硝酸钠蒸发结晶工艺及设备设计毕业论文

2020-06-20 19:16:50

摘 要

最近几年我们国家硝酸钠市场需求量呈现逐年上升的趋势。因为其用途广泛,例如:搪瓷、无机、玻璃、化肥、染料、冶金、机械等。所以相关应用技术的发展都对硝酸钠的进一步拓宽起到了积极的推动作用,极大地带动了硝酸钠市场需求量的增加。上下游行业快速的发展更是为硝酸钠行业带来了良好的发展基础,并且具有庞大的市场。市场需求量增大的同时,生产规模的增大、生产厂家的增多,带动硝酸钠的生产和生产过程中产生的硝酸钠废水的处理规模和处理要求日益增大。目前的生产工艺已经不能够满足当下的生产和市场需求,所以硝酸钠多效蒸发浓缩处理工艺在市场的需求下得到广泛应用。

关键词:硝酸钠 蒸发浓缩处理

a b s t r a c t

A triple-effect absorption cooling cycle using aqueous (lithium, potassium, sodium) nitrate solution (Alkitrate) as a working fluid in the high temperature stage is simulated in this work. This cycle takes advantage of the thermal potential of high temperature heat sources and has a configuration consisting of a H2O/LiBr double-effect cycle coupled with a single-effect cycle that uses Alkitrate as a working fluid.Heat is exchanged between the two cycles by thermal fluids which flow in the external circuits. The conventional working fluid H2O/LiBr suffers from serious problems of corrosion and thermal decomposition at temperatures of over 180 _C, which restricts its use in the high temperature components of a triple-effect absorption cooling cycle. At the nominal operating conditions selected, namely a heat source temperature TH of 250 _C and a cooling-water temperature TC of 30 _C the coefficient of performance achieved with the Alkitrate topping cycle is 1.73. The correct operation of the cycle is demonstrated by drawing the cycle in the Dühring diagram, where the safety margin for the crystallization of the working fluid is adhered to.

Key Words: aqueous nitrate solution

目录

摘要······························································I

a b s t r a c t··················································II

第一章.概述

1.1硝酸钠的介绍················································6

1.2硝酸钠蒸发结晶工艺方法·········································6

1.3本课题的工艺流程选择············································6

1.4本课题的要求················································6

第二章.三效蒸发主要设备的工艺计算

2.1 加热器的工艺计算···············································7

2.1.1方案简介···················································7

2.1.2方案设计················································7

2.1.2.1确定设计方案·········································7

2.1.2.2确定物性数据··········································7

2.1.2.3计算总传热系数·········································8

2.1.2.4计算传热面积···········································9

2.1.2.5工艺结构尺寸···········································9

2.2 分离器的工艺计算··············································11

2.2.1工艺设计参数·············································11

2.2.2设计方案确定·············································11

2.2.3工艺尺寸计算············································11

2.2.3.1气体流速计算····································11

2.2.3.2 结构尺寸设计····························11

第三章.三效蒸发主要设备设计

3.1加热器的设备设计·············································14

3.1.1壳体··················································14

3.1.1.1壳体直径············································14

3.1.1.2壳体壁厚·········································14

3.1.1.3水压校核···············································14

3.1.1.4壳体质量···········································15

3.1.2管板···················································15

3.1.2.1管板参数··········································15

3.1.2.2管板与壳体的连接·······································16

3.1.2.3管子在管板上的固定方式····························16

3.1.3拉杆···················································16

3.1.4分程隔板··············································17

3.1.5折流板··················································17

3.1.6封头及管箱·············································17

3.1.6.1 封头··········································17

3.1.6.2 管箱············································18

3.1.6.3封头法兰及管箱法兰·····································18

3.1.7接管及其法兰··············································18

3.1.8排气、排液管···············································19

3.1.9支座设计········································19

3.2分离器的设备设计···············································19

3.2.1设计参数选择············································19

3.2.1.1设计压力·····································20

3.2.1.2设计温度············································20

3.2.1.3主要材料选取·······································20

3.2.2容器结构设计············································21

3.2.2.1筒体厚度计算······································21

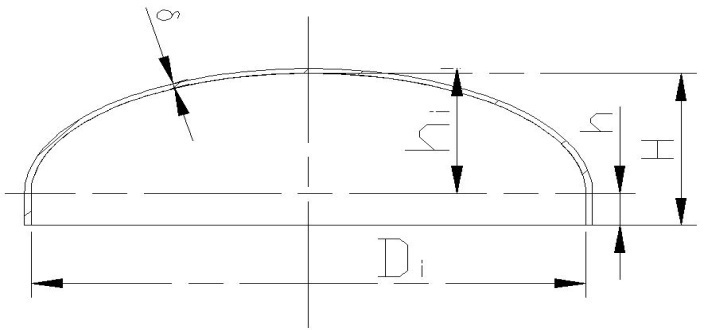

3.2.2.2封头壁厚设计······································21

3.2.2.3筒体和封头结构设计·································22

3.2.4接管、法兰、垫片和螺栓(螺柱)设计······················23

3.2.4.1接管和法兰··········································23

3.2.4.2垫片设计············································25

3.2.4.3螺栓(螺柱)选择·····································26

3.2.5支座选型和结构设计·······································27

3.2.5.1支座选型············································27

3.2.5.2支座系列参数尺寸···································28

第四章.三效蒸发主要设备的强度设计

4.1加热器的强度设计··············································30

4.1.1换热器核算···········································30

4.2.2承载能力校核··········································32

4.2分离器的强度设计···············································35

4.2.1筒体校核················································36

4.2.1.1筒体厚度参数··········································36

4.2.1.2筒体校核············································36

4.2.1.3开孔补强············································36

4.2.2法兰计算和校核··········································38

4.2.2.1垫片宽度计算·········································38

4.2.2.2螺栓载荷计算··········································39

4.2.2.3总力矩计算············································39

4.2.2.4应力计算与校核·······································40

4.2.3支腿校核················································41

4.2.3.1水平风载荷············································41

相关图片展示: