切削加工刀具磨损声发射信号的分析毕业论文

2020-04-15 17:46:49

摘 要

在切削加工中,刀具的磨损的状况在一定程度上直接影响了最后的工件尺寸精确性,使得工件的质量不高,不能有很高的生产效率,也会间接的导致生产成本变高。为了改善这些条件,运用了声发射检测技术。而且近几年来声发射技术在研究机加工切削过程中有了飞跃的发展,慢慢的成为了重要的研究方法。所以利用声发射检测技术的能够实现在线动态无损监测的长处,通过采集到的成分复杂的频率信号对其进行分解,提取特征信号,对应到刀具的磨损状态。

本文主要通过实验来获取刀具在不同的情况下的声发射信号数据并且对这些数据分析,得出结果。完成的主要工作如下:

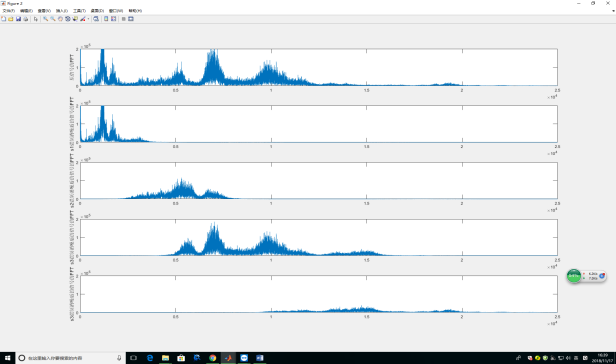

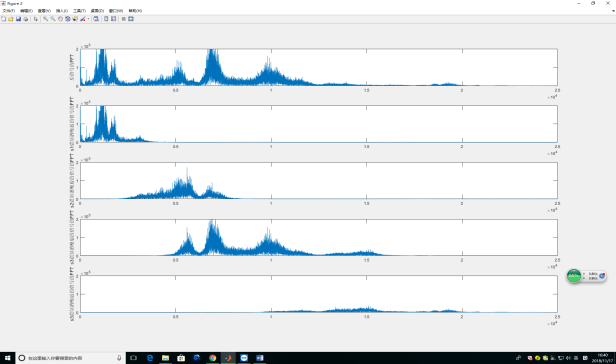

- 通过阅读可获得的资料,掌握运用傅里叶变换、小波包分析和能量法处理采集来的信号数据。特别是会运用傅里叶变换,目的是将信号中和刀具磨损变化相对应的特征信号寻找出来,对所采集到的数据对比分析,得出结论,最后把结果当做刀具做切削运动时的磨损状态的判断依据;

- 得到影响刀具切削的三个要素:切削速度、进给量、切削深度分别作用时的影响大小,比较总结;

- 因为小波分析相当于是对信号进行局部化处理,更为精准。本课题主要用小波包分析,尤其是使用能量法来观察频率的变化趋势,提取特征信号;

- 分析过程基于MATLAB软件,在MATLAB软件中编写合适的工程代码,实现信号的傅里叶变换和小波变换,得到各节点的能量图。

关键词:声发射信号 刀具磨损 傅里叶变换 小波分析 能量

Abstract

In the cutting machining, the wear condition of the tool directly affects the final workpiece size accuracy, so that the quality of the workpiece is not high, the production efficiency cannot be high, and the production cost is indirectly caused.So as to change these conditions, acoustic emission testing technology was used.Moreover, in recent years, acoustic emission technology has developed rapidly in the research of machining and cutting, and has gradually become an important research method.Therefore, the advantages of on-line dynamic non-destructive monitoring can be realized by using the acoustic emission detection technology, and the complex frequency signals of the components are decomposed to extract the characteristic signals, corresponding to the wear state of the tool.

In this paper, the acoustic emission signal data of the tool under different conditions is obtained through experiments and the data is analyzed to obtain the result.The main tasks completed are as follows:

- Understand the basic theory of acoustic emission technology, familiar with time domain analysis of acoustic emission signals, frequency domain analysis and time-frequency domain analysis.In particular, the Fourier transform is used to find the characteristic signal corresponding to the tool wear change in the signal, compare and analyze the collected data, draw conclusions, and finally use the result as the wear of the tool during the cutting motion. The basis for judging the status

- The three factors that affect the cutting of the tool are obtained: the influence of the cutting speed, the feed rate and the cutting depth respectively, and the comparison is summarized

- Since wavelet analysis is similar to amplifying the signal, it is more precision. This topic mainly uses wavelet packet analysis, especially the energy method to observe the frequency change trend and extract the characteristic signal

- The analysis process is based on MATLAB software, and the appropriate engineering code is written in MATLAB software to realize the Fourier transform and wavelet transform of the signal, and the energy map of each node is obtained.

Keywords: acoustic emission signal tool wear Fourier wavelet analysis energy

目录

第一章 绪论 6

1.1课题研究背景及意义: 6

1.2课题背景与国内外研究现状 6

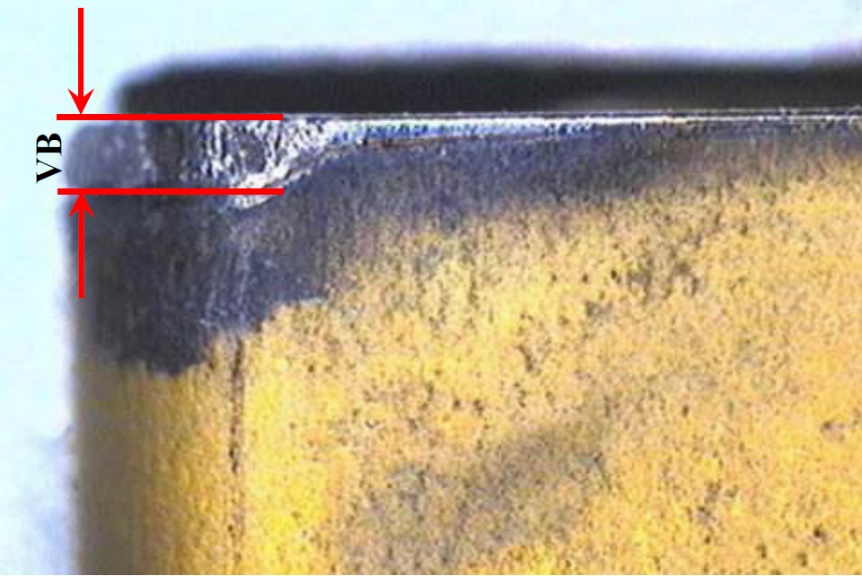

1.2.1切削刀具经历不同时期的磨损特点 6

1.2.2刀具磨损状态监测技术和研究现状 8

1.3本文的主要研究内容 9

第二章 刀具磨损监测系统方案设计 10

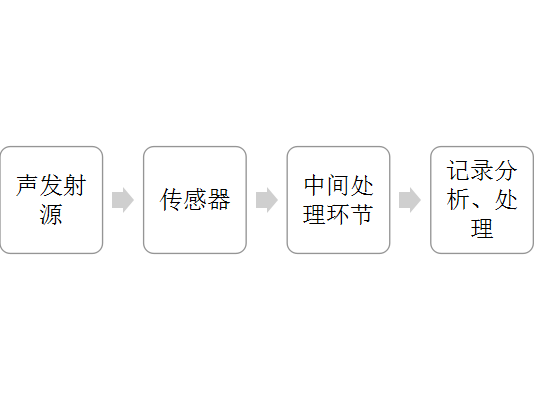

2.1声发射检测系统 10

2.2实验内容 11

第三章 声发射信号处理技术 12

3.1声发射信号处理基本理论 12

3.2声发射信号的时域分析 13

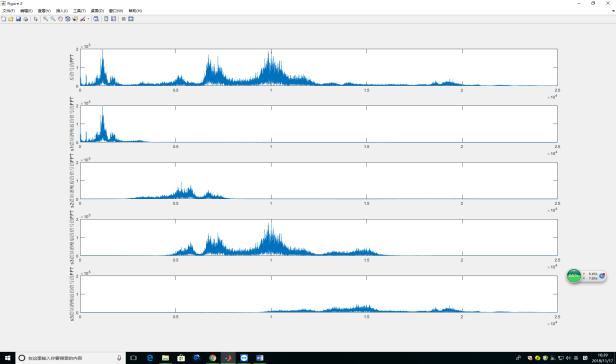

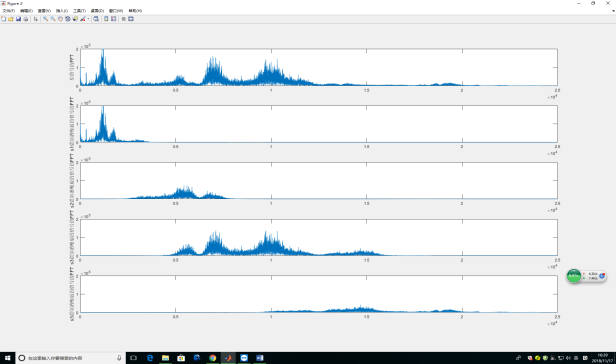

3.3声发射信号的频域分析 14

3.4切削三要素的对刀具磨损的影响 15

第四章 小波分析声发射信号 22

4.1小波分析的基本概念 22

4.1.1连续小波变换 22

4.1.2离散小波变换 23

4.2小波包分析 23

4.3小波包能量法 24

4.4小波包消噪 28

第五章 总结与展望 33

5.1总结 33

5.2展望 33

参考文献 34

致谢 36

第一章 绪论

1.1课题研究背景及意义:

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: