出口间隙逐渐扩大的罗茨鼓风机:数学建模与性能仿真外文翻译资料

2023-09-25 09:35:45

2nd International Conference on Advances in Mechanical Engineering and Industrial Informatics (AMEII 2016)

Roots Blower with Gradually Expanding Outlet Gap: Mathematical Modelling and Performance Simulation

Yingjie Cai 1, a, Ligang Yao 2, b

1School of Mechanical Engineering and Automation, Fuzhou University, Fuzhou, 350116, China 2School of Mechanical Engineering and Automation, Fuzhou University, Fuzhou, 350116, China aemail: cyj@fzu.edu.cn, bemail: ylgyao@fzu.edu.cn

Keywords: Gradually Expanding Gap; Roots blower; Basic inter-space; Simulation

Abstract. Gradually expanding gap in the outlet of the Roots blower can effectively reduce the backflow impact and the noise of the blower. The working principle for the Roots blower with the gradually expanding gap is investigated in this paper. And the mathematical modelling for backflow is proposed. Numerical methods are given to solve the outlet gap size. The performance parameters of different dimension gap are compared. The outlet flow field in Roots blower with gradually expanding gap is simulated by means of CFD simulation. Finally, the correctness of the numerical solution is verified.

Introduction

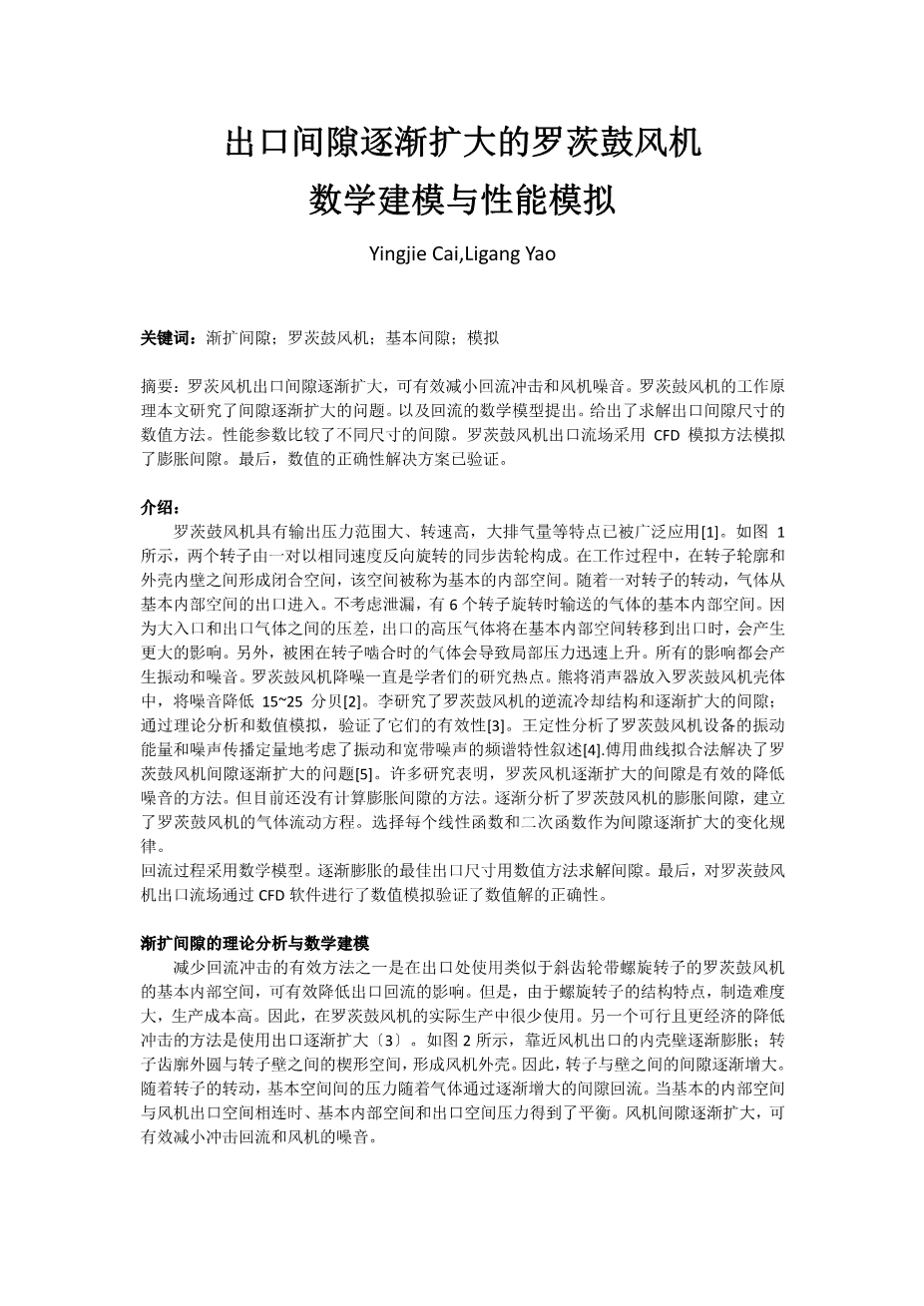

The Roots blower with the characteristics of large range of output pressure, higher speed, and large exhaust air rate has been used widely [1]. As shown in Fig.1, two rotors are driven by a pair of synchronous gears rotating in opposite direction at the same speed. While in working process, a closed space is formed between the rotor profile and the inner walls of the housing, and the closed space is called the basic inter-space. With the rotation of a pair of rotors, gas is pushed from the inlet to the outlet in the basic inter-spaces. Without taking into account the leakages, there are 6 basic inter-spaces of the gas which are delivered with a revolution of the rotors. Because of the large pressure differentials between the inlet and the outlet gas, the high pressure gas of the outlet will have a greater impact when the basic inter-space is transferred to the outlet. In addition, the trapped gas when the rotors engaging can cause the local pressure to rise rapidly. And all the impact will produce vibrations and noises. Roots blower noise reduction has been a research focus of scholars. Xiong put the muffler into the Roots blower shell, and reduced the noise by 15~25 dB [2]. Li studied the countercurrent cooling structure and gradually expanding gap of Roots blower, and verified the effectiveness of them with theoretical analysis and numerical simulation [3]. Wang analyzed the vibration energy of Roots blower equipments and noise propagation both qualitatively and quantitatively with the spectral characteristics of vibration and wideband noise taken into account [4]。Fu solved the gradually expanding gap of Roots blower by curve fitting method [5].

Many studies show that the gradually expanding gap of the Roots blower is one of the effective methods reducing noises. But there is no calculation method for the expanding gap. The gradually expanding gap of Roots blower is analyzed, and the gas flow equation is established in this paper. Each of linear and quadratic function is chosen as the changing rule of the gradually expanding gap. The backflow process is modeled by mathematics. The optimal exit size of the gradually expanding gap is solved with numerical method. Finally, the Roots blower outlet flow field is simulated by CFD software. And the correctness of the numerical solution is verified.

The Theoretical Analysis and Mathematical Modeling of the Gradually Expanding Gap

One of the effective ways to reduce the backflow impact is to use the helical rotors similar to the helical gear. The basic inter-space in the Roots blower with helical rotors is gradually opened at the outlet, which can effectively reduce the impact of the backflow at the outlet. However, due to the characteristics of the structure, the manufacturing of the helical rotors is difficult, and the

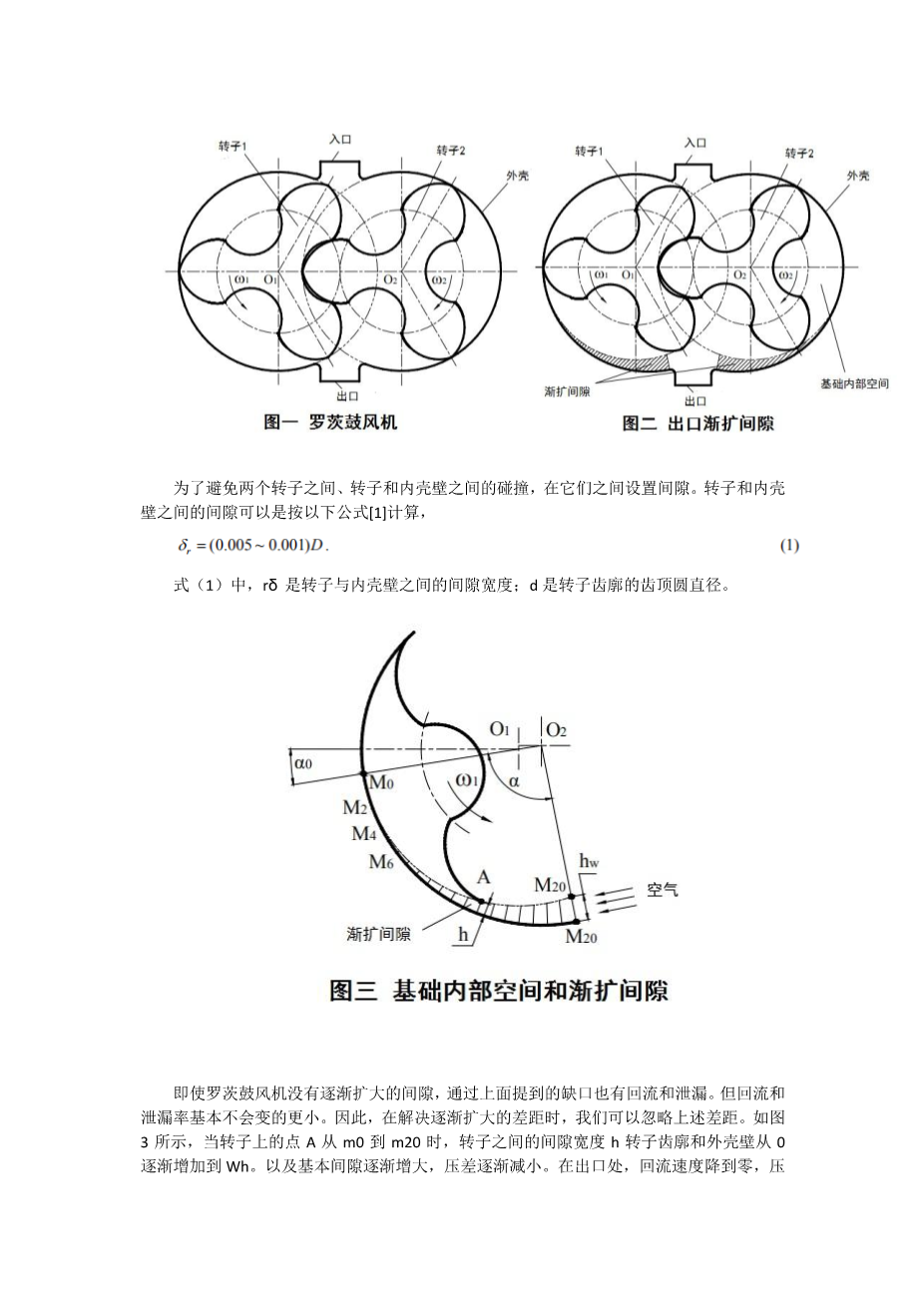

production cost is higher. So, it is rarely used in practical Roots blower production. And another feasible but more economical means to reduce the impact is to use the outlet gradually expanding gap [3]. As shown in Fig. 2, the inner housing wall near the outlet of the blower is gradually expanding; a wedge-shaped space between the outer circle of the rotor tooth profile and the wall of the blower housing is formed. So, the gap between the rotors and the walls is gradually increasing with the rotation of the rotors. The pressure of basic inter-space is gradually increasing when the backflow of the gas through the gap which are gradually increasing. When the basic inter-space connects with the outlet space of the blower, the pressure of the basic inter-space and the outlet space gets to balance. The gradually expanding gap of the blower can effectively reduce the impact of the backflow and the noise of the blower.

Rotor 1

Inlet

Rotor 2

Shell

Rotor 1

Inlet

Rotor 2

Shell

O1

O2

O1

O2

Outlet

Gradually expanding gaps

Outlet

Basic inter-space

Fig.1 Roots blower Fig. 2 The gradually expanding gaps of the outlet

In order to avoid the collision between the two rotors, between the rotors and the inner housing wall, the gap is set between them. The gap between rotor and the inner housing wall can be calculated by the following formula [1],

r (0.005 ~ 0.001)D . (1)

Where in Eq. (1), the r

is the width of gap between the rotor and the inner housing wall; D is

the addendum circle diameter of the rotor tooth profile.

O1 O2

alpha;0 M alpha;

0

M2

<p

剩余内容已隐藏,支付完成后下载完整资料</p

英语译文共 9 页,剩余内容已隐藏,支付完成后下载完整资料

资料编号:[609914],资料为PDF文档或Word文档,PDF文档可免费转换为Word