乘用车双横臂悬架系统设计及其运动特性分析软件开发毕业论文

2021-11-28 21:26:23

论文总字数:100200字

摘 要

本文以一型乘用车为研究对象,进行了双横臂前悬架的设计。考虑到普通乘用车的用途,选择了合适的悬架类型,对主要部件进行了设计计算,并通过仿真分析研究车轮定位参数的变化,最后借助MATLAB建立了人机交互式界面。

论文首先根据研究对象及设计类别选择了双横臂悬架作为设计对象。进行了悬架系统部件及前悬架的设计计算,获得了悬架的各个硬点坐标,运用ADAMS/Car根据硬点坐标进行模型建立,并针对车轮定位参数进行了双横臂悬架双轮平行跳动仿真实验,对各个参数随车轮跳动的变化曲线进行了分析。

接着运用ADAMS/Insight设计优化实验,对仿真实验中达不到设计要求的车轮定位参数进行优化设计,找出影响优化目标较大的高灵敏度硬点坐标,针对关键硬点坐标进行优化设计,对比优化后车轮定位参数曲线的变化,并多次重复实验,直至优化目标达到设计要求。

最后根据设计计算的步骤,利用MATLAB GUI设计能够良好反映悬架设计过程的人机交互式界面,用程序语言将计算过程固定下来,形成输入参数便可自动计算的交互式界面,提高悬架设计效率,省去冗杂的重复计算过程

关键词:双横臂悬架;悬架设计;ADAMS仿真;硬点坐标优化;人机交互界面

Abstract

In this paper, a type of passenger car is taken as the research object, and the design of double wishbone front suspension is carried out. Considering the use of ordinary passenger cars, the appropriate suspension type is selected, the main components are designed and calculated, and the changes of wheel alignment parameters are studied through simulation analysis. Finally, the human-computer interface is established with MATLAB.

Firstly, according to the research object and design category, the double wishbone suspension is selected as the design object. The whole design and calculation of the suspension system components and front suspension are carried out, and the hard point coordinates of the suspension are obtained. The model is established according to the hard point coordinates by using ADAMS / car. The simulation experiment of the parallel run out of the double wishbone suspension is carried out for the wheel alignment parameters, and the curves of the parameters with the wheel run out are analyzed.

Then using ADAMS / insight to design the optimization experiment, optimizing the wheel alignment parameters which can not meet the design requirements in the simulation experiment is the next step, find out the high sensitivity hard point coordinates which have great influence on the optimization goal, optimize the key hard point coordinates, compare the changes of the wheel alignment parameter curve after optimization, and repeat the experiment many times until the optimization goal reaches the design requirements.

Finally, according to the steps of design and calculation, we use Matlab GUI to design a man-machine interactive interface which can reflect the design process of suspension well. We use programming language to fix the calculation process and form an interactive interface where input parameters can be calculated automatically, so as to improvethe efficiency of suspension design and save redundant and repeated calculationprocess.

Key Words:Double wishbone suspension; suspension design; ADAMS simulation; hard point coordinate optimization; human computer interface

目 录

摘 要 I

Abstract II

ChapterⅠ Introduction 1

1.1Research background and significance 1

1.2Research status of suspension at home and abroad 2

1.3Main research contents of the paper 3

1.4Summary of this chapter 4

ChapterⅡ Structural design of suspension system 5

2.1Selection of suspension type 5

2.2Selection of frequency deviation,static deflection and dynamic deflection of front and rear suspension 8

2.3Design and calculation of elastic elements 10

2.3.1The selection of the ratio of spring winding 10

2.3.2Calculation of spring force and spring stiffness 11

2.3.3Calculation of basic parameters of spring 12

2.3.4Calculation and check of torsion stress of spring 13

2.4Design and calculation of shock absorber 14

2.4.1Selection of relative damping coefficient ψ 15

2.4.2Determination of the damping coefficient of shock absorber 16

2.4.3Determination of the maximum unloading force 17

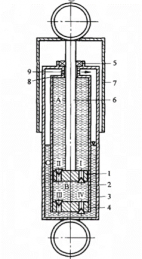

2.4.4Selection of main size of shock absorber 18

2.4.4.1Determination of the diameter D of the working cylinder of the shock absorber 18

2.4.4.2Determination of the diameter of the oil storage tank 18

2.5Camber stiffness of double wishbone independent suspension 19

2.6Design of guiding mechanism of double wishbone independent suspension 20

2.6.1Requirements for front wheel independent suspension guide mechanism 20

2.6.2The design of the hard point coordinate of the suspension guide mechanism 20

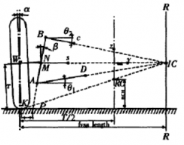

2.6.2.1Design of the length of upper and lower cross arms 20

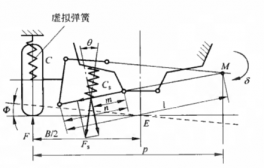

2.6.2.2Design calculation in transverse plane 21

2.6.2.3Design calculation in longitudinal plane 22

2.6.2.4Design calculation in horizontal plane 24

Chapter Ⅲ kinematics simulation analysis of double wishbone suspension 28

3.1Introduction to ADAMS software 28

3.1.1Overview of ADAMS software 28

3.1.2Adams / car simulation process 29

3.2The establishment of double wishbone front suspension model 30

3.2.1Space structure of double wishbone front suspension 30

3.2.2Simulation experiment of two wheels parallel run out of double wishbone front suspension 32

3.2.2.1Analysis of camber angle 33

3.2.2.2Analysis of toe angle 35

3.2.2.3Analysis of caster angle 36

3.2.2.4Analysis of kingpin inclination angle 36

3.3Summary of this chapter 37

Chapter Ⅳ optimization design of double wishbone suspension 38

4.1Overview of ADAMS / insight 38

4.2Optimization process 39

4.2.1Sensitivity analysis of optimization factor 39

4.2.2Optimized post-processing based on ADAMS / insight 40

4.3Analysis of optimization results 41

4.4Summary of this chapter 43

Chapter Ⅴ design of software interactive interface of double wishbone suspension based on MATLAB 44

5.1Introduction to Matlab software 44

5.2Matlab GUI interface design 45

5.2.1Overview of Matlab GUI 45

5.2.2Introduction of Matlab GUI interface 45

5.2.3.2Calculation interface of coil spring 51

5.2.3.3Calculation interface of shock absorber 53

5.2.3.4Calculation of suspension roll stiffness 55

5.2.3.5GUI general interface display 56

5.3Summary of this chapter 57

Chapter VI summary and Prospect 58

6.1Summary 58

6.2Research prospect 59

Thank 60

Reference 61

Appendix 63

ChapterⅠ Introduction

1.1Research background and significance

Passenger cars include sedans, minibuses and light buses with no more than 9 seats. In recent years, the production and export of passenger cars in China are increasing year by year. With the gradual popularization of passenger cars in households, users have higher and higher requirements for the performance of passenger cars. Passenger cars should have good power and economy, but also good handling Stability and ride comfort.

As one of the most important parts of the passenger car chassis system, suspension can transfer the force and torque between the body or frame and wheel, and reduce the impact on the vehicle, which has a great impact on the performance of the vehicle. The suspension is divided into independent suspension and non independent suspension. The traditional non independent suspension has been difficult to meet the requirements of driving comfort and handling stability of passenger cars. Therefore, the non independent suspension such as leaf spring suspension is only used in medium-sized or heavy-duty vehicles at present, while the independent suspension is widely used in light-duty trucks and light-duty passenger cars. This kind of suspension has unsprung quality Compared with non independent suspension, it has the advantages of small volume, less space occupied, less body roll, and better ride comfort. As a traditional independent suspension, double wishbone independent suspension is widely used in many passenger cars. For the unequal length double wishbone suspension, as long as the length of upper and lower wishbones is properly selected and optimized, and through reasonable arrangement, the changes of wheel track and front wheel alignment parameters can be within the acceptable limits, so as to ensure the good driving stability of the vehicle. With the continuous development of science and technology, vehicle designers gradually apply various kinds of design and simulation software, and use CAD / CAE technology for simulation analysis and optimization design, which simplifies the design process of vehicle and suspension, and greatly improves the design efficiency.

请支付后下载全文,论文总字数:100200字

相关图片展示: