车用SiC高温压力传感器设计与制造工艺毕业论文

2021-12-05 17:31:04

论文总字数:31755字

摘 要

现阶段,智能化、网联化已经成为汽车行业的主要发展趋势,传感器在车辆中的应用也愈发重要。比如通过传感器测量出发动机的排气压力对于改善车辆的动力性与经济性有着重要意义,但是普通的传感器无法承受发动机的排气温度,所以研制出能在高温恶劣环境下应用的压力传感器对于汽车工业的进步有着重要意义。

由于Si基压力传感器存在着高温漏电的问题,而作为第三代宽禁带半导体材料,SiC则具有优秀的机械、电子以及化学性能,在制作压力传感器方面具有广阔的应用前景。所以目前SiC高温压力传感器已经成为耐高温压力传感器方面的主要研究趋势。

基于上述应用背景以及技术背景,本文的主要目标为研制出一款压阻式高温压力传感器。该传感器的最高工作温度为600℃,量程为2MPa。主要研究内容包括传感器芯片与封装的设计、传感器性能的仿真分析以及芯片加工工艺流程与工艺参数的制定。具体研究内容如下:

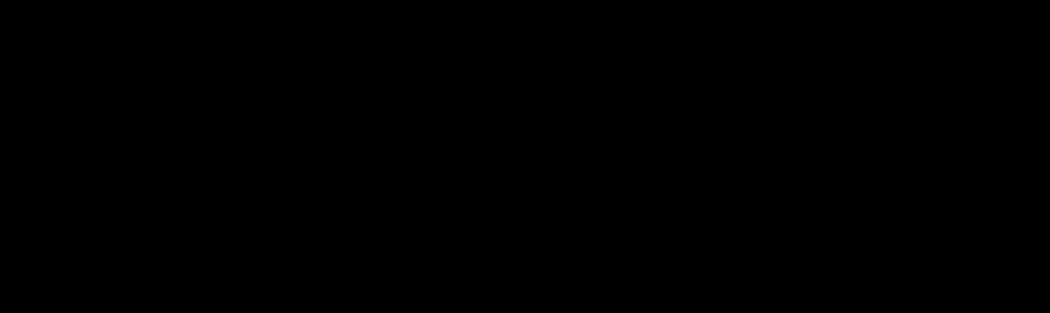

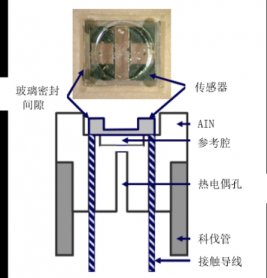

首先,根据灵敏度原则与线性原则,利用材料力学相关理论,设计了芯片的尺寸,并且根据ANSYS仿真结果进行了敏感膜片的结构选型。除此以外,还确定了压敏电阻的阻值、尺寸以及布置方案。之后,针对传感器的封装方案进行了设计,在结构上采用无引线封装方式,在材料上选用AlN为封装基体,玻璃胶为粘合材料。

接着,对于上述设计的传感器,进行输出特性、谐响应以及热效应仿真分析。通过有限元仿真与路径积分的方法得到传感器的灵敏度为76.59mV/MPa,线性度为与0.67%。利用ANSYS进行了芯片的模态分析,得到其前六阶振型与固有频率。并且以模态分析的结果为基础进行了谐响应分析,得到了芯片的振幅响应。利用ANSYS仿真分析了芯片在常温下工作时的热效应,同时还针对封装后的芯片在高温下的热应力进行了仿真分析。从仿真结果可以看出,所设计的芯片的尺寸结构以及封装方案在高温环境下能够保证传感器的工作性能。

最后,针对芯片的加工工艺展开了研究。主要确定了芯片加工的具体工艺流程、加工方法以及目标参数。深入探索了同质外延掺杂、深刻蚀与浅刻蚀、欧姆接触这几项关键工艺。设计并且绘制了在光刻工艺中需要用到的掩膜版版图。

关键词:碳化硅,高温,压力传感器,输出特性,加工工艺

Abstract

At the present stage, intelligence and networking have become the main development trend of the automobile industry. The application of sensors in vehicles has become increasingly important. For example, the measurement of exhaust back pressure has an important impact on the dynamic performance and economy of the vehicle. However, ordinary sensors cannot bear the exhaust temperature of the engine. Therefore, the development of pressure sensors that can be applied in the high-temperature and harsh environment is of great significance to the progress of the automobile industry.

The Si-based pressure sensor has the problem of electricity leakage at high temperature. As the third-generation wide-gap semiconductor material, SiC has excellent mechanical, electronic and chemical properties and has a broad application prospect in the fabrication of pressure sensors. Therefore, the SiC-based pressure sensor has become the main research trend of pressure sensor used in high temperature.

Under the above background, this paper is devoted to the development of a piezoresistive high temperature pressure sensor that can work at a high temperature of 600℃. The main research content includes the design of the sensor chip, the design of the sensor package, the simulation of the sensor performance, and the formulation of the chip processing process flow and process parameters. Specific research contents are as follows:

Firstly, according to the principle of sensitivity and linearity, the size of the chip is designed by using the theory of mechanics of materials, and select the structure of the sensitive diaphragm based on the simulation results of ANSYS. At the same time, the size, resistance value and layout scheme of the varistor are also designed. After that, the packaging scheme of the sensor is designed. The structure of the sensor is sealed without lead, and AlN was used as the packaging matrix and glass glue as the bonding material.

Then, for the sensor designed above, the output characteristic, harmonic response and thermal effect are simulated and analyzed. The sensitivity and linearity of the sensor are respectively 76.59mV/MPa and 0.67%. The first six modes and natural frequencies of the chip are obtained by means of ANSYS.Based on the results of modal analysis, the harmonic response is analyzed and the amplitude response of the chip is obtained. The thermal effect of the chip under normal temperature is simulated by ANSYS, and the thermal stress of the packaged chip under high temperature is simulated. According to the results, the design of chip size and structure and packaging scheme can ensure the performance of the sensor in high temperature environment.

Finally, the processing technology of the chip is studied. The specific process flow, processing method and target parameters of chip processing are determined. The key processes of homogeneous epitaxial doping, deep and shallow etching and ohmic contact are explored. The layout of the mask plate used in the lithography process is designed and drawn.

Keywords: SiC, High Temperature, Pressure Sensor, Output Characteristics, Processing Technology

目录

第1章 引言 1

1.1研究背景 1

1.2国内外研究现状 2

1.2.1压力传感器发展历史 2

1.2.2 SiC高温压力传感器研究现状 3

第2章 传感器芯片与封装设计 5

2.1引言 5

2.2压阻式传感器的原理 5

2.2.1压阻效应 5

2.2.2小挠度薄板理论 6

2.2.3惠斯通电桥 6

2.3压力芯片的设计 7

2.3.1敏感膜片尺寸设计 7

2.3.2敏感膜片结构选型 8

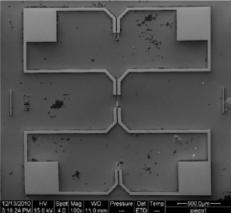

2.3.3压敏电阻设计 10

2.4 封装设计 12

2.4.1封装要求 12

2.4.2封装方案 13

第3章 传感器性能仿真分析 14

3.1引言 14

3.2传感器输出特性仿真分析 14

3.3传感器芯片谐响应仿真分析 17

3.4传感器热效应仿真分析 19

3.4.1芯片热分析 19

3.4.2封装芯片热应力分析 21

第4章 制造工艺与版图设计 25

4.1引言 25

4.2工艺流程设计 25

4.3关键加工工艺研究 27

4.3.1同质外延掺杂 27

4.3.2深刻蚀与浅刻蚀 28

4.3.3欧姆接触 30

4.4掩膜版版图设计 31

第5章 结论 34

5.1研究结果 34

5.2工作展望 35

参考文献 36

致谢 38

第1章 引言

1.1研究背景

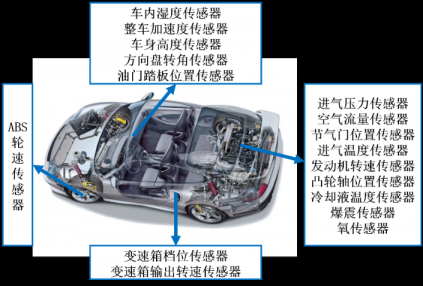

随着科学技术的不断发展与社会生活的进步,我国的机动车保有量不断增加,汽车工业快速发展,智能化、网联化已经成为主要发展趋势。面对汽车行业巨大的变革,电子技术领域的创新愈发重要。如图1所示,作为监测车辆运行状态的装置,传感器在汽车上的使用数量通常为几十只,在豪华轿车上甚至达到上百只。传感器不断增加的功能以及先进的技术能够提升汽车的安全性、可靠性以及其他各方面的性能[1]。因此,传感器技术的革新与发展对于汽车工业的进步有着十分重要的意义[2]。

请支付后下载全文,论文总字数:31755字

相关图片展示: