钛铝异种金属焊接工艺及接头性能研究毕业论文

2020-04-15 16:32:09

摘 要

钛和铝这两种金属都因其本身优良的性能在工业领域占了很大的应用比例,更值得关注的是钛/铝异种材料的复合构件可以综合体现铝合金和钛合金的优点,但钛/铝异种金属的连接因两种合金的性能差异而存在很大的问题。本文采用冷金属过渡焊技术,对TC4和7075铝合金进行对接焊实验,得到以下几点结论。

(1)TC4和7075铝合金进行CMT对接焊时,当焊接速度为10mm/s,送丝速度在4.5-4.8m/min时,钛/铝焊接接头的焊缝成形质量好;送丝速度和焊接速度在焊接过程过快或过慢时,会出现未焊透,未填满,焊缝表面粗糙等缺陷。

(2)钛/铝CMT熔钎焊焊接接头具有熔焊和钎焊的双重性质,接头可以明显划分为三个部分:热影响区,Ti/Al界面,热影响区。在接头焊缝中心会生成网状Al-Si共晶组织以及细小的α-Al等轴晶组织;靠近铝合金区域的热影响区由于部分晶粒受热发生熔化处于半熔化区,在靠近焊缝的区域有少量的柱状晶组织。

(3)钛/铝接头钎焊界面Ti-Al相互作用形成金属间化合物,结合Al-Ti二元相图,推测在TC4侧形成TiAl和Ti3Al组成的连续层和TiAl3金属间化合物。

(4)TC4钛合金和7075铝合金的硬度差别很大,在整个焊接接头,焊缝部分和7075铝合金的硬度差别不大,在钎焊界面区域,由于金属间化合物的存在,硬度有明显提高,焊缝的气孔会降低接头的硬度。

关键词: 7075铝合金;TC4钛合金;冷金属过渡焊;焊接接头;微观组织;硬度

ABSTRACT

Titanium and aluminium are two kinds of metals which occupy a large proportion of industrial applications because of their excellent properties. More noteworthy is that the composite components of titanium/aluminium dissimilar materials can have the advantages of both aluminium and titanium alloys. However, because of the great differences in chemical, physical and metallurgical properties between titanium and aluminium, the connection of titanium/aluminium dissimilar metals is more difficult. Using cold metal transition welding technology, the welding experiments of TC4 and 7075 aluminium alloys were carried out, and the following conclusions were obtained.

(1) When TC4 and 7075 aluminium alloys are welded by CMT butt welding, the wire feeding speed is 4.5-4.8 m/min and the welding speed is 10 mm/s, the weld shape of titanium/aluminium joint is beautiful, and the spreading effect of weld metal on the base metal surface is better. When wire feeding speed and welding speed are too fast or too slow in the welding process, defects such as incomplete penetration, incomplete filling and rough weld surface will appear.

(2) Titanium/aluminium joints are mainly composed of three parts: heat affected zone, fusion zone and welding seam. Due to the dual properties of melting and brazing of titanium/aluminium CMT welded joints, reticulated Al-Si eutectic structure and fine alpha-Al equiaxed structure are formed after solidification in the center of the weld due to the small temperature difference of the melt liquid;The fusion zone near the aluminium alloy is in the semi-melting zone due to the heating of some grains, and there are a few columnar grains near the fusion line.The observation organization is not obvious.

(3) Ti-Al intermetallic compound is formed at the brazing interface of Ti/Al joint. Combined with Al-Ti binary phase diagram, it is speculated that TiAl and Ti3Al continuous layer and TiAl3 intermetallic compound are formed at TC4 side.

(4) The hardness of TC4 titanium alloy and 7075 aluminium alloy varies greatly. The hardness of the weld and 7075 aluminium alloy varies little in the whole welded joint. In the brazing interface area, due to the presence of intermetallic compounds, the hardness of the weld increases significantly, and the porosity of the weld will reduce the hardness of the joint.

Key words: 7075 aluminium alloy; TC4 titanium alloy; cold metal transition welding; welding joint; microstructure; hardness

目录

第一章 绪论 1

1.1 课题研究的背景 1

1.2冷金属过渡焊技术介绍 2

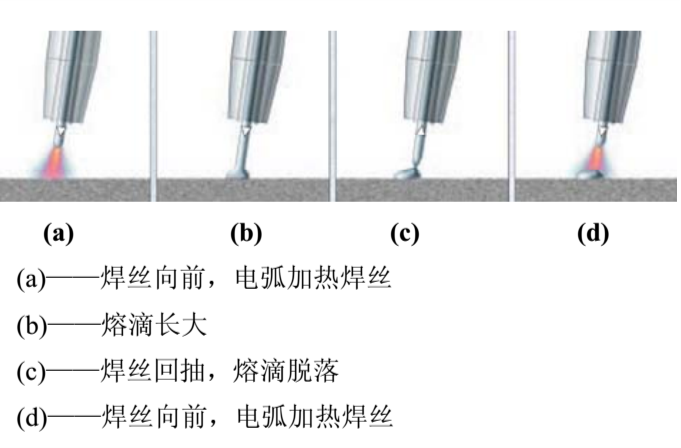

1.2.1冷金属过渡焊原理 2

1.2.2冷金属过度焊的优点 4

1.2.3冷金属过渡焊的发展与应用 5

1.3 在国内外钛/铝异种金属焊接的研究现状 7

1.4 本文研究的主要内容 7

第二章 实验材料、设备及实验过程 8

2.1 实验材料 8

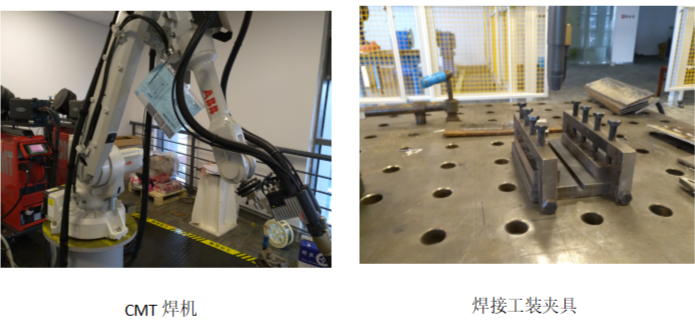

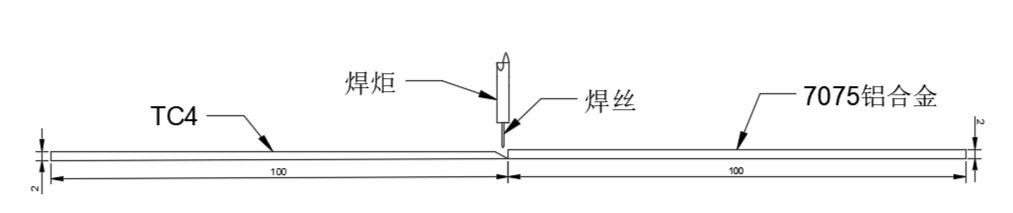

2.2 CMT焊接实验 8

2.3 微观组织分析实验 9

2.4 焊接接头硬度实验 11

第三章 钛/铝异种金属焊接工艺和焊缝成形分析 13

3.1 Ti/Al异种金属各组的焊接参数 13

3.2 送丝速度对焊缝成形的影响 14

3.2 焊接速度对焊缝成形的影响 16

3.2本章小结 17

第四章 Ti/Al焊接接头微观组织分析和力学性能 18

4.1 Ti/Al接头的微观组织分析 18

4.1.1 焊缝区微观组织分析 18

4.1.2 Al侧热影响区的微观组织 19

4.1.3 Ti/Al界面的的微观组织 20

4.2 焊接接头硬度分析 21

4.3 本章小结 23

第五章 经济性分析 24

第六章 结论 25

参考文献 26

致谢 28

第一章 绪论

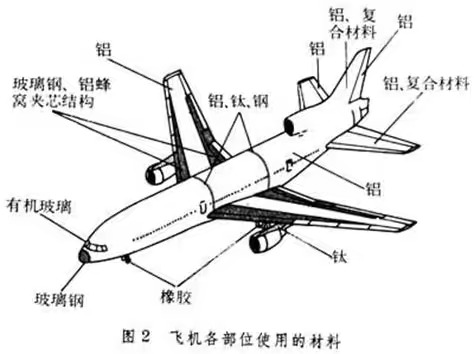

1.1 课题研究的背景

虽然钛元素在地壳中的含量很高,但在20世纪中期才逐渐得到运用,初期只是应用在军事领域,因其密度小,比强度高、耐高温、耐腐蚀以及良好的低温韧性等特性逐渐被应用在汽车航空,医疗化工等诸多行业中,可以称其是国防装备和国民经济重要工程的重要支撑材料,创造了极大的经济效益和社会效益[1]。

铝作为一种轻金属,在所有的金属品种,铝合金的用量越来越多,在金属材料的使用量中排第二,仅次于铁[2]。由于铝合金密度小,比强度高、熔点低、铸造性能好、力学性能佳、加工性能好、导电性、传热性及抗腐蚀性能优良的特点使其广泛应用于交通运输、化工工业、建筑、机械制造等领域。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: