补强剂对螺杆泵弹性体材料机械性能的影响毕业论文

2020-04-15 17:45:28

摘 要

螺杆泵是一种容积式泵,它的吸入能力好、结构稳定且对流体具有很好的兼容性,所以螺杆泵具有广泛的应用前景和经济价值。螺杆泵的定子作为螺杆泵中重要的一个环节,它的好坏决定着一台螺杆泵的使用寿命和性能,所以定子材料的选用至关重要。本文以螺杆泵定子材料氢化丁晴橡胶为主要研究对象,通过设计对照组试验来研究它的机械性能的变化。同时,通过对比试验,对配方进行优化。得以下结论:

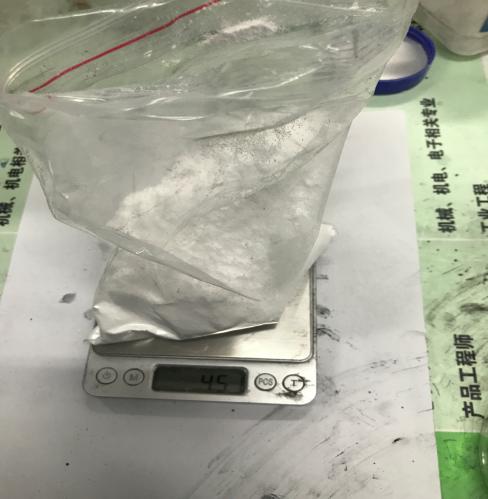

- 本次试验建立在螺杆泵的工作原理上,以氢化丁晴橡胶为主要材料,通过改变补强剂炭黑的含量来设计出配方并制备试样和弹性体材料。

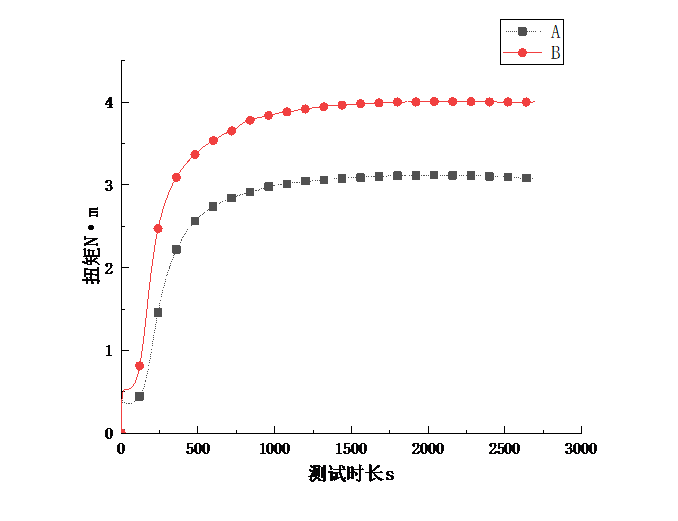

- 分别测定不同炭黑含量试样的硫化曲线,得到硫化时间。结果表明,在温度和压力都不变的情况下,硫化时间会随着炭黑含量的增加而增加。

- 通过待测试样研究分析炭黑含量的变化如何影响定子弹性体材料的机械性能。研究发现,在炭黑粒径和种类不变的情况下,随着炭黑的增加,氢化丁晴橡胶的各类机械性能都在上升。除抗拉强度有略微下降以外,炭黑的硬度、拉伸性能、压缩应力松弛等都处于上升阶段。

关键词:氢化丁晴橡胶 炭黑 机械性能 弹性体材料

Abstract

Screw pump is a positive displacement pump with good suction capacity, stable structure and good compatibility with fluids, so screw pump has a wide application prospect and economic value.As an important part of screw pump, the stator of screw pump determines the service life and performance of a screw pump. Therefore, the selection of stator material is very important.In this paper, hydrogenated Ding Qing rubber, which is the stator material of screw pump, is taken as the main research object, and the changes of its mechanical properties are studied by designing a control group experiment. At the same time, the formula was optimized through comparative tests.Get the following conclusion:

(1) This test is based on the working principle of screw pump. Hydrogenated Ding Qing rubber is used as the main material, and the formula is designed and samples and elastomer materials are prepared by changing the content of reinforcing agent carbon black.

(2) The vulcanization curves of samples with different carbon black contents were measured respectively to obtain the vulcanization time.The results show that the curing time will increase with the increase of carbon black content under the condition of constant temperature and pressure.

(3) Analyze how the change of carbon black content affects the mechanical properties of stator elastomer materials through the study of the samples to be tested. The study found that under the condition of the same particle size and type of carbon black, with the increase of carbon black, all kinds of mechanical properties of hydrogenated Ding Qing rubber are increasing. Except for the slight decrease in tensile strength, the hardness, tensile property and compressive stress relaxation of carbon black are all in the rising stage.

Keywords:Hydrogenated nitrile rubber carbon black mechanical properties elastomer materials

目 录

摘要 I

Abstract II

第一章 绪论 1

1.1螺杆泵定子常用材料概述 1

1.1.1丁晴橡胶概述 1

1.1.2氢化丁晴橡胶概述 2

1.2橡胶补强剂 2

1.3橡胶补强剂研究现状 3

1.4 本文主要的研究内容 5

1.4.1螺杆泵定子橡胶配方设计及材料制备 5

1.4.2硫化温度对HNBR材料性能的影响 5

1.4.3补强剂对HNBR材料性能的影响 5

第二章 螺杆泵定子弹性体材料配方设计及制备 6

2.1 引言 6

2.2 螺杆泵定子弹性体材料配方设计 6

2.2.1 试验主要材料 6

2.2.2 试验用设备 8

2.3 螺杆泵定子弹性体材料试样制备方法 8

2.3.1 塑炼 8

2.3.2 混炼 10

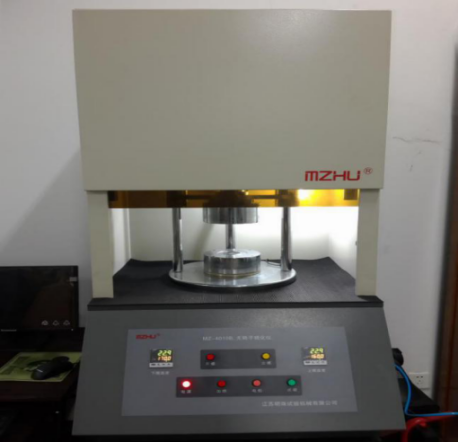

2.3.3 硫化特性参数确定 10

2.3.4 硫化 12

2.4 本章小结 13

第三章 补强剂对螺杆泵定子弹性体材料机械性能的影响 14

3.1 引言 14

3.2 材料机械性能测试及结果分析 14

3.2.1 拉伸性能试验 14

3.2.2 硬度试验 16

3.2.3压缩永久变形试验 16

3.2.4压缩应力应变试验 17

3.2.5 压缩应力松弛试验 18

3.2.6 机械性能结果分析 18

3.3本章小结 22

第四章 总结与展望及经济性评价 23

4.1 总结 23

4.2 展望 23

4.3 经济性评价 24

4.3.1 预估算 24

4.3.2 资金来源 25

参考文献 26

致谢 29

第一章 绪论

1.1螺杆泵定子常用材料概述

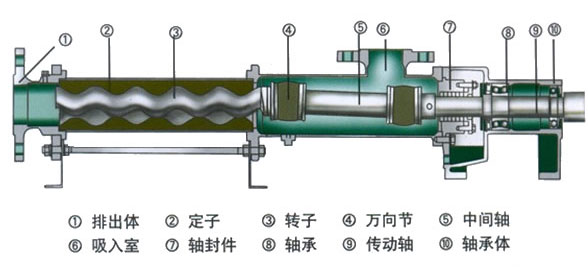

螺杆泵(如图一)所示,它的工作环境较为复杂,温度高,压力大,通常用于高粘度,高含沙等恶劣环境下的石油钻探、石油化工等领域。长时间的工作和载荷会使定子力学性能快速下降[1],从而产生材料老化和破损失效现象,使得螺杆泵的使用寿命缩短并限制其发展,所以研究螺杆泵定子材料的配方提高其性能就显得尤为重要。

螺杆泵定子橡胶配方有很多,根据所用原材料的比例不同,橡胶可以形成无数种配方,每种配方所制出的性能也是天差地别。目前关于定子材料的研究比较单一,而关于补强剂对橡胶机械性能影响的课题还比较少。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: