聚砜基嵌段共聚物膜的溶剂退火与选择性溶胀研究毕业论文

2020-05-19 21:25:51

摘 要

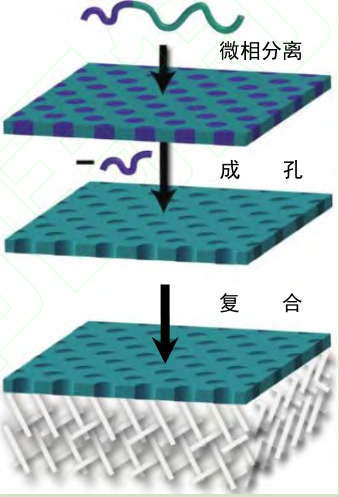

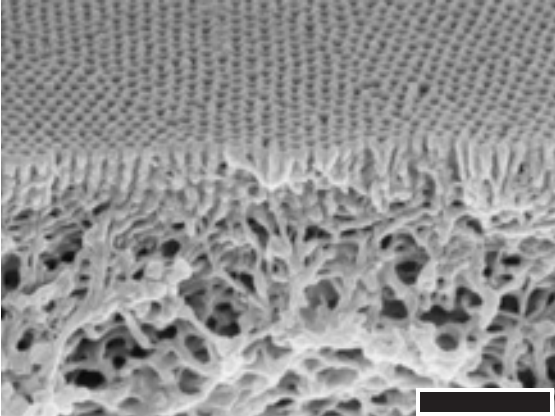

膜分离在水资源、能源、生态环境、传统工业上有广泛的应用,又因其高效节能、绿色环保、易耦合的优点,因此,可预见,在日后的清洁生产、环境保护与治理、资源利用上必将发挥着更加举足轻重的作用。而均孔膜由于其结构上孔径均一、孔道形状高度一致且垂直贯穿分离层,能有效克服传统多孔膜的Trade Off 效应,同步提升渗透性和选择性。嵌段共聚物,由于结构嵌段的热力学不相容性,而在共价键的束缚下,使其具有特殊的微相分离性质,在磁场、温度场、溶剂场等特殊条件下,通过自组装的方式,形成形状规整的分相结构,通过选择性受限溶胀的方法,将分散相转化为孔道。基于嵌段共聚物选择性受限溶胀制备均孔膜,具有操作简单、无质量损失、过程可逆、孔道表面功能化、孔道细小且高度规整等优点,在实现孔道纳米级、均一化的过程中,它的重要性不容忽视。

以四氢呋喃作为溶解嵌段共聚物聚砜-聚乙二醇(PSf-b-PEG)的溶剂,得到的孔结构优于本实验使用过的其他溶剂,为得到垂直或平行于基底的均孔结构,本实验研究了不同溶剂、退火时间、退火试剂、膜厚、基底对最终孔结构形貌的影响;通过加入溶剂蒸汽退火过程,以获得规整的分相结构,在选择性试剂的作用下,发生受限溶胀,选择性试剂挥发后,在主体相的支撑下,留下10-100 nm大小均一、贯穿整个分离层的孔道。

关键词:膜分离 均孔膜 嵌段共聚物 选择性溶胀 溶剂蒸汽退火

ABSTRACT

Membrane separation has shown a wide range of applications in the water, energy, environment and traditional industries, owing to its energy conservation, environmental protection, and the advantages of easy coupling with other processes, therefore. For the foreseeable, the uses of membrane separation will play a more pivotal role in the future cleaner production, environmental protection and governance and resources utilization. Homoporous membranes can overcome traditional Trade Off effects of the porous membrane by simultaneously enhancing the permeability and selectivity, due on their monodisperse pore size distribution and uniform pore configuration vertically highly consistent throughout the separation layer. Block copolymers, comprised of two or more chemically distinct chains covalently linked at one end, self-assemble into well-ordered morphologies, have a special micro-phase separation properties, under special conditions magnetic, temperature, solvent and other fields, through self-assemble manner, a shape of the regular phase separation structure by selectively constrained swelling of the method, the dispersed phase into the channel. The physical method of selectively constrained swelling play a vital role in the realization of the process of the nanoscale pores, because of the pore forming process extremely simple, no loss of quality, reversible process, surface functionalization pore, small pore and highly ordered.

Block copolymer polysulfone - polyethylene glycol (PSf-b-PEG) was dissolved in tetrahydrofuran (THF), the resulting pore structure better than other solvents used in this experiment. To obtain perpendicular or parallel to the substrate pore structure, the present experimental study of the influence of different solvents to the final pore morphology, including annealing time, annealing agents, film thickness and substrate; By adding a solvent vapor annealing process to obtain regular phase separation structure, selectively constrained swelling phenomenon occurs under the effect of selective solvent, after selective solvent volatilization, under the support of the main phase, leaving the 10-100 nm size uniform channel throughout the entire separation layer.

KEYWORDS:Membrane Separation; Homoporous Membranes; Block Copolymers; Selective Swelling; Solvent Vapor Annealing

目录

摘要 II

ABSTRACT I

第一章 绪论 1

1.1 嵌段共聚物 1

1.1.1 嵌段共聚物概念 1

1.1.2 嵌段共聚物微相分离和自组装 1

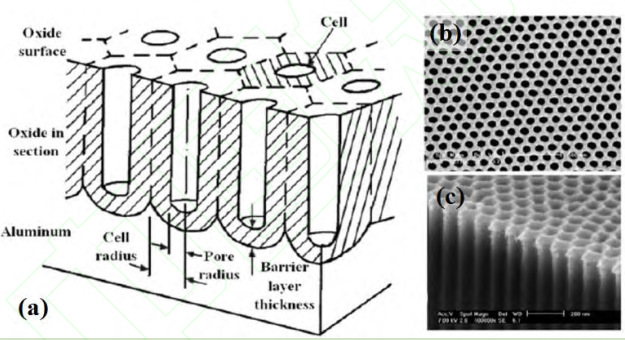

1.2 均孔结构的典型制备方法 3

1.2.1 阳极氧化 3

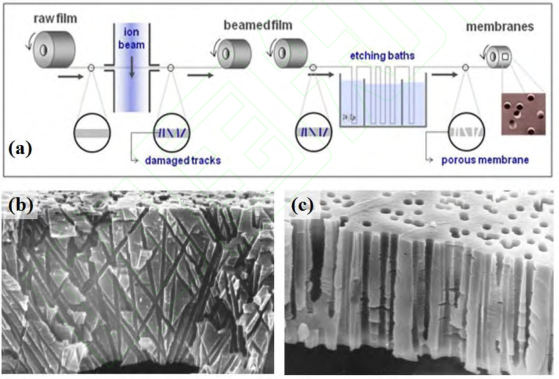

1.2.2 模板法 4

1.2.3 核径迹蚀刻 5

1.2.4 纳微加工 6

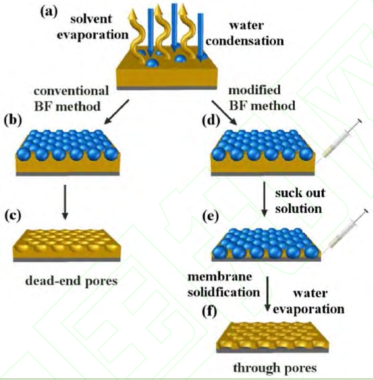

1.3 基于嵌段共聚物的均孔膜 7

1.3.1 选择性去除 7

1.3.2 非溶剂诱导相分离 8

1.3.3 选择性溶胀成孔 10

1.4 嵌段共聚物膜自组装纳米图案化取向控制方法简述 12

1.4.1 基底表面改性 12

1.4.2 电场诱导 13

1.4.3 溶剂蒸汽退火 14

1.5 本课题的研究思路和本论文的研究工作 14

1.5.1 研究思路 14

1.5.2 研究工作 15

第二章 实验部分 16

2.1 主要试剂和仪器 16

2.2 实验步骤及操作注意事项 18

2.3 溶剂蒸汽退火 19

2.4 膜厚影响 20

2.5 硅片基底改性 20

2.6 膜厚与形貌表征 21

第三章 结果与讨论 22

3.1 溶剂对成膜及孔结构影响 22

3.2退火试剂及退火时间对孔结构影响 24

3.2.1退火试剂影响 24

3.2.2退火时间影响 26

3.3 基底成孔结构影响 27

3.4 膜厚影响 29

3.5 湿度影响 30

第四章 总结与展望 32

4.1 总结 32

4.2 展望 32

参考文献 33

致谢 36

第一章 绪论

嵌段共聚物

嵌段共聚物概念

嵌段共聚物是两种或两种以上热力学不相容的聚合物链段,它们之间通过共价键连接[1]。嵌段共聚物链段的至少为两种,也可以为三种或多种,根据其连接方式,可分为线性的、梳型的、星型的等多种结构,如图1-1所示。实验室常用两嵌段或三嵌段共聚物,为获得较好的亲水性,常选用两亲嵌段共聚物,其中一段亲油,另一段亲水,在溶剂的作用下,可形成丰富的结构。

图 1‑1不同构型的嵌段共聚物

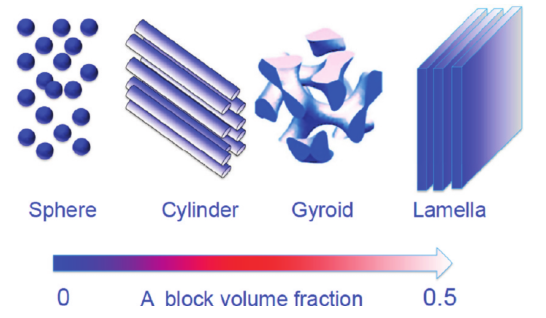

嵌段共聚物的数均分子量 Mn 、重均分子量Mw、分子量分布 PDI 以及各嵌段所占的体积分数 f 是合成嵌段共聚物时最主要的三个参数。

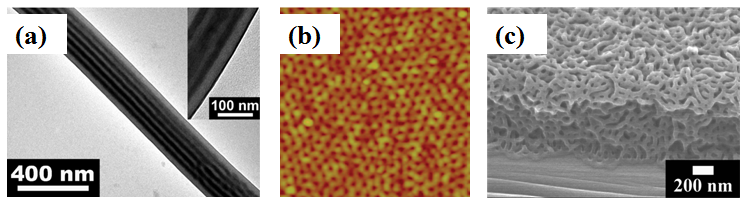

嵌段共聚物微相分离和自组装

嵌段共聚物由于其热力学性质的不相容,在特殊条件下会发生微相分离并自组装形成丰富的形貌结构,由于共价键的束缚,相比于宏观相分离,其分离尺寸被限制在纳米级,形成尺寸在5-100 nm的微结构,而嵌段共聚物的这个性质即被称为微相分离(Microphase Separation)[2]。

相关图片展示: