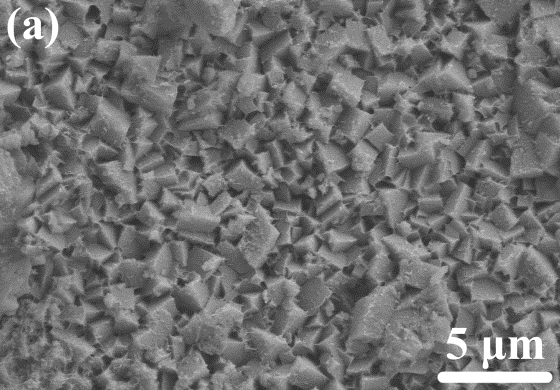

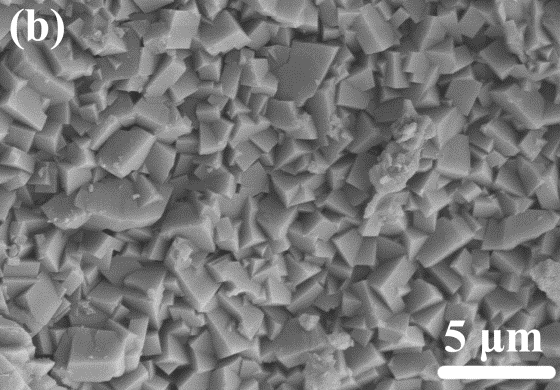

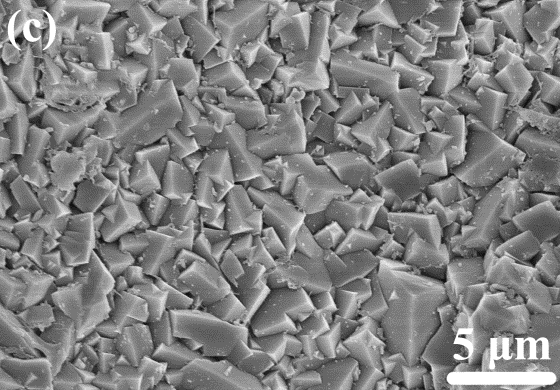

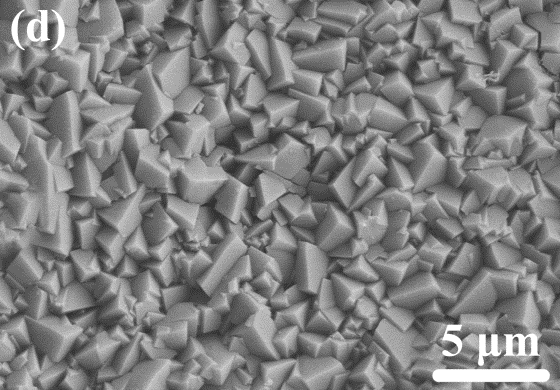

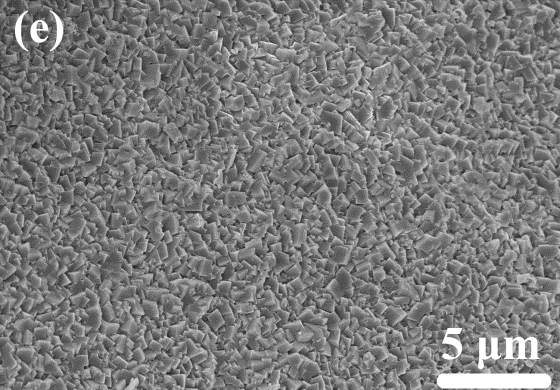

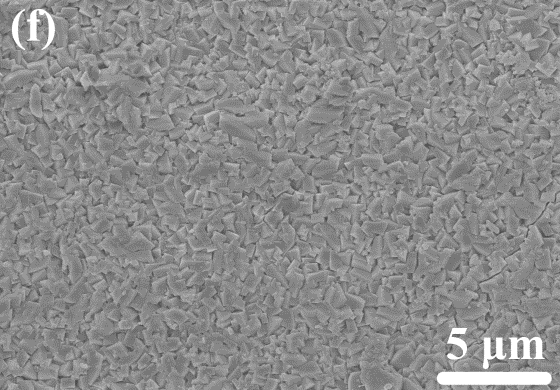

本论文首先以氯化胆碱为模板剂在四通道氧化铝中空纤维表面制备CHA分子筛膜,采用球磨CHA分子筛作为晶种,用浸渍提拉法在中空纤维表面得到均匀而又连续的CHA晶种层,系统考察了模板剂量、合成液硅铝比以及晶化时间对CHA分子筛膜性能的影响。实验结果表明,以球磨CHA分子筛为晶种,在413 K下,以28 SiO2 : 0.58 Al2O3 : 11.78 Na2O : 4.7-5.7 CC : 1260 H2O的比例配制合成液并水热晶化10 h,即可制备出性能优异的CHA分子筛膜。该条件下制备的膜表面致密,膜层厚度约8 μm。

将制备好的膜用于气体分离测试中,对于H2等分子动力学直径小于CHA分子筛孔道尺寸的气体具有较高的渗透性,在298 K时H2的渗透性达到13.17×10-7 mol∙m-2∙s-1∙Pa-1;而对于C3H8这类动力学直径较大的气体分子则相反,在298 K时C3H8的渗透性为2.66×10-7 mol∙m-2∙s-1∙Pa-1,此时H2/C3H8的分离性能为4.54。

关键词: 沸石分子筛 CHA分子筛膜 气体分离

Preparation and Hydrogen

Separation Research of CHA Zeolite Membranes

Abstract

Zeolite membranes were widely used in the separation of gases due to well-defined microporous structures and good chemical resistance. CHA zeolite has a three-dimensional pore structure containing an eight-membered ring with a pore diameter of 0.38 nm×0.38 nm, and the Si/Al ratio in the framework can be finely tuned from 2 to ∞, so CHA zeolite membranes have received extensive attention. In this paper, CHA zeolite membranes prepared by secondary synthesis were applied to the study of hydrogen separation performance. In this experiment, uniform and compact zeolite crystal films were prepared by dip-coating method with choline chloride as template and four-channel Al2O3 hollow fibers as support. The effects of template content, Si/Al ratio of synthetic liquid and crystallization time on the performance of CHA zeolite membrane were investigated systematically.

The preparation of four-channel Al2O3 hollow fiber CHA zeolite membranes by using choline chloride as template was studied first. A uniform and continuous CHA crystal layer was obtained with ball-milled CHA zeolite as seed crystal by dip-coating method. The effects of template content, Si/Al ratio of synthetic liquid and crystallization time on the performance of membrane were investigated systematically. The results indicated that high-quality CHA zeolite membranes were prepared from precursor 28 SiO2: 0.58 Al2O3: 4.7-5.7 CC: 11.78 Na2O: 1260 H2O at 413 K for 10 h. The surface of the zeolite membranes was dense, and the thickness of the membrane layer was about 8 μm.

The prepared membranes were used in the gas separation test. For gases with kinetic diameter smaller than the pore size of CHA molecular sieve such as H2, the permeability of H2 reached to 13.17×10-7 mol∙m-2∙s-1∙Pa-1 at 298 K. However, gas molecules with larger kinetic diameters such as C3H8 showed opposite cases, the permeation flux of C3H8 was 2.66×10-7 mol∙m-2∙s-1∙Pa-1 at 298 K, and the separation performance of H2/C3H8 was 4.54.

KEYWORDS: Zeolite molecular sieve; CHA zeolite membranes; gas separation

目录

摘 要 I

Abstract II

第一章 绪论 1

1.1 前言 1

1.2 膜分离技术 1

1.3 分子筛膜的研究概况 2

1.3.1 沸石分子筛 2

1.3.2 沸石分子筛膜 3

1.4 CHA分子筛膜研究现状 4

1.4.1 CHA分子筛简介 4

1.4.2 CHA分子筛膜研究进展 4

1.5 本文研究的内容和目的 5

第二章 CHA分子筛膜的制备与表征 7

2.1 合成方法 7

2.2 实验部分 7

2.2.1 实验仪器与试剂 7

2.2.2 CHA晶种的合成 8

2.2.3 分子筛膜的合成 8

2.3 CHA分子筛膜的表征 9

2.3.1 分析测试及表征方法 9

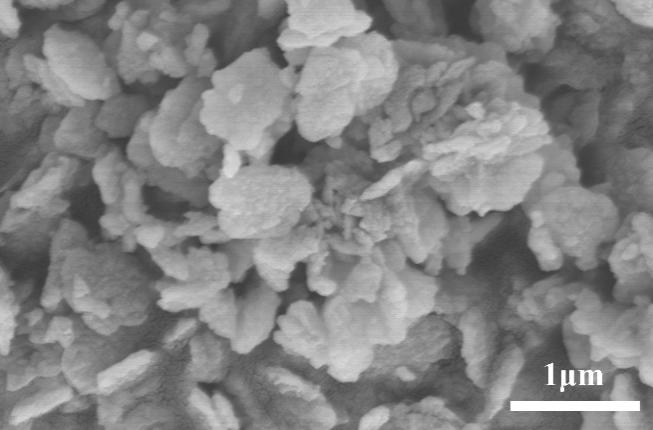

2.3.2 CHA分子筛晶种的表征 10

2.3.3 CHA分子筛膜的表征 10

2.4 本章小结 16

第三章 CHA分子筛膜的应用 17

3.1 实验部分 17

3.1.1 实验试剂及实验仪器 17

3.1.2 CHA分子筛膜的制备 17

3.1.3 气体分离测试 17

3.2 结果与讨论 18

参考文献 22

致谢 26

第一章 绪论

1.1 前言

作为一种重要的化工原料,氢气在化肥工业、石油化工与电子工业方面具有广阔的应用前景。目前化石燃料引起了许多环境问题,而氢气作为最清洁的能源,能够极好地避免这些问题[1]。在炼油厂的生产过程中,常常在大量氢气消耗的同时,存在相当一部分的氢气随尾气排放的现象,这造成了极大的浪费。与氢气资源匮乏相对应的是近年来柴油加氢以及加氢裂化装置生产能力的不断提升,这意味着巨大的成本[2]。以上种种极大地促进了制备与分离净化氢气技术的发展[3]。

目前,氢气分离方法主要有深冷分离、变压吸附以及膜分离。深冷分离方法的分离纯度很高但存在压缩冷却能耗较大的问题。变压吸附方法虽然能够适用于多种规模生产,但是其氢气回收率较低。相比较而言,膜分离因其设备简单能耗较低,且易于和其它分离过程结合等特点,因而具有巨大的应用前景[4]。

在一些石油化学工业生产过程中,如芳烃、柴油加氢及加氢裂化装置产生的酸性气、柴油加氢、加氢裂化低分气等含有大量氢气组分,同时还有一部分硫化氢、氮气及短链烷烃如丙烷等杂质影响了氢气的重复利用[2]。本文致力于通过对膜合成条件的优化,以达到对氢气和烷烃的良好分离性和稳定性。

相关图片展示: