双缸气动楔式闸阀设计PN16DN450毕业论文

2020-07-16 20:16:34

摘 要

阀门是一种压力管道元件,它是用来改变管路断面和介质流动方向、控制输送介质压力、流量、温度的一种装置。有以下几种用途:

(1)接通或切断管路中各段的介质;

(2)调节管路中介质的流量和压力;

(3)改变介质流动方向;

(4)用于超压保护;

(5)阻止管路中介质倒流;

(6)指示和调节液面。

阀门的种类高达上万种,分类方法也是多种多样,一般按驱动方式分为两类:

(1)自动阀门:依靠介质本身的能力而自行动作的阀门;

(2)驱动阀门:借助手动、电力、气力或液力来操纵的阀门。

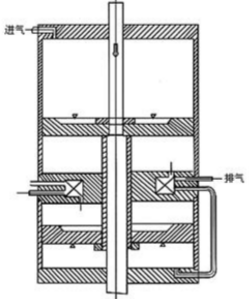

本设计为双缸气动楔式闸阀,闸阀(gate valve)是一个启闭件闸板,闸板的运动方向与流体方向相垂直,闸阀只能全开和全闭,不能用于调节或者节流。闸阀广泛应用于各种行业,一般口径DN≥50mm的切断装置都选用它。本文首先介绍双缸气动楔式闸阀的结构特点及工作原理,最后进行零部件的设计与计算,包含通用部分及闸阀专用部分的设计与计算,其中还包括各个零部件的强度校核。

本设计整个过程首先要确定阀门的工作环境以确定闸阀参数,包含介质温度、公称压力和公称尺寸。然后是熟悉闸阀的工作原理,进行受力分析、选取材料,再根据材料性能进行强度或稳定性校核。最后要进行零件图和总装图的绘制(AUTOCAD)。

关键词:阀门 阀门分类 双缸气动楔式闸阀 强度校核

Abstract

The valve is a kind of pressure pipeline element. It is a device used to change the pipeline section and the medium flow direction, and control the pressure, flow rate and temperature of the medium. There are several uses:

(1) Turn on or off the media in each section of the pipeline, such as: gate valves, globe valves, butterfly valves, ball valves, plug valves, diaphragm valves, etc.;

(2) Adjust the flow and pressure of medium in the pipeline, such as: regulating valve, throttle valve, pressure reducing valve, butterfly valve, ball valve, etc.;

(3) Change the medium flow direction, such as: distribution valve, three-way stopcock, three-way ball valve, four-way ball valve, etc.;

(4) For overpressure protection, such as: safety valve, relief valve;

(5) Prevent the back flow of medium in the pipeline, such as: check valve;

(6) Indicate and adjust the liquid level, eg level indicators, level regulators, etc.;

(7) Water and gas separation in pipelines, such as steam traps, air traps, etc.;

(8) Temperature adjustment in the pipeline, such as: temperature control valve, temperature reducing and decompression device.

There are many kinds of valves. With the continuous improvement of various types of complete sets of equipment and process flow, the types of valves are still increasing, but there are two general categories:

(1) Automatic valves: valves that rely on the ability of the medium (liquid, air, steam, etc.) to act on their own;

(2) Actuation valve: A valve operated by manual, electric, pneumatic or hydraulic force.

This design is a double-cylinder pneumatic wedge gate valve. The gate valve is a gate valve. The direction of movement of the gate is perpendicular to the direction of the flow. The gate valve can only be fully opened and fully closed. It cannot be adjusted or throttled. . The gate valve is a kind of valve with a wide range of use. Generally, the cutting device with a bore diameter of DN≥50mm is selected, and sometimes the cutting device with a small bore diameter also uses a gate valve. This paper first introduces the structural characteristics and working principles of the double-cylinder pneumatic wedge gate valve. Finally, the design of the components, including the design of the general part and the dedicated part of the gate valve, also includes the strength check of each component. The difficulty lies in the verification of the sealing surface of the valve seat, the strength of the valve stem, and the stability check.

The whole process of this design must first determine the working environment of the valve to determine the valve parameters, including the medium temperature, nominal pressure and nominal size. Then it is familiar with the working principle of the gate valve, carrying out force analysis, selecting materials, and then checking the strength or stability according to the material properties. Finally, drawing of parts and assembly drawings (AUTOCAD) is performed.

Key Words: Valves;Valve Category;Double Cylinder Air Wedge Valve;Strength Check

目 录

摘 要 I

Abstract II

第一章 绪论 1

1.1 选题背景 1

1.2 国内阀门发展状况 1

1.2.1 发展现状 1

1.2.2 发展趋势 1

第二章 双缸气动楔式闸阀结构特点及工作原理 3

2.1 结构特点 3

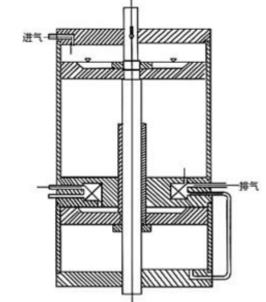

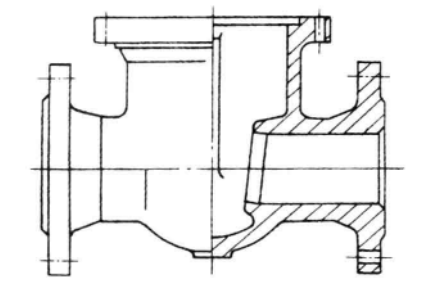

2.2 工作原理 3

第三章 阀门的设计与计算 6

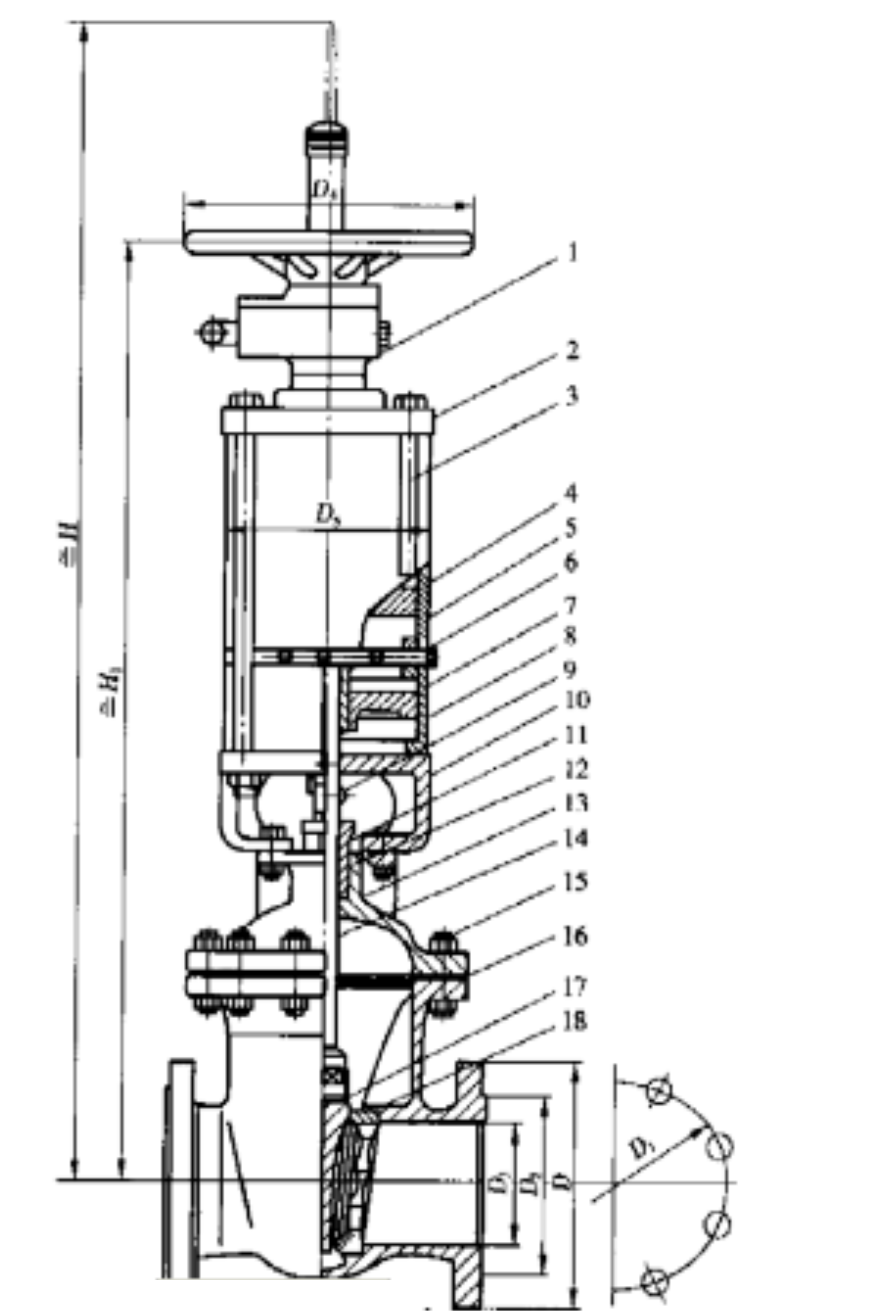

3.1 阀体的设计与计算 6

3.1.1 阀体材料选择 6

3.1.2 阀体的结构 6

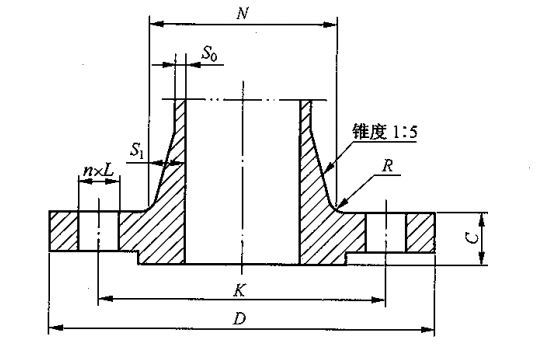

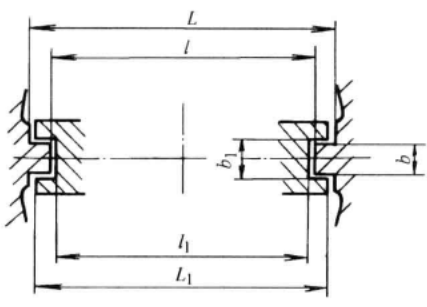

3.1.3 阀体连接形式及结构长度的选择 6

3.1.4 阀座密封设计 7

3.1.5 阀体壁厚的设计与计算 8

3.1.6 中法兰的设计与计算 8

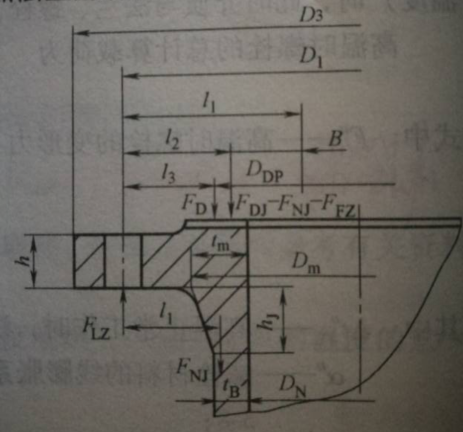

3.2 闸板的设计与计算 13

3.2.1 闸板密封面宽度和内径的选取 13

3.2.2 闸板主要尺寸确定 14

3.2.3 闸板密封面比压计算 15

3.3 阀杆的设计与计算 15

3.3.1 阀杆受力分析 15

3.3.2 阀杆强度校核 18

3.3.3 阀杆稳定性校核 18

3.3.4 阀杆主要尺寸确定 19

3.4 阀盖及填料箱装置的设计与计算 21

3.4.1 阀盖的设计与计算 21

3.4.2 填料箱装置的设计与计算 22

3.4.3 上密封座的设计 28

3.5 气动装置的设计与计算 28

3.5.1 气缸直径估算 29

3.5.2 气缸的校核 29

3.6 其他零件的设计与计算 30

3.6.1 滚动轴承的选择以及手轮直径的确定 30

3.6.2 阀杆螺母螺纹的强度校核 31

第四章 总结与展望 33

第五章 经济分析 34

参考文献 35

致谢 37

第一章 绪论

1.1 选题背景

阀门用途极为广泛,是各种管路的连接件和附件。众所周知无论是农业还是工业,都需要管道输送各种类型的介质,如水、石油、天然气、蒸汽和各种具有腐蚀介质的化工产品,还有近年来备受关注的核电、合成橡胶、PTA等新兴产业也都离不开各种各样的管道,这些管道像一根根血管撑起中国的发展。据不完全统计,一座发电量达到百万千瓦级别的核电站需要上万台阀门产品。

1.2 国内阀门发展状况

1.2.1 发展现状

相关图片展示: