废弃塑料瓶分拣系统运动仿真毕业论文

2020-02-19 18:23:03

摘 要

塑料瓶作为饮料包装在日常生活中被广泛使用,每年的使用量都达到了几百亿瓶,但是废旧塑料瓶处理不当会对周围环境和居民造成较大的影响。废弃塑料瓶在经过按照颜色分类筛选之后,再经过一些后续处理步骤,可以将废旧塑料瓶变成不同颜色的塑料颗粒,成为可以被再次利用的塑料原料。我国的废弃塑料瓶分拣回收主要依靠人工来完成颜色分拣工作。分拣效率低下严重制约了我国的废旧塑料瓶回收利用率,使其迟迟不能突破百分之五十这个门槛,而欧美国家在机器视觉和计算机图像识别技术的不断发展下,利用这些技术配合机械设备已经成功将废弃塑料回收利用率提高至百分之六十。为了改善我国塑料瓶分拣的窘镜,工业界正积极向欧美国家学习引进并开发适合我国国情的基于图像识别技术的废弃塑料瓶分拣设备。经过前辈们几年的努力,废弃塑料瓶分拣的理论研究和算法已经逐渐趋于完善,距离全面投入应用指日可待。

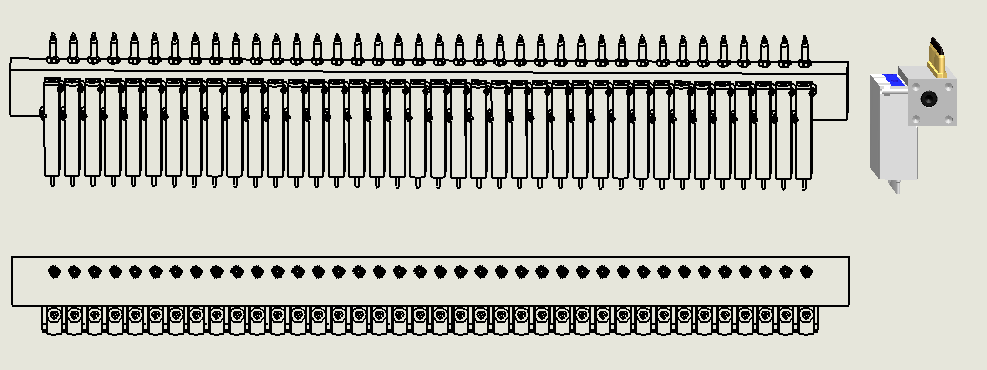

本文以solidworks软件为基础,结合机械、力学和气压传动等知识,对废旧塑料瓶分拣系统进行三维建模工作,对废旧塑料瓶分拣系统的运动仿真研究,主要研究分拣系统的工作原理并模拟其运动过程。通过模拟废旧塑料瓶分拣设备的运动过程,我们能充分了解分拣系统的工作原理和工作过程,以及一些参数的合理范围以及最佳参数,包括气体压力范围,振动给料机的激振频率等。

关键词:回收塑料瓶、运动仿真、分拣设备、图像识别

Abstract

Plastic bottles are widely used in daily life as beverage packaging. The annual usage of plastic bottles reaches tens of billions, but improper disposal of waste plastic bottles will have a greater impact on the surrounding environment and residents. Waste plastic bottles can be transformed into plastic granules of different colors and become reusable plastic materials after screening according to color classification and some subsequent treatment steps. In China, the sorting and recycling of waste plastic bottles mainly depends on manual work to complete the color sorting. The inefficiency of sorting seriously restricts the recycling efficiency of waste plastic bottles in China, which makes it unable to break through the threshold of 50%. With the continuous development of machine vision and computer image recognition technology, European and American countries have successfully increased the recycling efficiency of waste plastic bottles to 60%. In order to improve the dilemma of plastic bottle sorting in China, the industry is actively learning from European and American countries to introduce and develop waste plastic bottle sorting equipment based on image recognition technology which is suitable for our national conditions. After years of efforts of predecessors, the theoretical research and algorithm of waste plastic bottle sorting have gradually become perfect, and it is very near to be put into full application.

In this paper, based on SolidWorks software, combined with mechanical, mechanical and pneumatic transmission knowledge, the three-dimensional modeling of waste plastic bottle sorting system is carried out, and the motion simulation of waste plastic bottle sorting system is studied. The working principle of the sorting system is mainly studied and its motion process is simulated. By simulating the movement process of waste plastic bottle sorting equipment, we can fully understand the working principle and process of sorting system, as well as the reasonable range of some parameters and the best parameters, including gas pressure range, vibration frequency of vibration feeder and so on.

Key Words: recycling plastic bottles, motion simulation, sorting equipment, image recognition

目录

摘要············································································································Ⅰ

Abstract···································································································Ⅱ

第1章 绪论··································································································1

1.1课题研究背景及意义···············································································1

1.1.1 课题研究背景·················································································1

1.1.2 课题研究意义··················································································2

1.2课题来源及研究内容················································································2

1.3国内外研究现状······················································································3

1.3.1国外研究现状··················································································3

1.3.2国内研究现状··················································································4

第2章 分拣设备的方案设计··············································································6

2.1分拣设备的主要组成及功能····································································6

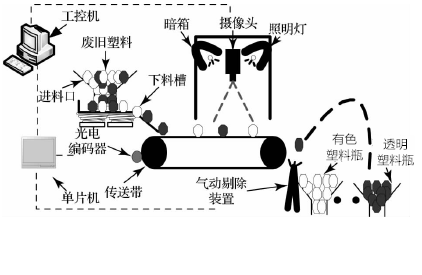

2.2分拣设备的工作原理···············································································8

第3章 气动控制系统工作原理及设计目标···························································10

3.1设计目标····························································································10

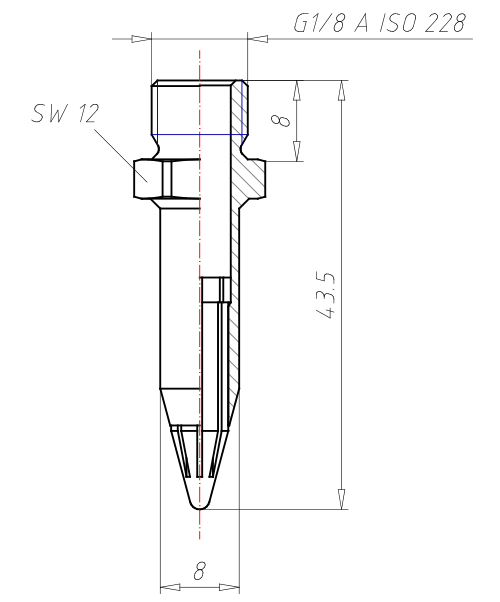

3.2气动元件的型号选择·············································································10

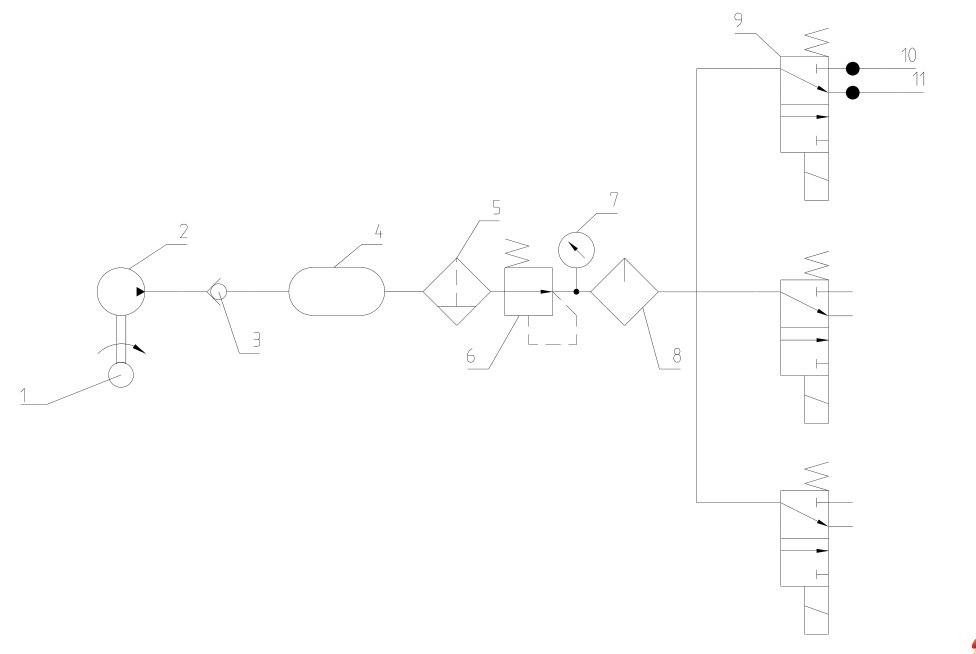

3.3气动系统的工作原理··············································································11

第4章 基于solidworks运动仿真·······························································14

4.1 solidworks软件简介············································································14

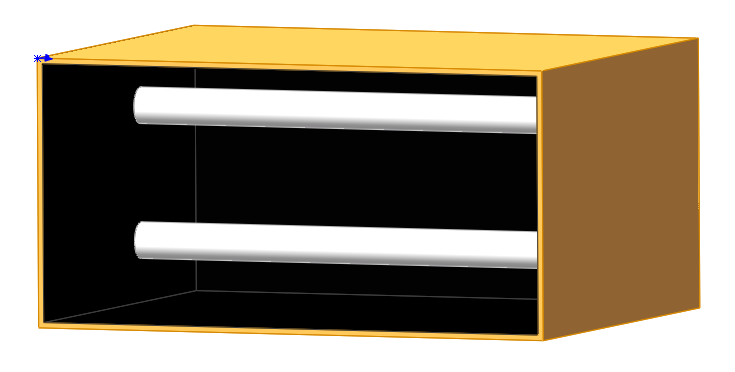

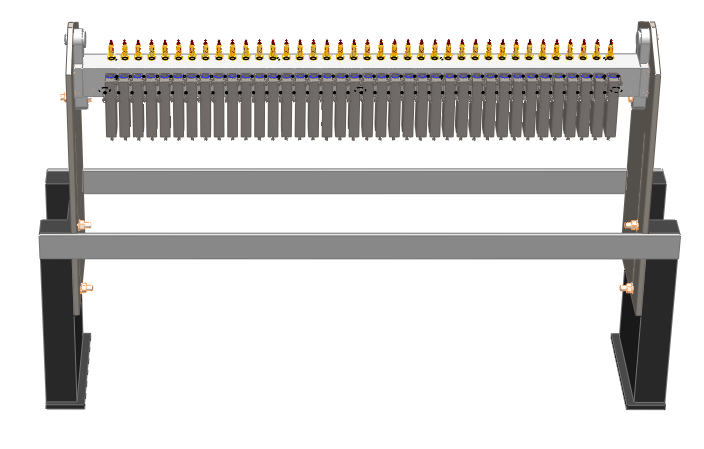

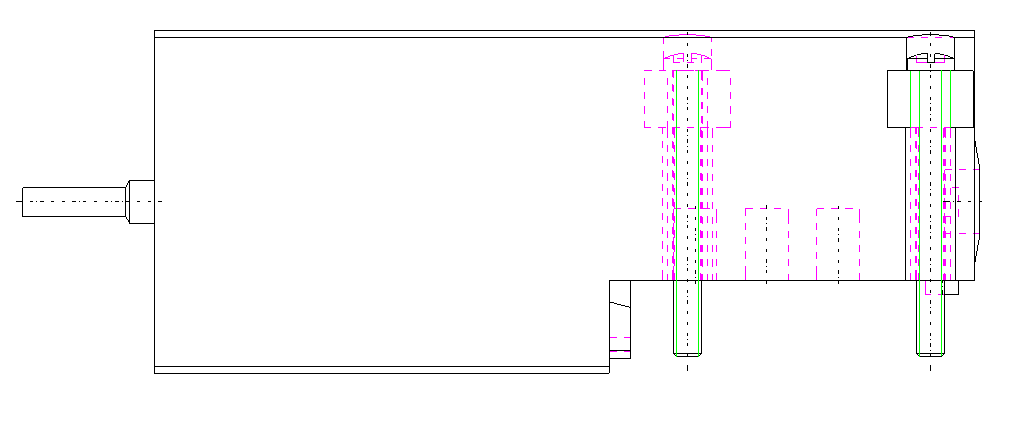

4.2 三维模型的建立··················································································15

4.3 仿真参数设定以及影响···········································································18

4.4 仿真结果分析·······················································································21

第5章 结论·································································································23

参考文献······································································································24

致谢············································································································25

第1章 绪论

1.1课题研究背景及意义

1.1.1 课题研究背景

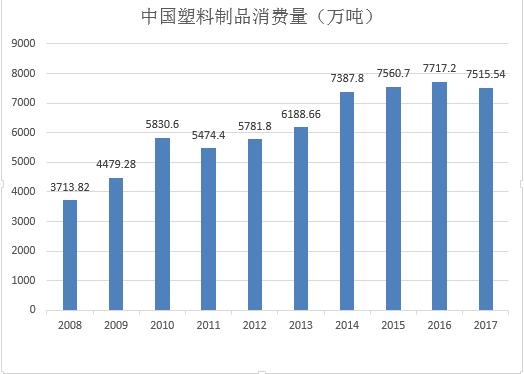

在中国改革开放等许多政策的扶持下,中国的塑料行业发展迅速,占据了国民经济较大的比重,塑料产业在我国逐渐成为了轻工业的支柱产业。塑料分为很多种类,其大多数是由高分子材料合成而来的,因其具耐腐蚀、不易发生氧化,质量轻强度高等优点,逐渐的取代了老牌的常用材料如铝及铝合金等材料,在各个行业都有广泛的应用,尤其是在包装和制造等行业[1]。我国近几年的塑料使用情况,2008~2017 年中国塑料制品消费量如图1-1所示[2],从图中我们能得出中国是塑料的消费和生产大国的结论 。

在中国改革开放等许多政策的扶持下,中国的塑料行业发展迅速,占据了国民经济较大的比重,塑料产业在我国逐渐成为了轻工业的支柱产业。塑料分为很多种类,其大多数是由高分子材料合成而来的,因其具耐腐蚀、不易发生氧化,质量轻强度高等优点,逐渐的取代了老牌的常用材料如铝及铝合金等材料,在各个行业都有广泛的应用,尤其是在包装和制造等行业[1]。我国近几年的塑料使用情况,2008~2017 年中国塑料制品消费量如图1-1所示[2],从图中我们能得出中国是塑料的消费和生产大国的结论 。

图1-1 2008~2017中国塑料制品消费量

2012年欧洲废弃塑料瓶回收量超过6000万个,超过52%的使用后的废弃塑料瓶被再度回收利用[3]。2018年5月15日据英国路透社报道,欧洲瓶装水生产商 15日设定了一项目标,即到2025年之前,要将塑料瓶的回收率从60%提高到90%,以提高回收利用率和减少污染[4]。对比而言,我国的塑料回收情况不容乐观,截止2018年我国废弃塑料瓶回收利用率仍然不足50%,我国的废弃塑料瓶回收利用行业还需要做出更多的努力。分析其原因,主要有几点:

一是我国废塑料行业缺乏行业指导,塑料回收没有明确的回收流程体系规范,回收难度加大。我国对于废旧塑料的回收利用没有健全的科学理论体系,无论是大批量回收分类设备还是废旧塑料瓶回收理论研究都没有形成一个体系整体。

二来是我国没有对废旧塑料瓶回收的统一政策,在我国很多行业都是在政策的扶持下逐步发展,尤其是在行业初期需要大量投入的时候。国家政策对于企业具有导向作用,能大幅度增加企业研究的积极性。

三则是人们的回收利用意识相对薄弱,需要进行普及资源回收教育。对于塑料瓶的回收利用许多居民都是心存芥蒂的,更多的是许多的居民没有认识到废旧塑料是可以进行回收利用的,在进行垃圾初步分类的时候废旧塑料就很难集中到一起。

综合以上,废旧塑料回收遭遇困难重重,企业要加强新技术、新设备、新工艺的研发。

随着人们生态环保意识和资源危机意识的觉醒,许多能够回收再利用资源的回收方法都得到了不同程度的研究,并且也取得了一定的成效。“十三五规划”指出“加强生活垃圾分类回收和再生资源回收的衔接”[5]。将回收的塑料瓶分类后作为原材料进行在再加工,能够在一定程度上减轻废旧塑料对于环境的污染同时也能减轻国家资源压力。通过本课题的研究,希望可以提供废弃塑料瓶分拣系统的运动过程参考。

1.1.2 课题研究意义

21世纪以来,国际社会上对于环境污染越发重视,也不断达成各项协定来节能减排保护环境。在生活中,许多的垃圾都是可以进行再回收利用的,尤其是废纸和废弃塑料瓶。塑料瓶在经过颜色分选并破碎之后,可以变成不同颜色的塑料小颗粒,成为可再次利用的再生原材料。单个废旧塑料瓶的价格过低,而回收成本过高,很难激发企业的回收意愿,很大程度上只能依靠国家政策扶持才能真正的发展起来。废弃塑料瓶分拣设备在欧美国家的成功经验,值得我们参考借鉴。废弃塑料瓶分拣设备假如能成功研发并投入市场,将很大程度上提高我国废弃塑料瓶的回收率,对于改善生活环境和可持续发展极其有利。

1.2 课题来源及研究内容

2015年,全球对于聚对苯二甲酸乙二醇酯(PET)材质瓶子的需求中有28%来自中国。2016年,中国消费者购买了738亿瓶瓶装水,比前一年增长了50亿瓶。追究其背后的原因是中产阶层的不断扩大和工资收入的提升[6]。当今社会塑料瓶已经变得无处不在,塑料瓶的大量应用既带来了经济发展和生活便利,也带来了环境污染和生态挑战。尤其是中国的大城市都缺乏有效的回收机制,而是依靠非正式的垃圾回收大军。

本次毕业设计的课题来源于武汉理工大学和南京中材国际集团的一个合作项目,旨在研发出高效率和高精确率的废弃塑料瓶分拣设备,并通过现代软件的仿真功能模拟其运动过程,以及在实际使用过程中可能遇见的一些问题。通过废弃塑料瓶分拣设备实现不同颜色塑料瓶的分类回收以及顺利开展后期处理利用,解决人力分拣不能长时间持续工作,无法高速高效的处理大批量塑料瓶的缺陷,使大规模的塑料瓶按颜色分类回收利用成为可能。工欲善其事必先利其器,想要将中国庞大的废弃塑料瓶回收率提高至相对较高的水平,一个成本较低,分拣效率适中的废弃塑料瓶分拣设备才是关键。

我国废弃塑料瓶的分拣工作如今仍依靠人工分拣,但是分拣的工作环境恶劣且存在隐患,塑料瓶种类过于繁多,工人需要集中精力分拣,非常容易产生视觉疲劳,长时间工作出错率极高。工业界正积极引进或开发精确的自动识别分拣设备,改善之前研发设备存在的一些缺陷,避免后续还需耍人工进行二次精确筛选。

就根据翻阅资料得到的情况看来,废弃塑料瓶分拣设备识别分类准确率低的原因主要是: 图像采集时塑料瓶容易重叠,这样容易导致混色而产生识别错误。塑料瓶重叠在分拣过程中是一个十分复杂的问题,很难通过算法来彻底解决重叠问题。其次就是塑料瓶表面对于光照的反射会影响成像质量,对颜色识别会产生干扰,影响准确率。

本课题以过程检测与控制技术兼以机械相关知识和现代软件仿真技术为基础,研究研究对象为废弃塑料瓶分拣系统,以完成废弃塑料瓶分拣系统运动仿真为目标,结合机械原理与机械设计、力学等相关知识,模拟废弃塑料瓶分拣设备的实际工作过程,备案实际运行中可能遇见的问题,理解废弃塑料瓶分拣设备的工作原理以及实现方式。需要完成废弃塑料瓶分拣设备机械部分的建模工作,以及整体的运动动画仿真工作,能完整的展示废弃塑料瓶分拣设备的运动过程以及分拣原理。将计算机图像识别技术与控制技术和机械运动有机的结合在一起,实现完全自动化分拣。具体内容如下:

- 针对本研究对象废弃塑料瓶的特点和实际设备基础,建立产品的三维设备模型,模拟其装配条件。

- 立足于现代软件的强大能力,模拟废弃塑料瓶分拣系统的运动过程,并对其进行参数设定和修改。

1.3 国内外研究现状

国内外关于废弃塑料瓶分拣的研究大都是基于计算图像识别技术算法的相关内容,主要以计算机图像获取和图像处理算法为主,而机械设备方面主要是对于不同工作环境和不同的产量要求进行不同的设备选型,理论研究就相对较少。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: