4J29TC4异种金属焊接接头的组织与性能研究毕业论文

2020-04-15 16:32:40

摘 要

钛合金因其具有高耐腐蚀、重量轻、比强度高等高温性能而广泛应用于核、航天、化工等行业。可伐合金具有与硬玻璃相似的热膨胀系数,在电子工业领域有着广泛的应用。钛合金和可伐合金的结合可以广泛应用于航空航天仪器领域。但两者焊接时会产生脆性金属间化合物,导致焊接性较差。本文采用添加中间层的方法,采用双道焊在中间层两侧各焊出一道焊缝,从而实现对TC4和4J29异种金属进行激光焊接,得出如下结论:

(1)对于4J29与TC4异种金属激光焊接,采用铌作为中间层时,由于产生脆性金属间化合物,铌中间层不能与4J29母材较好熔合,接头发生断裂。采用1mm钒作为中间层时,均可与两侧母材较好熔合。

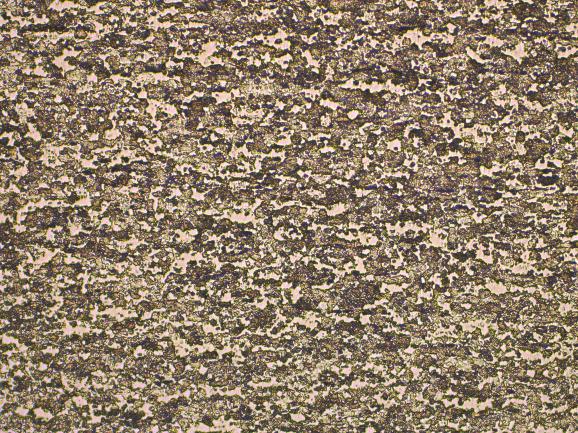

(2)4J29侧焊缝区(焊缝区Ⅰ)的组织为柱状晶和等轴晶。由于焊缝中含有一定含量的钒,起到了细晶强化的作用,故该区域组织细小且硬度较高。4J29侧热影响区(热影响区Ⅰ)组织为细小的奥氏体晶粒,由于晶粒细化,该区域成为整个接头硬度最高的部分。

(3)TC4侧焊缝区(焊缝区Ⅱ)组织主要由粗大的β柱状晶和由β相转变的α相组成,由于焊缝中钒含量增加,β到α β转变温度下降,所以柱状晶内只有极少量的针状马氏体α´。该区域由于存在粗晶组织,故硬度值高于母材。

(4)TC4侧热影响区(热影响区Ⅱ)靠近焊缝区的区域由于冷却速度大,β相发生非扩散型相变产生针状马氏体α´。该区域组织为初生α相 针状马氏体α´,并且由于存在大量针状马氏体α´,导致该区域硬度较高。在远离焊缝区的热影响区由于冷却速度较小,针状马氏体α´相数量减少,并存在一部分原始α β相,即组织由少量针状马氏体α´相 β相转变的α相 原始α β相组成。该区域由于针状马氏体α´数量减少,硬度值与母材相当。

.

关键词:4J29可伐合金;TC4钛合金;激光焊接;中间层

Microstructure and properties of 4J29/TC4 dissimilar metal welded joints

Abstract

Titanium alloy has high corrosion resistance, high specific strength and light weight, and has a wide range of applications in aerospace, chemical and nuclear fields. Kovar alloy has a similar thermal expansion coefficient as hard glass and has a wide range of applications in the electronics industry. The combination of TC4 and 4J29 can be used in a wide range of applications in aerospace equipment. However, when these two materials are welded, intermetallic compounds(IMCs) are produced, resulting in poor weldability. In this paper, the method of adding the intermediate layer is used to laser weld TC4 and 4J29 dissimilar metals. The main conclusions are as follows:

(1)For laser welding of 4J29 and TC4 dissimilar metals, when niobium is used as the intermediate layer, the niobium intermediate layer cannot fuse well with 4J29 base material due to the generation of brittle intermetallic compounds, and the joints are broken.When 1mm vanadium is used as the intermediate layer, it can fuse well with the base metal on both sides.

(2)The mircostructure of the 4J29 side weld zone (weld zone I) is columnar crystal and equiaxed crystal. Since the weld contains a certain amount of vanadium, it plays a role of fine grain strengthening, so the structure of the region is fine and the hardness is high. The mircostructure of 4J29 side heat-affected zone (heat-affected zone I) is fine austenite grains, which become the hardest part of the joint due to grain refinement.

(3)The TC4 side weld zone (weld zone II) consists mainly of coarse β-column crystals and α phase transformed by β phase. Due to the increase of vanadium content in the weld, the β--α β transition temperature decreases, so there is only a very small amount of acicular martensite α´ in the columnar crystals. Due to the presence of a coarse-grained structure, the hardness of this region is higher than that of the base metal

(4)Due to the fast cooling rate, the non-diffusive phase transformation of β happens in the TC4 side heat affected zone (HAZ Ⅱ),thus the microstructure of this region is primary α phase acicular martensite α´. due to the large amount of acicular martensite α´ the hardness of this region is high. In the heat affected zone away from the weld zone, the number of acicular martensite α´ phase decreases due to the small cooling rate, and there is a part of the original α β phase. So the microstructure of this region is a small amount of acicular martensite α´ primary α original α β. The hardness of this region is equivalent to the base metal due to the reduced number of acicular martensite α´.

Key words: 4J29 Kovar alloy; TC4 titanium alloy; laser welding; intermediate layer

目录

第一章 绪论 1

1.1 课题研究的意义及背景 1

1.2 激光焊接技术的原理及特点 3

1.3 4J29/TC4异种金属焊接性分析 4

1.4 4J29和TC4焊接工艺国内外研究现状及分析 5

1.5 课题研究的内容 6

第二章 实验材料、设备及实验过程 8

2.1 实验材料 8

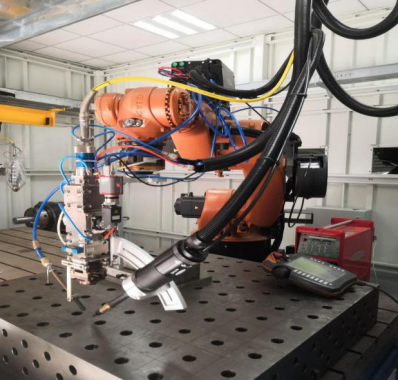

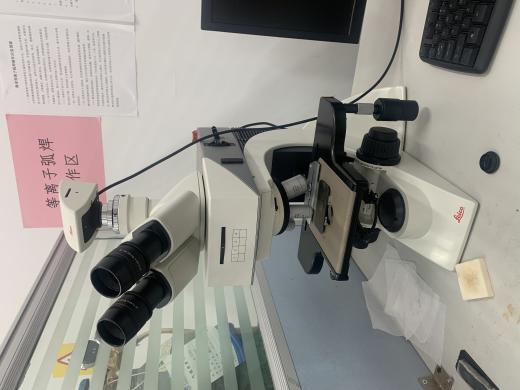

2.2 实验设备 8

2.3实验方法 10

第三章 4J29/TC4激光焊接工艺及焊缝成形 14

3.1 铌作中间层焊缝宏观形貌分析 14

3.2 钒中间层焊缝宏观形貌分析 17

3.3 本章小结 20

第四章 1mm钒中间层4J29/TC4激光焊接接头微观组织和力学性能 21

4.1 添加1mm钒中间层4J29/TC4接头截面宏观特征 21

4.2 添加1mm钒中间层4J29侧焊缝区(焊缝区Ⅰ)微观组织 22

4.3 添加1mm钒中间层4J29侧热影响区(热影响区Ⅰ)微观组织 23

4.4 添加1mm钒中间层TC4侧焊缝区(焊缝区Ⅱ)微观组织 24

4.5 添加1mm钒中间层TC4侧热影响区(热影响区Ⅱ)微观组织 27

4.6 接头显微硬度分析 29

4.7 本章小结 30

第五章 经济性分析 32

第六章 结论 33

参考文献 34

致谢 37

第一章 绪论

1.1 课题研究的意义及背景

4J29合金即可伐合金。膨胀系数与硅硼硬玻璃非常接近。问世后被广泛应用于电真空器件的密封,以及集成电路和晶体管等的加工制造中。此外,4J29合金是单一的奥氏体组织,不能用热处理的方法提高强度,仅可以通过加工硬化方法促进其硬度的提升[1]。4J29合金有着特殊的膨胀特性,其在不同温度下的膨胀系数见表1-1。4J29具有较高的居里点和良好的低温组织稳定性[3]。其焊接性良好,可采用如钎焊、熔焊、电阻焊等方法与Cu、Fe、Ni等金属焊接。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: