基于UG的准双曲面齿轮建模及运动仿真分析毕业论文

2020-04-12 15:43:12

摘 要

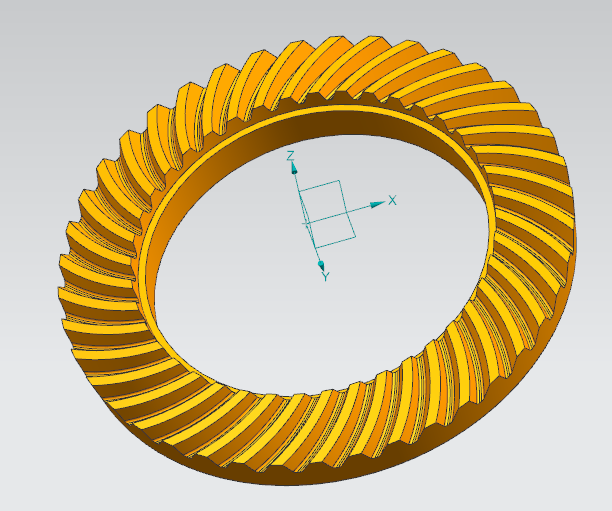

主减速器是汽车后桥重要组成部分,其机械性能对汽车在运转过程中产生的的振动噪声有很大的影响,而准双曲面齿轮作为汽车主减速器中最主要的部件,在汽车正常行驶情况下其振动特性直接关系着噪音的形成。因此,对准双曲面齿轮副的动态啮合特性进行研究,探究各结构参数对其性能的影响,并寻求轮齿的啮合规律具有十分重要的意义。

本文在充分了解国内外研究现状的基础上,通过软件模拟仿真,从模态分析、动力学分析以及疲劳分析三个方面,对准双曲面齿轮进行分析研究。本文针对所选取的车型设计以及校核准双曲面齿轮副,并讨论了各结构参数的选取对准双曲面齿轮副力学性能的影响,基于以上参数,完成了准双曲面齿轮副的建模、装配以及干涉检查。在理论分析的基础上,得到了准双曲面齿轮副在啮合传动过程中的碰撞力计算模型,并对齿轮副进行运动仿真分析。利用仿真软件对齿轮进行模态分析,分别得到了准双曲面齿轮副的前六阶固有频率以及相应的振型,并对其进行了瞬态动力学分析以及疲劳强度校核。然后,分别在两种典型的轴向安装误差情况下,通过对其进行接触分析,探讨了这两种安装误差对其动态啮合性能的影响。

研究结果表明,通过成形法以及滚切法分别得到的准双曲面齿轮副的从动轮以及主动轮的模型精度符合要求,其运动特性符合实际情况。在齿轮副运转过程中,轮齿啮合变形量处于累积的状态,仿真所得到的接触区域较良好,疲劳寿命符合要求。对于齿轮的轴向安装误差而言,这两种安装误差对轮齿的应力集中影响不大,轮齿之间接触情况基本和理论安装位置相符,但是主动轮对安装误差的响应更加明显。

关键词:准双曲面齿轮;三维建模;动力学分析;模态分析;接触分析;疲劳分析

Abstract

The main reducer is an important part of the rear axle of the car. Its mechanical properties have a great influence on the vibration and noise generated during the operation of the car. The hypoid gear is used as the main component of the main decelerator in normal driving conditions. Its vibration characteristics directly relate to the formation of noise. Therefore, researches on the dynamic meshing characteristics of hyperboloidal gear pairs have been carried out to explore the influence of various structural parameters on their performance, and it is of great significance to seek the meshing law of gear teeth.

Based on the full understanding of the research status at home and abroad, this paper analyzes and studies the hyperboloid gears through three aspects of modal analysis, dynamic analysis and fatigue analysis through software simulation. This paper designs and verifies hyperboloid gear pairs for selected models, discusses the influence of the selection of structural parameters on the mechanical properties of hypoid gears, and completes the modeling of hypoid gear pairs. , assembly and interference check. Based on the theoretical analysis, the collision force calculation model of the hypoid gear pair in the process of meshing transmission is obtained, and its motion simulation analysis is carried out. The modal analysis of the gears was performed using simulation software. The first six natural frequencies of the hypoid gear pair and the corresponding vibration modes were obtained respectively. Transient dynamics analysis and fatigue strength checking were performed. Then, in the case of two typical axial installation errors, through contact analysis, the effects of the two mounting errors on their dynamic meshing performance were discussed.

The results show that the model accuracy of the driven wheel and the driving wheel of the hypoid gear pair obtained by the forming method and the hobbing method meets the requirements, and its kinematics accords with the actual situation. During the operation of the gear pair, the meshing deformation of the gears is in an accumulated state. The contact area obtained by the simulation is good and the fatigue life meets the requirements. For the axial installation error of gears, these two installation errors have little effect on the stress concentration of the gear teeth. The contact conditions are basically the same as the theoretical installation position, but the response of the drive wheel to the installation error is more obvious.

Key Words:Hypoid gears; 3D modeling; dynamic analysis; modal analysis; contact analysis; fatigue analysis

目 录

摘 要 I

Abstract II

第1章 绪论 1

1.1 概述 1

1.2 研究目的及意义 2

1.3 国内外研究现状 2

1.4 研究目标、研究内容 3

1.4.1 研究目标 3

1.4.2 研究内容 3

1.5 拟采取的研究方法和技术路线 4

1.5.1 拟采取的研究方法 4

1.5.2 技术路线 4

1.6 本章小结 5

第2章 准双曲面齿轮的参数设计及校核 6

2.1 准双曲面齿轮副的基本参数选择与设计 6

2.1.1 主、从动锥齿轮齿数Z1和Z2 6

2.1.2 从动轮大端分度圆直径 和端面模数

和端面模数 7

7

2.1.3 准双曲面齿轮副的从动齿轮齿宽 的选择 7

的选择 7

2.1.4 准双曲面齿轮副的偏置距以及偏置方向的选择 8

2.1.5 准双曲面齿轮副的螺旋角 的选择 9

的选择 9

2.1.6 准双曲面齿轮副螺旋方向的选择 10

2.1.7 准双曲面齿轮副法向压力角的选择 10

2.1.8 准双曲面齿轮副加工刀具名义半径选择 10

2.2 准双曲面齿轮的参数设计 11

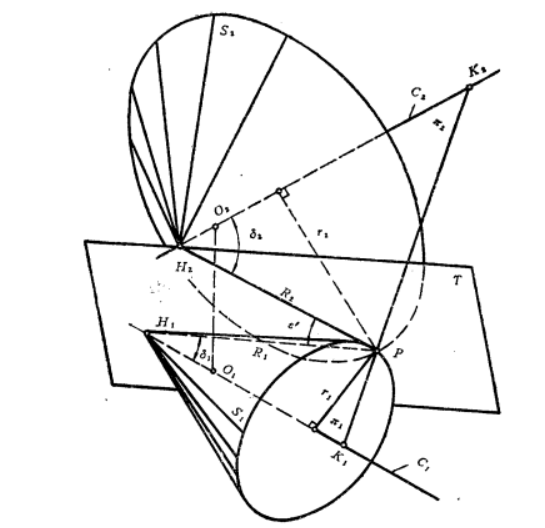

2.2.1 准双曲面齿轮的几何设计原理 11

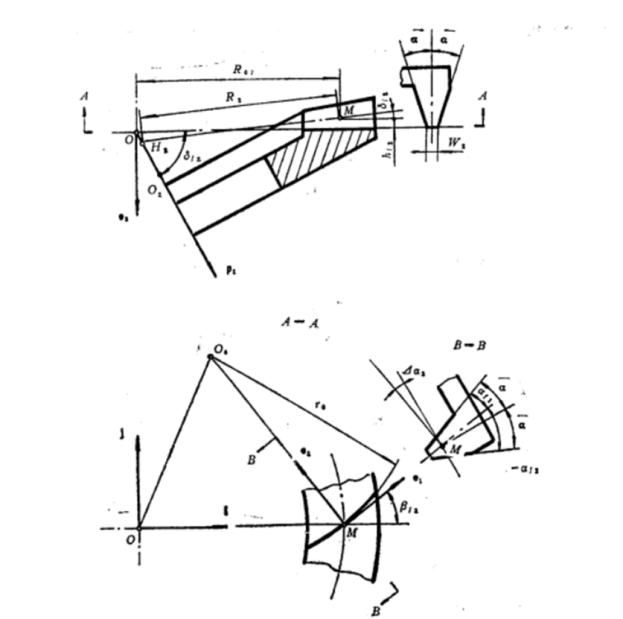

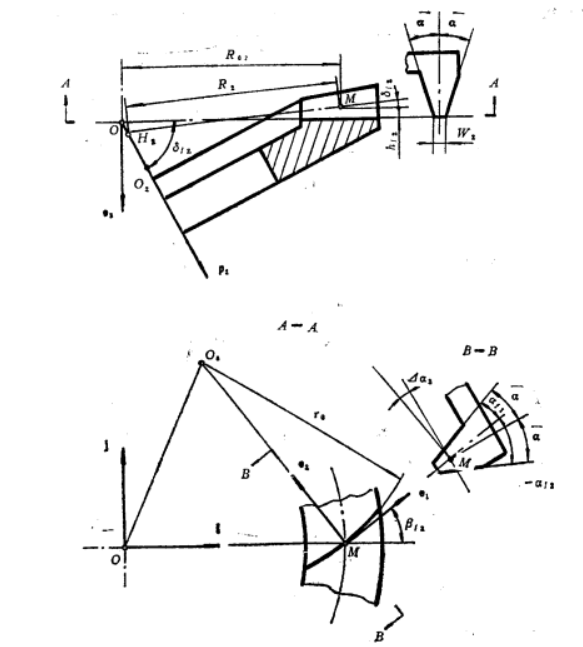

2.2.2 准双曲面齿轮副轮坯参数的设计 13

2.3 准双曲面齿轮的强度计算及校核 15

2.3.1 准双曲面齿轮的损坏形式 15

2.3.2 准双曲面齿轮的强度计算及校核 15

2.3.3 准双曲面齿轮小轮根切检查 18

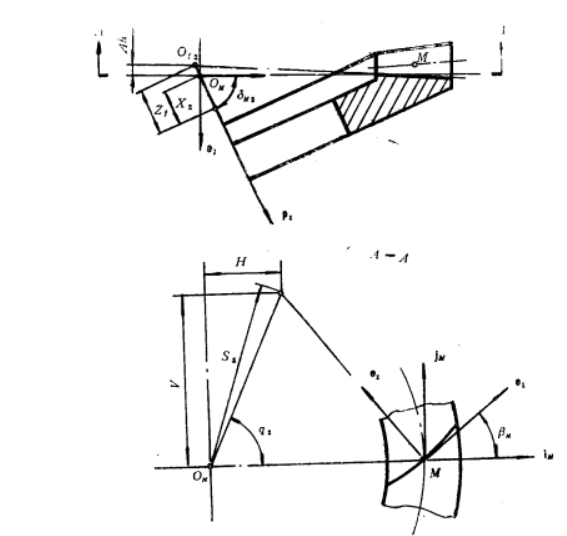

2.4 成形法加工大齿轮的刀具参数的计算 18

2.4.1 刀具齿顶距的计算 19

2.4.2 刀具圆角半径的计算 19

2.4.3 机床加工参数的计算 21

2.5主减速器齿轮的材料及热处理 24

2.6 本章小结 25

第3章 准双曲面齿轮的建模及运动仿真 26

3.1准双曲面齿轮副的建模 26

3.1.1 被动齿轮模型的建立 26

3.1.2 主动齿轮模型的建立 27

3.1.3 准双曲面齿轮的干涉检查 28

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: