800立方液氨罐区安全设计与评价毕业论文

2020-07-08 21:30:38

摘 要

液氨本身具有剧毒性,极易挥发,挥发后与空气混合可形成可燃性气体爆炸混合物,所以发生事故的几率相对较高。且液氨作为一种重要的化工原材料在化工领域中被广泛使用。近年来,随着合成氨技术的不断发展,产品氨的纯度也越来越高,相应地,对于储存液氨的要求也越来越高。很多的食品厂、冷库等企业都需要用液氨进行产品冷却保鲜,液氨与我们的生活息息相关。近年来发生过很多液氨泄露火灾爆炸事故,大量人员伤亡,因此合理设计并评价液氨储罐对于提高社会的安全指数,减伤人员伤亡有着重要意义。根据一些国家规范的要求以及参考权威论文和期刊,对800 m3液氨储罐区、包含8个液氨储罐进行合理设计,包括储罐的选型、选材、筒体尺寸及厚度的计算、安全附件的选择、罐区设计、消防设施的选择与计算、火灾爆炸危险区域划分、防雷防静电设计。安全评价方面先确认罐区为几级重大危险源,再根据道化学法计算确认暴露区域等参数,事故树求出各基本事件的结构重要度,并根据结构重要度系数的大小确定基本事件的影响程度。TNT当量法确定死亡半径、超压等参数。根据事故树分析,应着重对结构重要度大的基本事件进行改进。最后进行总结分析,并展望未来。

关键词:液氨 罐区 安全设计 安全评价

Safety Design and Evaluation of 800m3 Liquid Ammonia Tank Area

Abstract

Liquid ammonia itself is highly toxic and highly volatile. After volatilization, it is mixed with air to form a flammable gas explosion mixture, so the chance of accidents is relatively high. Liquid ammonia is widely used in the chemical industry as an important chemical raw material. In recent years, with the continuous development of synthetic ammonia technology, the purity of the product ammonia has become higher and higher, and accordingly, the requirements for the storage liquid ammonia have become higher and higher. Many companies such as food factories and cold stores need to use liquid ammonia to cool and preserve products. Liquid ammonia is closely related to our lives. In recent years, there have been many fire and explosion accidents involving leakage of liquid ammonia and a large number of casualties. Therefore, the rational design and evaluation of liquid ammonia storage tanks is of great significance for improving the social safety index and reducing casualties. According to the requirements of some national regulations and reference to authoritative papers and periodicals, the 800 m3 liquid ammonia storage tank area and 8 liquid ammonia storage tanks are rationally designed, including the tank selection, material selection, cylinder size and thickness calculation, Selection of safety accessories, design of tank areas, selection and calculation of fire protection facilities, division of fire and explosion hazard areas, and lightning protection and anti-static design. In the safety assessment, the tank area is first identified as several major hazard sources, and then the parameters such as the exposure area are calculated according to the chemical method of the road, and the accident tree is used to determine the structural importance of each basic event, and the basic event is determined according to the size of the structural importance coefficient. influence level. The TNT equivalent method determines parameters such as the radius of death and overpressure. According to the accident tree analysis, it is important to improve the basic events with a high degree of structural importance. Lastly, it concludes and analyzes and looks forward to the future.

Key Words:Liquid ammonia;Tank area;Safety design;Safety Evaluation

目录

摘要 I

Abstract II

第一章概述 1

1.1背景介绍 1

1.2国内外研究现状 1

1.3研究内容及意义 2

第二章 储罐设计 3

2.1储罐的选型与选材 3

2.1.1储罐的选型 3

2.1.2液氨储罐的选材 3

2.2 液氨储罐的结构设计 3

2.2.1储罐设计参数的确定 3

2.2.2储罐筒体尺寸的计算 4

2.2.3选择储罐封头型号 4

2.2.4计算筒体壁厚 5

2.2.5计算封头壁厚 5

2.4安全附件 6

2.4.1安全阀 6

2.4.2液位计 7

2.4.3压力表 8

2.4.4温度计 8

2.5小结 8

第三章 罐区设计 9

3.1罐区平面布置及防火堤设置 9

3.2消防设施 10

3.2.1消防车道的布置 10

3.2.2消防冷却系统用水量 10

3.2.3消防给水管道及消火栓 12

3.2.4泡沫灭火系统设计 12

3.3火灾爆炸危险区域划分 13

3.3.1影响因素 13

3.3.2危险区域划分 14

3.4罐区有毒气体报警仪布置 14

3.4.1报警仪的种类及选型 14

3.4.2检测器 14

3.4.3报警器 15

3.5防雷防静电设计 15

3.6小结 16

第四章 储罐区安全评价 17

4.1重大危险源辨识 17

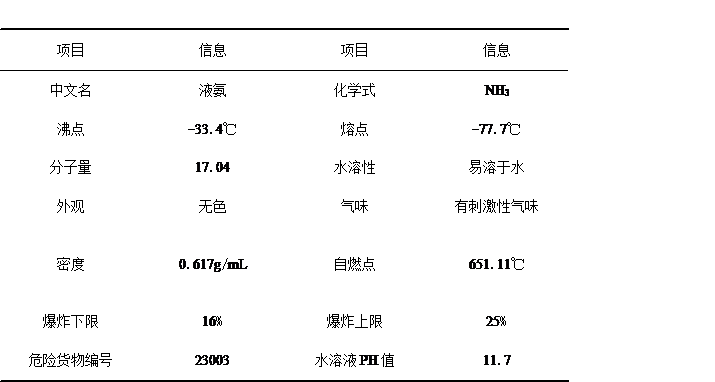

4.1.1液氨理化性质 17

4.1.2重大危险源辨识 18

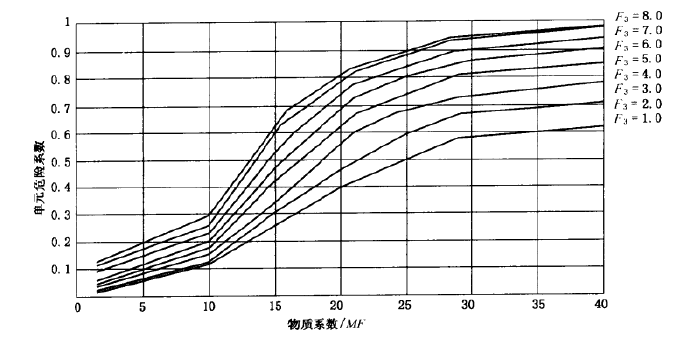

4.2道化学公司火灾爆炸危险指数评价方法 18

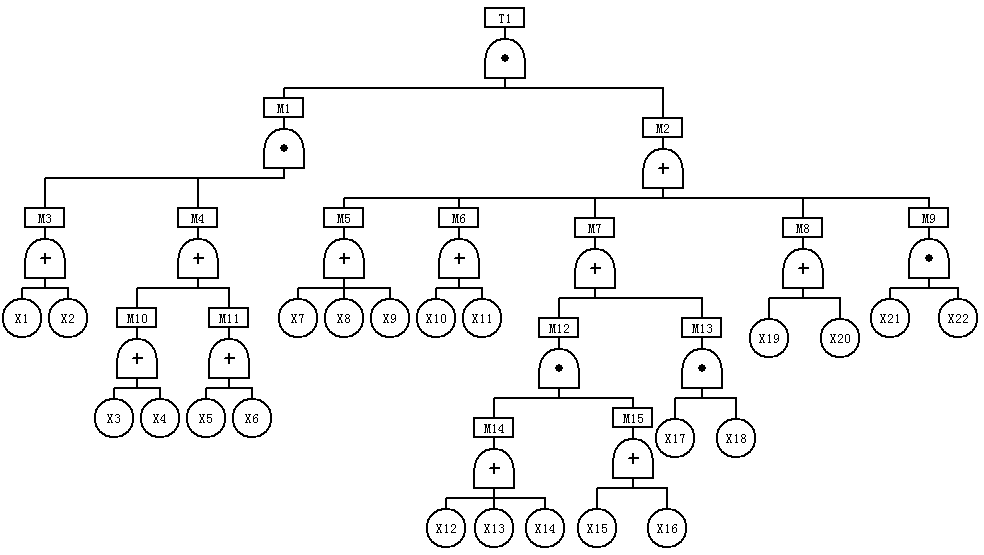

4.3液氨储罐事故树分析 22

4.3.1液氨储罐化学爆炸事故树 24

4.3.2液氨储罐物理爆炸事故树 28

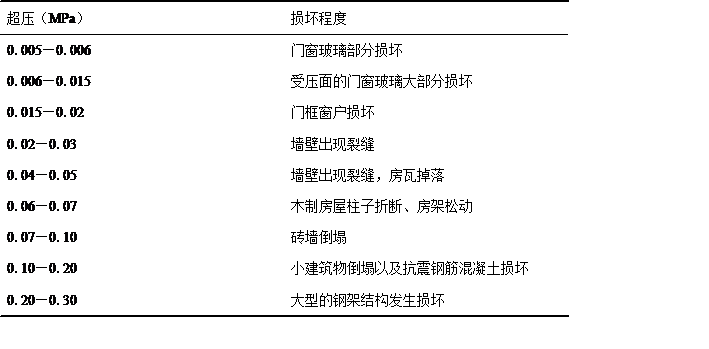

4.4TNT当量法 30

4.5小结 32

总结与展望 34

参考文献 35

第一章概述

1.1背景介绍

液氨作为一种重要的化工原材料在化工领域中被广泛使用。近年来,随着合成氨技术的不断发展,产品氨的纯度也越来越高,相应地,对于储存液氨的要求也越来越高,液氨本身具有剧毒性,极易挥发,挥发后与空气混合可形成可燃性气体爆炸混合物,由于液氨本身的不稳定性及人的不安全行为因素,所以其发生事故的几率相对较高,开展液氨储罐区安全设计与评价工作变的尤为重要。

大量的因液氨泄漏而发生的火灾爆炸事故给予我们一些警示。2004年河南骏马化工有限公司液氨罐车在进行液氨充装过程中发生泄漏,随后被静电火花引燃发生火灾,造成3死9伤的悲剧;2007年四川省康达肉类食品加工厂在进行液氨转存过程中发生液氨泄漏事故,两人被毒死;2013年吉林省宝源丰禽业公司因液氨泄露从而发生了特别严重的火灾爆炸事故,121人因此死亡,76人因此受伤,爆炸原因主要是储罐材料的低劣和液氨制冷操作不当造成其中一只液氨储罐爆炸,引燃周围其它储罐。

相关图片展示: