汽车动力电池热管理系统设计与分析毕业论文

2020-04-05 10:54:01

摘 要

本文以纯电动客车为研究对象,针对其动力电池的热管理系统进行设计与仿真分析,从而使动力电池的温度控制在合理的范围之内,提高动力电池的效率和寿命以及整车的安全性。

本文首先根据电动客车的基本性能参数和目标需求对整车的动力系统进行参数的选取以及设计,为后文的热管理系统的设计奠定了基础;分析电池的生热机理和传热特性,构建电池的生热模型,计算相关热物性参数和生热速率,为之后的三维仿真的热源设置提供依据;对不同工况条件下进行热分析,针对高倍率工况下电动客车的热管理系统主要是风冷系统进行设计,包括风道的设计以及风扇的选取,并对设计出的冷却系统进行三维仿真分析,仿真结果表明冷却系统的散热效果基本达到预期目标要求。

关键词:电动客车;动力电池;热管理;三维仿真

Abstract

This article takes the electric bus as the research object, carries on the design and the simulation analysis to its thermal battery's thermal management system, thus causes the battery temperature to control within the reasonable scope in order to enhance the power battery's efficiency and the life time as well as the vehicle safety.

Firstly, according to the basic performance parameters and target requirements of the electric bus, this paper selects and designs the parameters of the power system of the vehicle, which lays the foundation for the design of the thermal management system.

The heat generation mechanism and heat transfer characteristics of the battery are analyzed. A battery's heat model is built. The related thermal properties and heat rate are calculated, which provides basis for heat source setting in 3D simulation.

The thermal analysis under different working conditions are performed. The air cooling system is mainly designed under high-magnification discharging conditions, including the design of the air duct and the selection of the fan. The 3D simulation of the designed cooling system is performed. The simulation results show that the cooling effect of the cooling system basically meets the desired target.

Key Words:electric bus;power battery;thermal management;3D simulation

CONTENTS

Chapter 1 Introduction 1

1.1 The Purpose and Significance of the Study 1

1.2 Development and Research Status of Power Battery Thermal Management System 2

1.2.1 Air Cooling 3

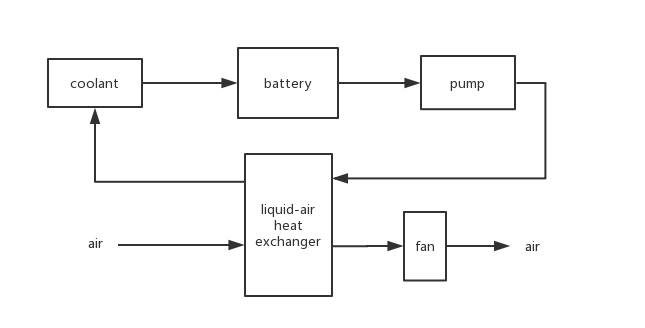

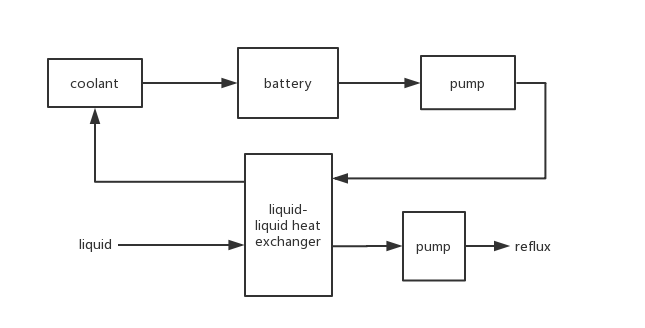

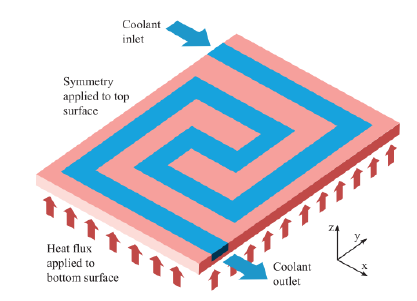

1.2.2 Liquid Cooling 4

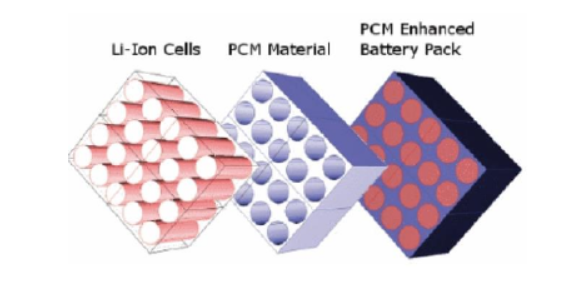

1.2.3 Phase Change Material Cooling 6

1.3 The Main Research Content of This Paper 6

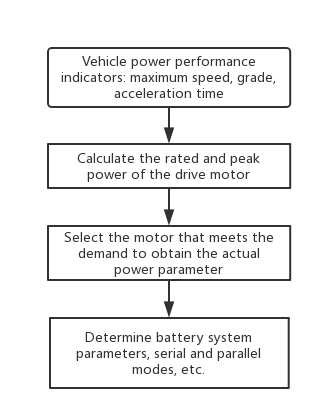

Chapter 2 Pure Electric Bus Power System Design 8

2.1 Vehicle Performance Parameters and Target Performance Requirements 8

2.2 Motor Parameter Matching 9

2.3 Power Battery Parameter Matching 10

2.3.1 Power Battery Performance Parameters 11

2.3.2 Battery Selection 11

2.3.3 Battery Total Energy Matching 13

2.3.4 Battery Parameter Acquisition 14

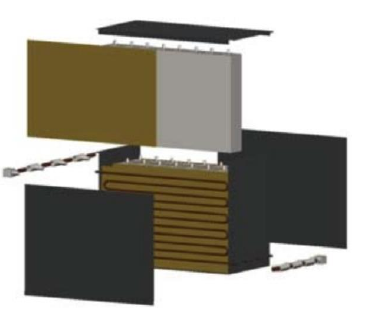

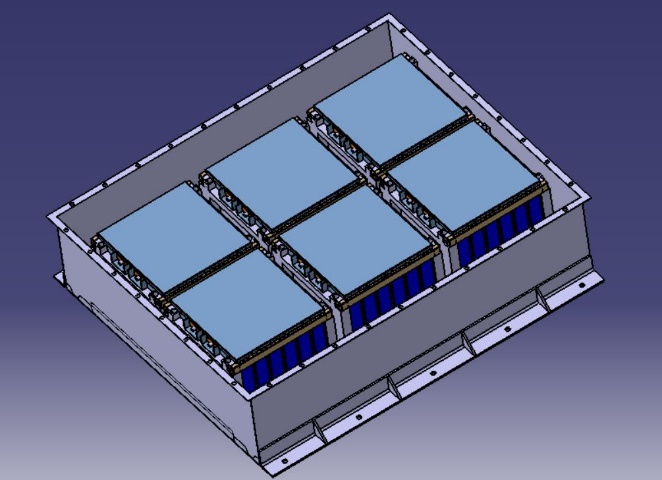

2.3.5 Module and Battery Pack Design 15

Chapter 3 Power Battery Thermal Modeling 18

3.1 Power Battery Heating Mechanism 18

3.2 Heat Transfer Characteristics of the Battery Pack 19

3.2.1 The Way of Heat Transfer In Battery Pack 19

3.2.2 Battery Heat Transfer Process 20

3.3 Power Battery Thermal Model Establishment 20

3.3.1 Battery Thermal Model 20

3.3.2 Battery Thermal Property Parameters Acquisition 21

3.3.3 Heat Rate Acquisition 23

3.3.4 Initial and Boundary Conditions 24

Chapter 4 Power Battery Thermal Management System Design 25

4.1 Thermal Analysis of Battery Packs 25

4.2 Air-duct design 26

4.3 Fan Selection 27

4.3.1 Fan Required Parameter Acquisition 27

4.3.2 Fan specification selection 29

4.4 Thermal Flow Simulation and Result Analysis of Battery Pack 30

4.4.1 Modeling and meshing 30

4.4.2 Related condition settings 31

4.4.3 Analysis of simulation results 33

Chapter 5 Summary and Outlook 37

5.1 Summary 37

5.2 Outlook 38

References 39

Thanks 41

Chapter 1 Introduction

1.1 The Purpose and Significance of the Study

With the continuous development of society, social problems such as energy crisis and environmental deterioration have become increasingly prominent. Among the automotive industry, the development of new energy vehicles is imperative. The development status in recent years is not difficult to see, in sharp contrast with the slowdown in the growth of the traditional automotive market, China's new energy vehicles show a booming production and sales situation, the development of new energy vehicles has been strongly supported by policies. The most prominent area is public transportation, it has been observed that the number of buses driven by internal combustion engines is significantly reduced, and the number of new energy vehicles driven by power batteries is gradually increasing. Among them, pure electric buses have already occupied a large proportion in the entire bus field

As the only power source for pure electric buses, the power battery has a direct impact on the overall performance of the vehicle. With the continuous improvement of the automotive performance requirements of the market, that is the higher requirements for power batteries, in the case of existing battery technology is difficult to break through, the battery can be maintained under normal operating conditions through external conditions, so as to achieve its maximum performance, but too high or too low temperature conditions greatly affect the performance of the battery. Taking a lithium-ion battery as an example, the temperature has a great influence on various parameters of the lithium-ion battery, including charge and discharge capacity, battery internal resistance, and battery life. The electrochemical reaction inside the battery will increase the heat release under high temperature conditions, which will further increase the battery temperature. At the same time, the high temperature will accelerate the aging of the electrolyte, electrodes and separators, and the battery performance will decrease. The high temperature of the battery will not only cause its performance to attenuate, but also causes potential safety hazards. When the battery temperature exceeds a certain threshold, a series of exothermic reactions will occur inside the battery, such as the thermal decomposition of the electrolyte, negative electrode, and positive electrode. When the positive and negative electrodes thermally decompose, they will also react with the electrolyte, which will further increase the temperature of the battery and cause great danger. On the other hand, if the battery's heat generation rate is greater than its heat dissipation rate, its internal temperature will rise and cause the active material to decompose, which reacts with the electrolyte to release gas and causes the battery to bulge, or even explode. Under low temperature conditions, the battery's charge and discharge capacity will drastically decrease, causing irreversible decay of the battery capacity. The internal resistance of the battery will increase dramatically, resulting in poor battery performance at low temperatures, such as difficult charging and discharging. And the batteries are assembled in a car, because the tight space leads to the tight arrangement, so during the charge and discharge process, there will be different heat accumulation inside the battery pack, the temperature inside the battery pack will be uneven, and the capacity gap between the batteries will become larger and larger. As a result, certain cell batteries reach the cutoff voltage in advance during charge and discharge, and the battery's charge and discharge efficiency decreases.

To sum up, in order to ensure that the battery operates within a suitable temperature range, and to ensure the consistency of the internal temperature of the battery pack, thereby improving the battery performance and personnel safety, the thermal management of the power battery needs to be studied and designed.

This article takes a pure electric bus as the research object and designs the thermal management system of the power battery system so that the battery pack can dissipate heat in time, thereby ensuring that the battery pack is within a suitable temperature range and the uniformity of the temperature field distribution, improving the safety of the battery, extending the battery life, and ensuring the car's driving performance.

1.2 Development and Research Status of Power Battery Thermal Management System

The battery thermal management technology is to solve the problem of thermal runaway or low performance of the battery under extreme temperature conditions and to improve the overall performance of the battery. To do this, it is necessary to understand the effect of temperature on the battery, the heat generation mechanism and heat transfer characteristics of the battery itself, and the optimal operating temperature range of the battery.

The work related to battery thermal management in foreign countries was first carried out in the 1980s. Domestic battery thermal management was first proposed by Dr. Zhang in the 1990s, but it was not paid enough attention at the time. With the development of electric vehicles today, people's pursuit of power battery performance continues to increase. With the modularization of the battery, the performance of the battery caused by the heat generation has become increasingly significant, and the research on the thermal management of the battery has been continuously carried out.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: