多孔金属灶头全预混燃气灶性能分析毕业论文

2020-06-19 21:53:21

摘 要

人类社会的进步与发展离不开能源。在过去的两个多世纪里,人类对能源的需求呈现爆炸式的增长,对其依赖程度也是愈来愈深。面对如此沉重的压力,人们一方面开发新能源,而另外一方面也在积极寻求更加高效的能源利用方式。

说到耗能大户,往往想到的是一些冶金制铁企业。殊不知人们的日常生活中也存在着极大的能源浪费。燃气灶是我们日常生活中常见的烹饪器具,但是传统的家用灶具能源利用率低,其热效率一般只在50%-60%,且会排放出大量的CO与NOx,严重降低了室内空气质量,威胁人类的健康。现有的全预混燃烧热效率高,而且火焰均匀,可以降低CO和NOx的排放,但是其火焰不稳定,这也是该技术没有得到推广的重要原因。因此,“多孔金属灶头全预混燃气灶性能分析”的研究正是基于这样的背景之下。通过多孔金属灶头,在实现高热效率、低污染物排放的同时,还保证火焰的稳定。

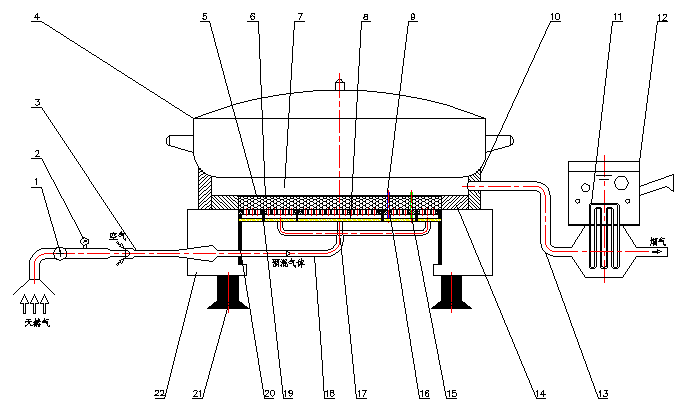

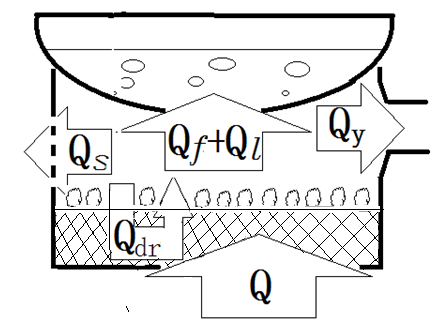

这种节能环保灶结构与传统灶有很大不同,主要增加了以下装置:引射器、混合室、均流板、多孔金属、氧化铝陶瓷和环状封闭灶膛壁。引射器是实现燃气与空气混合的核心部件。预热作用使灶具内温度超过传统燃烧器的绝热燃烧温度,形成“超焓”燃烧。多孔金属长期处于高温环境之中易被氧化腐蚀,所以在其上表面加有氧化铝陶瓷涂层。灶膛及灶头处使用的其余材料均要求有一定的耐高温性能。

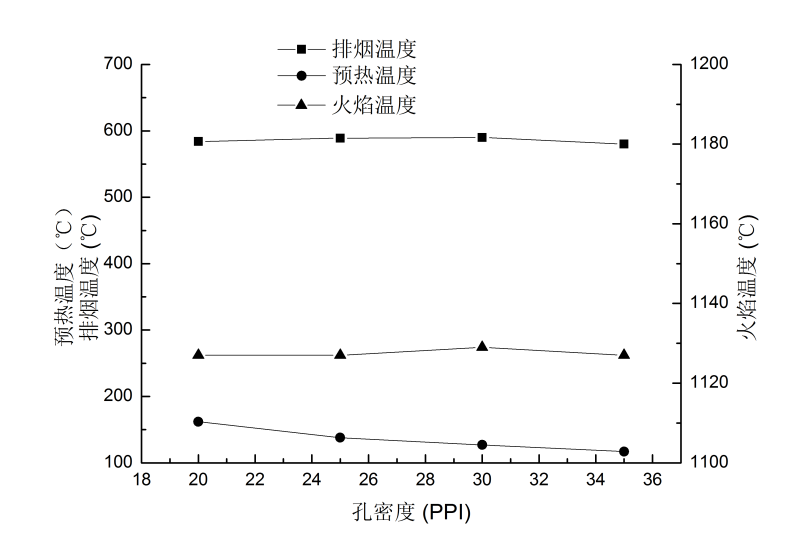

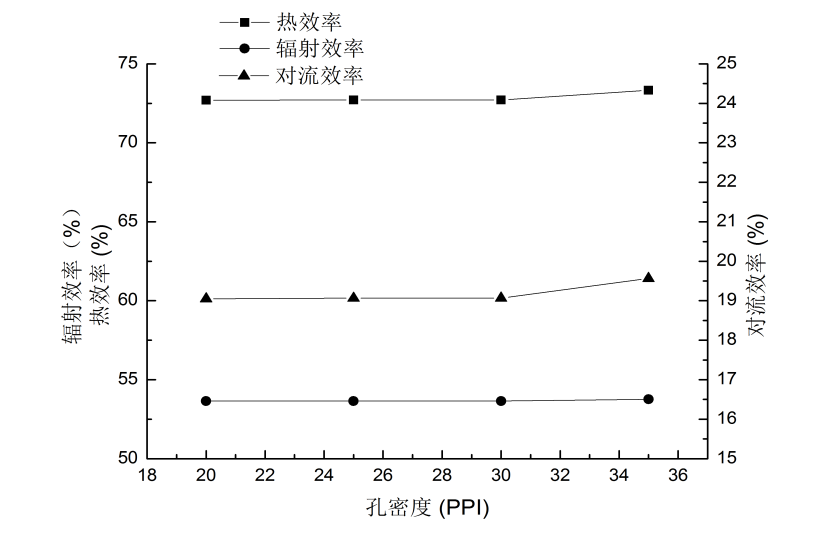

具体研究思路如下:先进行灶具的结构设计,参考相关文献选定一组灶具与多孔金属的几何参数。再建立理论计算模型,根据燃烧灶系统热平衡方程和火焰面燃烧热平衡方程,采用迭代计算的方式,得出灶具的各项性能指标。在分析灶具性能时,依据的指标是火焰温度、排烟温度、预热温度、热效率、辐射效率以及对流效率。

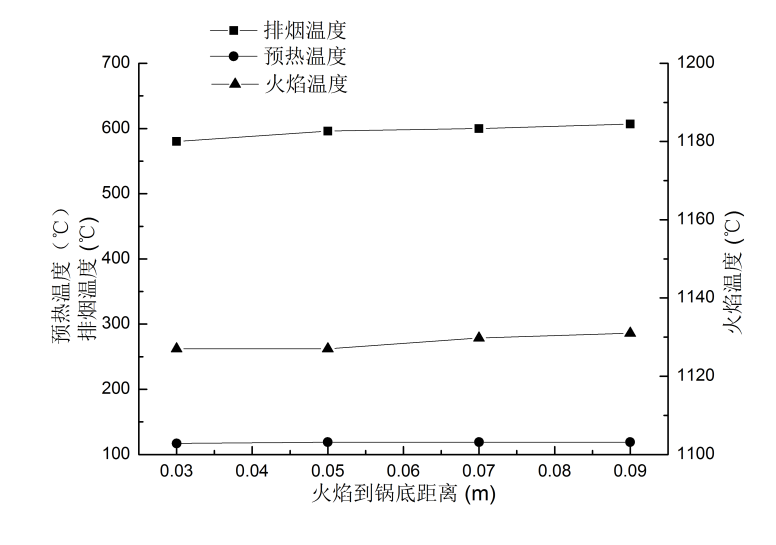

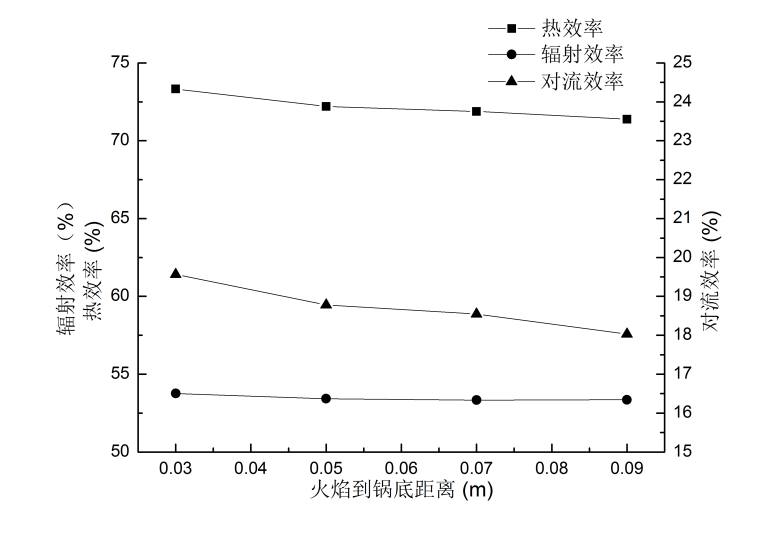

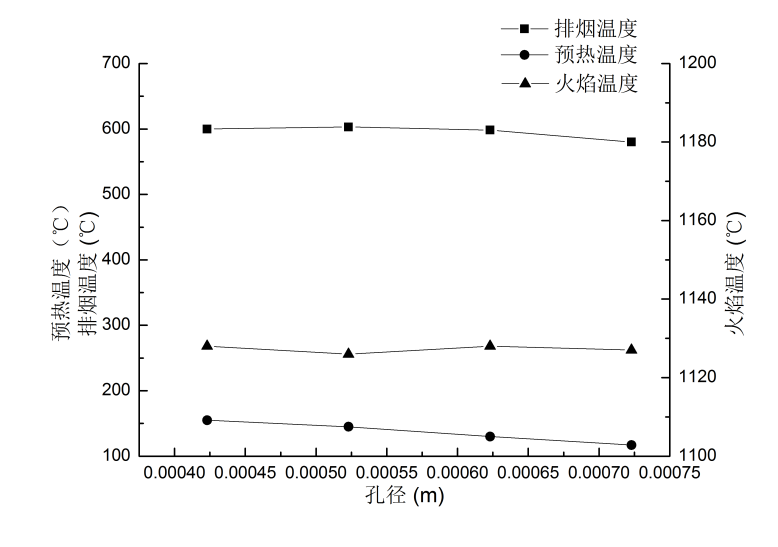

接着在原始参数的基础上,采用控制变量法,研究多孔金属的几何参数变化对灶具性能的影响,采用Originlab制成折线图,找出最优几何参数,达到优化灶具结构的目的。最终的研究发现几何结构为孔密度35PPI、灶膛高度0.03m、孔径7.23×10-4m、材料厚度0.005m、孔隙率90%时灶具性能达到最佳。

最后是负荷变化对灶具性能影响的研究。由于家用灶具往往会遇到变负荷的问题,所以变工况研究显得更加重要。根据家用灶单眼功率范围选定一个额定负荷,再研究额定负荷的33%、67%、100%和110%四种情况,得出变负荷所产生的影响。最终的研究发现额定负荷在3.5kW左右时较为合理。

在最优的几何结构和额定负荷下,研究发现这种新型环保灶具的理论热效率达到73%,但考虑实际因素修正后的热效率要低于这一数值。此外,燃气灶火焰温度在1127℃左右。多孔金属灶头可以将混合气体预热到117℃左右。总之,多孔金属灶头全预混燃气灶可以实现节能环保的作用。

本次研究完成了多孔金属灶头全预混燃气灶具的系统总图、装配图以及主要零件图。因此希望通过本次课题的研究,对多孔介质全预混燃烧灶具的设计提出改进,实现结构与性能的最大合理优化,推动实际的生产运用。

关键词:多孔金属 家用灶具 全预混燃烧 超焓燃烧 热效率

Performance analysis of full-premixed combustion in a cooking stove with porous metal materials

Abstract

The progress and development of human society can do nothing without energy. In the past two century, energy demand growth was becoming explosive and the dependence of it was deeper. Facing up with so tremendous burden, in one way, we can exploit new sources of energy, in the other way actively seek more efficient way of energy utilization.

When it comes to energy hungry, people often think of some iron and steel metallurgy enterprises. But people's daily life also has a great waste of energy. The gas stove is common in our lives. But the traditional household cooking energy utilization rate is low and thermal efficiency is generally only in the 50%-60%. Apart from this, it would emit a large number of CO and NOx, which reduces indoor air quality and threats human health. The full premixed combustion could achieve high thermal efficiency and even flame, and also reduce CO and NOx emissions, but the flame is not stable, the technology has not been prevalent for this reason. So properties analysis of full-premixed combusion in gas stoves with porous metal study was based on such background. Through the porous metal materials, the stove could not only realize high efficiency and low pollutant emissions, but also ensure the stability of the flame.

This kind of energy saving and environmental protection stove's structure had much differences with traditional stove's, which added the following devices: ejector mixing chamber, a flow equalizing plate, porous metal, alumina ceramic and annular closed hearth wall. Ejector was the core components of gas and air mixture. The effect of preheating maked its temperature exceed the traditional burner' adiabatic combustion temperature, calling this super enthalpy combustion. In the high temperature environment, porous metal could be susceptible to oxidation corrosion, so the surface with alumina ceramic coating. The materials and stove hearth used were required to have certain performance at high temperature.

The results were as follows: firstly studyed the stove's structural design and selected a group of geometric parameters of stove and porous metal by reference literatures. Then establishing the theoretical calculation model, With combustion stove system heat balance equation and the flame combustion heat balance equation, using the iterative calculation method, got the stove's property indices. The analysis of range performance accorded to the index of the flame temperature, exhaust gas temperature, preheating temperature, thermal efficiency, radiation efficiency and convection efficiency.

Based on the original parameters, using the control variable method, studyed the influence of geometric parameters on the performance of the stove, and used Originlab to make line charts to find the optimal parameters, then optimized the structure of stove purpose. The research found that geometric structure of hole density was 35PPI, the height 0.03m, pore size 7.23×10-4m, material thickness 0.005m and porosity 90% when property was more optimal.

The last is to study the influence of load variation on the performance of the stove. Because domestic appliances often encountered the problem of variable load, so variable condition research became more and more important. According to the monocular power range of domestic stove, this research selected the rated load, then studyed the rated load of 33%, 67%, 100% and 110%, so the effect of variable load generated. The study found the rated load in 3.5kW when property was more reasonable.

In the optimal geometric structure and rated load, this research found that the thermal efficiency of the new environmental protection stove theoretically reached 73%.Cosidering the actual factors, it would be less than this efficiency. The flame temperature of gas stove reached 1127℃. Mixed gas could be preheated to a temperature of about 117℃. In conclusion, the full premixed gas stove with porous metal could realize energy conservation and environmental protection.

This study had completed the system layout, assembly drawing and some parts drawing. So do hope the research can improve the design of full-premixed combustion in cooking stoves with porous metal, achieve the most reasonable optimization of structure and performance and finally promote the actual production.

Key words: porous metal; household cookers; full premixed combustion; excess enthalpy combustion; thermal efficiency

目 录

摘要 I

Abstract III

第1章 绪论 1

1.1课题研究背景与目的 1

1.2传统灶具的种类与存在的问题 2

相关图片展示: