邮轮典型通气管路噪声数值仿真及控制毕业论文

2020-04-11 18:00:27

摘 要

在现代邮轮的内部广泛分布着各种各样的管路系统,这些管路系统是保证邮轮正常工作的关键因素。但是,在这些管路系统正常工作的同时,也会给邮轮以及在邮轮中的工作人员们带来这样或那样的问题和困扰,例如噪声问题就是其中之一。对于噪声问题,邮轮中通气管路产生的气动噪声是噪声问题的主要原因。因此,对邮轮中典型通气管路的噪声分析就显得格外重要。在邮轮各式各样的通气管路中,我们可以按照对横截面、结构等因素对它们进行分类,典型的有正方形截面通气管路、圆形截面通气管路、直角弯头L型通气管路以及圆角弯头L型通气管路等。由于邮轮通气管路分布广泛并且其结构复杂多样,再加上噪声问题的重要性,因此,对邮轮典型通气管路噪声的数值仿真及控制方法一直以来都是船舶与海洋工程中的焦点。

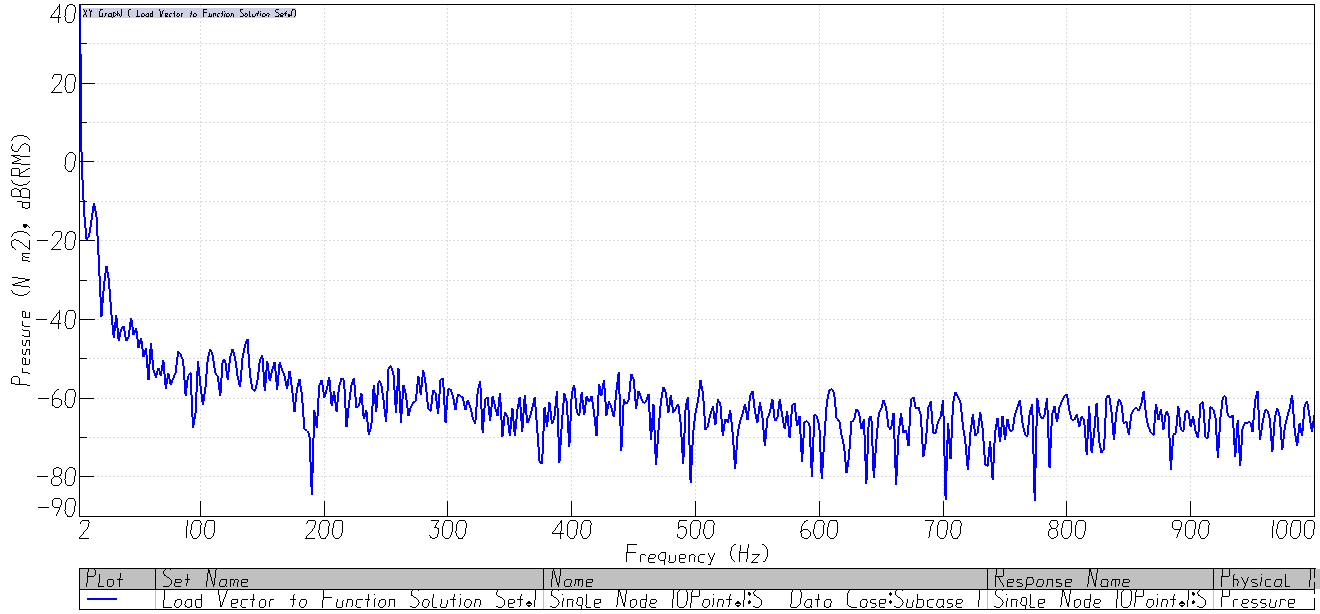

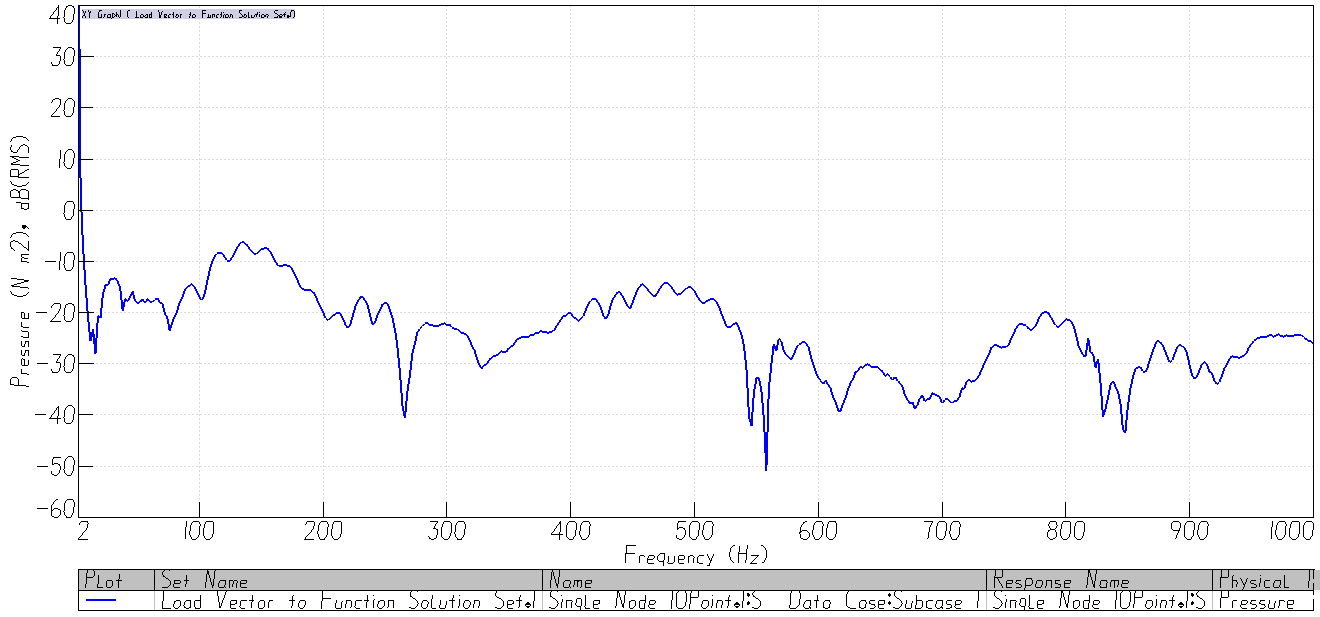

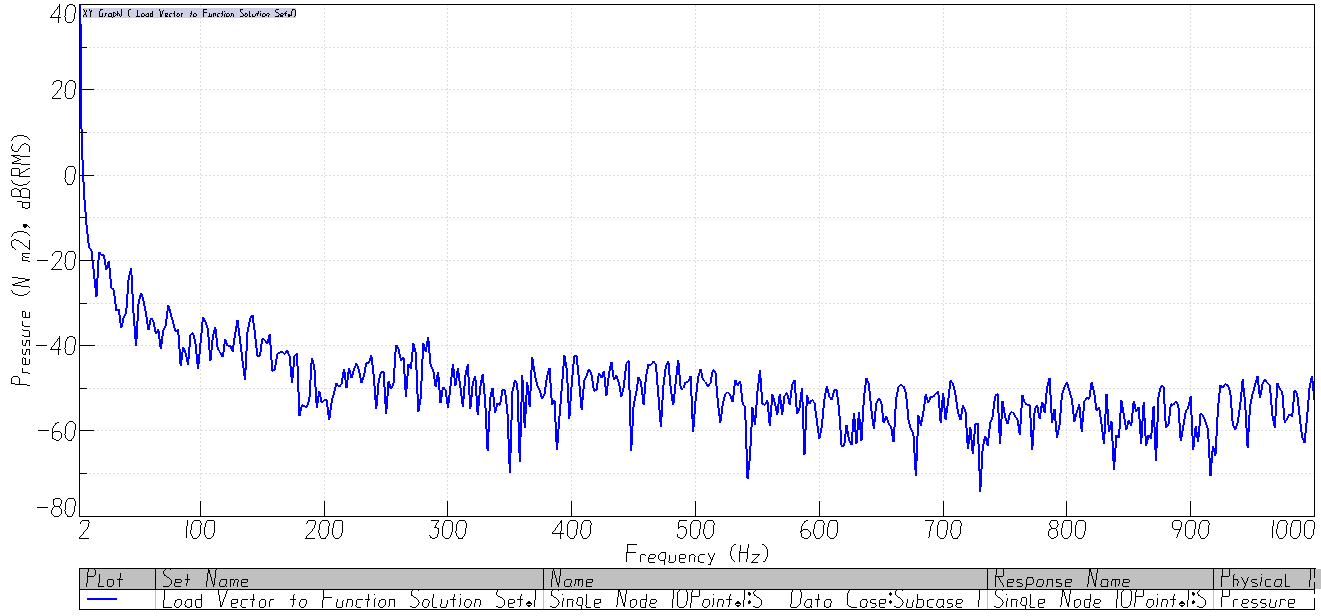

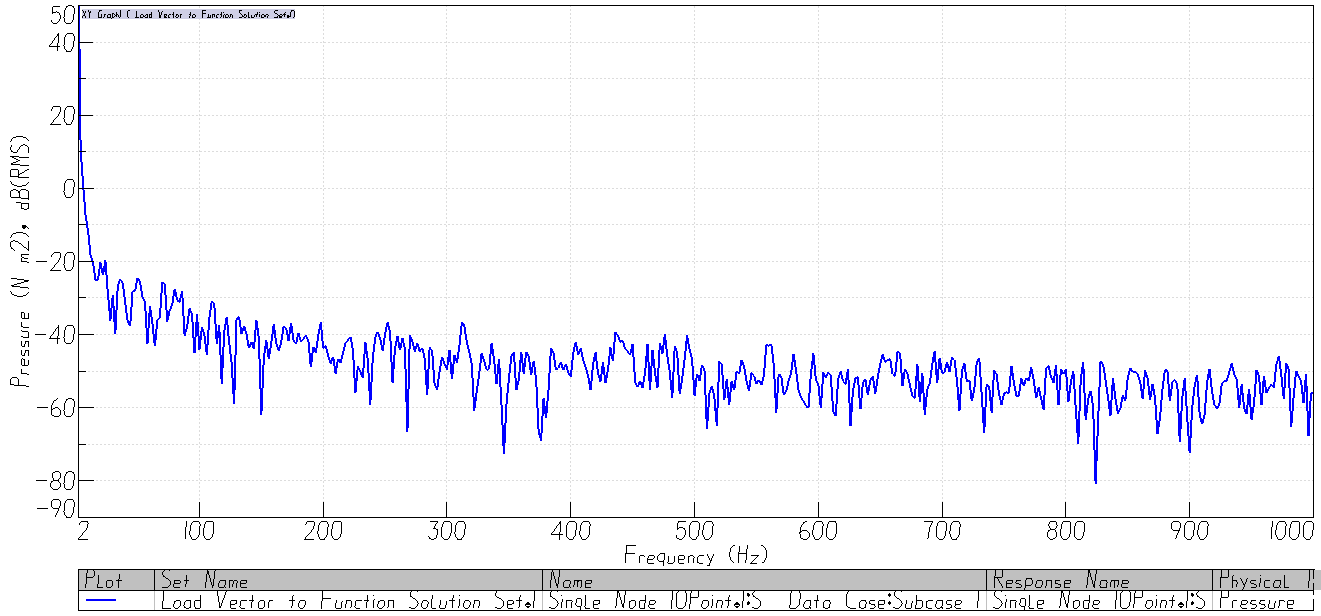

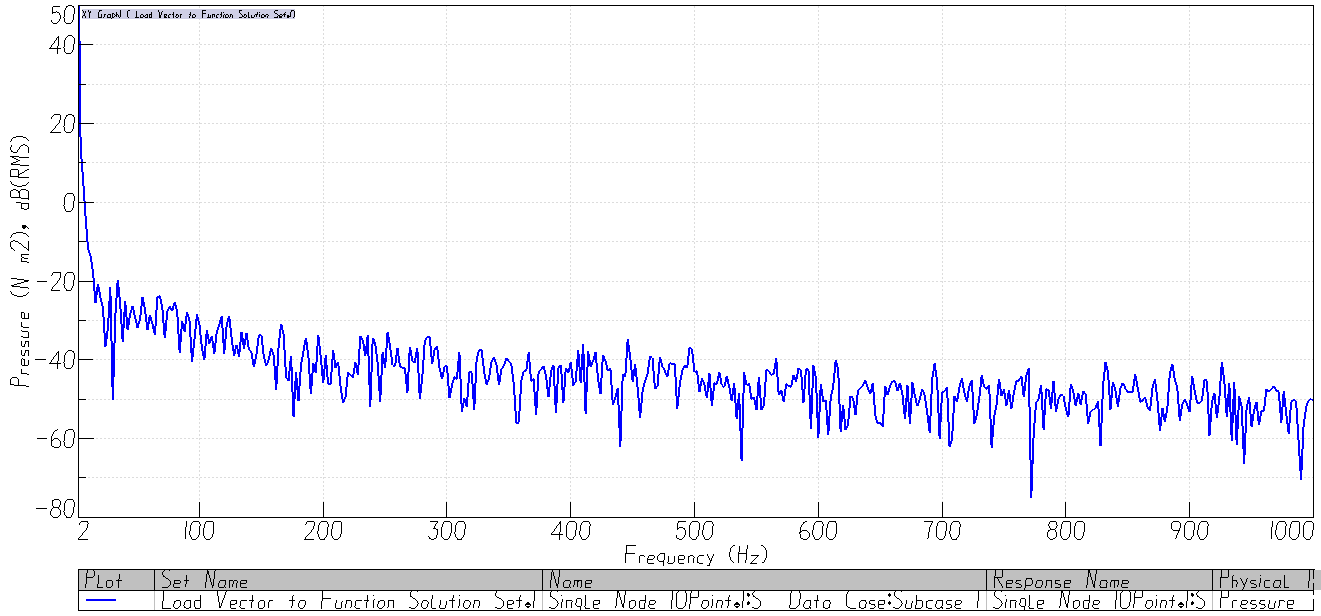

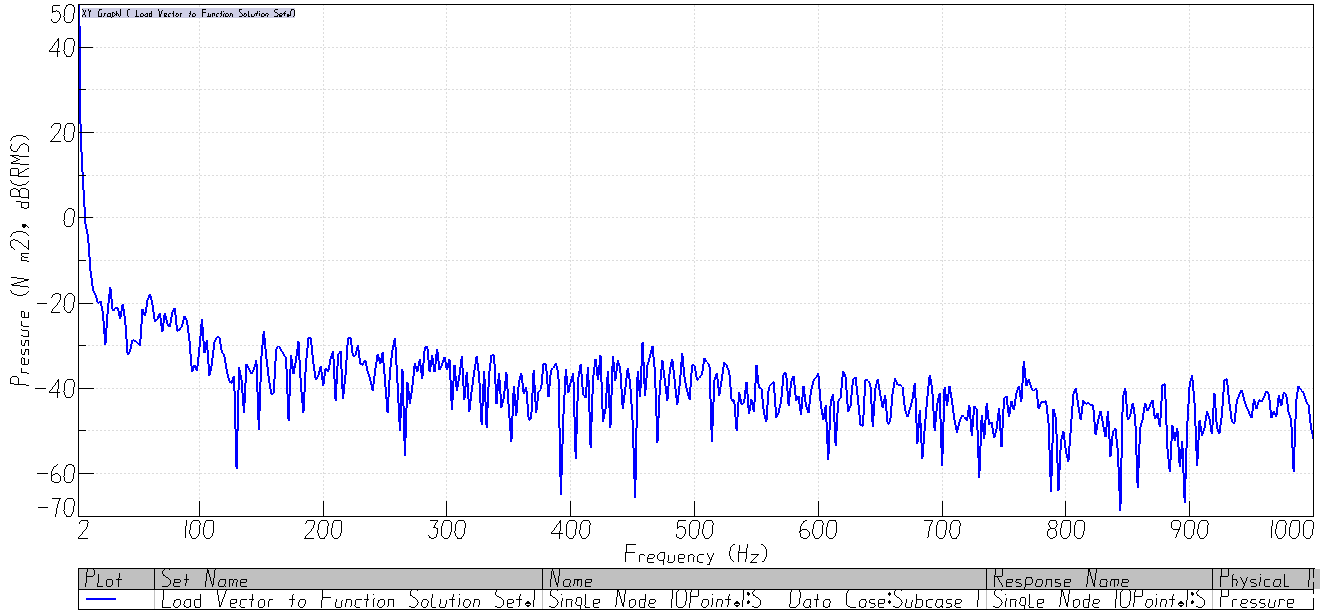

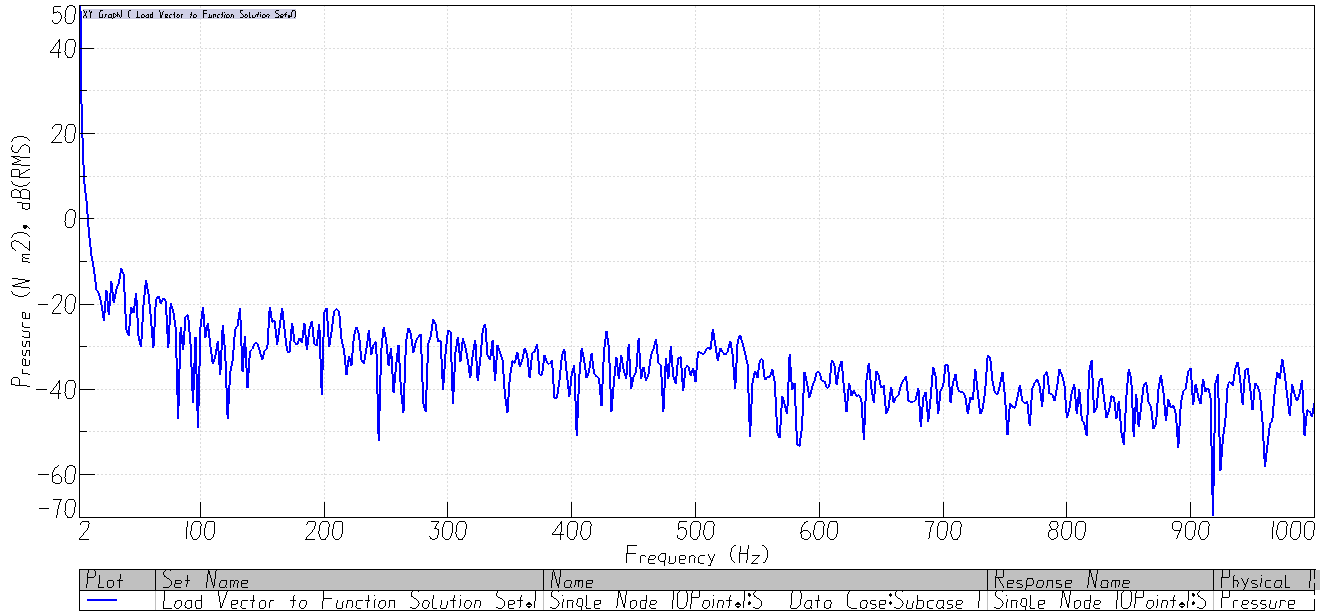

本文首先归纳出了邮轮上两类典型的通气管路,并构建出相应的几何模型,然后在几何模型的基础上对其划分CFD网格以及声学计算网格;接着利用Fluent对CFD网格先进行稳态计算,再在稳态计算结果的基础上进行稳态计算,从而大大减少计算时间;然后,将在Fluent中计算得到的结果导入LMS Virtual. Lab Acoustics中进行声学有限元计算,得到正方形截面和圆形截面的直通气管路、直角弯头和圆角弯头的L型通气管路以及不同横截面面积的正方形截面直通气管路在出口监测点处的声压级频率响应曲线和总声压级;最后,将对上述三组通气管路的计算结果进行比较分析,得到具有较好气动噪声特性的通气管路形式,从而提出几种邮轮通气管路气动噪声控制技术。

通过计算,发现对于邮轮通气管路,无论是正方形截面或圆形截面还是直角弯头或圆角弯头L型通气管路,出口处监测点位置上的声压级都会随入口流速的增大而增大,声压级的增长速度也都会随入口流速的增大而略有减小。圆形截面通气管路的气动噪声水平要低于正方形截面通气管路,圆形截面通气管路的气动噪声特性要好于正方形截面通气管路。并且通气管路横截面形状对总声压级随入口流速的变化趋势影响不大。圆角弯头L型通气管路的气动噪声水平要低于直角弯头L型通气管路,圆角弯头L型通气管路的气动噪声特性要好于直角弯头L型通气管路。因此,在设计邮轮通气管路时,应尽量选用圆形截面以及带有圆角弯头的管路,以降低噪声水平。在流量不变的条件下,正方形截面通气管路的总声压级随截面边长的增大而减小,减小的速率随截面边长的增大而减小,最终可能无限趋近于某一定值。因此,在邮轮通气管路的设计过程中,在满足空间和重量控制、安全、工艺等要求下,可以适当增加横截面积大小以达到降低通气管路气动噪声的目的。通过对三组通气管路计算得出的声压级频率响应曲线,发现它们都具有低频段的声压级较大,高频段的声压级较小的特点,说明邮轮通气管路噪声主要是由低频段引起的。因此在进行邮轮通气管路设计时,应注意控制低频段的噪声。

关键词:气动噪声;数值仿真;邮轮通气管路

Abstract

There are all kinds of pipe systems widely distributed inside the modern cruises, which are the key factors to ensure the normal operation of the cruise liner. But, with the normal operation of these pipe systems, it brings many problems to cruise and staff working in the cruise, such as noise problem is one of them. For the noise problem, the aerodynamic noise generated by the ventilation pipeline is the main cause of noise problem. Therefore, it is very important to analyze the noise of typical ventilation pipeline in cruise ship. In cruise a variety of ventilation pipe, we can according to the factors such as the structure of cross section, classifying them, the typical line, the circular cross section has a square cross section ventilation, right-angle bend L ventilation pipe lines and rounded corners bend L ventilation pipe, etc. Due to cruise ventilation pipe distribution and its structure is complex and diverse, the importance of plus noise problem, therefore, the numerical simulation of noise of cruise typical ventilation ducts and control method has long been a focus in ship and ocean engineering.

In this paper, several typical ventilation lines on cruise ships are summarized, and corresponding geometric models are constructed. Then, CFD grids and acoustic computing grids are divided on the basis of geometric models. Secondly, Fluent was used to calculate CFD grid steady-state first and then calculate CFD grid steady-state on the basis of steady-state calculation results, thus greatly reducing computation time. Is then computed results in Fluent import LMS. Virtual Lab Acoustics of acoustic finite element calculation, get a square cross section and circular cross section through tracheal road, right-angle bend and rounded corners bend L ventilation pipe and the different cross-sectional area of the square through tracheal path in the outlet of monitoring the sound pressure level of frequency response curve and the total sound pressure level; Finally, the comparison of calculation results of the above three kinds of ventilation pipe, with good ventilation pipe of the aerodynamic noise characteristics form, thus proposed several cruise ventilation pipe pneumatic noise control technology.

Through calculation, found that for cruise ventilation pipe, a square cross section or circular cross section or right-angle bend or rounded bend L ventilation pipe, monitoring position at the exit of sound pressure level will increase along with the increase of inlet velocity, sound pressure level of growth will slightly decrease with the increase of inlet velocity. The aerodynamic noise level of circular section ventilation pipeline is lower than that of square section. In addition, the shape of the cross section of the ventilation pipeline has little influence on the variation trend of the total sound pressure level with the inlet velocity. Rounded corners bend L ventilation pipe pneumatic noise level is lower than quarter bend L ventilation pipe, rounded bend L ventilation pipe pneumatic noise characteristics are better than quarter bend L ventilation pipe. Therefore, in the design of the cruise ship ventilation pipeline, the circular section and the pipe with rounded corners should be adopted as far as possible to reduce the noise level. Under the condition of flow is constant, square cross section ventilation pipe of the total sound pressure level decreases with increasing section length, reduce the rate decreases with increasing section length, may eventually tend to a certain value. Thus, in the process of cruise ventilation piping design, in the space and weight under control, safety and technology requirements, can be appropriately increased cross-sectional area size to achieve the goal of reducing ventilation pipe pneumatic noise. Calculated based on three groups of ventilation pipe sound pressure level of the frequency response curve, found that they all have the low frequency sound pressure level is bigger, the characteristics of the sound pressure level is small, high frequency band that cruise ventilation pipe is mainly caused by the low frequency noise. Therefore, attention should be paid to the control of low frequency noise in the design of the cruise line.

Key Words: aerodynamic noise; numerical simulation; ventilation pipe

目录

摘要 I

Abstract II

第1章 绪论 1

1.1 引言 1

1.2 研究背景及意义 1

1.3 k-ε湍流模型 2

1.4 大涡模拟 3

1.5 Ffowcs-Williamsamp;Hawkings模型 4

1.6 本文的主要研究内容 6

第2章 管路气动噪声的数值仿真方法 8

2.1 引言 8

2.2 LMS Virtual. Lab Acoustics软件 8

2.3 声学网格的要求 8

2.3.1 单元尺寸与计算频率的关系 8

2.3.2 声学单元的类型 9

2.4 气动声学的计算流程 9

2.5 本章小结 10

第3章 邮轮典型通气管路气动声学分析 11

3.1 引言 11

3.2 不同截面形状的直通气管路声学分析 12

3.2.1 正方形截面的直通气管路声学分析 12

3.2.2 圆形截面的直通气管路声学分析 17

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: