双缸气动楔式闸阀设计PN40DN400毕业论文

2020-07-16 20:17:11

摘 要

阀门是管路附件的一种,是管路中流体输送系统的控制部件之一,它是用来改变通路断面和介质流动方向、控制输送介质运动的一种装置,具有调节、节流、导流、分流等功能。阀门的用途极广,无论是工业、农业、国防尖端,还是交通运输、人民生活等部门都需要大量的、各种类型的阀门。国民经济以农业为基础,要实行农业技术改造,也得提供很多的阀门,例如:化肥厂、农药厂、农田水利排灌和农业机械化、电气化等部门,阀门都是必不可少的。

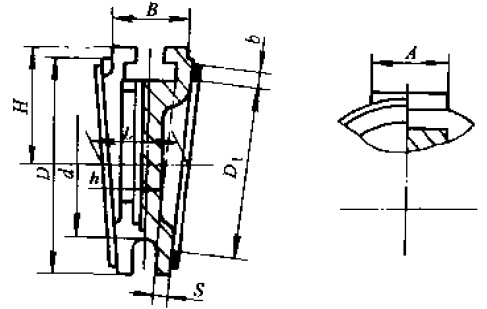

闸阀是指关闭件(闸板)沿通路中心线垂直方向进行移动的阀门,在管道上主要起切断作用,具有流体阻力小、开关所需的力较小、介质流向不受限制、全开时密封面受工作介质的冲蚀比截止阀小、体形简单铸造工艺性好、结构长度小等优点。

我的毕业设计题目:双缸气动楔式闸阀设计的公称通径PN=400mm,公称压力DN4.0Mpa。主要是为了表达阐明楔式闸阀结构的特点,阀门在生活中的生产工作原理,以及气动、手动转换装置的特点。这次阀门设计包括通用标准部件和专业特殊应用部件的设计,以及阀门各部件尺寸的按标准选取、计算和强度校核,密封的设计是关键所在,另外阀杆的强度校核和稳定性校核也是重中之重不和或缺。

我把本次毕业设计课题分为以下几个步骤——1、根据给定设计题目给定的公称压力和公称直径确定阀门的基本结构 2、仔细分析探讨设计方案做好任务设计步骤书 3、准确做好阀门结构各部件的受力分析,并进行部件强度的计算,然后校核稳定性,根据前边的计算参数按标准选取各部件材料,4、用Auto CAD绘制总装备图和所有的零部件图。具体步骤的主要顺序如下所示,首先确定工作室环境使合理设计方案,对阀门中各部件进行仔细准确的受力分析,然后根据国家标准选取确定各尺寸大小,最后在各强度上进行校核,绘制阀门总图、零部件图。

关键词:楔式闸阀 密封面 气动 计算和校核 绘图

Abstract

The valve is a kind of pipeline accessory and it is one of the control parts of the fluid conveying system in the pipeline. It is a device used to change the direction of the passage section and the direction of medium flow and control the movement of the conveying medium. It has adjustment, throttling and conduction. Flow, diversion and other functions. The valve has a wide range of uses. Whether it is the industrial, agricultural, cutting-edge national defense, or transportation, people's life, and other departments need a large number of various types of valves. The national economy is based on agriculture, and it is necessary to implement agro-technical reforms. It also has to provide a lot of valves, such as chemical fertilizer plants, pesticide plants, farmland water conservancy irrigation and drainage, and agricultural mechanization and electrification. Valves are indispensable.

The gate valve is the valve that the closing member (the gate) moves along the centerline of the channel in the vertical direction. It mainly plays a role in cutting off the pipeline. It has the advantages of low fluid resistance, low force required for the switch, unlimited flow of the medium, and full opening. The sealing surface is eroded by the working medium with smaller advantages than the shut-off valve, simple body shape, good casting processability, and small structure length. The gate valve cannot be used for regulation and throttling and can only be fully or completely closed in the pipeline.

My graduation project title: Double cylinder pneumatic wedge valve design nominal diameter PN = 400mm, nominal pressure DN = 40Mpa. The main purpose is to express the characteristics of the wedge gate valve structure, the working principle of the valve in life, and the characteristics of pneumatic and manual switching devices. This valve design includes the design of general-purpose standard components and professional special application components, as well as the standard selection, calculation and strength check of the size of each component of the valve. The design of the seal is the key, and the strength and stability of the valve stem are also verified. Nuclear is also the most important thing.

I divided the graduation project topic into the following steps: 1. Determine the basic structure of the valve according to the given nominal pressure and nominal diameter of the given design problem. 2. Carefully analyze and discuss the design plan and do the task design procedure. 3. Accurately analyze the force of each part of the valve structure, and calculate the strength of the part, then check the stability, select the various parts of the material according to the calculation parameters in front, 4, use Auto CAD to draw the total equipment diagram and all zero Parts diagram. The main steps of the specific steps are as follows. First, determine the studio environment to make a rational design plan, perform careful and accurate force analysis on the various components in the valve, and then select and determine each size according to the national standards, and finally check on each strength. , Draw the general valve, component drawings.

Keywords: wedge gate valve sealing surface aerodynamic calculation and check drawi

摘 要 I

Abstract II

目录 IV

第一章 绪 论 1

1.1 闸阀的定义及工作原理 1

1.2 阀门设计的选题意义 3

1.3 阀门的发展 3

第二章 阀门的设计与计算 5

2.1 阀体的功能 5

2.2 阀体的选材 5

2.3 阀体的结构形式和制造方法 5

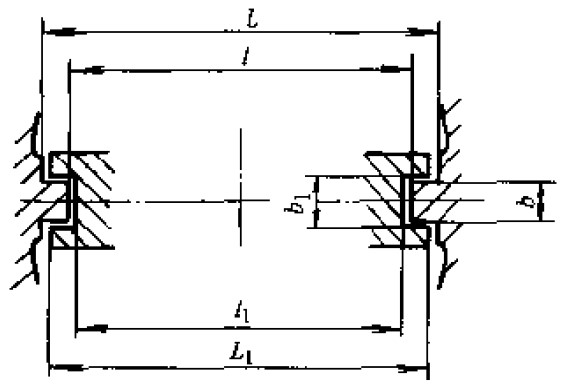

2.4 确定阀体的结构长度和连接尺寸 6

2.5 结构设计与计算 7

2.6 阀体壁厚的设计与计算 8

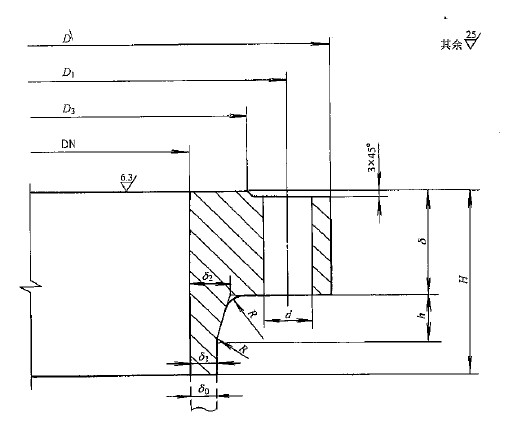

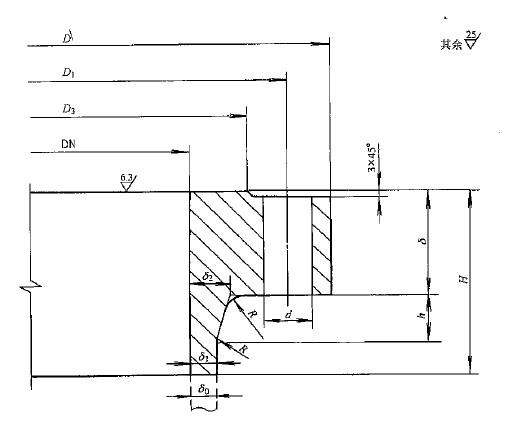

2.7 中法兰的设计与计算 9

第三章 闸板的设计与计算 14

3.1 闸板密封面宽度和内径的选取 14

3.2 闸板与阀体档宽及相应公差的计算 14

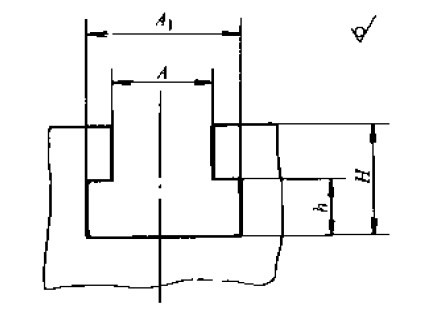

3.3 闸板主要结构尺寸的确定 15

3.4 闸板密封面比压计算 16

3.5 闸板强度的校核 16

第四章 阀杆的设计与计算 18

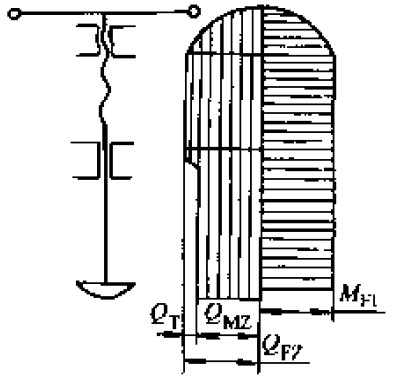

4.1 阀杆总轴向力 18

4.2 阀杆的直径估算 19

4.3 阀杆的强度校核 19

4.4 阀杆的稳定性校核 22

4.5 阀杆主要尺寸的确定 23

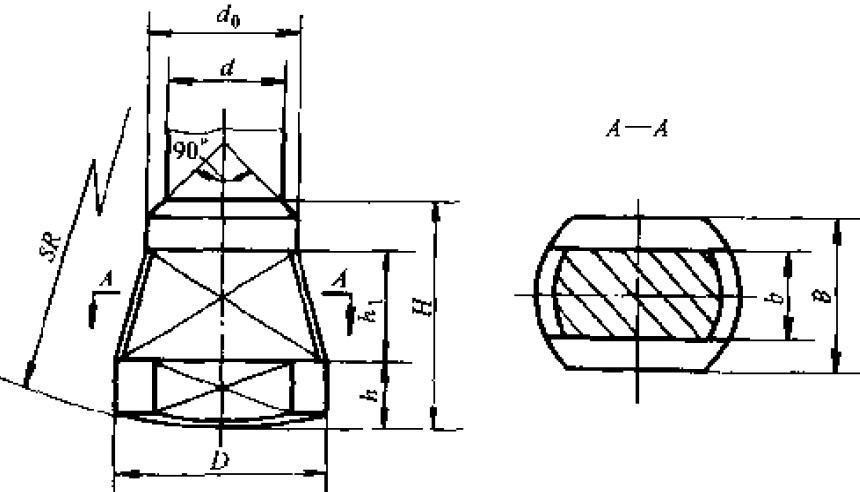

第五章 阀盖及填料装置的设计与计算 25

5.1 阀盖的设计与计算 25

5.2 填料压盖的设计与计算 26

5.3 上密封座尺寸 31

第六章 气缸的设计与计算 32

6.1 气缸的直径粗估算与选取 32

6.2 气缸的校核 32

第七章 其他主要零件的设计与校核 34

7.1 滚动轴承的选取 34

7.2 手轮直径的确定 34

7.3 阀杆螺母的校核 35

7.4 上活塞与 T 型槽接头连接螺栓的校核 36

第八章 法兰连接气动楔式闸阀设计的成本核算 37

8.1 书籍文献材料费用 37

8.2 设备制造费用 37

8.3 本章小结 39

参考文献 40

致 谢 42

第一章 绪 论

阀门是管道上面的控制单元,它有着控制管道内流体流动的基本功能。特殊的阀门还能起到调节流体或者防逆流等一系列复杂的功能。阀门的尺寸有大有小,微小的仪表阀和直径数十米的工业阀门都是非常常见的阀门。各种阀门的工作压力范围很大,接近真空的低压和高达一千多度的超高压都是它的工作压力。并且不同阀门的工作温度也是相差特别大,有低至零下270℃的阀门同样也要工作压力高达1000℃的阀门。

阀门通常用于控制流体的流动,是管道系统中不可或缺的物件。阀门结构有的非常简单,有的为了满足特别的需求也会被设计成特别复杂的形式,品种非常繁多。随着国家工业的发展,各种类型的阀门正在被逐步研发出来,还形成了许多系统的分类标准和方法。

相关图片展示: