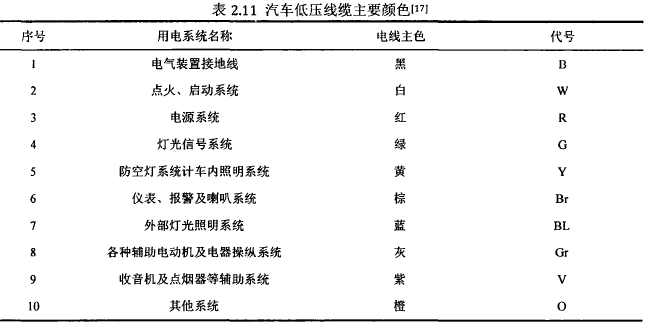

重载无人驾驶电动集装箱运输车电池系统设计与分析毕业论文

2020-04-09 15:25:55

Graduate design of Wuhan University of Engineering

Design and analysis of battery system for heavy-duty unmanned electric container transportation vehicle

College (Department): International College of Education

Professional class: vehicle gj1402

Student Name:_______Li Shi

Instructor:_________ Qin XunPeng

Original Statement of degree thesis

I solemnly declare that the paper presented is the research results obtained by my independent research under the guidance of the tutor. In addition to the content specifically cited in the text, this paper does not include any other individuals or groups have published or written results. I am fully aware that the legal consequences of this statement are borne by me.

Author Signature:

year Month Day

Authorization for the use of copyright in a dissertation

The author of this dissertation is fully aware of the school's provisions on the protection and use of dissertations, and agrees that the school should keep and send copies and electronic versions of papers to the relevant degree thesis Management Department or institution, allowing the papers to be consulted and borrowed. I authorize the provincial excellent bachelor thesis selection organization to compile all or part of the contents of the dissertation into the relevant data for retrieval, which can be used for the preservation and compilation of the dissertations by means of photocopying, reducing or scanning.

This degree thesis belongs to 1 , Confidential Kou, in apply this license after year of decryption

2 , non-confidential Kou .

(please play in the appropriate box above √ )

Author Signature: year month Day

Mentor Signature: year month Day

(Note: This page content binding in the title of the paper)

Abstract

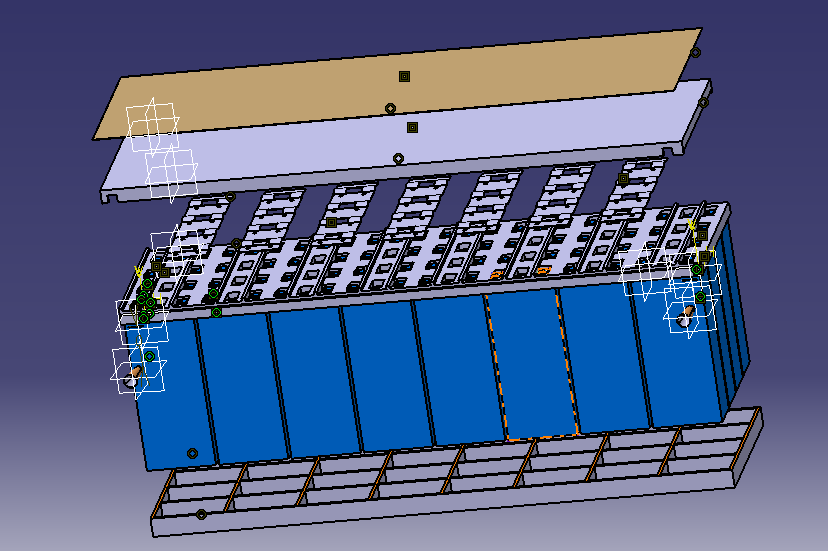

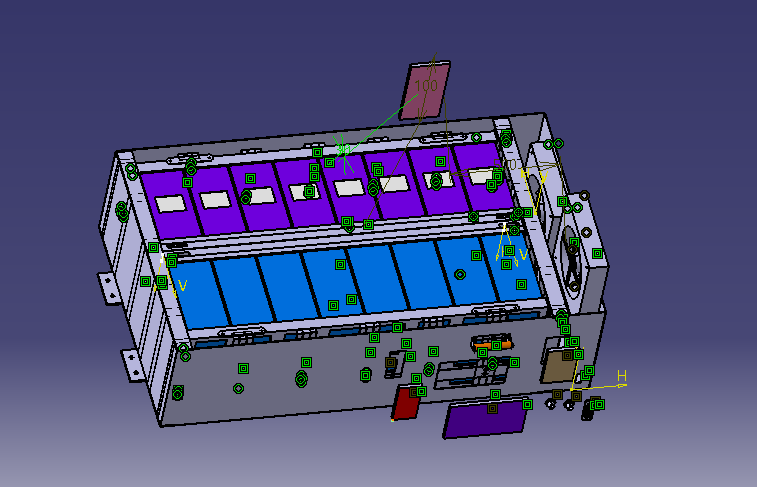

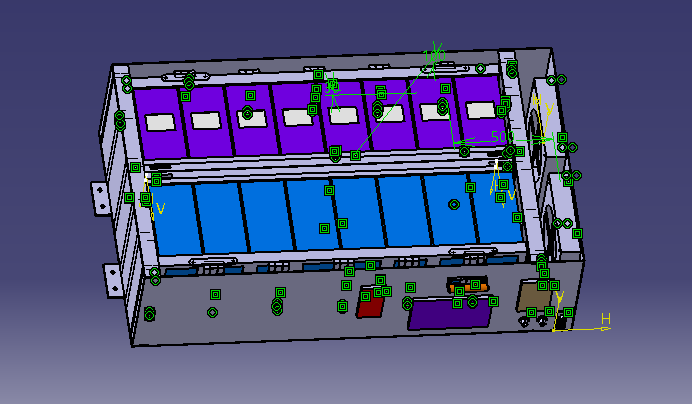

With the development of the port logistics which are going for large-scale, large-flow, high-speed. Large-scale container ships, large-tonnage containers, and the loading, unloading equipment and the supporting large-scale shore bridges have been built for it. This article mainly designs and analyzes the battery system of heavy-duty unmanned electric container transporter. After consulting the literature, and analyzing the environmental conditions and working requirements of the port AGV, finally GYS LIM50H-12 lithium ion battery is chosen as the battery module for the project, according to the data of the electric drive system from my partner to calculate the required power and he requirements of the target model to design The parameters of the electric vehicle system reasonably, determine the basic structure of a single battery pack, that is, 8 battery cells are connected in parallel to form a battery module, and 8 battery modules are connected in series to form a power battery pack. I designed the overwrap and the fixed way of the battery pack in view of the design of the car's driving conditions and speed. Simplified the battery cell model for temperature field analysis.

Key words: pure electric vehicle, battery pack, mechanical structure, thermal analysis

目 录

Chapter 1 Chapter Introduction 5

1.1 background and significance 5

1.2 research developments and trends at home and abroad: 6

1.2.1 Domestic Research Developments 6

1.2.2 Research Trends Abroad 6

Chapter 2 chapter battery pack Mechanical structure Design 8

2.1 Basic requirements for the design of the battery pack mechanical structure 8

2.2 Determination of basic parameters for battery pack 9

2.2.1 Power System Parameters 9

2.2.2 Determine the basic parameters of the power system 9

2.2.3 Determination of power system capacity 9

2.2.4 structure of the power system 10

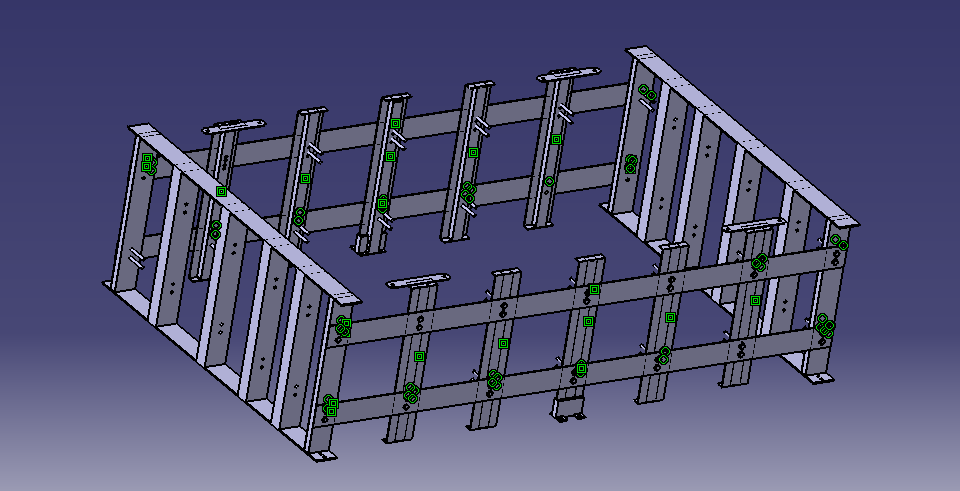

2.2.5 Battery pack Framework Design 12

2.3 Battery Module Design 14

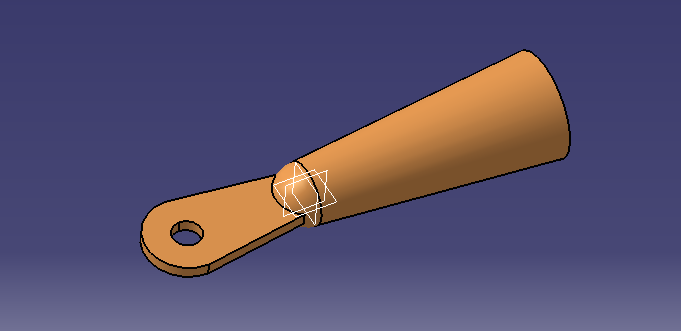

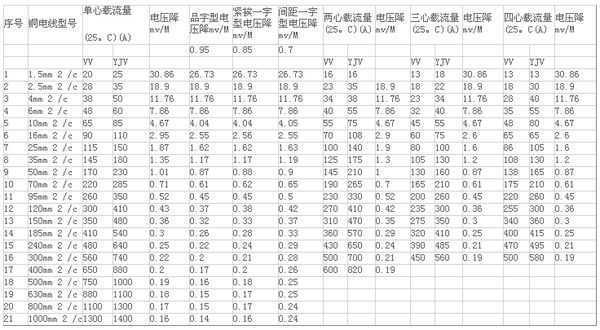

2.3.1 bus and copper nose design. 14

2.3.2 Battery Module Specific Energy 16

2.3.3 Processing technology for battery modules 16

2.4 battery pack Structure Design 17

2.4.1 placement of the battery module in the battery pack 17

2.4.2 Battery fixed structure design 17

2.4.3 design of battery pack cooling structure 18

2.5 Battery pack Box design 22

2.6 battery pack model and physical drawings 24

2.7 Summary of this chapter 25

Chapter 3 Battery pack Thermal Analysis 26

3.1 theoretical basis of the thermal model of lithium-ion batteries 26

3.1.1 thermal principle of lithium-ion battery 26

3.1.2 Heat transfer inside the battery 28

3.1.3 how the battery and external heat transfer 30

3.2 Lithium-ion battery thermal model establishment 32

3.2.1 Building a battery thermal model 32

3.2.2 determination of cooling mode and simplification of simulation conditions 33

3.2.3 Battery Thermal Analysis 34

3.3 Summary of this chapter 36

Chapter 4 The summary and Prospect 36

4.1 summary 36

4.2 prospects 37

References (Bold second number) 37

Thanks 38

Chapter 1 Chapter Introduction

1.1 background and significance

The automated guided vehicles, AGV, also known as an unmanned van, appeared in the century era, is an automated unmanned intelligent handling device, which belongs to the mobile robot system and can drive along a predetermined path. it is one of the key equipment in the modern industrial automation logistics system such as computer Integrated manufacturing system (CIMS) . The AGV has the characteristics of high flexibility and intelligence, and can reorganize the system to reach the flexible transportation in the production process easily. Compared with the traditional manual or semi artificial material conveying methods, the AGV system reduces the labor intensity, lower the risk and increases the production efficiency, plays an important role in all walks of life.

Primarily the early AGV was an automated trailer. In the middle of the century era, the AGV industry developed greatly for the first time due to the introduction of the load AGV ( also known as Automatic van ) . Load AGV is widely accepted for providing multi-functional services in the field of material handling, such as work stations in factories, transmission equipment, and connections between the control systems and information system. At present, there are hundreds of kinds of load AGV system have been produced by many manufacturers, working in warehouses, factories, workshops, hospitals and many other areas.

In the post offices, libraries, stations, docks and airports, the transportation of goods has some features such as a large amount of changes in the volume of work, dynamic, and often adjust the operation process, as well as the process of handling a single operation. The parallel operation, automation, Intelligent and flexible characteristics of the AGV can meet the requirements of the above occasions. In addition, in military and hazardous areas, the integration of other detection and disassembly equipment, based on automatic driving of AGV , can be used for battlefield demining, position reconnaissance, hazardous environment operations, such as military robots, dangerous goods handling robots, steel charge delivery vehicles, radioactive material trucks, submarine cable laying, etc.

At present, Port logistics are developing towards large-scale, large flow and high speed. Large-scale container ship, large tonnage container, loading transport equipment that suits the big shore bridge are coming into being. AGV which as an unmanned automatic handling device, is gradually being applied to container automation handling in large international ports in recent years. As the market competition intensifies, the cost of the logistics is being controlled more and more stringent, How to solve the four difficult problems of multiple loading, fast handling, fast handling and less transit , has been one of the objectives of port container logistics. One of the difficulties in designing an AGV is the design of its power source device. The capacity factor of the power source has a direct influence on the function of the AGV , and the volume of the power source will directly affect the size and appearance of the vehicle. In order to let the AGV to be able to load more cargo and move quickly in the dock, the battery system of the AGV must ensure that the AGV can have a certain power and continuous mileage, which should also ensuring its security in the complex environment.

1.2 research developments and trends at home and abroad:

1.2.1 Domestic Research Developments

For the traditional AGV, the battery is generally as a storage carrier, nowadays the following types have been invented for using: Lead acid / pure lead, Ni-MH, cadmium nickel, lithium-ion batteries, these batteries are based on the "electrochemical" principle. In recent years, with the maturation of battery technology, the application of the super capacitor on the AGV is promoted gradually, the biggest characteristic of the capacitance is "physical linear discharge", which has high efficiency and long service life. In addition, with the development of contactless energy transmission technology, the related products represented by some German enterprises have replaced the traditional power supply mode of AGV in some fields.

The main factors that affect the power configuration of an AGV are usually the characteristics and costs of various power supply modes, and the working mode of the AGV when it is used. From the point of view of the AGV application, the battery is still the main direction of the current AGV power supply, in which lead acid, cadmium nickel battery is being used the most widely and safest ones. Although lithium battery has some applications due to its high energy density and good flushing discharge characteristics, But the use of environment and conditions are also more stringent, the quality of the supporting batteries and the power management system require a high level of security, it need to be used with caution in the application areas of high demand; the application of super capacitor is limited by its capacity factor, which will be used to complement the battery. Application of contactless power supply technology for AGV with a fixed path system is competitive, make it possibly for the AGV to obtain power continuously, thereby extending the AGV job. In the AGV System that with partial fixed lines, the contacts power supply technology also serves as a supplement to the battery, which ensure the side-and-side charging, thereby improving the efficiency of the AGV.

1.2.2 Research Trends Abroad

The development of electric vehicle needs better battery, power battery than energy, life, safety and price, they are all very important for the development of pure electric drive car. There are mainly three levels of the invention and application of the LI batteries for the countries, which are represented by The United States, Japan, Korea, Germanys: the practical technology of lithium-ion batteries (recent Industrialization technology); High performance technology of lithium-ion battery (near-medium performance improvement) The innovative battery has a large high-performance technology (long-term exploration of theoretical).

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: