大型火电机组空压机状态检修研究毕业论文

2020-04-12 14:11:56

摘 要

当今世界,人类的用电需求越来越高,电力行业竞争压力加大,电力设备的负担也随之增加,故障频率日益增大。面对这种境况,传统的检修方式已经满足不了需求,提高电力设备的工作效率和经济效益,降低发电成本,尤其是降低庞大的维修费用,变得非常迫切。

本文了解了大型火电机组设备检修方式的种类及发展现状,并针对电厂实际情况及空压机组运行特点,提出了一种既能准确有效的对电力设备进行检修,又能节约成本的检修方式——状态检修。

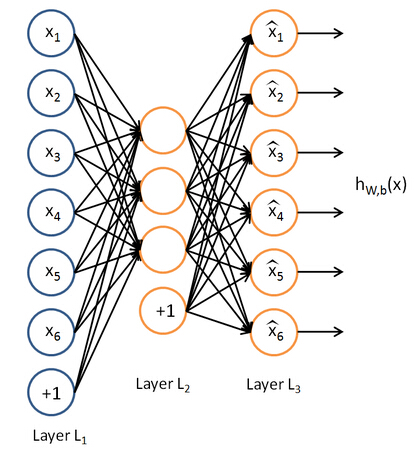

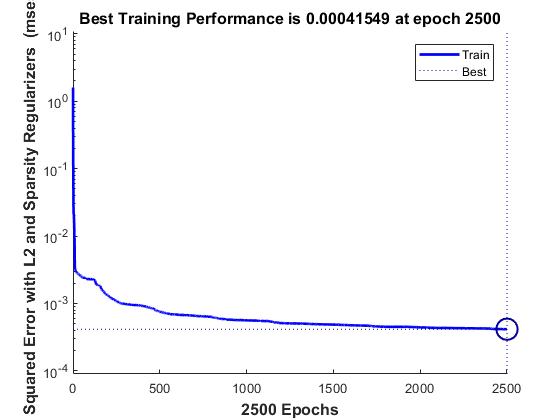

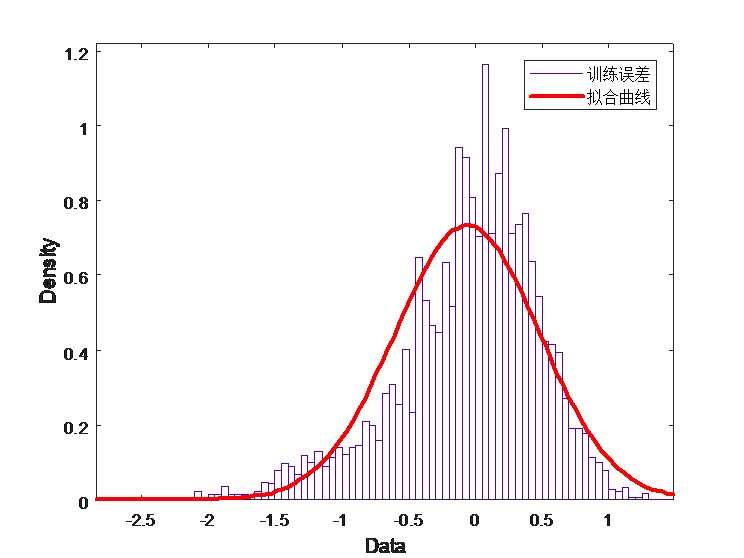

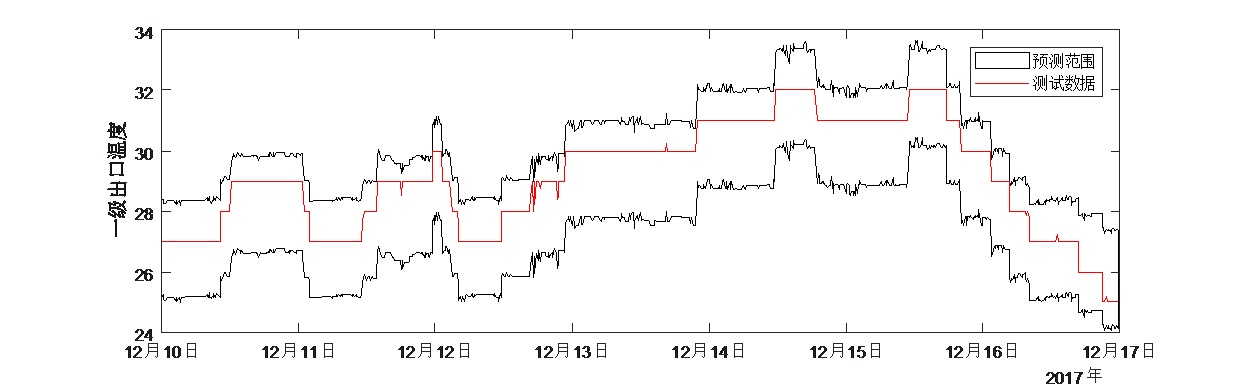

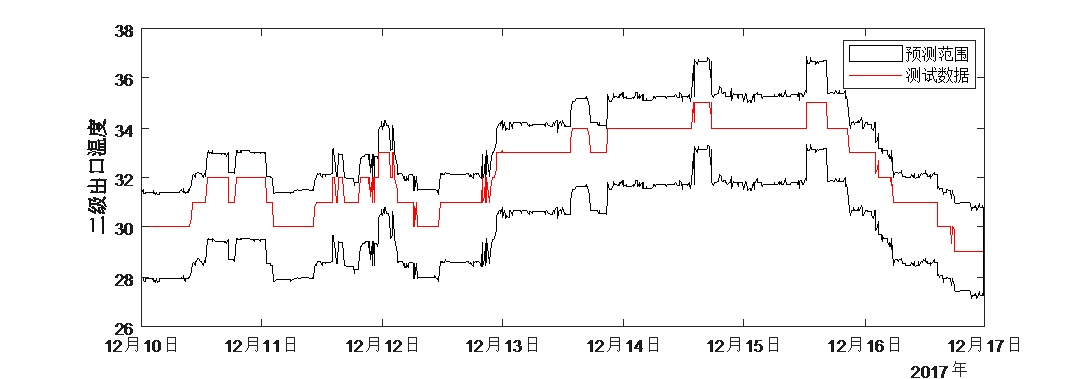

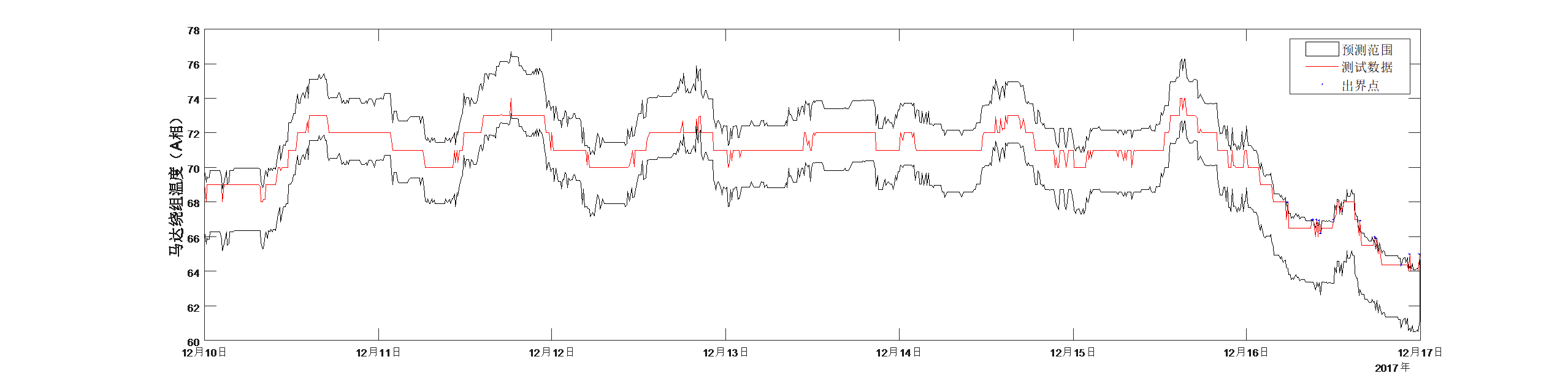

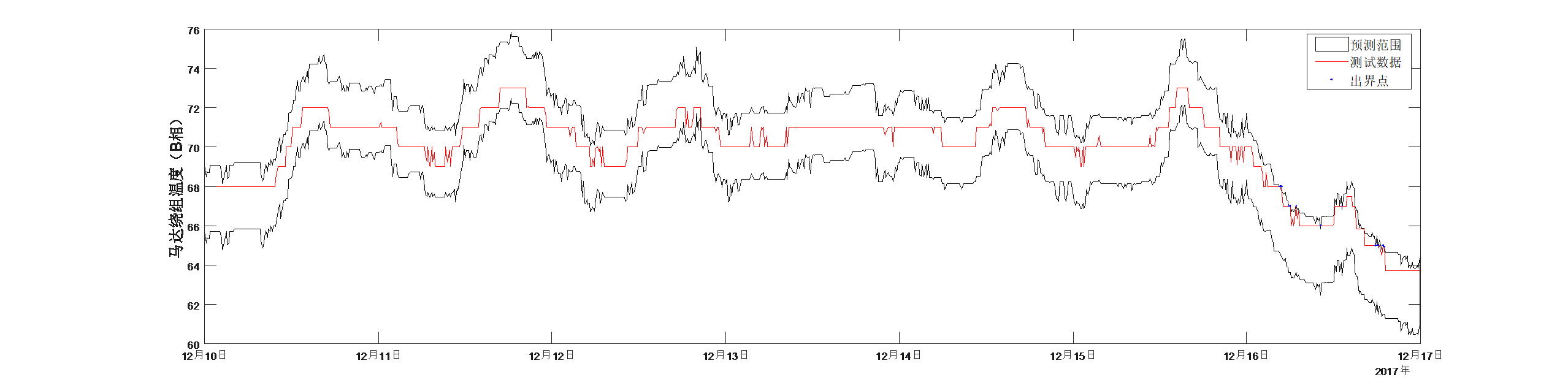

在对空压机的工作原理、设备部件及功能进行了解的前提下,通过查阅资料及现场调研,对空压机组进行故障模式及后果分析,得到设备的故障模式表;根据“设备维修台账”了解空压机历史故障,梳理其故障形式,得到设备故障征兆表;故障模式往往对应一组故障征兆,结合故障模式表及故障征兆表,整理其对应关系,建立故障推理模型;通过使用MATLAB软件,建立自编码模型,并用选取的样本数据对模型进行训练,使其能够很好的预测空压机正常运行的范围并在其运行发生异常时发出报警;预警结果对应一个故障征兆,将该征兆代入故障推理模型,可得到故障模式;利用模糊评判法对故障模式进行风险评估;将评估信息反馈给专业的技术人员,技术人员结合实际情况及工作经验,最终制定出合理的检修策略。

本文以广东沙角C电厂1号空压机组为研究对象,对其进行状态检修,介绍了状态检修的内容及大致流程,并详细介绍了本文在故障预警模型建立时,MATLAB软件自编码模型的原理及使用方法,验证结果表明,该预警模型可以较为准确的预测空压机运行的异常情况,在整个状态检修流程中起到了承上启下的重要作用。通过本文对空压机状态检修的研究表明,状态检修这个目前较为先进的检修方式,可以准确的预测故障的发生时间、位置,判断故障的严重程度,从而制定最为合理的检修策略。实现了在保证电力设备工作效率的前提下,降低维修费用的目的,具备很高的工程价值。

关键词:状态检修(CBM) 故障模式与后果分析 自编码器 空压机

Abstract

Nowdays, the demand for electricity of human beings is getting higher and higher, the pressure in the electric power industry has increased, the burden on electrical equipment has also increased, and the frequency of faults has increased. Faced with this situation, traditional inspection and maintenance methods have failed to meet the demand. It has become very urgent to increase the work efficiency and economic efficiency, reduce the cost of power generation especially the huge maintenance costs.

This paper understands the types and development status of equipment overhauls for large-scale thermal power generation units. It also proposes an accurate and effective overhaul of power equipment that can save energy, both in light of the actual conditions of the power plant and the operating characteristics of the air compressor unit. The cost of maintenance - Condition Based Maintenance.

Under the premise of understanding the working principle, equipment components and functions of the air compressor, through consulting data and on-site investigation, the failure mode and effect analysis of the air compressor unit was obtained. Failure mode table; According to the "equipment maintenance account" to understand the historical failure of the air compressor, sort out its failure form, get the equipment failure symptoms table; failure mode often corresponds to a set of failure symptoms, combined with the failure mode table and failure symptoms table, collate their corresponding Relationships, the establishment of fault reasoning model; through the use of MATLAB software, the establishment of self-coding model, and use the selected sample data to train the model so that it can well predict the scope of normal operation of the compressor and send an alarm when the operation occurs abnormal; The warning result corresponds to a fault symptom, and the result is substituted into the fault inference model to obtain the failure mode; the failure mode is evaluated by the fuzzy evaluation method; the evaluation information is fed back to the professional technicians, and the technical personnel combines the actual situation and work experience. Finally develop a reasonable maintenance strategy.

This paper takes No. 1 air compressor unit of Shajiao C Power Plant in Guangdong as the research object, implements state maintenance, introduces the content and general flow of state maintenance, and describes in detail the self-coding model of MATLAB software when the fault early warning model is established. The principle and method of use, the verification results show that the early warning model can accurately predict the abnormal operation of the air compressor, and plays an important role in the entire state maintenance process. Through the research on air compressor state maintenance, this paper shows that the state-of-the-art maintenance method, which is currently more advanced, can accurately predict the time and location of the fault, determine the severity of the fault, and formulate the most reasonable maintenance strategy. The purpose of reducing the maintenance cost under the premise of guaranteeing the working efficiency of the electrical equipment has been achieved and has high engineering value.

Key words:Condition Based Maintenance Failure Mode and Effects Analysis

Auto Enconder Compressor

目 录

第1章 绪论 1

1.1研究背景 1

1.2 课题的提出 2

1.3国内外发展现状 2

1.4 研究目标及内容 3

第2章 状态检修方法概述 4

2.1状态检修的基本介绍 4

2.2 状态检修基本模式 4

2.3 状态检修基本系统 5

2.4 空压机状态检修实施策略与步骤 5

2.5 空压机状态检修基本流程 6

第3章 空压机状态检修设计 7

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: